ASTM A955/A955M-04ae1

(Specification)Standard Specification for Deformed and Plain Stainless Steel Bars for Concrete Reinforcement

Standard Specification for Deformed and Plain Stainless Steel Bars for Concrete Reinforcement

SCOPE

1.1 This specification covers deformed and plain stainless steel bars for concrete reinforcement used in applications requiring resistance to corrosion or controlled magnetic permeability. The standard sizes and dimensions of deformed bars and their numerical designation shall be those listed in Table 1. The text of this specification references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.1.1 Supplementary requirement (S1) of an optional nature is provided. It shall apply only when specified by the purchaser. In order to obtain a controlled magnetic permeability product, steel conforming to Supplementary Requirement S1 should be ordered.

1.2 The chemical composition of the stainless steel alloy shall be selected for suitability to the application involved by agreement between the manufacturer and the purchaser. This is an important consideration in achieving the desired corrosion resistance and/or controlled magnetic permeability.

Note 1—The alloys shown in Table 2 have found the most use in North America. These and other stainless steel alloys specified in A 276 or other specifications are available for consideration in product selection. Consult with the steel manufacturer for stainless steel alloy availability.

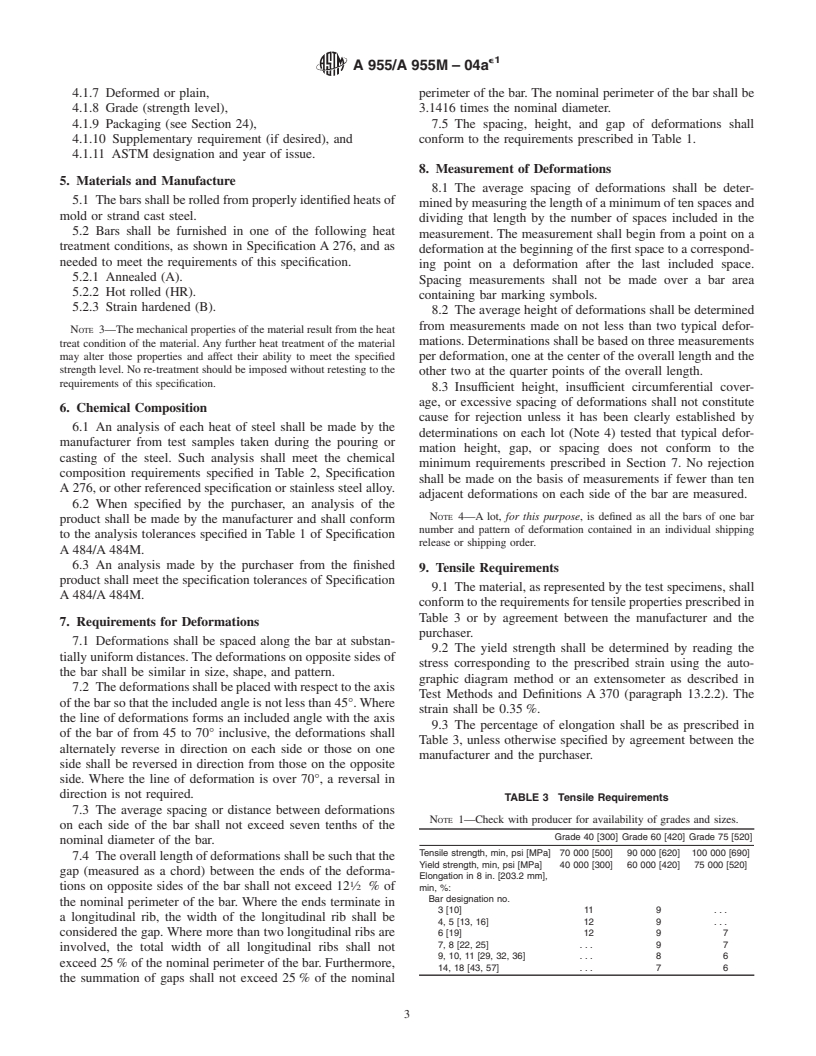

1.3 Bars are generally of three minimum yield levels, namely, 40 000 [300 MPa], 60 000 [420 MPa], and 75 000 psi [520 MPa], designated as Grade 40 [300], Grade 60 [420], and Grade 75 [520], respectively.

