ASTM D5839-96(2001)

(Test Method)Standard Test Method for Trace Element Analysis of Hazardous Waste Fuel by Energy-Dispersive X-Ray Fluorescence Spectrometry

Standard Test Method for Trace Element Analysis of Hazardous Waste Fuel by Energy-Dispersive X-Ray Fluorescence Spectrometry

SCOPE

1.1 This test method applies to the determination of trace element concentrations by energy-dispersive X-ray fluorescence (EDXRF) spectrometry in typical liquid hazardous waste fuels (LHWF) used by industrial furnaces.

1.2 This test method has been used successfully on numerous samples of LHWF that are mixtures of solvents, oils, paints, and pigments for the determination of the following elements: Ag, As, Ba, Cd, Cr, Hg, Ni, Pb, Sb, Se, and Tl.

1.3 This test method also may be applicable to elements not listed above and to the analysis of trace metals in organic liquids other than those used as LHWF.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5839–96 (Reapproved 2001)

Standard Test Method for

Trace Element Analysis of Hazardous Waste Fuel by

Energy-Dispersive X-Ray Fluorescence Spectrometry

This standard is issued under the fixed designation D 5839; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 TheKSpectralX-rayemissionlinesareusedforAg,As,

Ba, Cd, Cr, Ni, Sb, and Se.

1.1 This test method applies to the determination of trace

3.3 The Lspectral X-ray emission lines are used for Hg, Pb,

element concentrations by energy-dispersive X-ray fluores-

and Tl.

cence(EDXRF)spectrometryintypicalliquidhazardouswaste

fuels (LHWF) used by industrial furnaces.

4. Significance and Use

1.2 This test method has been used successfully on numer-

4.1 The analysis of trace elements is often a regulatory and

ous samples of LHWF that are mixtures of solvents, oils,

process specific requirement for facilities utilizing LHWF.

paints, and pigments for the determination of the following

With proper instrument standardization, set-up, and quality

elements: Ag, As, Ba, Cd, Cr, Hg, Ni, Pb, Sb, Se, and Tl.

control, this test method provides the user an accurate, rapid,

1.3 This test method also may be applicable to elements not

nondestructive method for trace element determinations.

listed above and to the analysis of trace metals in organic

liquids other than those used as LHWF.

5. Interferences

1.4 This standard does not purport to address all of the

5.1 Spectral Overlaps:

safety concerns, if any, associated with its use. It is the

5.1.1 Samples containing a mixture of elements often ex-

responsibility of the user of this standard to establish appro-

hibit X-ray emission line overlap. Modern Si (Li) detectors

priate safety and health practices and determine the applica-

generally provide adequate resolution to minimize the effects

bility of regulatory limitations prior to use.

of spectrum overlaps on the analytical results of the LHWF. In

2. Referenced Documents those cases where direct emission line overlap exists, spectral

2 deconvolution methods extract corrected analyte emission line

2.1 ASTM Standards:

intensities. Table 1 lists the significant line overlaps observed

C 982 Guide for Selecting Components for Energy-

for the elements analyzed in LHWF. Follow the EDXRF

Dispersive X-Ray Fluorescence (XRF) Systems

manufacturer’s recommendations concerning spectral decon-

3. Summary of Test Method volution of the emission lines.

3.1 A weighed portion of the sample is transferred to a

NOTE 1—NotallpossibleinterferencesarelistedinTable1.TheLHWF

porcelain evaporating dish and placed on a hot plate. The samples to be analyzed may have other emission line interferences not

mentioned. Consult the manufacturer’s recommendations for optimum

sample is heated for 15 to 30 min at a temperature not

deconvolution methods.

exceeding 105°C to evaporate highly volatile components.The

dish is removed from the hot plate and allowed to cool.

