ASTM F3022-13

(Test Method)Standard Test Method for Evaluating the Universal Design of Fitness Equipment for Inclusive Use by Persons with Functional Limitations and Impairments

Standard Test Method for Evaluating the Universal Design of Fitness Equipment for Inclusive Use by Persons with Functional Limitations and Impairments

SCOPE

1.1 This test method2 specifies procedures and equipment used for testing and evaluating the accessibility of fitness equipment for compliance to Specification F3021 design parameters. Where possible and applicable, accepted test methods from other recognized bodies will be used and referenced. In case of a conflict between this document and Specification F3021, Specification F3021 takes precedence.

1.2 This test method is to be used in conjunction with Specification F3021.

1.3 This standard is to be used as additional requirements to address the accessibility of the equipment for persons with disabilities.Note 1—Additional test methods applicable to specific pieces of equipment, such as treadmills, bicycles, ellipticals, and strength equipment are currently under development.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3022 − 13

StandardTest Method for

Evaluating the Universal Design of Fitness Equipment for

Inclusive Use by Persons with Functional Limitations and

Impairments

This standard is issued under the fixed designation F3022; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The goal of this test method is to provide reliable and repeatable methods for the evaluation of

universally designed fitness equipment.

The equipment user must recognize, however, that the standard alone will not necessarily prevent

injuries.Likeotherphysicalactivities,exerciseinvolvingfitnessequipmentinvolvestheriskofinjury,

particularly if the equipment is used improperly or not properly maintained. In addition, users with

physical limitations should seek medical advice and instruction from the fitness facility prior to using

this equipment. Certain physical conditions or limitations may preclude some persons from using the

equipment properly and without increasing the risk of serious injury.

1. Scope responsibility of the user of this standard to establish appro-

2 priate safety and health practices and determine the applica-

1.1 This test method specifies procedures and equipment

bility of regulatory limitations prior to use.

used for testing and evaluating the accessibility of fitness

equipment for compliance to Specification F3021 design pa-

2. Referenced Documents

rameters. Where possible and applicable, accepted test meth-

2.1 ASTM Standards:

ods from other recognized bodies will be used and referenced.

E177 Practice for Use of the Terms Precision and Bias in

In case of a conflict between this document and Specification

ASTM Test Methods

F3021, Specification F3021 takes precedence.

E691 Practice for Conducting an Interlaboratory Study to

1.2 This test method is to be used in conjunction with

Determine the Precision of a Test Method

Specification F3021.

F2571 TestMethodsforEvaluatingDesignandPerformance

1.3 This standard is to be used as additional requirements to Characteristics of Fitness Equipment

F3021 Specification for Universal Design of Fitness Equip-

address the accessibility of the equipment for persons with

disabilities. ment for Inclusive Use by Persons with Functional Limi-

NOTE 1—Additional test methods applicable to specific pieces of tations and Impairments

equipment, such as treadmills, bicycles, ellipticals, and strength equip-

ment are currently under development. 3. Terminology

1.4 The values stated in SI units are to be regarded as the

3.1 Definitions—For definitions applicable to this standard

standard. The values given in parentheses are for information

see Specification F3021.

only.

4. Certification

1.5 This standard does not purport to address all of the

4.1 These test methods permit self-certification. It is recom-

safety concerns, if any, associated with its use. It is the

mended that each manufacturer employ an independent labo-

ratory to evaluate and validate that their designs and test

This test method is under the jurisdiction of ASTM Committee F08 on Sports

procedures conform and comply with these test methods and

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.30 on Fitness Products.

Specification F3021.

Current edition approved June 1, 2013. Published July 2013. DOI: 10.1520/

F3022-13.

2 3

This work was funded, in part, by the Rehabilitation Engineering Research For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Center on RecTech through the National Institute on Disability and Rehabilitation contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Research under the US Department of Education grant #H133E070029 and Standards volume information, refer to the standard’s Document Summary page on

H133120005. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3022 − 13

NOTE 2—The test methods and procedures described in Section 7

Procedure—Inspect all access paths to verify that the path

should be supported by conducting user testing using subjects across a

is clear of any obstruction by the frame or other structural

rangeofdisabilities,impairments,andagesandthosewithoutdisabilityon

parts.

the sample equipment.

Pass/Fail Criteria—The access path shall conform to the

clear space requirements of subsection 5.1.1.1 of Specification

5. Sample Preparation

F3021.