1.4 Plain rounds in sizes up to and including 2 in. [50.8 mm] in diameter, when specified for dowels, spirals, structural ties, and supports, shall be furnished under this specification in Grade 40 [300], Grade 60 [420], and Grade 75 [520], respectively. Bending properties, when required, shall be by agreement between the manufacturer and purchaser. Requirements providing for deformations and marking shall not be applicable to plain bars.

1.5 Weldability of most stainless steel compositions is generally good, however, pre-weld or post-weld procedures, or both, are necessary. Where material is to be welded, a welding procedure suitable for the chemical composition and intended use or service shall be used. Retesting of physical properties should be considered following welding procedures depending upon the steel composition and welding operation involved.

Note 2—It is recommended that the user consult the manufacturer for information available from the Nickel Development Institute (NIDI) (Toronto, Canada).

1.6 This specification is applicable for orders in either inch-pound units (as Specification A 955) or in SI units (as Specification A 955M).

1.7 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: A 955/A 955M – 04a

Standard Specification for

Deformed and Plain Stainless Steel Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designationA955/A955M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Editorial changes were made to Table 1 in August 2004.

1. Scope* ment between the manufacturer and purchaser. Requirements

providingfordeformationsandmarkingshallnotbeapplicable

1.1 This specification covers deformed and plain stainless

to plain bars.

steel bars for concrete reinforcement used in applications

1.5 Weldability of most stainless steel compositions is

requiring resistance to corrosion or controlled magnetic per-

generally good, however, pre-weld or post-weld procedures, or

meability. The standard sizes and dimensions of deformed bars

both, are necessary. Where material is to be welded, a welding

and their numerical designation shall be those listed inTable 1.

procedure suitable for the chemical composition and intended

The text of this specification references notes and footnotes

use or service shall be used. Retesting of physical properties

which provide explanatory material. These notes and footnotes

should be considered following welding procedures depending

(excluding those in tables and figures) shall not be considered

upon the steel composition and welding operation involved.

as requirements of the specification.

1.1.1 Supplementary requirement (S1) of an optional nature

NOTE 2—It is recommended that the user consult the manufacturer for

isprovided.Itshallapplyonlywhenspecifiedbythepurchaser.

information available from the Nickel Development Institute (NIDI)

(Toronto, Canada).

In order to obtain a controlled magnetic permeability product,

steel conforming to Supplementary Requirement S1 should be

1.6 This specification is applicable for orders in either

ordered.

inch-pound units (as Specification A 955) or in SI units (as

1.2 The chemical composition of the stainless steel alloy

Specification A 955M).

shall be selected for suitability to the application involved by

1.7 The values stated in either inch-pound or SI units are to

agreement between the manufacturer and the purchaser.This is

be regarded separately as standard.Within the text, the SI units

an important consideration in achieving the desired corrosion

are shown in brackets.The values stated in each system are not

resistance and/or controlled magnetic permeability.

exact equivalents; therefore, each system shall be used inde-

pendentlyoftheother.Combiningvaluesfromthetwosystems

NOTE 1—ThealloysshowninTable2havefoundthemostuseinNorth

may result in nonconformance with the standard.

America. These and other stainless steel alloys specified inA 276 or other

specifications are available for consideration in product selection. Consult

2. Referenced Documents

with the steel manufacturer for stainless steel alloy availability.

2

2.1 ASTM Standards:

1.3 Bars are generally of three minimum yield levels,

A 6/A6M Specification for General Requirements for

namely, 40 000 [300 MPa], 60 000 [420 MPa], and 75 000 psi

Rolled Structural Steel Bars, Plates, Shapes, and Sheet

[520 MPa], designated as Grade 40 [300], Grade 60 [420], and

Piling

Grade 75 [520], respectively.

A 262 Practices for Detecting Susceptibility to Intergranu-

1.4 Plainroundsinsizesuptoandincluding2in.[50.8mm]

lar Attack in Austenitic Stainless Steels

in diameter, when specified for dowels, spirals, structural ties,

A 276 Specification for Stainless Steel Bars and Shapes

and supports, shall be furnished under this specification in

A 342 Test Methods for Permeability of Feebly Magnetic

Grade 40 [300], Grade 60 [420], and Grade 75 [520], respec-

Materials

tively. Bending properties, when required, shall be by agree-

A 370 Test Methods and Definitions for MechanicalTesting

of Steel Products

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

A01.05 on Steel Reinforcement.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2004. Published May 2004. Originally

Standards volume information, refer to the standard’s Document Summary page on

approved in 1996. Last previous edition approved in 2004 as A 955M - 04.

the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.