ASTM C1624-05

(Test Method)Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing

Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing

SCOPE

1.1 This test method covers the determination of the practical adhesion strength and mechanical failure modes of hard (Vickers Hardness HV = 5 GPa or higher), thin (≤30 μm) ceramic coatings on metal and ceramic substrates at ambient temperatures. These ceramic coatings are commonly used for wear/abrasion resistance, oxidation protection, and functional (optical, magnetic, electronic, biological) performance improvement.

1.2 In the test method, a diamond stylus of defined geometry (Rockwell C, a conical diamond indenter with an included angle of 120° and a spherical tip radius of 200 μm) is drawn across the flat surface of a coated test specimen at a constant speed and a defined normal force (constant or progressively increasing) for a defined distance. The damage along the scratch track is microscopically assessed as a function of the applied force. Specific levels of progressive damage are associated with increasing normal stylus forces. The force level(s) which produce a specific type/level of damage in the coating are defined as a critical scratch load(s). The test method also describes the use of tangential force and acoustic emission signals as secondary test data to identify different coating damage levels.

1.3 Applicability to Coatings—This test method is applicable to a wide range of hard ceramic coating compositions: carbides, nitrides, oxides, diamond, and diamond-like carbon on ceramic and metal substrates. The test method, as defined with the 200 μm radius diamond stylus, is commonly used for coating thicknesses in the range of 0.1 to 30 μm. Test specimens generally have a planar surface for testing, but cylinder geometries can also be tested with an appropriate fixture.

1.4 Principal Limitations:

1.4.1 The test method does not measure the fundamental adhesion strength of the bond between the coating and the substrate. Rather, the test method gives an engineering measurement of the practical (extrinsic) adhesion strength of a coating-substrate system, which depends on the complex interaction of the test parameters (stylus properties and geometry, loading rate, displacement rate, and so forth) and the coating/substrate properties (hardness, fracture strength, modulus of elasticity, damage mechanisms, microstructure, flaw population, surface roughness, and so forth).

1.4.2 The defined test method is not directly applicable to metal or polymeric coatings which fail in a ductile, plastic manner, because plastic deformation mechanisms are very different than the brittle damage modes and features observed in hard ceramic coatings. The test method may be applicable to hard metal coatings which fail in a brittle mode with appropriate changes in test parameters and damage analysis procedures and criteria.

1.4.3 The test method, as defined with the Rockwell C diamond stylus and specific normal force and rate parameters, is not recommended for very thin (30 μm). Such coatings may require different stylus geometries, loading rates, and ranges of applied normal force for usable, accurate, repeatable results.

1.4.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. Test data values in SI units (newtons (N) for force and millimetres (mm) for displacement) are to be considered as standard and are in accordance with IEEE/ASTM SI 10.

1.4.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1624 – 05

Standard Test Method for

Adhesion Strength and Mechanical Failure Modes of

Ceramic Coatings by Quantitative Single Point Scratch

Testing

This standard is issued under the fixed designation C1624; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope surement of the practical (extrinsic) adhesion strength of a

coating-substrate system, which depends on the complex

1.1 This test method covers the determination of the prac-

interaction of the test parameters (stylus properties and geom-

tical adhesion strength and mechanical failure modes of hard

etry, loading rate, displacement rate, and so forth) and the

(Vickers Hardness HV = 5 GPa or higher), thin (#30 µm)

coating/substrateproperties(hardness,fracturestrength,modu-

ceramic coatings on metal and ceramic substrates at ambient

lus of elasticity, damage mechanisms, microstructure, flaw

temperatures. These ceramic coatings are commonly used for

population, surface roughness, and so forth).

wear/abrasion resistance, oxidation protection, and functional

1.4.2 The defined test method is not directly applicable to

(optical, magnetic, electronic, biological) performance im-

metal or polymeric coatings which fail in a ductile, plastic

provement.

manner, because plastic deformation mechanisms are very

1.2 Inthetestmethod,adiamondstylusofdefinedgeometry

different than the brittle damage modes and features observed

(Rockwell C, a conical diamond indenter with an included

inhardceramiccoatings.Thetestmethodmaybeapplicableto

angle of 120° and a spherical tip radius of 200 µm) is drawn

hard metal coatings which fail in a brittle mode with appro-

across the flat surface of a coated test specimen at a constant

priate changes in test parameters and damage analysis proce-

speed and a defined normal force (constant or progressively

dures and criteria.

