ASTM D4525-90(1995)e1

(Test Method)Standard Test Method for Permeability of Rocks by Flowing Air

Standard Test Method for Permeability of Rocks by Flowing Air

SCOPE

1.1 This test method covers the determination of the coefficient of specific permeability for the flow of air through rocks. The procedure is to establish representative values of the coefficient of permeability of rocks or well-indurated soils.

1.2 This test method is limited to permeability values greater than 0.9869 nm (1.0 microdarcy), and is limited to rocks free of oil or unctuous matter.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 4525 – 90 (Reapproved 1995)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Permeability of Rocks by Flowing Air

This standard is issued under the fixed designation D 4525; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 12 was changed editorially in December 1991.

1. Scope ing to an infinite mean air pressure to obtain an equivalent

permeability value for liquids.

1.1 This test method covers the determination of the coef-

ficient of specific permeability for the flow of air through

4. Significance and Use

rocks. The procedure is to establish representative values of the

4.1 This test method is designed to measure the permeabil-

coefficient of permeability of rocks or well-indurated soils.

ity to air of a small sample of rock. By extrapolation, this test

1.2 This test method is limited to permeability values

method also determines an equivalent of the liquid permeabil-

greater than 0.9869 nm (1.0 microdarcy), and is limited to

ity. This parameter is used to calculate the flow through rock of

rocks free of oil or unctuous matter.

fluids subjected to a pressure differential.

1.3 The values stated in SI units are to be regarded as the

standard.

5. Apparatus

1.4 This standard does not purport to address all of the

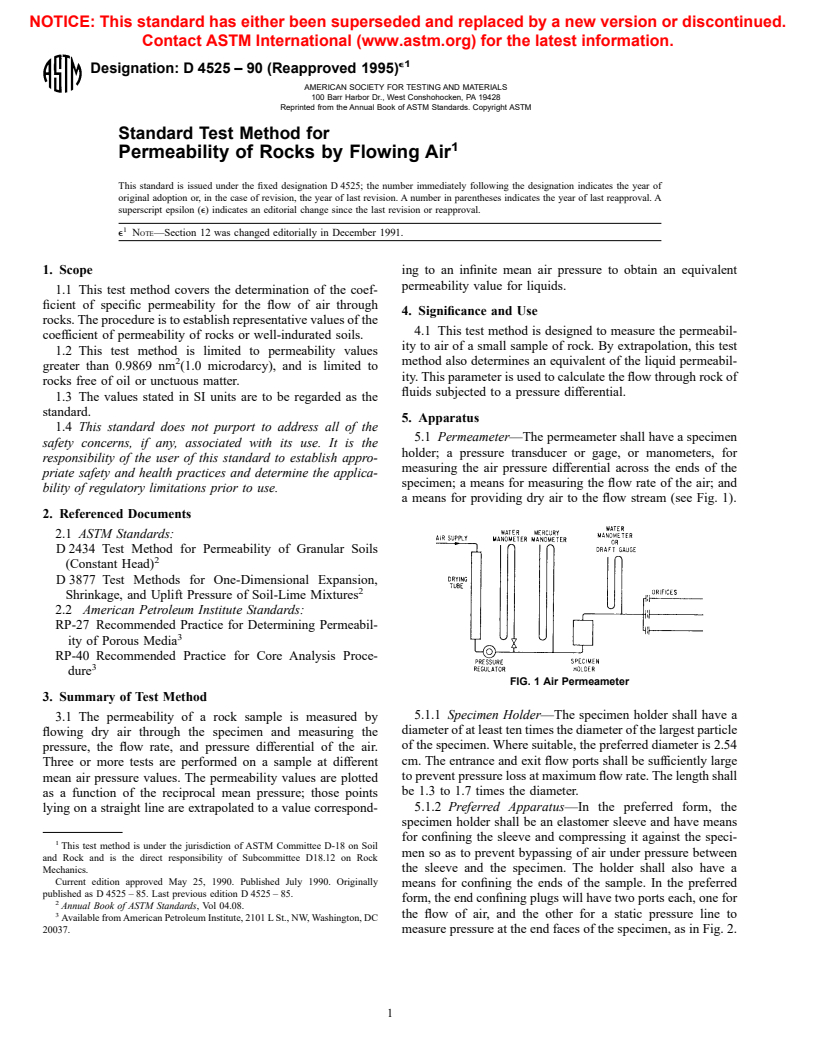

5.1 Permeameter—The permeameter shall have a specimen

safety concerns, if any, associated with its use. It is the

holder; a pressure transducer or gage, or manometers, for

responsibility of the user of this standard to establish appro-

measuring the air pressure differential across the ends of the

priate safety and health practices and determine the applica-

specimen; a means for measuring the flow rate of the air; and

bility of regulatory limitations prior to use.

a means for providing dry air to the flow stream (see Fig. 1).