5.2 Matrix Interferences:

Graphite powder is blended with the evaporated sample until a

5.2.1 Large concentration variations of metal or matrix

homogeneous paste is produced and the sample weight is

components, or both, in LHWF samples can result in non-

recorded. The blended sample is inserted in a disposable

linear metal X-ray intensity response at increasing metal

sample cup and placed in the X-ray spectrometer for analysis.

concentrations. Untreated matrix interactions may have a

deleterious effect on metal determination accuracy. Matrix

interactions, if exhibited by the LHWF samples, must be

accounted for by method calibration.

This guide is under the jurisdiction of ASTM Committee D34 on Waste

Management and is the direct responsibility of Subcommittee D34.01.06 on

6. Apparatus

Analytical Methods.

Current edition approved Jan. 10, 1996. Published March 1996.

6.1 Energy Dispersive X-Ray Spectrometer,capableofmea-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

suring the wavelengths listed in Table 1. Refer to C 982 for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

system specifications.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.2 Hot Plate, with temperature control to 105°C.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5839–96 (2001)

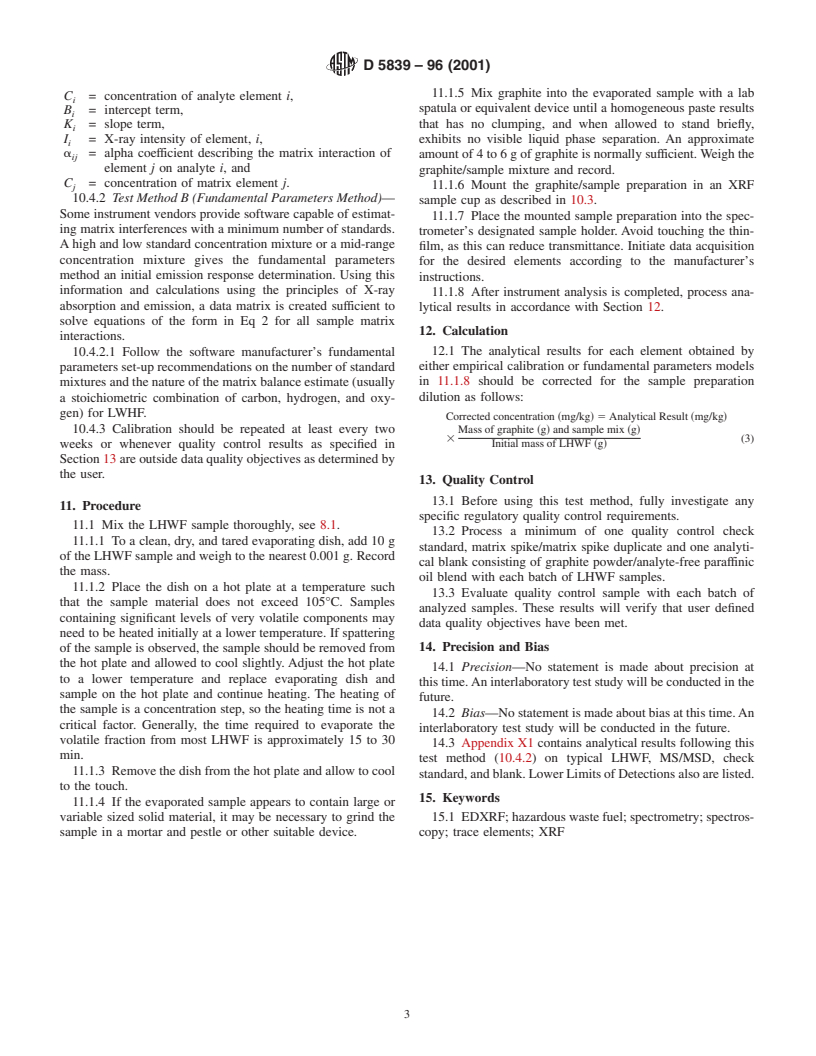

TABLE 1 Common Emission Line Spectral Interferences for

shaking prior to withdrawing a portion for testing, or use a

LHWF Analysis

sampling method that assures all portions of the sample are

Lines

represented.

