ASTM D7301-08

(Specification)Standard Specification for Nuclear Graphite Suitable for Components Subjected to Low Neutron Irradiation Dose

Standard Specification for Nuclear Graphite Suitable for Components Subjected to Low Neutron Irradiation Dose

SCOPE

1.1 This specification covers the classification, processing, and properties of nuclear grade graphite billets with dimensions sufficient to meet the designer’s requirements for reflector blocks and core support structures, in a high temperature gas cooled reactor. The graphite classes specified here would be suitable for reactor core applications where neutron irradiation induced dimensional changes are not a significant design consideration.

1.2 The purpose of this specification is to document the minimum acceptable properties and levels of quality assurance and traceability for nuclear grade graphite suitable for components subjected to low irradiation dose. Nuclear graphites meeting the requirements of Specification D 7219 are also suitable for components subjected to low neutron irradiation dose.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D7301 – 08

Standard Specification for

Nuclear Graphite Suitable for Components Subjected to

Low Neutron Irradiation Dose

This standard is issued under the fixed designation D7301; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1233 Practice for Determining Equivalent Boron Contents

of Nuclear Materials

1.1 This specification covers the classification, processing,

D346 Practice for Collection and Preparation of Coke

and properties of nuclear grade graphite billets with dimen-

Samples for Laboratory Analysis

sions sufficient to meet the designer’s requirements for reflec-

D2638 TestMethodforRealDensityofCalcinedPetroleum

tor blocks and core support structures, in a high temperature

Coke by Helium Pycnometer

gas cooled reactor. The graphite classes specified here would

D7219 Specification for Isotropic and Near-isotropic

be suitable for reactor core applications where neutron irradia-

Nuclear Graphites

tion induced dimensional changes are not a significant design

IEEE/ASTM SI 10 American National Standard for Use of

consideration.

the International System of Units (SI): The Modern Metric

1.2 The purpose of this specification is to document the

System

minimum acceptable properties and levels of quality assurance

2.2 ASME Standards:

and traceability for nuclear grade graphite suitable for compo-

NQA-1 Quality Assurance Program Requirements for

nents subjected to low irradiation dose. Nuclear graphites

Nuclear Facilities

meeting the requirements of Specification D7219 are also

suitable for components subjected to low neutron irradiation

3. Terminology

dose.

3.1 Definitions—Definitionsrelatingtothisspecificationare

1.3 The values stated in SI units are to be regarded as

given in Terminology C709. See Table 1.

standard. No other units of measurement are included in this

3.2 Definitions of Terms Specific to This Standard:

standard.

3.3 anistropic nuclear graphite, n—graphite in which the

2. Referenced Documents isotropy ratio based on the coefficient of thermal expansion is

2 greater than 1.15.

2.1 ASTM Standards:

3.4 baking/re-baking charge, n—number of billets in a

C559 Test Method for Bulk Density by Physical Measure-

baking/re-baking furnace run.

ments of Manufactured Carbon and Graphite Articles

3.5 bulk density, n—mass of a unit volume of material

C709 Terminology Relating to Manufactured Carbon and

including both permeable and impermeable voids.

Graphite

3.6 extrusion forming lot, n—number of billets of the same

C781 Practice for Testing Graphite and Boronated Graphite

size extruded in an uninterrupted sequence.

Materials for High-Temperature Gas-Cooled Nuclear Re-

3.7 green batch, n—mass of coke, recycle green mix,

actor Components

recycle graphite, and pitch that is required to produce a

C838 Test Method for Bulk Density of As-Manufactured

forming lot.

Carbon and Graphite Shapes

3.8 green mix, n—percentage of mix formulation, pitch and

additives required for the forming lot, which is processed and

ready to be formed.

This specification is under the jurisdiction of ASTM Committee D02 on

3.9 graphite billet, n—extruded, molded, or iso-molded

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

graphite artifact with dimensions sufficient to meet the design-

D02.F0 on Manufactured Carbon and Graphite Products.

er’s requirements for reactor components.