increasing) for a defined distance. The damage along the

1.4.3 The test method, as defined with the Rockwell C

scratch track is microscopically assessed as a function of the

diamond stylus and specific normal force and rate parameters,

applied force. Specific levels of progressive damage are

isnotrecommendedforverythin(<0.1µm)orthickercoatings

associated with increasing normal stylus forces. The force

(>30 µm). Such coatings may require different stylus geom-

level(s) which produce a specific type/level of damage in the

etries, loading rates, and ranges of applied normal force for

coatingaredefinedasacriticalscratchload(s).Thetestmethod

usable, accurate, repeatable results.

alsodescribestheuseoftangentialforceandacousticemission

1.4.4 The values stated in SI units are to be regarded as

signals as secondary test data to identify different coating

standard. No other units of measurement are included in this

damage levels.

standard. Test data values in SI units (newtons (N) for force

1.3 Applicability to Coatings—This test method is appli-

andmillimetres(mm)fordisplacement)aretobeconsideredas

cable to a wide range of hard ceramic coating compositions:

standard and are in accordance with IEEE/ASTM SI10.

carbides, nitrides, oxides, diamond, and diamond-like carbon

1.4.5 This standard does not purport to address all of the

on ceramic and metal substrates. The test method, as defined

safety concerns, if any, associated with its use. It is the

with the 200 µm radius diamond stylus, is commonly used for

responsibility of the user of this standard to establish appro-

coating thicknesses in the range of 0.1 to 30 µm. Test

priate safety and health practices and determine the applica-

specimens generally have a planar surface for testing, but

bility of regulatory limitations prior to use.

cylinder geometries can also be tested with an appropriate

1.5 Organization—The test method is organized into the

fixture.

following sections:

1.4 Principal Limitations:

Section

1.4.1 The test method does not measure the fundamental

Scope 1

adhesion strength of the bond between the coating and the

Purpose and Description 1.1

substrate. Rather, the test method gives an engineering mea-

Applicability 1.3

Principal Limitations 1.4

Organization 1.5

Referenced Documents 2

This test method is under the jurisdiction of ASTM Committee C28 on

ASTM Standards 2.1

Advanced Ceramics and is the direct responsibility of Subcommittee C28.04 on

Other Standards and References 2.2

Applications.

Current edition approved June 1, 2005. Published June 2005. DOI: 10.1520/

C1624-05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1624 – 05

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Section

Terminology 3

terials

Summary of Test Method 4

E750 Practice for CharacterizingAcoustic Emission Instru-

Significance and Use 5

mentation

Test Methodology and Experimental Control 6

Test Overview 6.1

E1316 Terminology for Nondestructive Examinations

Test Modes 6.2

E1932 Guide for Acoustic Emission Examination of Small

Primary and Supplementary Measurements 6.3

Parts

Critical Scratch Load Damage Criteria and Scratch Atlas 6.4

Experimental Factors and Variables 6.5

IEEE/ASTM SI10 Standard for Use of the International

Interferences 7

System of Units (SI) (The Modern Metric System)

Material and Specimen Related 7.2

Test Method Related 7.3 2.2 ASME Standard:

Apparatus 8

ASME B46.1 Surface Texture (Surface Roughness, Wavi-

General Description 8.1

ness, and Lay)

Stylus and Stylus Mounting 8.2

Mechanical Stage and Displacement Control 8.3 2.3 CEN Standard:

Test Frame and Force Application System 8.4

CEN prEN 1071-3 Advanced Technical Ceramics—

Force and Displacement Sensors 8.5

Methods of Test for Ceramic Coatings—Part 3: Determi-

Optical Analysis and Measurement 8.6

nation OfAdhesiveAnd Other Mechanical Failure Modes

Data Acquisition and Recording 8.7

Acoustic Emission (Optional) 8.8

By A Scratch Test

Coating Adhesion Reference Specimens (Optional) 8.9

Coating Surface Profilometry (Optional) 8.10

3. Terminology

Data Analysis and Output Software (Optional) 8.11

Test Specimens 9

3.1 Definitions:

Specimen Requirements 9.1

3.1.1 acoustic emission, n—class of phenomenon in which

Specimen Characterization 9.2

Specimen Size 9.3 elasticwavesaregeneratedbytherapidreleaseofenergyfrom

Specimen Flatness and Level 9.4

localized sources within a material, or the transient waves so

Polishing (Optional) 9.5

generated. E1316

Specimen Exposure Conditioning (Optional) 9.6

Specimen Cleaning 9.7

3.1.2 adhesive failure, n—detachment and separation of a

Specimen Handling and Storage 9.8

coating from the substrate with cracking and debonding at the

Calibration 10

coating-substrate interface.

System Calibration 10.1

Reference Specimens 10.2 3.1.3 cohesive failure, n—material damage and cracking in

Test Procedure 11

the coating or in the substrate, separate and distinct from

Calibration 11.1

detachment and adhesive debonding at the coating-substrate

Test Mode Selection 11.2

Test Planning 11.3

interface.