5.1 Assemble and adjust the fitness equipment apparatus on

Precision and Bias—No information is presented about

a horizontal surface according to the manufacturer’s instruc-

either the precision or bias of test 7.1.1.1 for evaluating access

tions. Verify that assembled units are done so according to the

since the test result is non-quantitative.

manufacturer’s instructions. Unless otherwise stated, the fit-

NOTE 3—Performance tests to get on/off the equipment from the

nessequipmentapparatusmustpassthefollowingtestswithout

perspective of a broad range of people with disabilities, including people

adjustment from this initial condition.

using wheelchairs or those who have functional limitations, sensory

5.2 Any equipment with a removable/movable seat shall be deficits, cognitive impairments, visual, or hearing impairments, or a

combination thereof, is suggested. One possible method would be to use

set up with the seat in the non-moved position.

testers with disabilities.

5.3 The individual test methods will describe any variations

7.1.1.2 Maximum Approach Positions—This test is a visual

or modifications that are required to the test sample.

inspectionofthesampletoensurethataccesspathstothepiece

of equipment, set in the start position, are available from as

6. Report

many positions as possible (i.e., front, rear, left, and right).

6.1 RecordofTests—Maintaincompletetestrecordsandtest

Apparatus and Set Up—The sample shall be set up as

summary reports for all testing, whether performed by the

described in Section 5.

manufacturer or an independent laboratory. The records can be

Calibration—No calibration required. Visual inspection

stored on paper, electronically, or on photographs, or a com-

only.

bination thereof. A copy of the test summary must be kept by

Procedure—Inspect access paths from the front, rear, left,

the laboratory that performed the test for a minimum of five

andrightoftheequipmenttoverifythatthepathisclearofany

years from the date of the test and by the manufacturer for a

obstruction by the frame or other structural parts from as many

minimum of five years past the end of production of the model

points of access as possible.

tested. The summary shall include the signature of the per-

Pass/Fail Criteria—Equipment must be accessible and

son(s)performingthetestsandamanagementrepresentativeof

shall avoid left/right bias as specified in the requirements of

the laboratory performing the test. The test summary shall

subsection 5.1.1.2 of Specification F3021. There is no pass/fail

include the following information:

criteria.

6.1.1 Manufacturer’s name and location,

Precision and Bias—Equipment must be accessible and

6.1.2 Information provided by the manufacturer to accu-

shall avoid left/right bias as specified in the requirements of

rately identify the configuration of, and specific unit provided

subsection 5.1.1.2 of Specification F3021. There is no pass/fail

to, the testing agency,

criteria.

6.1.3 Dates over which the tests were conducted,

7.1.1.3 Step-On Height—This test is a dimensional inspec-

6.1.4 Name and location of the testing laboratory, if differ-

tion of the sample to ensure the dimensional compliance of the

ent from the manufacturer, and

step-on height.

6.1.5 Summary and results of each test performed including

Apparatus and Set Up—The sample shall be set up as

method and apparatus used.This shall include what the desired

described in Section 5 in the neutral position with 0%

requirement was and whether the test sample met that param-

grade/zero incline.

eter or failed. If the test requires a specific number of cycles to

Calibration—Verify that the distance measuring equipment

be met, then the report must include the number of cycles

is calibrated and accurate to within 1 mm (0.040 in.).