Current edition approved July 1, 2008. Published August 2008. DOI: 10.1520/

D7301-08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7301 – 08

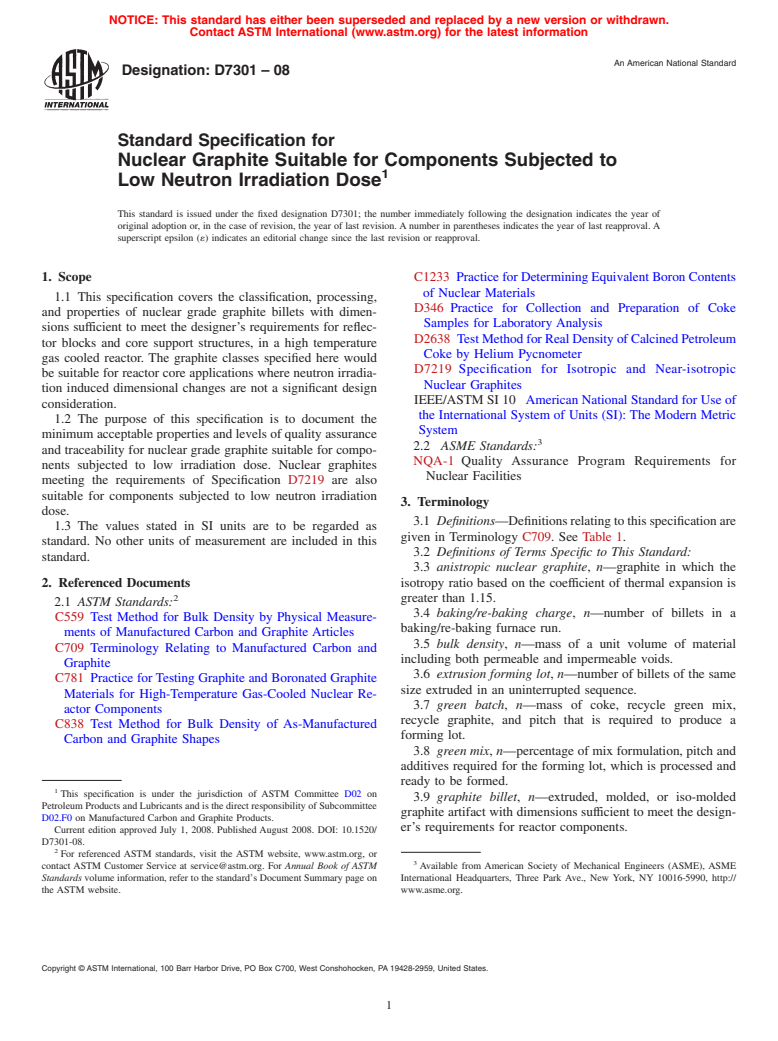

TABLE 1 ASTM Graphite Grain Size Definitions from

4. Materials and Manufacture

Terminology C709

4.1 Nuclear Graphite Classes—See Table 2.

Graphite Definition of Grains in

A

4.2 Raw Materials:

Designation the Starting Mix that are:

B

Medium Grained Generally<4mm

4.2.1 Fillers:

Fine Grained Generally < 100 µm

Superfine Grained Generally < 50 µm 4.2.1.1 The filler shall consist of a coke derived from a

Ultrafine Grained Generally < 10 µm

petroleum oil or coal tar.

Microfine Grained Generally<2µm

4.2.1.2 The coke shall have a coefficient of linear thermal

A

Grain size as defined in Terminology C709.

B expansion (CTE), determined in accordance with Practice

For Nuclear graphite, the maximum grain size is 1.68 mm in accordance with

4.2.1.6.

C781 and measured over the temperature range 25 to 500°C,

-6 -1

less than 5.5 3 10 °C .

4.2.1.3 The coke shall be sampled and distributed as de-

3.10 graphite grade, n—designation given to a material by

scribed in Table 3.

a manufacturer such that it is always reproduced to the same

4.2.1.4 Graphite manufactured in compliance with this

specification and from the same raw materials and mix

specification but failing to meet the property requirements of

formulation.

Sections 5-7 may be used as recycle material in the mix

3.11 graphitizing furnace run, n—total number of billets

formulation.

graphitized together in one graphitization furnace.

3.12 graphitization charge, n—total number of billets

4.2.1.5 Recyclegreenmixmanufacturedfromrawmaterials

graphitized together in one graphitization furnace. in compliance with this specification may be used in the mix

3.13 high purity nuclear graphite, n—nuclear graphite with formulation.

an Equivalent Boron Content less than 2 ppm.

4.2.1.6 The maximum filler particle size used in the mix

3.14 impregnation charge, n—number of billets in an auto-

formulation shall be 1.68 mm.

clave cycle.

4.3 Binder—The binder shall consist of coal tar pitch of the

3.15 low purity nuclear graphite, n—nuclear graphite with

same grade from the same manufacturer.The specific binder(s)

an Equivalent Boron Content greater than 2 ppm but less than

used shall be identified to the purchaser and be traceable

10 ppm.

through the forming lot.

3.16 mix formulation, n—percentages of each specifically

4.4 Impregnant—The impregnant shall consist of a petro-

sized filler used to manufacture a graphite grade.

leum or coal tar pitch of the same grade from the same

3.17 molding forming lot, n—number of billets molded

manufacturer. The specific impregnant(s) used shall be identi-

from a molding powder lot.

fied to the purchaser and be traceable through the impregnation

3.18 molding powder lot, n—sufficient quantity of re-milled

steps.

and blended green batch produced from an uninterrupted flow

4.5 Manufacturing or Processing Additives—Additives (for

of raw materials, or produced in a sequence of identical

example, extrusion aids) may be used to improve the process-

materials batches, to produce a molding forming lot.

ing, quality and properties of the product, but only with the

3.19 nuclear graphite class, n—designation of a nuclear

consent and approval of the purchaser, and they must be

graphite based upon its forming method, isotropy, purity and

traceable through the forming lot.

density (see Table 2).

