ASTM A1039/A1039M-04

(Specification)Standard Specification for Steel, Sheet, Hot Rolled, Carbon, Commercial and Structural, Produced by the Twin-Roll Casting Process

Standard Specification for Steel, Sheet, Hot Rolled, Carbon, Commercial and Structural, Produced by the Twin-Roll Casting Process

SCOPE

1.1 This specification covers commercial and structural steel sheet in coils and cut lengths produced by the twin-roll casting process.

1.2 The steel sheet is available in the designations listed in Section .

1.3 The material is available in the following sizes:Thickness-0.027 in. [0.7 mm] to 0.078 in. [2.0 mm]Width-up to 79 in. [2000 mm]

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.Note 1

A description of the Twin-Roll Casting Process is included in Appendix X1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

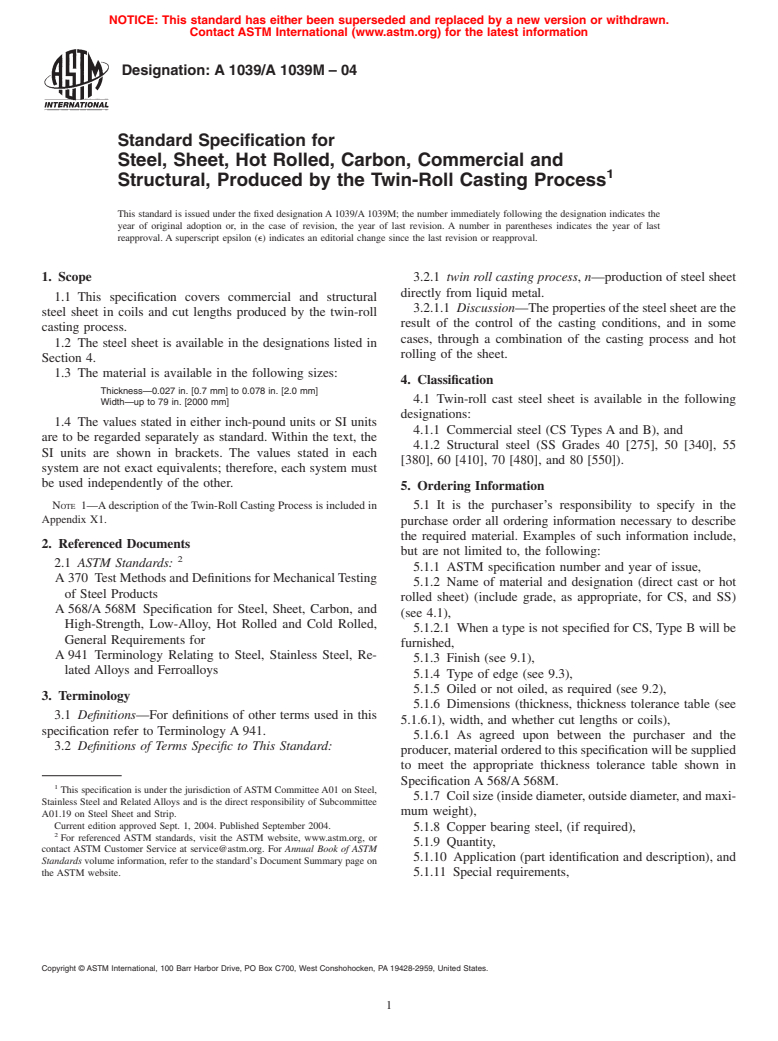

Designation: A 1039/A 1039M – 04

Standard Specification for

Steel, Sheet, Hot Rolled, Carbon, Commercial and

Structural, Produced by the Twin-Roll Casting Process

This standard is issued under the fixed designation A 1039/A 1039M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 twin roll casting process, n—production of steel sheet

directly from liquid metal.

1.1 This specification covers commercial and structural

3.2.1.1 Discussion—Thepropertiesofthesteelsheetarethe

steel sheet in coils and cut lengths produced by the twin-roll

result of the control of the casting conditions, and in some

casting process.

cases, through a combination of the casting process and hot

1.2 The steel sheet is available in the designations listed in

rolling of the sheet.