actually conducted. If the apparatus fails to meet a parameter,

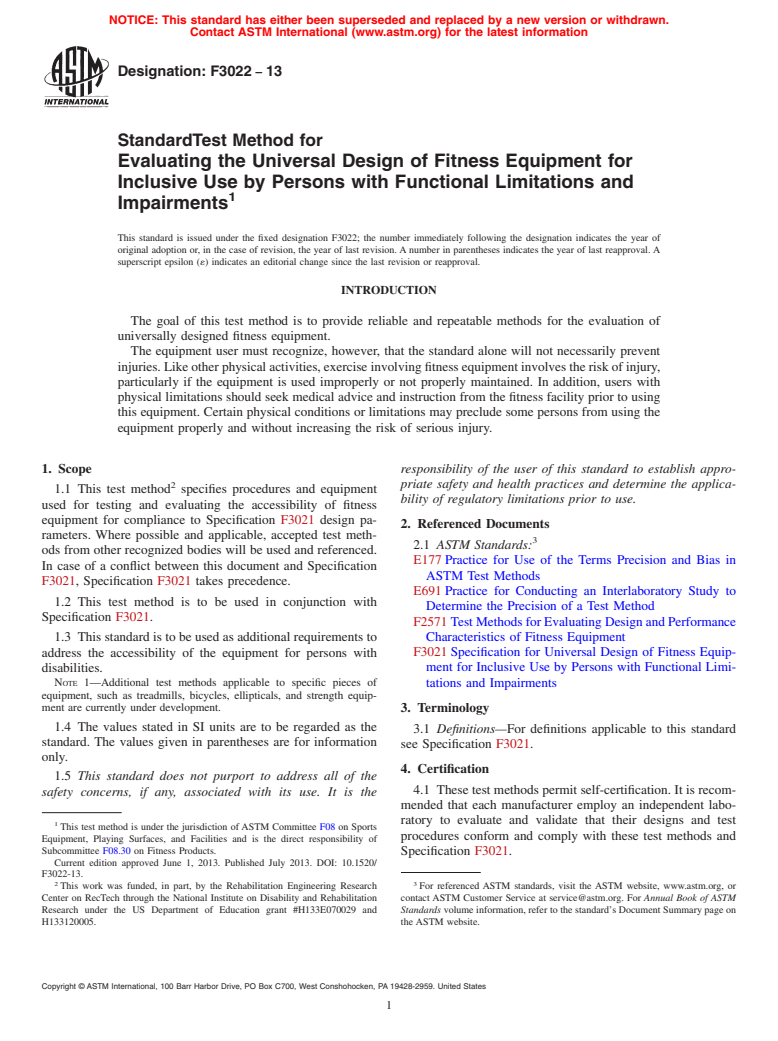

Procedure—Measure the height from the floor to the top of

then that failure must be noted in clear and accurate terms to

the highest portion of the step-on surface/frame or top of the

enable a reader of the report to understand at a later date what

transfer surface (see Fig. 1).

transpired.

Pass/Fail Criteria—The dimensions of the step-on height

shall conform to dimensional requirements of subsection

7. Test Methods and Procedures

5.1.1.3 of Specification F3021.

7.1 General Requirements: Precision and Bias—No information is presented about

7.1.1 Access and Set Up: eithertheprecisionorbiasoftest7.1.1.3formeasuringstep-on

7.1.1.1 Access, Egress, and Transfer—This test is a visual height dimensions since the test result is non-quantitative.

inspection of the sample to ensure that all access paths to the 7.1.1.4 Step-Over Height—This test is a dimensional in-

piece of equipment, set in the start position, are not obstructed spectionofthesampletoensurethedimensionalcomplianceof

by the frame or other structural parts of the equipment. the step-over height.

Apparatus and Set Up—The sample shall be set up as Apparatus and Set Up—The sample shall be set up as

described in Section 5. described in Section 5.

Calibration—No calibration required. Visual inspection Calibration—Verify that the distance measuring equipment

only. is calibrated and accurate to within 1 mm (0.040 in.).

F3022 − 13

FIG. 1 Maximum Step-on Height Example

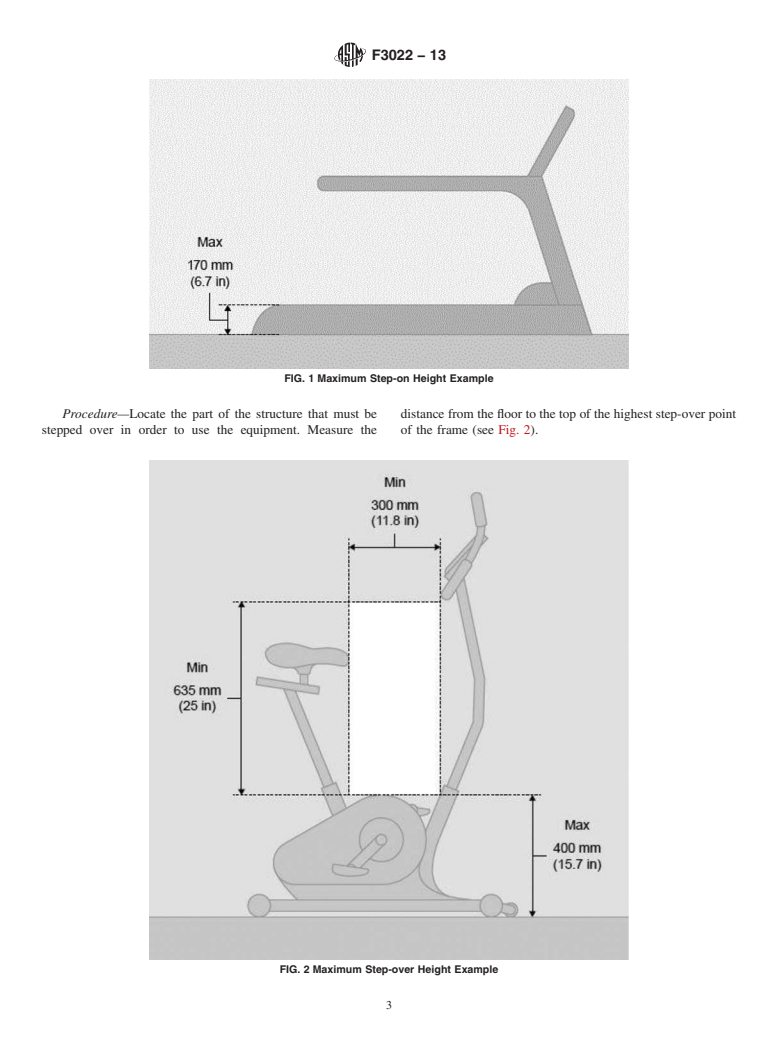

Procedure—Locate the part of the structure that must be distance from the floor to the top of the highest step-over point

stepped over in order to use the equipment. Measure the of the frame (see Fig. 2).

