ASTM A757/A757M-00(2004)

(Specification)Standard Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing and Other Applications, for Low-Temperature Service

Standard Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing and Other Applications, for Low-Temperature Service

ABSTRACT

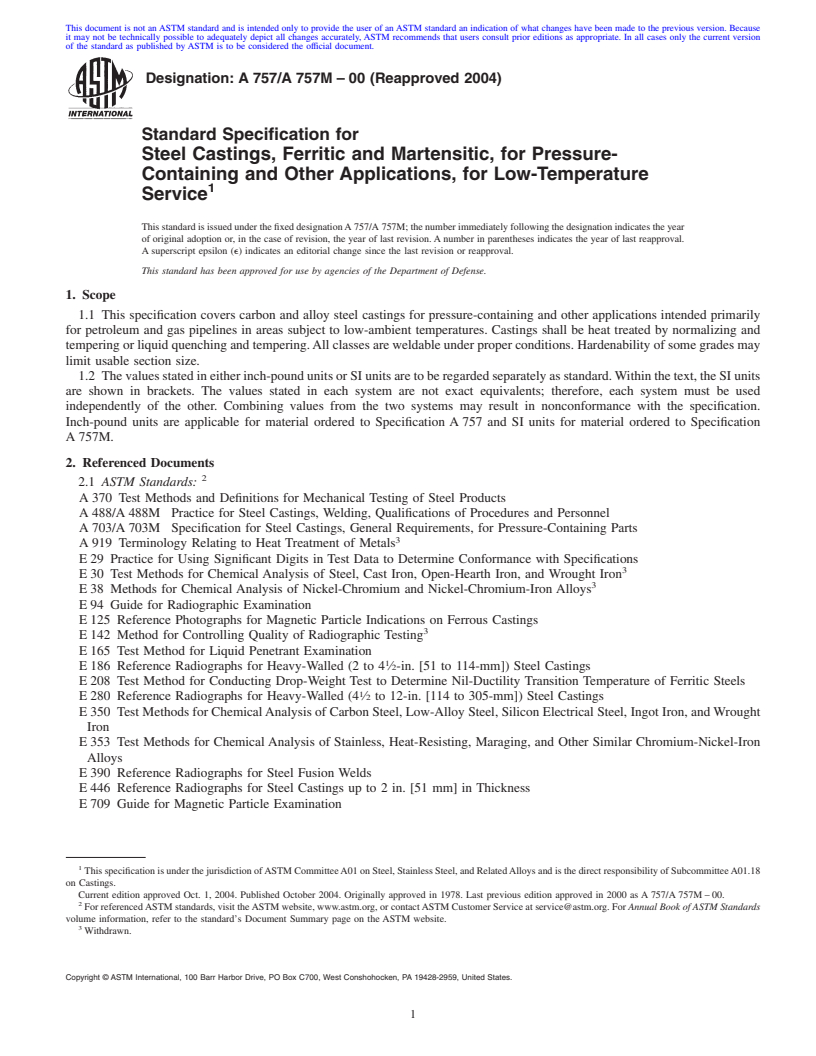

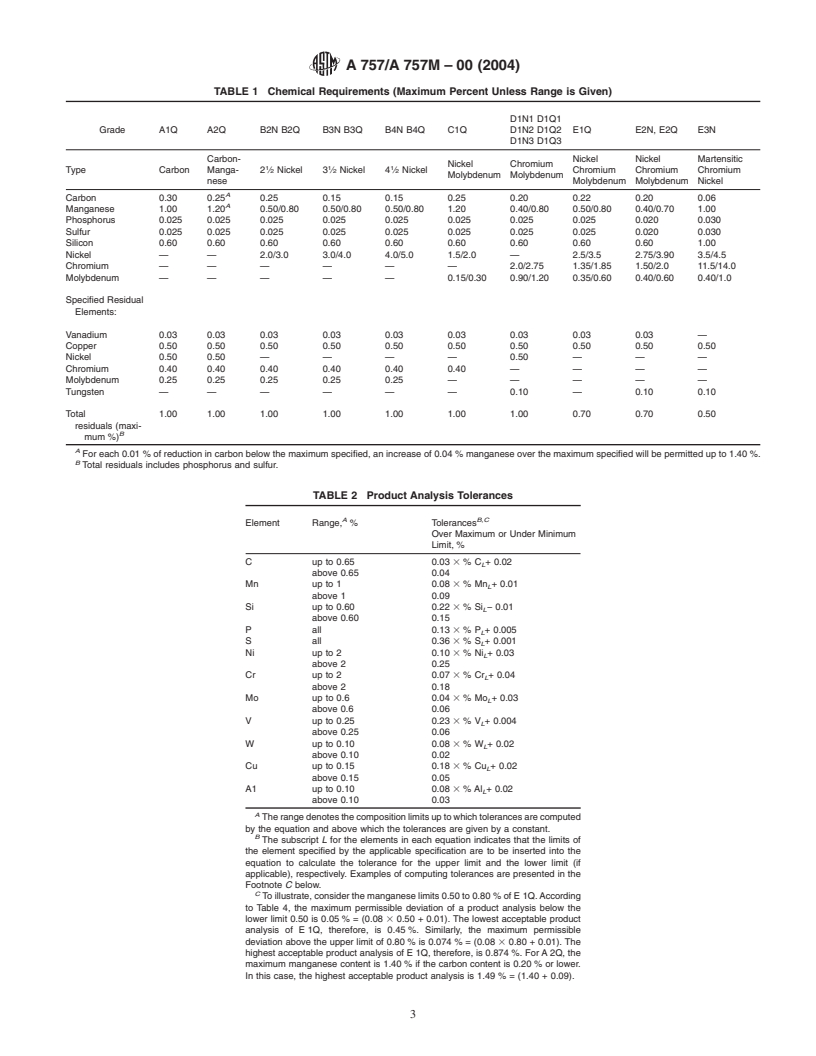

This specification covers carbon and alloy steel castings for pressure-containing and other applications intended primarily for petroleum and gas pipelines in areas subject to low-ambient temperatures. Castings shall be heat treated by normalizing and tempering or liquid quenching and tempering. The steel shall be made by the electric furnace process or other primary processes. Heat and product analyses shall be performed on the material and the chemical composition shall conform to the prescribed values for carbon, manganese, nickel, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, also for residual elements like vanadium, copper, nickel, chromium, molybdenum, and tungsten. Tensile test shall be made and the mechanical properties thus determined shall conform to the required tensile strength, yield strength, elongation, and reduction of area. Charpy V-notch testing shall be done to determine the impact properties on each heat by specimen type like coupons representing the weld deposits and coupons representing the heat-affected zone. Impact properties shall also be determined on both the heat-affected zone of the base metal and the weld metal of the welding procedure qualification test. After machining, each pressure-containing casting shall undergo hydrostatic pressure testing and shall not leak.

SCOPE

1.1 This specification covers carbon and alloy steel castings for pressure-containing and other applications intended primarily for petroleum and gas pipelines in areas subject to low-ambient temperatures. Castings shall be heat treated by normalizing and tempering or liquid quenching and tempering. All classes are weldable under proper conditions. Hardenability of some grades may limit usable section size.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Inch-pound units are applicable for material ordered to Specification A757 and SI units for material ordered to Specification A757M.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A757/A757M – 00 (Reapproved 2004)