Section 4.

1.3 The material is available in the following sizes:

4. Classification

Thickness—0.027 in. [0.7 mm] to 0.078 in. [2.0 mm]

4.1 Twin-roll cast steel sheet is available in the following

Width—up to 79 in. [2000 mm]

designations:

1.4 The values stated in either inch-pound units or SI units

4.1.1 Commercial steel (CS Types A and B), and

are to be regarded separately as standard. Within the text, the

4.1.2 Structural steel (SS Grades 40 [275], 50 [340], 55

SI units are shown in brackets. The values stated in each

[380], 60 [410], 70 [480], and 80 [550]).

system are not exact equivalents; therefore, each system must

be used independently of the other.

5. Ordering Information

NOTE 1—Adescription of the Twin-Roll Casting Process is included in 5.1 It is the purchaser’s responsibility to specify in the

Appendix X1.

purchase order all ordering information necessary to describe

the required material. Examples of such information include,

2. Referenced Documents

but are not limited to, the following:

2.1 ASTM Standards:

5.1.1 ASTM specification number and year of issue,

A 370 TestMethodsandDefinitionsforMechanicalTesting

5.1.2 Name of material and designation (direct cast or hot

of Steel Products

rolled sheet) (include grade, as appropriate, for CS, and SS)

A 568/A 568M Specification for Steel, Sheet, Carbon, and

(see 4.1),

High-Strength, Low-Alloy, Hot Rolled and Cold Rolled,

5.1.2.1 When a type is not specified for CS, Type B will be

General Requirements for

furnished,

A 941 Terminology Relating to Steel, Stainless Steel, Re-

5.1.3 Finish (see 9.1),

lated Alloys and Ferroalloys

5.1.4 Type of edge (see 9.3),

5.1.5 Oiled or not oiled, as required (see 9.2),

3. Terminology

5.1.6 Dimensions (thickness, thickness tolerance table (see

3.1 Definitions—For definitions of other terms used in this

5.1.6.1), width, and whether cut lengths or coils),

specification refer to Terminology A 941.

5.1.6.1 As agreed upon between the purchaser and the

3.2 Definitions of Terms Specific to This Standard:

producer, material ordered to this specification will be supplied

to meet the appropriate thickness tolerance table shown in

Specification A 568/A 568M.

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

5.1.7 Coilsize(insidediameter,outsidediameter,andmaxi-

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

mum weight),

A01.19 on Steel Sheet and Strip.

Current edition approved Sept. 1, 2004. Published September 2004.

5.1.8 Copper bearing steel, (if required),

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.9 Quantity,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.10 Application (part identification and description), and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.1.11 Special requirements,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 1039/A 1039M – 04

5.1.12 A report of heat analysis will be supplied, if re- 8.2.2 Tension Tests:

quested, for CS. For materials with required mechanical

8.2.2.1 Requirements—Material as represented by the test

properties, SS, a report is required of heat analysis and

specimen shall conform to the mechanical property require-

mechanical properties as determined by the tension test.

ments specified in Table 4.

8.2.2.2 Number of Tests—Two tension tests shall be made

NOTE 2—A typical ordering description is as follows: ASTM A 1039/

A 1039M steel sheet, CSTypeA, pickled and oiled, cut edge, 0.075 by 36 from each heat or from each 50 tons [45 000 kg]. When the

by 96 in., thickness tolerance Table 4 of Specification A 568/A 568M.

amount of finished material from a heat is less than 50 tons

100 000 lb, for part no. 6310, for shelf bracket, or

[45 000 kg], one tension test shall be made. When material

ASTM A 1039/A 1039M, hot rolled steel sheet, SS Grade 40, pickled

rolled from one heat differs 0.050 in. [1.27 mm] or more in

and oiled, cut edge, 1.5 by 117 mm by coil, ID 600 mm, OD 1500 mm,

thickness, one tension test shall be made from the thickest and

max weight 10 000 kg, thickness tolerance Table A1.1 of Specification

thinnest material regardless of the weight represented.

A 568/A 568M, 100 000 kg, for part number A4885 for lower housing.