Stylus Inspection and Cleaning 11.4

3.1.4 critical scratch load (L ), n—appliednormalforceat

CN

Environmental Conditions 11.5

which a specific, well-defined, recognizable damage/failure

System Set-Up and Check 11.6

Test Specimen Mounting 11.7

event occurs or is observed in the scratch test of a specific

Conducting the Test 11.8

coating on a specific substrate.

Specimen Count 11.9

3.1.4.1 Discussion—The subscript N is used to identify

Invalid and Censored Data 11.10

Scratch Damage Assessment 11.11

progressive failure events. For example, L is often used to

C1

Calculations 12

identify the first level of cohesive failure in the coating itself;

Report 13

L is often used to identify first adhesive failure between the

Test Identification 13.2

C2

Specimen Information 13.3

coating and the substrate. Multiple subscripts can be used for

Test Equipment and Procedure Information 13.4

progressive levels of distinct damage in a specific coating-

Test Data and Statistics 13.5

substrate systems.

Precision and Bias 14

Keywords 15

3.1.5 fundamental adhesion, n—summation of all interfa-

Rockwell Diamond Indenter Specifications Annex A1

cial intermolecular interactions between a film or coating and

Alignment and Calibration Annex A2

its substrate.

Repeatability and Reproducibility Studies Annex A3

Coating Damage Criteria and Scratch Atlas Appendix X1

3.1.6 normal force (L ), n—in a scratch test, the force

N

Experimental Variables in Scratch Adhesion Testing Appendix X2

exerted by the stylus, perpendicular to the test surface of the

Bibliography

test specimen.

3.1.7 practical adhesion, n—force or work required to

2. Referenced Documents

2 remove or detach a film or coating from its substrate irrespec-

2.1 ASTM Standards:

tive of the locus of failure.

B659 Guide for Measuring Thickness of Metallic and Inor-

3.1.7.1 Discussion—“Practical adhesion” is a test concept

ganic Coatings

which uses various engineering coating adhesion test methods

E4 Practices for Force Verification of Testing Machines

Available from American Society of Mechanical Engineers (ASME), ASME

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Three ParkAve., NewYork, NY10016-5990, www.as-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM me.org.

Standards volume information, refer to the standard’s Document Summary page on Available from European Committee for Standardization (CEN), 36 rue de

the ASTM website. Stassart, B–1050 Brussels, www.cenorm.be.

C1624 – 05

to obtain a quantitative, reproducible adhesion measurement

which can be related to the functional performance of the

coating. The practical adhesion is an extrinsic property which

depends on the complex interaction of coating/substrate prop-

erties and characteristics with the specific test parameters.

3.1.8 stylus drag coeffıcient, n—in scratch testing, the di-

mensionless ratio of the tangential force to the normal force

applied to the stylus at a specific point in the scratch test.