Element Spectral Interferences

Determined

As Ka,Kb Pb La,HgLb,Tl La Lb

9. Preparation of Apparatus

Cr Ka,Kb VKb,MnKa

9.1 Follow the manufacturer’s instructions for set-up, con-

Hg La,Lb As Kb,SeKa,PbLb,Tl La,BrKa

Ni Ka,Kb Cu Kb,CuKa

ditioning, preparation, and maintenance of the XRF spectrom-

Pb La,Lb As Ka,SeKb Hg Lb Tl La,Tl Lb,BrKa,BrKb

eter.

Se Ka,Kb Pb Lb,HgLb,Tl Lb

9.2 Obtain reference spectra from pure element standards

Tl La,Lb As Ka,As Kb,SeKb,PbLa,BrKa,HgLa,HgLb

for all analytes and interelement correction metals.

9.3 Address spectral interferences, as listed in 5.1.1,in

accordance with manufacturer’s recommendations.

6.3 Analytical Balance, capable of weighing to 0.001 g.

6.4 Porcelain Evaporating Dishes, 70 to 150 mL capacity. 10. Calibration and Standardization

10.1 Calibrate the spectrometer to an appropriate reference

7. Reagents and Materials

element at the minimum frequency specified by the manufac-

7.1 Purity of Reagents—Use reagent grade chemicals in all turer.

tests. Unless otherwise indicated, all reagents will conform to 10.2 Analytical standards should be gravimetrically pre-

pared by blending the elemental standards and graphite listed

the specifications of the Committee on Analytical Reagents of

the American Chemical Society where such specifications are in Section 7. These preparations can contain single or multiple

elements and should be prepared at combinations and ratios to

available. Other grades may be used, provided it is first

ascertainedthatthereagentisofsufficienthighpuritytopermit meet the user’s individual needs. For example, a Pb and Cd

standard at 125 ppm each could be prepared by gravimetrically

its use without lessening the accuracy of the determination.

7.2 Use graphite powder, mixing grade, 44 µm, 325 mesh. combining 2 g oil-based Pb standard (500 ppm), 2 g oil-based

Cd standard (500 ppm) and 4 g graphite and blending to a

7.3 Use oil-basedAg,As, Ba, Cd, Cr, Hg, Ni, Pb, Sb and Se

standards, 10 to 10 000 mg/kg depending on the user’s homogeneous mixture. For this example, the Pb concentration

analytical requirements. If the results of this test method are to is calculated as follows:

be used for compliance purposes, standards or a commercial

Pb Standard Concentration 5 500 ppm

source must be traceable to NIST or other certifying body.

Pb Std. ~g!

Quality control samples for analyses done for compliance graphite ~g!1 Cd Std. ~g!1 Pb Std. ~g!

(1)

purposes may need to be prepared with standards from a

different vendor or lot number.

10.3 Themetalsstandard/graphitepasteisplacedinanXRF

7.4 Use oil or solvent-based Tl standard, 10 to 1000 mg/kg

sample cup and affixed with a thin-film support. The sample

depending on the user’s analytical requirements. If the results

cup is inverted and lightly tapped on a level surface until the

of this test method are to be used for compliance purposes,

blended paste makes full contact (no air spaces) with the

standards or a commercial source must be traceable to NISTor

thin-film support.

other certifying body.

10.3.1 The standard blends in the sample cups are placed

7.5 Use paraffinic base oil.

into the spectrometer’s designated sample holder.Avoid touch-

7.6 Use sample cups, vented or unvented.

ing the thin-film, as this can further reduce transmittance.

7.7 Use thin-film sample support.

Initiate data acquisition for the desired elements according to

the manufacturer’s instructions.

NOTE 2—The user should select a thin-film support that provides for

10.4 Two alternative standards calibration methods may be

maximum transmittance and is resistant to typical components in LHWF.

The thin-film supports used in the development of this test method were

used:

4 µm Prolene.

10.4.1 Test Method A (Empirical Calibration Method)—

Organic-based metals

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.