ASTM D4024-00

(Specification)Standard Specification for Machine Made "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

Standard Specification for Machine Made "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

SCOPE

1.1 This specification covers reinforced-thermosetting-resin flanges other than contact-molded flanges. Included are requirements for materials, workmanship, performance, and dimensions.

1.2 Flanges may be produced integrally with a pipe or fitting, may be produced with a socket for adhesive bonding to a pipe or fitting, or may be of the type used in conjunction with either a metallic or nonmetallic backup ring.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only. In cases where materials, products, or equipment are available only in SI units, inch-pound units are omitted.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-Contact molded flanges are covered in Specification D5421. Note 2-There is no similar or equivalent ISO standard. Note 3-For purposes of this specification, polyester includes vinylester resins.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4024 – 00

Standard Specification for

Machine Made “Fiberglass’’ (Glass-Fiber-Reinforced

Thermosetting Resin) Flanges

This standard is issued under the fixed designation D 4024; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1600 Terminology for Abbreviated Terms Relating to

Plastics

1.1 This specification covers reinforced-thermosetting resin

D 1898 Practice for Sampling of Plastics

flanges other than contact-molded flanges. Included are re-

D 5421 Specification for Contact Molded “Fiberglass’’

quirements for materials, workmanship, performance, and

(Glass-Fiber-Reinforced Resin) Flanges

dimensions.

D 5685 Specification for “Fiberglass” (Glass-Fiber-

1.2 Flanges may be produced integrally with a pipe or

Reinforced Thermosetting-Resin) Pressure Pipe Fittings

fitting, may be produced with a socket for adhesive bonding to

F 412 Terminology Relating to Plastic Piping Systems

a pipe or fitting, or may be of the type used in conjunction with

2.2 ANSI Standards:

either a metallic or nonmetallic backup ring.

B 16.1 Cast Iron Pipe Flanges and Flanged Fittings

1.3 The values stated in inch-pound units are to be regarded

B 16.5 Pipe Flanges and Flanged Fittings

as the standard. The values in parentheses are given for

information only. In cases where materials, products, or equip-

3. Terminology

ment are available only in SI units, inch-pound units are

3.1 Definitions:

omitted.

3.1.1 General—Definitions are in accordance with Termi-

1.4 The following precautionary caveat pertains only to the

nology D 883 or Terminology F 412. Abbreviations are in

test methods portion, Section 11, of this specification: This

accordance with Terminology D 1600, unless otherwise indi-

standard does not purport to address all of the safety concerns,

cated.The abbreviation for reinforced-thermosetting-resin pipe

if any, associated with its use. It is the responsibility of the user

is RTRP.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

4. Classification

tions prior to use.

4.1 General—This specification covers machine-made

NOTE 1—Contact molded flanges are covered in Specification D 5421

reinforced-thermosetting-resinflangesdefinedbytype(method

and referenced in Specification D 5685.

of manufacture), grade (generic type of resin), class (configu-

NOTE 2—There is no similar or equivalent ISO standard.

ration of joining system), and pressure rating. Flanges com-

NOTE 3—For purposes of this specification, polyester includes viny-

plying with this specification are also given numerical classi-

lester resins.

fications relating to rupture pressure, sealing test pressure, and

2. Referenced Documents

bolt torque limit.

4.1.1 Types:

2.1 ASTM Standards:

4.1.1.1 Type 1—Filament-wound flanges manufactured by

D 618 Practice for Conditioning Plastics and Electrical

winding continuous fibrous glass strand roving or roving tape,

Insulating Materials for Testing

either preimpregnated or impregnated during winding, into a

D 883 Terminology Relating to Plastics

flange cavity under controlled tension.

D 1599 TestMethodforShort-TimeHydraulicFailurePres-

4.1.1.2 Type 2—Compression-molded flanges made by ap-

sure of Plastic Pipe, Tubing, and Fittings

plying external pressure and heat to a molding compound that

is confined within a closed mold.

This specification is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment.

Current edition approved March 10, 2000. Published May 2000. Originally

published as D 4024 – 81. Last previous edition D 4024 – 00. Annual Book of ASTM Standards, Vol 08.02.

2 5

Annual Book of ASTM Standards, Vol 08.01. Available from American National Standards Institute, 11 West 42nd Street,

Annual Book of ASTM Standards, Vol 08.04. 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4024

4.1.1.3 Type 3—Resin-transfer-molded flanges manufac- 200 psi (1.4 MPa) pressure rating, a burst pressure in excess of

tured by pumping a thermosetting resin into glass reinforce- 600 psi (4.1 MPa), a sealing test pressure of 225 psi (1.6 MPa),

ments that have been cut to size and clamped between matched and a bolt torque limit greater than 75 lbf·ft (102 N·m).

molds.