Standard Specification for

Steel Castings, Ferritic and Martensitic, for Pressure-

Containing and Other Applications, for Low-Temperature

1

Service

This standard is issued under the fixed designationA757/A757M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E30 Test Methods for Chemical Analysis of Steel, Cast

3

Iron, Open-Hearth Iron, and Wrought Iron

1.1 This specification covers carbon and alloy steel castings

E38 Methods for Chemical Analysis of Nickel-Chromium

for pressure-containing and other applications intended prima-

3

and Nickel-Chromium-Iron Alloys

rily for petroleum and gas pipelines in areas subject to

E94 Guide for Radiographic Examination

low-ambient temperatures. Castings shall be heat treated by

E125 Reference Photographs for Magnetic Particle Indica-

normalizingandtemperingorliquidquenchingandtempering.

tions on Ferrous Castings

All classes are weldable under proper conditions. Hardenabil-

E142 MethodforControllingQualityofRadiographicTest-

ity of some grades may limit usable section size.

3

ing

1.2 The values stated in either inch-pound units or SI units

E165 PracticeforLiquidPenetrantExaminationforGeneral

are to be regarded separately as standard. Within the text, the

Industry

SI units are shown in brackets. The values stated in each

E186 Reference Radiographs for Heavy-Walled (2 to 412-

system are not exact equivalents; therefore, each system must

in. [51 to 114-mm]) Steel Castings

beusedindependentlyoftheother.Combiningvaluesfromthe

E208 Test Method for Conducting Drop-Weight Test to

two systems may result in nonconformance with the specifi-

Determine Nil-DuctilityTransitionTemperature of Ferritic

cation. Inch-pound units are applicable for material ordered to

Steels

Specification A757 and SI units for material ordered to

E280 Reference Radiographs for Heavy-Walled (412 to

Specification A757M.

