ASTM D1945-14(2019)

(Test Method)Standard Test Method for Analysis of Natural Gas by Gas Chromatography

Standard Test Method for Analysis of Natural Gas by Gas Chromatography

SIGNIFICANCE AND USE

4.1 This test method is of significance for providing data for calculating physical properties of the sample, such as heating value and relative density, or for monitoring the concentrations of one or more of the components in a mixture.

SCOPE

1.1 This test method covers the determination of the chemical composition of natural gases and similar gaseous mixtures within the range of composition shown in Table 1. This test method may be abbreviated for the analysis of lean natural gases containing negligible amounts of hexanes and higher hydrocarbons, or for the determination of one or more components, as required.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1945 − 14 (Reapproved 2019)

Standard Test Method for

Analysis of Natural Gas by Gas Chromatography

This standard is issued under the fixed designation D1945; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* calibration data obtained under identical operating conditions

from a reference standard mixture of known composition. The

1.1 This test method covers the determination of the chemi-

numerous heavy-end components of a sample can be grouped

cal composition of natural gases and similar gaseous mixtures

into irregular peaks by reversing the direction of the carrier gas

within the range of composition shown in Table 1. This test

through the column at such time as to group the heavy ends

method may be abbreviated for the analysis of lean natural

either as C and heavier, C and heavier, or C and heavier. The

5 6 7

gases containing negligible amounts of hexanes and higher

composition of the sample is calculated by comparing either

hydrocarbons, or for the determination of one or more

the peak heights, or the peak areas, or both, with the corre-

components, as required.

sponding values obtained with the reference standard.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Significance and Use

standard.

4.1 This test method is of significance for providing data for

1.3 This standard does not purport to address all of the

calculating physical properties of the sample, such as heating

safety concerns, if any, associated with its use. It is the

value and relative density, or for monitoring the concentrations

responsibility of the user of this standard to establish appro-

of one or more of the components in a mixture.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5. Apparatus

1.4 This international standard was developed in accor-

5.1 Detector—The detector shall be a thermal-conductivity

dance with internationally recognized principles on standard-

type, or its equivalent in sensitivity and stability. The thermal

ization established in the Decision on Principles for the

conductivity detector must be sufficiently sensitive to produce

Development of International Standards, Guides and Recom-

a signal of at least 0.5 mV for 1 mol % n-butane in a 0.25-mL

mendations issued by the World Trade Organization Technical

sample.

Barriers to Trade (TBT) Committee.

5.2 Recording Instruments—Either strip-chart recorders or

2. Referenced Documents

electronic integrators, or both, are used to display the separated

2.1 ASTM Standards:

components. Although a strip-chart recorder is not required

D2597 Test Method for Analysis of Demethanized Hydro-

when using electronic integration, it is highly desirable for

carbon Liquid Mixtures Containing Nitrogen and Carbon

evaluation of instrument performance.

Dioxide by Gas Chromatography (Withdrawn 2016)

5.2.1 The recorder shall be a strip-chart recorder with a

E260 Practice for Packed Column Gas Chromatography

full-range scale of 5 mV or less (1 mV preferred). The width of

the chart shall be not less than 150 mm. A maximum pen

3. Summary of Test Method

response time of 2 s (1 s preferred) and a minimum chart speed

3.1 Components in a representative sample are physically

of 10 mm/min shall be required. Faster speeds up to 100 mm-

separated by gas chromatography (GC) and compared to

⁄min are desirable if the chromatogram is to be interpreted

using manual methods to obtain areas.

This test method is under the jurisdiction of ASTM Committee D03 on Gaseous

5.2.2 Electronic or Computing Integrators—Proof of sepa-

Fuels and is the direct responsibility of Subcommittee D03.06.01 on Analysis of

ration and response equivalent to that for a recorder is required

Major Constituents by Gas Chromatography.

for displays other than by chart recorder. Baseline tracking

Current edition approved Dec. 1, 2019. Published January 2020. Originally

approved in 1962. Last previous edition approved in 2014 as D1945 – 14. DOI:

with tangent skim peak detection is recommended.

10.1520/D1945-14R19.