2. Referenced Documents

2.1 ASTM Standards:

D 2434 Test Method for Permeability of Granular Soils

(Constant Head)

D 3877 Test Methods for One-Dimensional Expansion,

Shrinkage, and Uplift Pressure of Soil-Lime Mixtures

2.2 American Petroleum Institute Standards:

RP-27 Recommended Practice for Determining Permeabil-

ity of Porous Media

RP-40 Recommended Practice for Core Analysis Proce-

dure

FIG. 1 Air Permeameter

3. Summary of Test Method

5.1.1 Specimen Holder—The specimen holder shall have a

3.1 The permeability of a rock sample is measured by

diameter of at least ten times the diameter of the largest particle

flowing dry air through the specimen and measuring the

of the specimen. Where suitable, the preferred diameter is 2.54

pressure, the flow rate, and pressure differential of the air.

cm. The entrance and exit flow ports shall be sufficiently large

Three or more tests are performed on a sample at different

to prevent pressure loss at maximum flow rate. The length shall

mean air pressure values. The permeability values are plotted

be 1.3 to 1.7 times the diameter.

as a function of the reciprocal mean pressure; those points

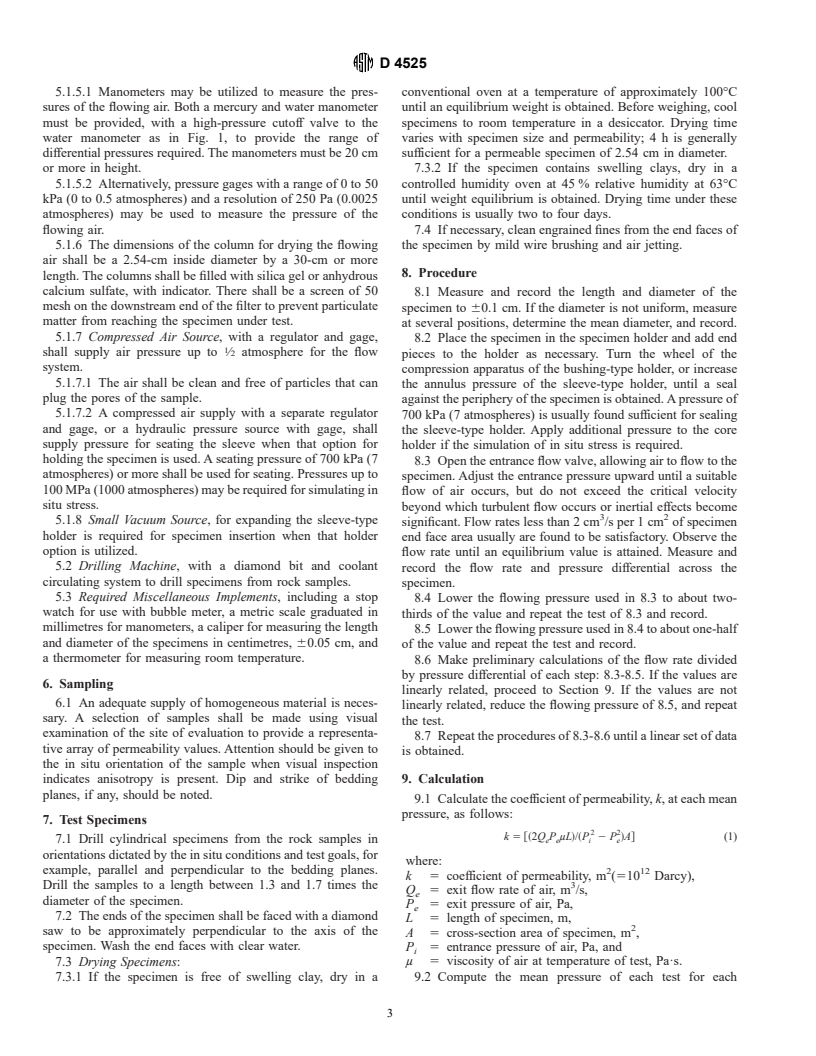

5.1.2 Preferred Apparatus—In the preferred form, the

lying on a straight line are extrapolated to a value correspond-

specimen holder shall be an elastomer sleeve and have means

for confining the sleeve and compressing it against the speci-

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

men so as to prevent bypassing of air under pressure between

and Rock and is the direct responsibility of Subcommittee D18.12 on Rock

the sleeve and the specimen. The holder shall also have a

Mechanics.

Current edition approved May 25, 1990. Published July 1990. Originally

means for confining the ends of the sample. In the preferred

published as D 4525 – 85. Last previous edition D 4525 – 85.

form, the end confining plugs will have two ports each, one for

Annual Book of ASTM Standards, Vol 04.08.

the flow of air, and the other for a static pressure line to

Available from American Petroleum Institute, 2101 L St., NW, Washington, DC

20037. measure pressure at the end faces of the specimen, as in Fig. 2.

D 4525

FIG. 2 Hassler Type Specimen Holder

This type of holder is suitable for many types of flowing fluids

FIG. 4 Compression Cell for Ring-Mounted Specimens

and allows the simulation of overburden stress on the speci-

men.

5.1.3 Alternative Apparatus—An elastomer bushing may be

used to confine the specimen, as in Fig. 3. This holder is

suitable for confining well-indurated specimens of a fine to

moderate texture. This holder allows rapid operation; it cannot

be used for simulating overburden stress.