8.2.2.3 Tension test specimens shall be taken at a point

6. General Requirements for Delivery

immediately adjacent to the material to be qualified.

6.1 Material furnished under this specification shall con-

8.2.2.4 Tension test specimens shall be taken from the full

form to the applicable requirements of the current edition of

thickness of the sheet as rolled.

Specification A 568/A 568M for steel sheet.

8.2.2.5 Tension test specimens shall be taken from a loca-

tionapproximatelyhalfwaybetweenthecenterofsheetandthe

7. Chemical Composition

edge of the material as-cast or as-rolled.

7.1 The heat analysis of the steel shall conform to the

8.2.2.6 Tension test specimens shall be taken with the

chemical requirements of the appropriate designation shown in

lengthwise axis of the test specimen parallel to the rolling

Table 1 for CS and Table 2 for SS.

direction (longitudinal test).

7.2 Each of the elements listed in Tables 1 and 2 shall be

8.2.2.7 Test Method—Yield strength shall be determined by

included in the report of the heat analysis.When the amount of

either the 0.2 % offset method or the 0.5 % extension under

copper, nickel, chromium, or molybdenum is less than 0.02 %,

load method unless otherwise specified.

the analysis shall be reported as “<0.02 %” or the actual

8.2.3 Bending Properties:

determined value. When the amount of vanadium, columbium,

8.2.3.1 The suggested minimum inside radii for cold bend-

or titanium is less than 0.008 %, the analysis shall be reported

ing are listed in Appendix X2. More detail on this topic is

as “<0.008 %”or the actual determined value.

provided in the section on Mechanical Properties of Specifi-

7.3 Sheet steel grades defined by this specification are

cationA 568/A 568M. Where a tighter bend radius is required,

suitable for welding if appropriate welding conditions are

or where curved or offset bends are involved, or where

selected. Certain welding processes may require more restric-

stretching or drawing are also a consideration, the producer

tive composition limits than those included in Table 1 or Table

shall be consulted.

2, and in these cases, the restrictive limits shall be reviewed

with the producer at the time of inquiry and ordering.

9. Finish and Appearance

NOTE 3—The twin-roll cast product may be deoxidized using either

silicon or aluminum. 9.1 Surface Finish:

9.1.1 The material shall be furnished as-cast or as-rolled,

8. Mechanical Properties

(that is, without removing the surface oxide or scale), unless

8.1 CS:

otherwise specified.

8.1.1 Typical, non-mandatory mechanical properties for CS

9.1.2 When required, the material shall be specified as

are found in Table 3.

pickled or blast cleaned (descaled).

8.1.2 The material shall be capable of being bent at room

9.2 Oiling:

temperature in any direction through 180° flat on itself without

9.2.1 Unless other specified, as-cast or as-rolled material

crackingontheoutsideofthebentportion(seesectiononbend

shall be furnished not oiled (that is, dry), and pickled or blast

test of Test Methods and Definitions A 370).

cleaned material shall be furnished oiled.

8.2 SS:

9.3 Edges:

8.2.1 The available grades and corresponding mechanical

property requirements for SS steels are shown in Table 4. 9.3.1 Steel sheet is available with mill edge or cut edge.

A

TABLE 1 Chemical Requirements for Twin Roll Cast Hot Rolled Steel Sheet Designations CS

Composition, % Heat Analysis, Element Maximum Unless Otherwise Shown

B C

CMn P S Al Si Cu Ni Cr Mo V Cb Ti N

D

CS Type A 0.10 0.70 0.030 0.035 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 0.008 . . .

CS Type B 0.02 to 0.15 0.70 0.030 0.035 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 0.008 . . .

A

Where an ellipsis (…) appears in the table, there is no requirement, but the analysis shall be reported.

B

When aluminum deoxidized steel is required, it may be ordered to a minimum of 0.01 % total aluminum.

C

When copper steel is specified, the copper limit is a minimum of 0.20 %.

D

Specify Type B to avoid carbon levels below 0.02 %.