5.3 Attenuator—If the chromatogram is to be interpreted

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

using manual methods, an attenuator must be used with the

Standards volume information, refer to the standard’s Document Summary page on

detector output signal to maintain maximum peaks within the

the ASTM website.

3 recorder chart range. The attenuator must be accurate to within

The last approved version of this historical standard is referenced on

www.astm.org. 0.5 % between the attenuator range steps.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1945 − 14 (2019)

TABLE 1 Natural Gas Components and Range of

5.4.3 An optional manifold arrangement for entering

Composition Covered

vacuum samples is shown in Fig. 1.

Component Mol %

5.5 Column Temperature Control:

Helium 0.01 to 10

5.5.1 Isothermal—When isothermal operation is used,

Hydrogen 0.01 to 10

maintain the analyzer columns at a temperature constant to

Oxygen 0.01 to 20

Nitrogen 0.01 to 100

0.3 °C during the course of the sample run and corresponding

Carbon dioxide 0.01 to 20

reference run.

Methane 0.01 to 100

Ethane 0.01 to 100 5.5.2 Temperature Programming—Temperature program-

Hydrogen sulfide 0.3 to 30

ming may be used, as feasible. The oven temperature shall not

Propane 0.01 to 100

exceed the recommended temperature limit for the materials in

Isobutane 0.01 to 10

n-Butane 0.01 to 10 the column.

Neopentane 0.01 to 2

5.6 Detector Temperature Control—Maintain the detector

Isopentane 0.01 to 2

n-Pentane 0.01 to 2 temperature at a temperature constant to 0.3 °C during the

Hexane isomers 0.01 to 2

course of the sample run and the corresponding reference run.

Heptanes+ 0.01 to 1

The detector temperature shall be equal to or greater than the

maximum column temperature.

5.7 Carrier Gas Controls—The instrument shall be

5.4 Sample Inlet System:

equipped with suitable facilities to provide a flow of carrier gas

5.4.1 The sample inlet system shall be constructed of

through the analyzer and detector at a flow rate that is constant

materials that are inert and nonadsorptive with respect to the

to 1 % throughout the analysis of the sample and the reference

components in the sample. The preferred material of construc-

standard. The purity of the carrier gas may be improved by

tion is stainless steel. Copper, brass, and other copper-bearing

flowing the carrier gas through selective filters prior to its entry

alloys are unacceptable. The sample inlet system from the

into the chromatograph.

cylinder valve to the GC column inlet must be maintained at a

5.8 Columns:

temperature constant to 61 °C.

5.8.1 The columns shall be constructed of materials that are

5.4.2 Provision must be made to introduce into the carrier

inert and nonadsorptive with respect to the components in the

gas ahead of the analyzing column a gas-phase sample that has

sample. The preferred material of construction is stainless

been entrapped in a fixed volume loop or tubular section. The

steel. Copper and copper-bearing alloys are unacceptable.

fixed loop or section shall be so constructed that the total

5.8.2 An adsorption-type column and a partition-type col-

volume, including dead space, shall not normally exceed

umn may be used to make the analysis.

0.5 mL at 100 kPa. If increased accuracy of the hexanes and

NOTE 2—See Practice E260.

heavier portions of the analysis is required, a larger sample size

5.8.2.1 Adsorption Column—This column must completely

may be used (see Test Method D2597). The sample volume

separate oxygen, nitrogen, and methane. A 13X molecular

must be reproducible such that successive runs agree within

sieve 80/100 mesh is recommended for direct injection. A 5A

1 % on each component. A flowing sample inlet system is

column can be used if a pre-cut column is present to remove

acceptable as long as viscosity effects are accounted for.

interfering hydrocarbons. If a recorder is used, the recorder pen

NOTE 1—The sample size limitation of 0.5 mL or smaller is selected

must return to the baseline between each successive peak. The

relative to linearity of detector response, and efficiency of column

resolution (R) must be 1.5 or greater as calculated in the

separation. Larger samples may be used to determine low-quantity

components to increase measurement accuracy. following equation:

FIG. 1 Suggested Manifold Arrangement for Entering Vacuum Samples

D1945 − 14 (2019)

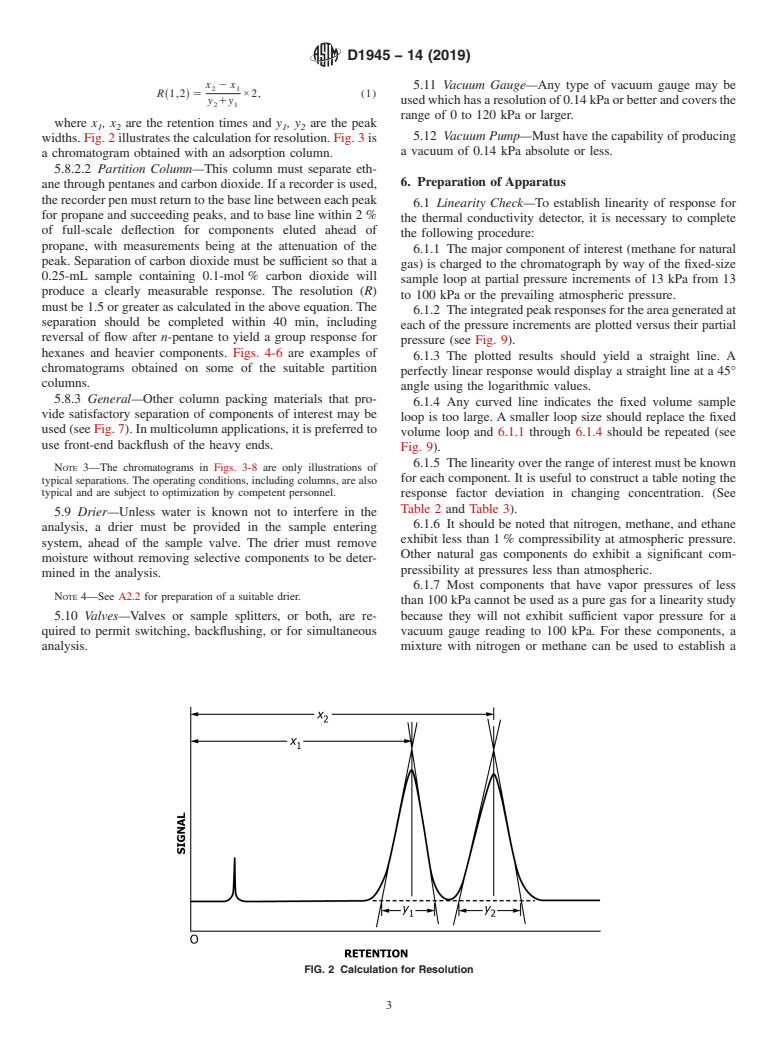

x 2 x 5.11 Vacuum Gauge—Any type of vacuum gauge may be

2 1

R~1,2! 5 × 2, (1)

y 1y used which has a resolution of 0.14 kPa or better and covers the

2 1

range of 0 to 120 kPa or larger.

where x , x are the retention times and y , y are the peak

1 2 1 2

5.12 Vacuum Pump—Must have the capability of producing

widths. Fig. 2 illustrates the calculation for resolution. Fig. 3 is

a vacuum of 0.14 kPa absolute or less.

a chromatogram obtained with an adsorption column.

5.8.2.2 Partition Column—This column must separate eth-

6. Preparation of Apparatus

ane through pentanes and carbon dioxide. If a recorder is used,

the recorder pen must return to the base line between each peak

6.1 Linearity Check—To establish linearity of response for

for propane and succeeding peaks, and to base line within 2 %

the thermal conductivity detector, it is necessary to complete

of full-scale deflection for components eluted ahead of

the following procedure:

propane, with measurements being at the attenuation of the

6.1.1 The major component of interest (methane for natural

peak. Separation of carbon dioxide must be sufficient so that a

gas) is charged to the chromatograph by way of the fixed-size

0.25-mL sample containing 0.1-mol % carbon dioxide will

sample loop at partial pressure increments of 13 kPa from 13

produce a clearly measurable response. The resolution (R)

to 100 kPa or the prevailing atmospheric pressure.

must be 1.5 or greater as calculated in the above equation. The

6.1.2 The integrated peak responses for the area generated at

separation should be completed within 40 min, including

each of the pressure increments are plotted versus their partial

reversal of flow after n-pentane to yield a group response for

pressure (see Fig. 9).

hexanes and heavier components. Figs. 4-6 are examples of

6.1.3 The plotted results should yield a straight line. A

chromatograms obtained on some of the suitable partition

perfectly linear response would display a straight line at a 45°

columns.

angle using the logarithmic values.