NOTE 4—Flanges with identical classification from different manufac-

4.1.1.4 Type 4—Centrifugally-cast flanges are made by

turers may not be interchangeable due to nonstandardization of pipe or

applying resin and reinforcement to the inside of a mold that is

socket diameter, socket length, taper angle, or combination thereof.

rotated and heated, subsequently polymerizing the resin sys-

5. Materials and Manufacture

tem.

4.1.2 Grades:

5.1 Flanges manufactured in accordance with this specifi-

4.1.2.1 Grade 1—Epoxy resin.

cation shall be composed of reinforcement imbedded in or

4.1.2.2 Grade 2—Polyester resin.

surrounded by cured thermosetting resin. The composite struc-

4.1.2.3 Grade 3—Furan resin.

ture may contain granular or platelet fillers, thixotropic agents,

4.1.3 Classes:

pigments, or dyes.

4.1.3.1 Class 1—Integrally-molded flange manufactured di-

5.2 The resins, reinforcements, and other materials, when

rectly on a pipe section, pipe stub, or fitting.

combined as composite structure, shall produce a flange that

4.1.3.2 Class 2—Taper to taper adhesive joint flange manu-

will meet the performance requirements of this specification.

factured with a tapered socket to be used in conjunction with a

pipe or fitting with a tapered spigot section and a suitable

6. Performance Requirements

adhesive. This joining method provides an interference fit over

6.1 Flanges shall meet the following performance require-

the entire length of the bond line.

ments when joined for testing according to the manufacturer’s

4.1.3.3 Class 3—Straight-taper adhesive joint flange manu-

recommended practice for field installation:

factured with a tapered socket to be used with a pipe or fitting

6.1.1 Sealing—Flanges shall withstand a pressure of at least

with an untapered spigot section and a suitable adhesive. This

1.5timestherateddesignpressurewithoutleakagewhentested

joining method provides an interference fit at the bottom of the

in accordance with 11.4.

socket.

6.1.2 Short-Term Rupture Strength—Flanges shall with-

4.1.3.4 Class 4—Straight adhesive joint flange manufac-

stand a hydrostatic load of at least four times their rated design

tured with an untapered socket for use with a pipe or fitting

pressure without damage to the flange when tested in accor-

with an untapered spigot and a suitable adhesive. This joint

dance with 11.5.

provides no interference fit.

6.1.3 Bolt Torque—Flanges shall withstand, without visible

4.1.4 Pressure Rating—Pressure rating shall be categorized

sign of damage, a bolt torque of at least 1.5 times that

by a single letter designation. Pressure designations are shown

recommended by the manufacturer for sealing of the flange at

in Table 1.

its rated pressure when tested in accordance with 11.6.