A 1039/A 1039M – 04

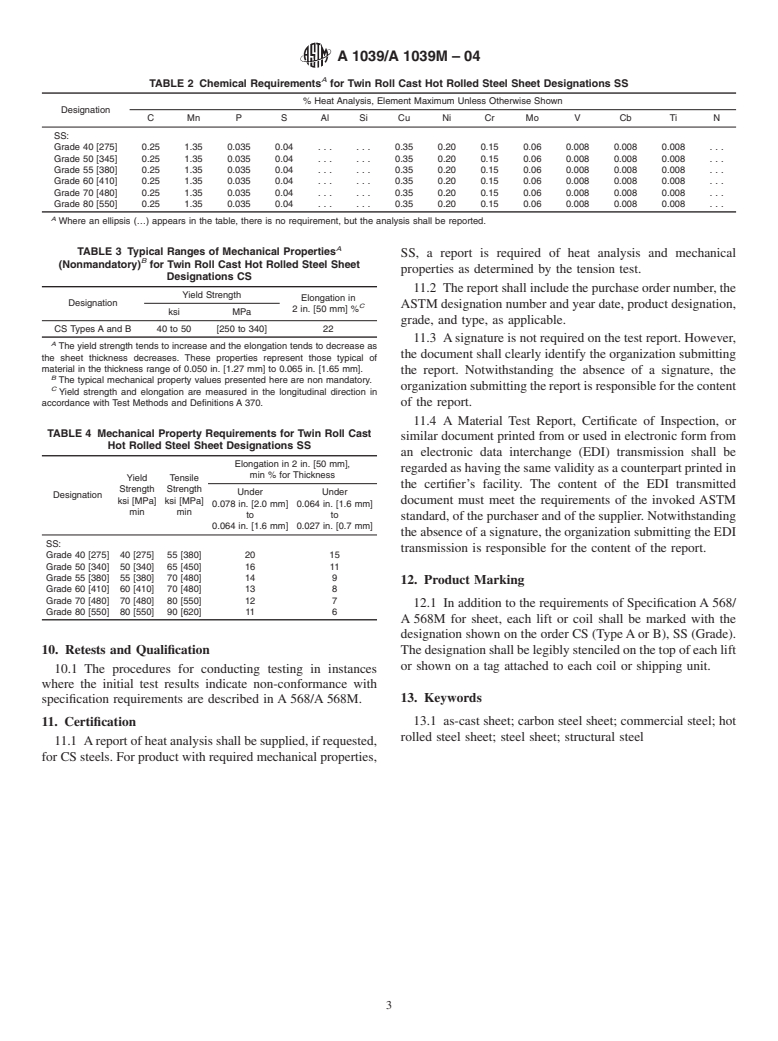

A

TABLE 2 Chemical Requirements for Twin Roll Cast Hot Rolled Steel Sheet Designations SS

% Heat Analysis, Element Maximum Unless Otherwise Shown

Designation

C MnP S Al Si Cu Ni Cr MoV Cb Ti N

SS:

Grade 40 [275] 0.25 1.35 0.035 0.04 . . . . . . 0.35 0.20 0.15 0.06 0.008 0.008 0.008 . . .

Grade 50 [345] 0.25 1.35 0.035 0.04 . . . . . . 0.35 0.20 0.15 0.06 0.008 0.008 0.008 . . .

Grade 55 [380] 0.25 1.35 0.035 0.04 . . . . . . 0.35 0.20 0.15 0.06 0.008 0.008 0.008 . . .

Grade 60 [410] 0.25 1.35 0.035 0.04 . . . . . . 0.35 0.20 0.15 0.06 0.008 0.008 0.008 . . .

Grade 70 [480] 0.25 1.35 0.035 0.04 . . . . . . 0.35 0.20 0.15 0.06 0.008 0.008 0.008 . . .

Grade 80 [550] 0.25 1.35 0.035 0.04 . . . . . . 0.35 0.20 0.15 0.06 0.008 0.008 0.008 . . .

A

Where an ellipsis (…) appears in the table, there is no requirement, but the analysis shall be reported.

A

TABLE 3 Typical Ranges of Mechanical Properties

SS, a report is required of heat analysis and mechanical

B

(Nonmandatory) for Twin Roll Cast Hot Rolled Steel Sheet

properties as determined by the tension test.