3.1.8.1 Discussion—The term stylus drag coefficient is

preferred to the more common term scratch coefficient of

friction (SCF). The tangential force is primarily a measure of

the perpendicular force required to plow the indenter through

the coating, rather than to slide it on the surface (sliding

friction is a relatively minor contribution to the measured

tangential force unless penetration is very small and surface

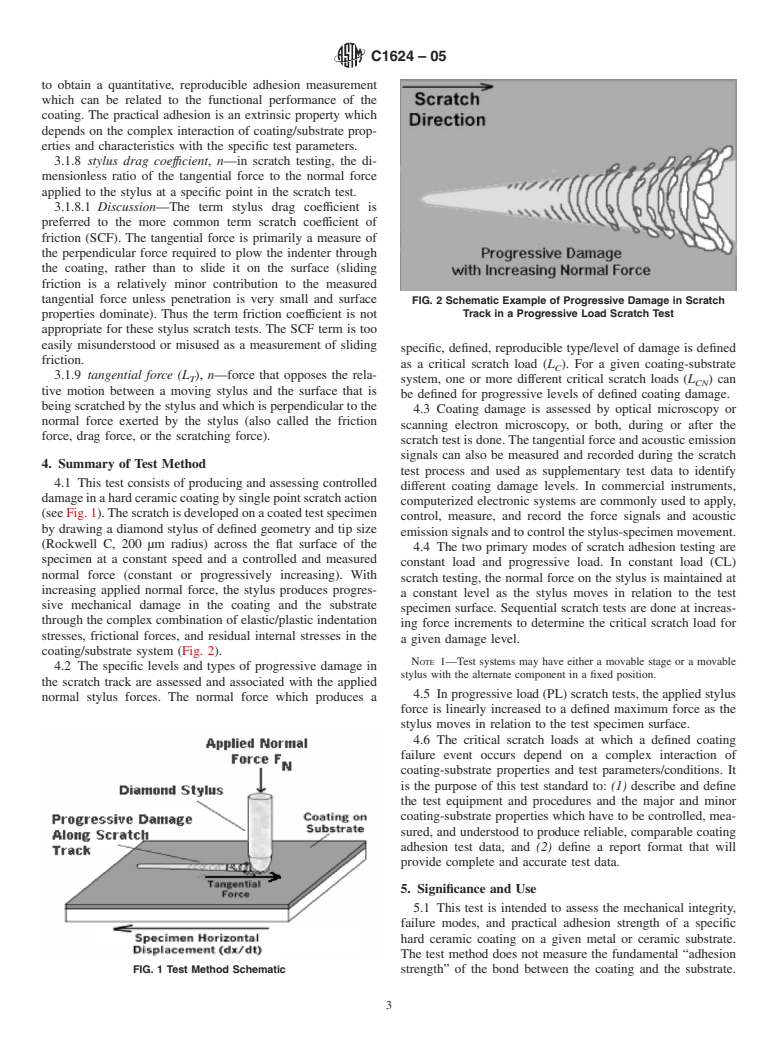

FIG. 2 Schematic Example of Progressive Damage in Scratch

properties dominate). Thus the term friction coefficient is not Track in a Progressive Load Scratch Test

appropriate for these stylus scratch tests. The SCF term is too

easily misunderstood or misused as a measurement of sliding

specific, defined, reproducible type/level of damage is defined

friction.

as a critical scratch load (L ). For a given coating-substrate

C

3.1.9 tangential force (L ), n—force that opposes the rela-

T system, one or more different critical scratch loads (L ) can

CN

tive motion between a moving stylus and the surface that is

be defined for progressive levels of defined coating damage.

beingscratchedbythestylusandwhichisperpendiculartothe

4.3 Coating damage is assessed by optical microscopy or

normal force exerted by the stylus (also called the friction

scanning electron microscopy, or both, during or after the

force, drag force, or the scratching force).

scratchtestisdone.Thetangentialforceandacousticemission

signals can also be measured and recorded during the scratch

4. Summary of Test Method

test process and used as supplementary test data to identify

4.1 This test consists of producing and assessing controlled

different coating damage levels. In commercial instruments,

damageinahardceramiccoatingbysinglepointscratchaction

computerized electronic systems are commonly used to apply,

(seeFig.1).Thescratchisdevelopedonacoatedtestspecimen

control, measure, and record the force signals and acoustic

by drawing a diamond stylus of defined geometry and tip size

emissionsignalsandtocontrolthestylus-specimenmovement.

(Rockwell C, 200 µm radius) across the flat surface of the

4.4 The two primary modes of scratch adhesion testing are

specimen at a constant speed and a controlled and measured

constant load and progressive load. In constant load (CL)

normal force (constant or progressively increasing). With

scratch testing, the normal force on the stylus is maintained at

increasing applied normal force, the stylus produces progres-

a constant level as the stylus moves in relation to the test

sive mechanical damage in the coating and the substrate

specimen surface. Sequential scratch tests are done at increas-

through the complex combination of elastic/plastic indentation

ing force increments to determine the critical scratch load for

stresses, frictional forces, and residual internal stresses in the

a given damage level.

coating/substrate system (Fig. 2).

NOTE 1—Test systems may have either a movable stage or a movable

4.2 The specific levels and types of progressive damage in

stylus with the alternate component in a fixed position.

the scratch track are assessed and associated with the applied

4.5 In progressive load (PL) scratch tests, the applied stylus

normal stylus forces. The normal force which produces a

force is linearly increased to a defined maximum force as the

stylus moves in relation to the test specimen surface.

4.6 The critical scratch loads at which a defined coating

failure event occurs depend on a complex interaction of

coating-substrate properties and test parameters/conditions. It

is the purpose of this test standard to: (1) describe and define

the test equipment and procedures and the major and minor

coating-substrate properties which have to be controlled, mea-

sured, and understood to produce reliable, comparable coating

adhesion test data, and (2) define a report format that will

provide complete and accurate test data.

5. Significance and Use

5.1 This test is intended to assess the mechanical integrity,

failure modes, and practical adhesion strength of a specific

hard ceramic coating on a given metal or ceramic substrate.

The test method does not measure the fundamental “adhesion

FIG. 1 Test Method Schematic strength” of the bond between the coating and the substrate.

C1624 – 05

Rather, the test method gives a quantitative engineering mea- 5.8 The test is commonly conducted under unlubricated

surement of the practical (extrinsic) adhesion strength and conditionsandatroomtemperature.However,itisfeasibleand

possib

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.