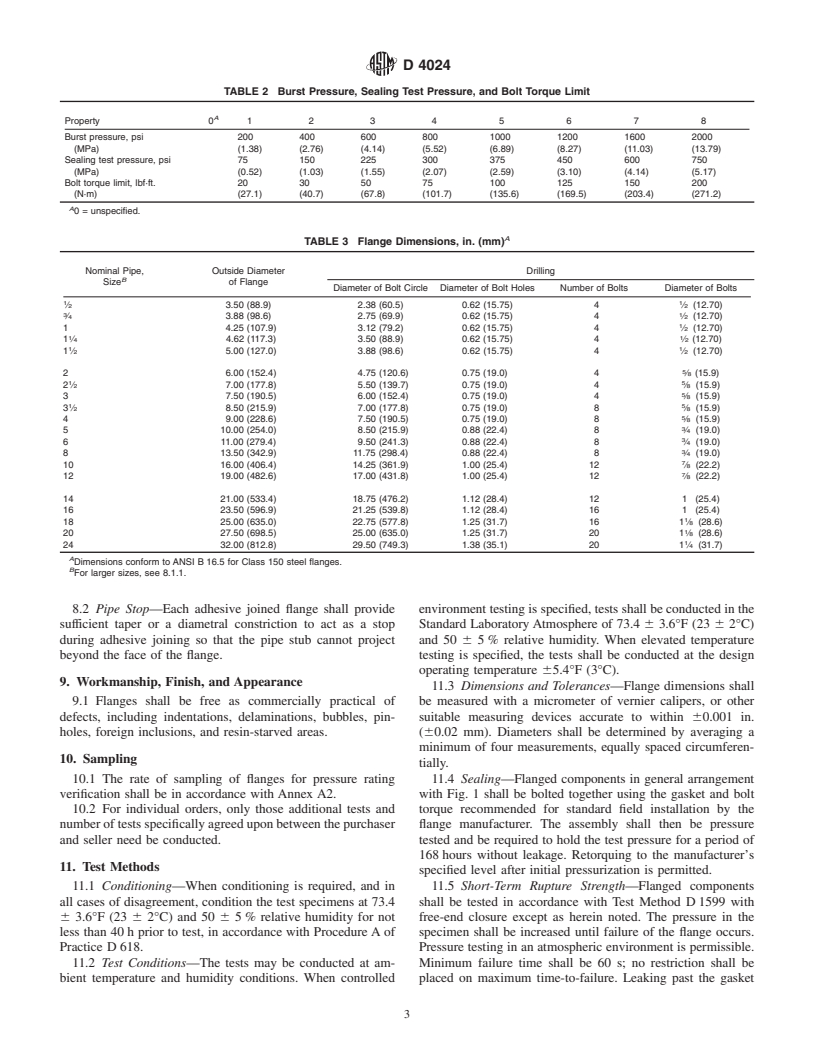

4.1.5 Rupturepressure,sealingtestpressure,andbolttorque

limit shall be categorized by single arabic number designations

7. Content Requirements

as indicated by the cell classification system of Table 2.

7.1 Percentage Extractable Material— Flanges shall con-

4.2 Designation Code—The flange designation code shall

tain no more than 5 % extractable material when tested in

consist of the abbreviation RTR, followed by the type, grade,

accordance with Annex A1.

and class in arabic numerals, the pressure rating category as a

7.2 Recycled or Repprocessed Thermosetting Plastics—

capital letter, and three arabic numbers identifying the cell

Flanges shall not contain any recylced or reprocessed thermo-

classification designations of the rupture pressure, sealing test

setting plastics which might otherwise be added as fillers.

pressure, and the bolt torque limit, respectively. Thus, a

complete flange designation code shall consist of three letters,

8. Dimensions

three numerals and one letter, and three numerals.

8.1 Dimensions and Tolerances:

4.2.1 Example—RTR-112D-334.Thisdesignationdescribes

8.1.1 Flange and Bolt Dimensions—Flanges of 24 in. (610

a filament-wound, glass fiber-reinforced epoxy resin flange

mm) or smaller diameter shall conform to the values given in

with a taper to taper adhesive joining system. The flange has a

Table 3 for bolt circle, number and size of bolt holes, and

outside diameter. Flanges larger than 24 in. (610 mm) in

TABLE 1 Pressure Categories diameter shall conform to the values for bolt circle, number

and size of bolt holes, and outside diameter for Class 125 cast

Pressure Rating

iron flanges in ANSI B 16.1. The tolerance for the flange

Designation

psi MPa

dimensions provided in Table 3 shall be the same as those

A 50 0.35 contained in ANSI B 16.1.

B 100 0.69

8.1.2 Flange Face—The flange face shall be perpendicular

C 150 1.03

1 1

to the axis of the fitting within ⁄2°, and shall be flat to 6 ⁄32 in.

D 200 1.38

E 250 1.72 (1 mm) for sizes up to and including 18 in. (457 mm) diameter

F 300 2.07

and 6 ⁄16 in. (2 mm) for larger diameters.

G 400 2.76

8.1.3 Washer Bearing Surface—Washer bearing surface

H 500 3.45

shall be flat and parallel to the flange face within 61°.

D 4024

TABLE 2 Burst Pressure, Sealing Test Pressure, and Bolt Torque Limit

A

Property 0 1 2 3 45678

Burst pressure, psi 200 400 600 800 1000 1200 1600 2000

(MPa) (1.38) (2.76) (4.14) (5.52) (6.89) (8.27) (11.03) (13.79)

Sealing test pressure, psi 75 150 225 300 375 450 600 750

(MPa) (0.52) (1.03) (1.55) (2.07) (2.59) (3.10) (4.14) (5.17)

Bolt torque limit, lbf·ft. 20 30 50 75 100 125 150 200

(N·m) (27.1) (40.7) (67.8) (101.7) (135.6) (169.5) (203.4) (271.2)

A

0 = unspecified.

A

TABLE 3 Flange Dimensions, in. (mm)

Nominal Pipe, Outside Diameter Drilling

B

Size of Flange

Diameter of Bolt Circle Diameter of Bolt Holes Number of Bolts Diameter of Bolts

1 1

⁄2 3.50 (88.9) 2.38 (60.5) 0.62 (15.75) 4 ⁄2 (12.70)

3 1

⁄4 3.88 (98.6) 2.75 (69.9) 0.62 (15.75) 4 ⁄2 (12.70)

1 4.25 (107.9) 3.12 (79.2) 0.62 (15.75) 4 ⁄2 (12.70)

1 1

1 ⁄4 4.62 (117.3) 3.50 (88.9) 0.62 (15.75) 4 ⁄2 (12.70)

1 1

1 ⁄2 5.00 (127.0) 3.88 (98.6) 0.62 (15.75) 4 ⁄2 (12.70)

2 6.00 (152.4) 4.75 (120.6) 0.75 (19.0) 4 ⁄8 (15.9)