Designations CS

11.2 Thereportshallincludethepurchaseordernumber,the

Yield Strength

Elongation in

Designation

C ASTM designation number and year date, product designation,

2 in. [50 mm] %

ksi MPa

grade, and type, as applicable.

CS Types A and B 40 to 50 [250 to 340] 22

11.3 Asignature is not required on the test report. However,

A

The yield strength tends to increase and the elongation tends to decrease as

the document shall clearly identify the organization submitting

the sheet thickness decreases. These properties represent those typical of

material in the thickness range of 0.050 in. [1.27 mm] to 0.065 in. [1.65 mm].

the report. Notwithstanding the absence of a signature, the

B

The typical mechanical property values presented here are non mandatory.

organizationsubmittingthereportisresponsibleforthecontent

C

Yield strength and elongation are measured in the longitudinal direction in

accordance with Test Methods and Definitions A 370. of the report.

11.4 A Material Test Report, Certificate of Inspection, or

TABLE 4 Mechanical Property Requirements for Twin Roll Cast

similar document printed from or used in electronic form from

Hot Rolled Steel Sheet Designations SS

an electronic data interchange (EDI) transmission shall be

Elongation in 2 in. [50 mm],

regardedashavingthesamevalidityasacounterpartprintedin

min % for Thickness

Yield Tensile

the certifier’s facility. The content of the EDI transmitted

Strength Strength

Under Under

Designation

ksi [MPa] ksi [MPa] document must meet the requirements of the invoked ASTM

0.078 in. [2.0 mm] 0.064 in. [1.6 mm]

min min

to to

standard, of the purchaser and of the supplier. Notwithstanding

0.064 in. [1.6 mm] 0.027 in. [0.7 mm]

the absence of a signature, the organization submitting the EDI

SS:

transmission is responsible for the content of the report.

Grade 40 [275] 40 [275] 55 [380] 20 15

Grade 50 [340] 50 [340] 65 [450] 16 11

Grade 55 [380] 55 [380] 70 [480] 14 9

12. Product Marking

Grade 60 [410] 60 [410] 70 [480] 13 8

Grade 70 [480] 70 [480] 80 [550] 12 7

12.1 In addition to the requirements of SpecificationA 568/

Grade 80 [550] 80 [550] 90 [620] 11 6

A 568M for sheet, each lift or coil shall be marked with the

designation shown on the order CS (TypeAor B), SS (Grade).

10. Retests and Qualification

Thedesignationshallbelegiblystenciledonthetopofeachlift

or shown on a tag attached to each coil or shipping unit.

10.1 The procedures for conducting testing in instances

where the initial test results indicate non-conformance with

specification requirements are described in A 568/A 568M. 13. Keywords

13.1 as-cast sheet; carbon steel sheet; commercial steel; hot

11. Certification

rolled steel sheet; steel sheet; structural steel

11.1 Areportofheatanalysisshallbesupplied,ifrequested,

for CS steels. For product with required mechanical properties,

A 1039/A 1039M – 04

APPENDIXES

(Nonmandatory Information)

X1. TWIN-ROLL CASTING PROCESS

X1.1 Overview of the Twin-Roll Casting Process for the cial heat transfer rates resulting from the direct contact of the

Production of Steel Sheet steel with the casting roll surface (see Table X1.1). This rapid

solidification results in the production of unique microstruc-

X1.2 Twin-Roll Casting Process Development

tures that can be manipulated to produce conventional low-

X1.2.1 Sir Henry Bessemer originally conceived and pat- carbon steels as well as steels not easily produced from

ented the concept of casting sheet and strip directly from liquid conventional sheet steel production (for example, thick slab

metal about 150 years ago. Despite decades of research and casting and thin slab casting processes coupled with conven-

development, twin-roll casting has now achieved commercial tional hot rolling mills).

success for the production of plain-carbon steel sheet. Key

breakthroughs in the areas of mold/refractory materials, a X1.4 Overview of Product Attributes

better understanding of the fundamentals of metal solidifica-

X1.4.1 Product attributes of twin-roll cast material are

tion, and process control have contributed to the successful

comparable to conventional hot strip mill products with regard

commercialization of this process. Twin-roll cast

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.