5.1.3.1 Alternatively, a rigid bushing may be cast around the

specimen (see Fig. 4). The casting material shall be one that

will adhere well to both the specimen and the bushing, without

penetration of the specimen beyond the superficial pores.

Epoxies, polyesters, and sealing wax are suitable for this

purpose. This method of mounting samples is particularly well

suited for testing less well-indurated specimens. This technique

is not applicable for tests requiring the simulation of overbur-

den stress.

5.1.4 The flow rate of the air shall be sensed downstream

from the specimen by means of calibrated orifices (Fig. 1),

rotameters (Fig. 5), or a bubble meter (Fig. 6).

FIG. 5 Shielded Microflowmeter

5.1.5 The preferred method of sensing pressure to obtain the

pressure differential across the specimen is by means of

FIG. 6 Bubble Meter

pressure transducers located at the ends of the specimen. The

transducers must operate over a range of 0 to 50 kPa (0 to 0.5

atmospheres) with a resolution of 250 Pa (0.0025 atmospheres)

or better. Alternatively, the sensors may be connected to the

end faces of the specimen with static lines, or placed in

sufficiently large flow lines to cause less than 250 Pa (0.0025

atmospheres) loss of head at maximum flow rate. Pressure

must be sensed between the downstream end of the specimen

FIG. 3 Fancher-Type Specimen Holder and the orifice if such a flow sensor is utilized.

D 4525

5.1.5.1 Manometers may be utilized to measure the pres- conventional oven at a temperature of approximately 100°C

sures of the flowing air. Both a mercury and water manometer until an equilibrium weight is obtained. Before weighing, cool

must be provided, with a high-pressure cutoff valve to the specimens to room temperature in a desiccator. Drying time

water manometer as in Fig. 1, to provide the range of varies with specimen size and permeability;4his generally

differential pressures required. The manometers must be 20 cm sufficient for a permeable specimen of 2.54 cm in diameter.

or more in height. 7.3.2 If the specimen contains swelling clays, dry in a

5.1.5.2 Alternatively, pressure gages with a range of 0 to 50 controlled humidity oven at 45 % relative humidity at 63°C

kPa (0 to 0.5 atmospheres) and a resolution of 250 Pa (0.0025 until weight equilibrium is obtained. Drying time under these

atmospheres) may be used to measure the pressure of the conditions is usually two to four days.

flowing air. 7.4 If necessary, clean engrained fines from the end faces of

5.1.6 The dimensions of the column for drying the flowing the specimen by mild wire brushing and air jetting.

air shall be a 2.54-cm inside diameter by a 30-cm or more

8. Procedure

length. The columns shal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.