1 5

2 ⁄2 7.00 (177.8) 5.50 (139.7) 0.75 (19.0) 4 ⁄8 (15.9)

3 7.50 (190.5) 6.00 (152.4) 0.75 (19.0) 4 ⁄8 (15.9)

1 5

3 ⁄2 8.50 (215.9) 7.00 (177.8) 0.75 (19.0) 8 ⁄8 (15.9)

4 9.00 (228.6) 7.50 (190.5) 0.75 (19.0) 8 ⁄8 (15.9)

5 10.00 (254.0) 8.50 (215.9) 0.88 (22.4) 8 ⁄4 (19.0)

6 11.00 (279.4) 9.50 (241.3) 0.88 (22.4) 8 ⁄4 (19.0)

8 13.50 (342.9) 11.75 (298.4) 0.88 (22.4) 8 ⁄4 (19.0)

10 16.00 (406.4) 14.25 (361.9) 1.00 (25.4) 12 ⁄8 (22.2)

12 19.00 (482.6) 17.00 (431.8) 1.00 (25.4) 12 ⁄8 (22.2)

14 21.00 (533.4) 18.75 (476.2) 1.12 (28.4) 12 1 (25.4)

16 23.50 (596.9) 21.25 (539.8) 1.12 (28.4) 16 1 (25.4)

18 25.00 (635.0) 22.75 (577.8) 1.25 (31.7) 16 1 ⁄8 (28.6)

20 27.50 (698.5) 25.00 (635.0) 1.25 (31.7) 20 1 ⁄8 (28.6)

24 32.00 (812.8) 29.50 (749.3) 1.38 (35.1) 20 1 ⁄4 (31.7)

A

Dimensions conform to ANSI B 16.5 for Class 150 steel flanges.

B

For larger sizes, see 8.1.1.

8.2 Pipe Stop—Each adhesive joined flange shall provide environment testing is specified, tests shall be conducted in the

sufficient taper or a diametral constriction to act as a stop Standard Laboratory Atmosphere of 73.4 6 3.6°F (23 6 2°C)

during adhesive joining so that the pipe stub cannot project and 50 6 5 % relative humidity. When elevated temperature

beyond the face of the flange. testing is specified, the tests shall be conducted at the design

operating temperature 65.4°F (3°C).

9. Workmanship, Finish, and Appearance

11.3 Dimensions and Tolerances—Flange dimensions shall

9.1 Flanges shall be free as commercially practical of be measured with a micrometer of vernier calipers, or other

defects, including indentations, delaminations, bubbles, pin- suitable measuring devices accurate to within 60.001 in.

holes, foreign inclusions, and resin-starved areas. (60.02 mm). Diameters shall be determined by averaging a

minimum of four measurements, equally spaced circumferen-

10. Sampling

tially.

10.1 The rate of sampling of flanges for pressure rating 11.4 Sealing—Flanged components in general arrangement

verification shall be in accordance with Annex A2. with Fig. 1 shall be bolted together using the gasket and bolt

10.2 For individual orders, only those additional tests and torque recommended for standard field installation by the

numberoftestsspecificallyagreeduponbetweenthepurchaser flange manufacturer. The assembly shall then be pressure

and seller need be conducted. tested and be required to hold the test pressure for a period of

168 hours without leakage. Retorquing to the manufacturer’s

11. Test Methods

specified level after initial pressurization is permitted.

11.1 Conditioning—When conditioning is required, and in 11.5 Short-Term Rupture Strength—Flanged components

all cases of disagreement, condition the test specimens at 73.4 shall be tested in accordance with Test Method D 1599 with

6 3.6°F (23 6 2°C) and 50 6 5 % relative humidity for not free-end closure except as herein noted. The pressure in the

less than 40 h prior to test, in accordance with Procedure A of specimen shall be increased until failure of the flange occurs.

Practice D 618. Pressure testing in an atmospheric environment is permissible.

11.2 Test Conditions—The tests may be conducted at am- Minimum failure time shall be 60 s; no restriction shall be

bient temperature and humidity conditions. When controlled placed on maximum time-to-failure. Leaking past the gasket

D 4024

FIG. 2 Bolt Torquing Sequence

FIG. 1 Test Assembly Configuration

interface is permissible during this test. Bolt torque may be

12. Product Marking

increased as necessary during the test in order to minimize

12.1 Each flange shall be marked with the following infor-

gasket leaking and to achieve the pressure necessary to cause

mation:

flange failure. The assembly used for the test in 11.4 may be

12.1.1 The designation “ASTM D 4024” indicating compli-

used for this test.

ance with this specification,

11.6 Maximum Bolt Torque—Using the gasket and hard-

12.1.2 Identification of the flange in accordance with the

ware recommended by the flange manufacturer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.