ASTM A913/A913M-04

(Specification)Standard Specification for High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)

Standard Specification for High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)

SCOPE

1.1 This specification covers high-strength low-alloy structural steel shapes in Grades 50 [345], 60 [415], 65 [450] and 70 [485], produced by the quenching and self-tempering process (QST). The shapes are intended for riveted, bolted or welded construction of bridges, buildings and other structures.

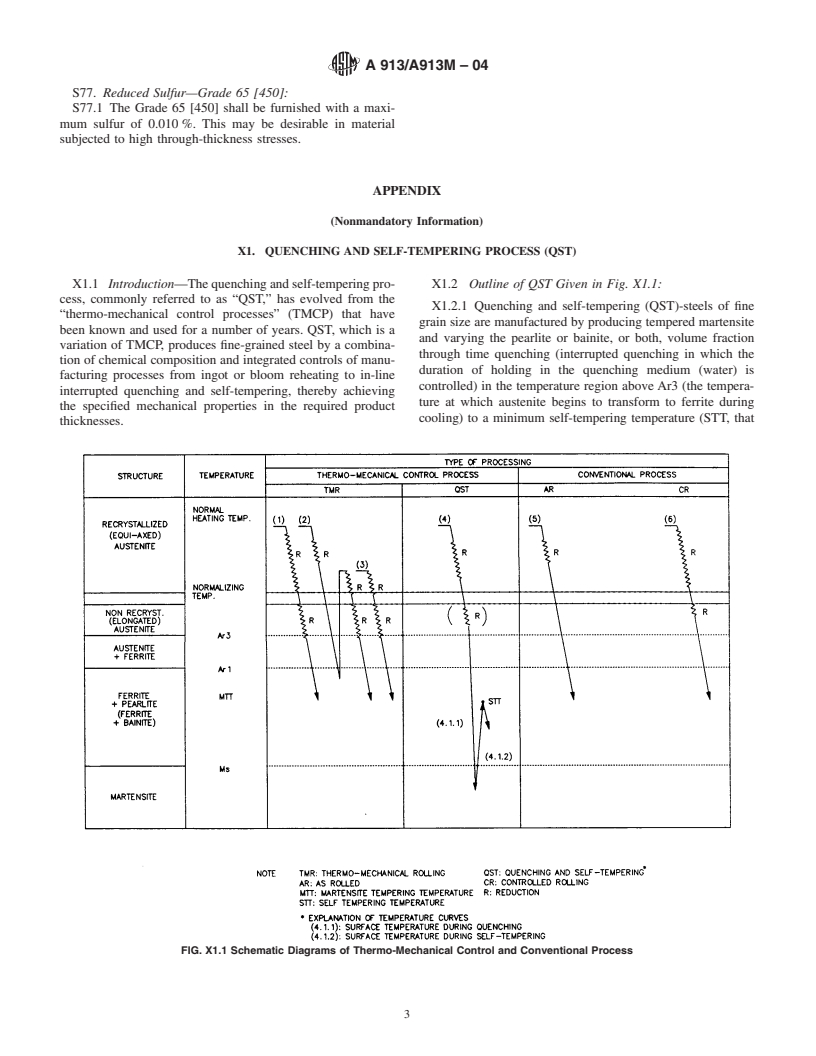

1.2 The QST process consists of in line heat treatment and cooling rate controls which result in mechanical properties in the finished condition that are equivalent to those attained using heat treating processes which entail reheating after rolling. A description of the QST process is given in .

1.3 Due to the inherent characteristics of the QST process, the shapes shall not be formed and post weld heat treated at temperatures exceeding 1100F [600C].

1.4 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A 6/A 6M for information on weldability.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 913/A913M – 04

Standard Specification for

High-Strength Low-Alloy Steel Shapes of Structural Quality,

1

Produced by Quenching and Self-Tempering Process (QST)

This standard is issued under the fixed designationA913/A913M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

3

1.1 This specification covers high-strength low-alloy struc- 2.1 ASTM Standards:

turalsteelshapesinGrades50[345],60[415],65[450]and70 A 6/A6M Specification for General Requirements for

[485], produced by the quenching and self-tempering process Rolled Structural Steel Bars, Plates, Shapes, and Sheet

2

(QST). The shapes are intended for riveted, bolted or welded Piling

construction of bridges, buildings and other structures. A 673/A673M Specification for Sampling Procedure for

1.2 The QST process consists of in line heat treatment and Impact Testing of Structural Steel

cooling rate controls which result in mechanical properties in A 898/A898M Specification for Straight Beam Ultrasonic

the finished condition that are equivalent to those attained Examination of Rolled Steel Structural Shapes

using heat treating processes which entail reheating after

3. General Requirements for Delivery

rolling.Adescription of the QST process is given inAppendix

X1. 3.1 Material furnished under this specification shall con-

form to the applicable requirements of the current edition of

1.3 Due to the inherent characteristics of the QST process,

the shapes shall not be formed and post weld heat treated at Specification A 6/A 6M.

temperatures exceeding 1100°F [600°C].

4. Materials and Manufacture

1.4 When the steel is to be welded, it is presupposed that a

4.1 The shapes shall be produced by the quenching and

welding procedure suitable for the grade of steel and intended

self-tempering process (QST). Self-tempering temperature

use or service will be utilized. See Appendix X3 of Specifica-

shall be a minimum of 1100°F [600°C] and the self-tempering

tion A 6/A 6M for information on weldability.

temperature for the material represented shall be reported on

1.5 The values stated in either inch-pound units or SI units

the mill test report. See appendix for Process Description.

are to be regarded separately as standard. Within the text, the

4.2 For grades 60 [415], 65 [450], and 70 [485], the

SI units are shown in brackets. The values stated in each

requirements for fine austenitic grain size in Specification A

system are not exact equivalents; therefore, each system must

6/A 6M shall be met.

be used independently of the other. Combining values from the

two systems may result in nonconformance with this specifi-

5. Chemical Composition

cation.

5.1 The chemical analysis of the heat shall conform to the

requirements prescribed in Table 1.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

5.2 The steel shall conform on product analysis to the

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

requirements prescribed in Table 1 subject to the product

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock, and Ships.

analysis tolerances in Specification A 6/A 6M.

Current edition approved April 1, 2004. Published May 2004. Originally

approved in 1993. Last previous edition approved in 2003 as A 913/A 913M – 03.

2

The quenching and self-tempering process (QST) and the used apparatus are

covered by patents held by the Centre de Recherches Métallurgiques (CRM)—Rue

Ernest Solvay, 11, B 4000, Liège (Belgium). Interested parties are invited to submit

information regarding the identification of acceptable alternatives to these patented

3

items to the Committee on Standards,ASTM Headquarters, 100 Barr Harbor Drive, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

West Conshohocken, PA19428–2959. Comments will receive careful consideration contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

at the meeting of the responsible technical committee, which any interested party Standards volume information, refer to the standard’s Document Summary page on

may attend. the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 913/A913M – 04

TABLE 1 Chemical Requirements (Heat Analysis)

6.2 Charpy V-notch tests shall be made in accordance with

Specification A 673/A 673M, Frequency H:

Maximum content in %

6.2.1 The test results of full-s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.