12-in. [114 to 305-mm]) Steel Castings

2. Referenced Documents E350 Test Methods for ChemicalAnalysis of Carbon Steel,

2

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

2.1 ASTM Standards:

Wrought Iron

A370 Test Methods and Definitions for Mechanical Testing

E353 Test Methods for Chemical Analysis of Stainless,

of Steel Products

Heat-Resisting, Maraging, and Other Similar Chromium-

A488/A488M Practice for Steel Castings, Welding, Quali-

Nickel-Iron Alloys

fications of Procedures and Personnel

E390 Reference Radiographs for Steel Fusion Welds

A703/A703M Specification for Steel Castings, General Re-

E446 Reference Radiographs for Steel Castings Up to 2 in.

quirements, for Pressure-Containing Parts

3

[51 mm] in Thickness

A919 Terminology Relating to Heat Treatment of Metals

E709 Guide for Magnetic Particle Testing

E29 Practice for Using Significant Digits in Test Data to

4

2.2 American Society of Mechanical Engineers:

Determine Conformance with Specifications

ASME Boiler and Pressure Vessel Code

2.3 Manufacturers Standardization Society of the Valve and

1

5

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Fittings Industry Standards:

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

MSS SP-53 Quality Standard for Steel Castings for Valves,

A01.18 on Castings.

Flanges and Fittings, and Other Piping Components (Dry

Current edition approved Oct. 1, 2004. Published October 2004. Originally

approved in 1978. Last previous edition approved in 2000 as A757/A757M–00. Powder Magnetic Particle Inspection Method)

DOI: 10.1520/A757/A757M-00R04. DOI: 10.1520/A0757_A0757M-00R04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Three Park Ave., New York, NY 10016-5990.

5

the ASTM website. AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

3

Withdrawn. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A757/A757M – 00 (2004)

MSS SP-54 Quality Standard for Steel Casting for Valves, 5. Materials and Manufacture

Flanges and Fittings, and Other Piping Components (Ra-

5.1 Melting Process—The steel shall be made by the

diographic Inspection Method)

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A 757/A 757M – 00 (Reapproved 2004)

Standard Specification for

Steel Castings, Ferritic and Martensitic, for Pressure-

Containing and Other Applications, for Low-Temperature

1

Service

ThisstandardisissuedunderthefixeddesignationA757/A757M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers carbon and alloy steel castings for pressure-containing and other applications intended primarily

for petroleum and gas pipelines in areas subject to low-ambient temperatures. Castings shall be heat treated by normalizing and

temperingorliquidquenchingandtempering.Allclassesareweldableunderproperconditions.Hardenabilityofsomegradesmay

limit usable section size.

1.2 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

Inch-pound units are applicable for material ordered to Specification A757 and SI units for material ordered to Specification

A757M.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A488/A488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A703/A703M Specification for Steel Castings, General Requirements, for Pressure-Containing Parts

3

A919 Terminology Relating to Heat Treatment of Metals

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3

E30 Test Methods for Chemical Analysis of Steel, Cast Iron, Open-Hearth Iron, and Wrought Iron

3

E38 Methods for Chemical Analysis of Nickel-Chromium and Nickel-Chromium-Iron Alloys

E94 Guide for Radiographic Examination

E125 Reference Photographs for Magnetic Particle Indications on Ferrous Castings

3

E142 Method for Controlling Quality of Radiographic Testing

E165 Test Method for Liquid Penetrant Examination

1

E186 Reference Radiographs for Heavy-Walled (2 to 4 ⁄2-in. [51 to 114-mm]) Steel Castings

E208 Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

1

E280 Reference Radiographs for Heavy-Walled (4 ⁄2 to 12-in. [114 to 305-mm]) Steel Castings

E350 TestMethodsforChemicalAnalysisofCarbonSteel,Low-AlloySteel,SiliconElectricalSteel,IngotIron,andWrought

Iron

E353 Test Methods for Chemical Analysis of Stainless, Heat-Resisting, Maraging, and Other Similar Chromium-Nickel-Iron

Alloys

E390 Reference Radiographs for Steel Fusion Welds

E446 Reference Radiographs for Steel Castings up to 2 in. [51 mm] in Thickness

E709 Guide for Magnetic Particle Examination

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteel,andRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.18

on Castings.

Current edition approved Oct. 1, 2004. Published October 2004. Originally approved in 1978. Last previous edition approved in 2000 as A757/A757M–00.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 757/A 757M – 00 (2004)

4

2.2 American Society of Mechanical Engineers:

ASME Boiler and Pressure Vessel Code

5

2.3 Manufacturers Standardization Society of the Valve and Fittings Industry Standards:

MSS SP-53 Quality Standard for Steel Castings for Valves, Flanges and Fittings, and Other Piping Components (Dry Powder

Magnetic Particle Inspection Method)

MSS SP-54 Quality Standard for Steel Casting for Valves, Flanges and Fittings, and Other Piping Components (Radiographic

Inspection Method)

MSS SP-55 Quality Standard for Steel Castings for Valves, Flanges and Fittings, and Other Piping Components (Visual

Method)

3. Terminology

3.1 Definitions:

3.1.1 Definitions in Test Methods and Definitions A370 and Terminology A919 are a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.