4.6 Manufacture:

3.20 production lot, n—specified number of billets made in

4.6.1 Formulation—The mix formulation (as defined in

accordance with this specification and additional requirements

3.16) and recycle green mix fraction (as defined in 3.22)inthe

determined by the purchaser.

filler shall be recorded. This information shall be reported to

3.21 purification charge, n—number of billets in a purifi-

the purchaser if requested.

cation run.

3.22 recycle green mix, n—ground non-baked billets or 4.6.2 Forming—The green mix may be formed by extru-

non-used green mix manufactured in compliance with the mix sion, molding (including vibrationally molding), or iso-

formulation specified here. molding.

TABLE 2 ASTM Standard Classes of Nuclear Graphite

Purity

A B C D

Class CTE Isotropy Ratio Ash Content, Boron Equivalent, Density, Class

(a /a ) ppm (max) ppm (max) g/cm (min) Designation

AG AG

Isomolded, anisotropic-HP >1.15 300 2 1.7 IAHP

Isomolded, anisotropic-LP >1.15 1000 10 1.7 IALP

Extruded, anisotropic-HP >1.15 300 2 1.7 EAHP

Extruded, anisotropic-LP >1.15 1000 10 1.7 EALP

Molded, anisotropic-HP >1.15 300 2 1.7 MAHP

Molded, anisotropic-LP >1.15 1000 10 1.7 MALP

A

These classes may be further modified by the grain size as defined in Terminology C709.

B

Determined in accordance with Practice C781.

C

Determined in accordance with Test Method C559.

D

Determined in accordance with Practice C1233.

D7301 – 08

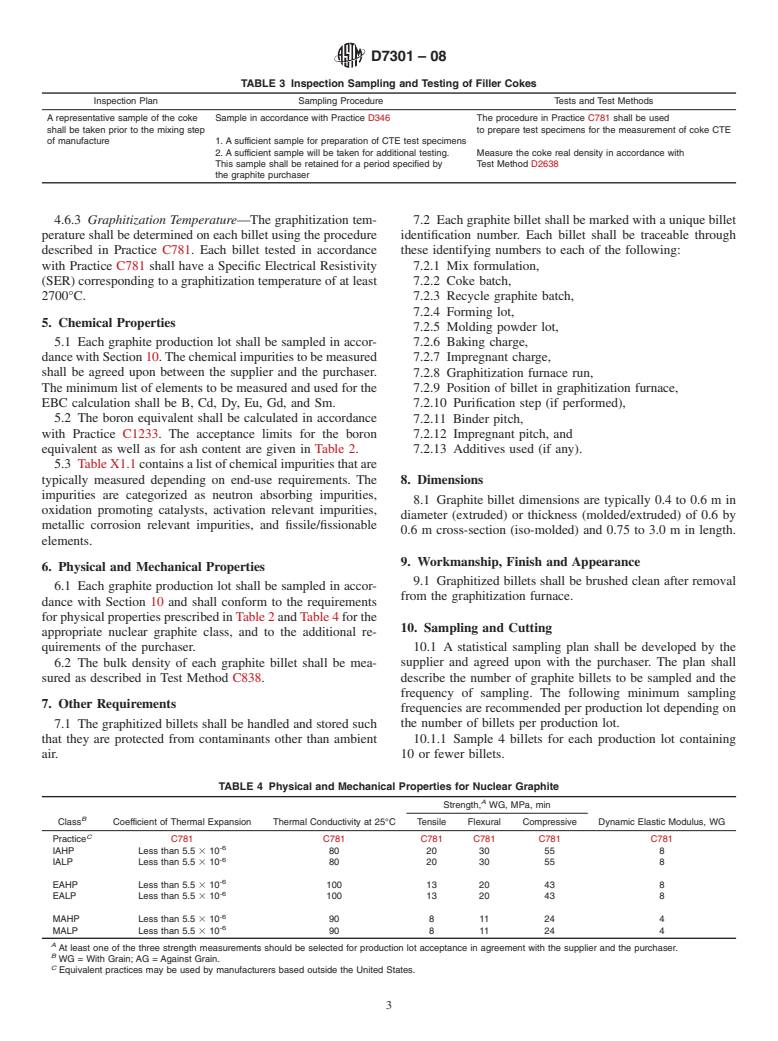

TABLE 3 Inspection Sampling and Testing of Filler Cokes

Inspection Plan Sampling Procedure Tests and Test Methods

A representative sample of the coke Sample in accordance with Practice D346 The procedure in Practice C781 shall be used

shall be taken prior to the mixing step to prepare test specimens for the measurement of coke CTE

of manufacture 1. A sufficient sample for preparation of CTE test specimens

2. A sufficient sample will be taken for additional testing. Measure the coke real density in accordance with

This sample shall be retained for a period specified by Test Method D2638

the graphite purchaser

4.6.3 Graphitization Temperature—The graphitization tem- 7.2 Each graphite billet shall be marked with a uniqu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.