5.8.3 General—Other column packing materials that pro-

6.1.4 Any curved line indicates the fixed volume sample

vide satisfactory separation of components of interest may be

loop is too large. A smaller loop size should replace the fixed

used (see Fig. 7). In multicolumn applications, it is preferred to

volume loop and 6.1.1 through 6.1.4 should be repeated (see

use front-end backflush of the heavy ends.

Fig. 9).

6.1.5 The linearity over the range of interest must be known

NOTE 3—The chromatograms in Figs. 3-8 are only illustrations of

for each component. It is useful to construct a table noting the

typical separations. The operating conditions, including columns, are also

typical and are subject to optimization by competent personnel.

response factor deviation in changing concentration. (See

Table 2 and Table 3).

5.9 Drier—Unless water is known not to interfere in the

6.1.6 It should be noted that nitrogen, methane, and ethane

analysis, a drier must be provided in the sample entering

exhibit less than 1 % compressibility at atmospheric pressure.

system, ahead of the sample valve. The drier must remove

Other natural gas components do exhibit a significant com-

moisture without removing selective components to be deter-

pressibility at pressures less than atmospheric.

mined in the analysis.

6.1.7 Most components that have vapor pressures of less

NOTE 4—See A2.2 for preparation of a suitable drier.

than 100 kPa cannot be used as a pure gas for a linearity study

5.10 Valves—Valves or sample splitters, or both, are re- because they will not exhibit sufficient vapor pressure for a

quired to permit switching, backflushing, or for simultaneous vacuum gauge reading to 100 kPa. For these components, a

analysis. mixture with nitrogen or methane can be used to establish a

FIG. 2 Calculation for Resolution

D1945 − 14 (2019)

FIG. 3 Separation Column for Oxygen, Nitrogen, and Methane (See Annex A2)

FIG. 4 Chromatogram of Natural Gas (BMEE Column) (See Annex A2)

partial pressure that can extend the total pressure to 100 kPa. where:

Using Table 4 for vapor pressures at 38 °C, calculate the

B = blend pressure, max, kPa;

maximum pressure to which a given component can be blended

V = vapor pressure, kPa;

with nitrogen as follows: i = mol %;

P = partial pressure, kPa; and

B 5 100 × V /i (2)

~ !

M = vacuum gauge pressure, kPa.

P 5 ~i × M!/100 (3)

D1945 − 14 (2019)

FIG. 5 Chromatogram of Natural Gas (Silicone 200/500 Column) (See Annex A2)

FIG. 6 Chromatogram of Natural Gas (See Annex A2)

6.2 Procedure for Linearity Check: 6.2.2 Carefully open the needle valve to admit the pure

6.2.1 Connect the pure-component source to the sample- component up to 13 kPa of partial pressure.

entry system. Evacuate the sample-entry system and observe

6.2.3 Record the exact partial pressure and actuate the

the vacuum gauge for leaks. (See Fig. 1 for a suggested

sample valve to place the sample onto the column. Record the

manifold arrangement.) The sample-entry system must be

peak area of the pure component.

vacuum tight.

D1945 − 14 (2019)

FIG. 7 Chromatogram of Natural Gas (Multi-Column Application) (See Annex A2)

FIG. 8 Separation of Helium and Hydrogen

6.2.4 Repeat 6.2.3 for 26, 39, 52, 65, 78, and 91 kPa on the 6.2.6 An alternative method is to obtain a blend of all the

vacuum gauge, recording the peak area obtained for sample components and charge the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.