FIG. 2 Maximum Step-over Height Example

F3022 − 13

Pass/FailCriteria—Thedimensionsofthestep-overheight use and that they have appropriate mechanisms to facilitate

shall conform to dimensional requirements of subsection intentional movement.

5.1.1.4 of Specification F3021. Apparatus and Set Up—The sample shall be set up as

Precision and Bias—No information is presented about described in Section 5 on carpet for testing the ease of moving

either the precision or bias of test 7.1.1.4 for measuring the step and on tile or similar flooring for testing for uninten-

step-over height dimensions since the test result is non- tional movement during use.

quantitative. Calibration—Verify that the force measuring equipment is

calibrated and accurate to within 0.5 N (0.1 lbf) over its entire

7.1.1.5 Integral Surface/Separate Step Height—This test is

range.

a dimensional inspection of the sample to ensure the dimen-

Procedure—Check for skids or wheel lock mechanism.

sional compliance of the step-over height, with the addition of

Step on/off the step on tile or similar flooring and visually

an integral surface or separate step.

inspect for unintentional movement during use. Pull the step

Apparatus and Set Up—The sample shall be set up as

over carpet flooring and measure the pull force.

described in Section 5 with an integral surface or separate step

Pass/Fail Criteria—The step unintentional/intentional

intact.

movement shall conform to performance requirements of

Calibration—Verify that the distance measuring equipment

subsection 5.1.1.8 of Specification F3021.

is calibrated and accurate to within 1 mm (0.040 in.).

Precision and Bias—No information is presented about

Procedure—Measure the height of the part of the structure

either the precision or bias of test 7.1.1.8 for evaluating and

that must be stepped over in order to use the equipment.

measuring step unintentional/intentional movement since the

Measurethedistancefromthesurfaceoftheintegralsurfaceor

test result is non-quantitative.

separate step to the top of the highest step-over point of the

frame (see 7.1.1.4). 7.1.1.9 Walk Through Structure Clear Area—This test is a

Pass/Fail Criteria—The dimensions of the integral surface performance inspection of the sample to ensure the dimen-

or separate step height shall conform to dimensional require- sional compliance of walk through structure height.

ments of subsection 5.1.1.5 of Specification F3021.

Apparatus and Set Up—The sample shall be set up as

Precision and Bias—No information is presented about described in Section 5.

eithertheprecisionorbiasoftest7.1.1.5formeasuringintegral

Calibration—Verify that the distance measuring equipment

surface or separate step height dimensions since the test result

is calibrated and accurate to within 1 mm (0.040 in.).

is non-quantitative.

Procedure—Step through the walk through area of the

equipment. Make sure that there is adequate low structure

7.1.1.6 Integral Surface/Separate Step Length/Width—This

height to step through without impediment or obstruction.

test is a dimensional inspection of the sample to ensure the

dimensional compliance of the integral surface and separate Measure the height from the floor to the highest part of the

walk through structure.

step length and width.

Apparatus and Set Up—The sample shall be set up as Pass/Fail Criteria—The dimensions of the walk through

structure area shall conform to dimensional requirements of

described in Section 5 with an integral surface or separate step

intact. subsection 5.1.1.9 of Specification F3021.

Precision and Bias—No information is presented about

Calibration—Verify that the distance measuring equipment

is calibrated and accurate to within 1 mm (0.040 in.). either the precision or bias of test 7.1.1.9 for measuring walk

Procedure—Measure the height from the floor to the top of through structure area dimensions since the test result is

the stepping surface of the integral surface or separate step. non-quantitative.

Measure the length and width from the outer edge of the

7.1.1.10 Recumbent Transition Area Box—This test is a

stepping surface lengthwise and the outer edge of the stepping

dimensionalinspectionofthesampletoensurethedimensional

surface widthwise on the integral surface or separate step.

compliance of walk through structure area.

Pass/Fail Criteria—Measure the height from the floor to

Apparatus and Set Up—The sample shall be set up as

the top of the stepping surface of the integral surface or

described in Section 5.

separate step. Measure the len

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.