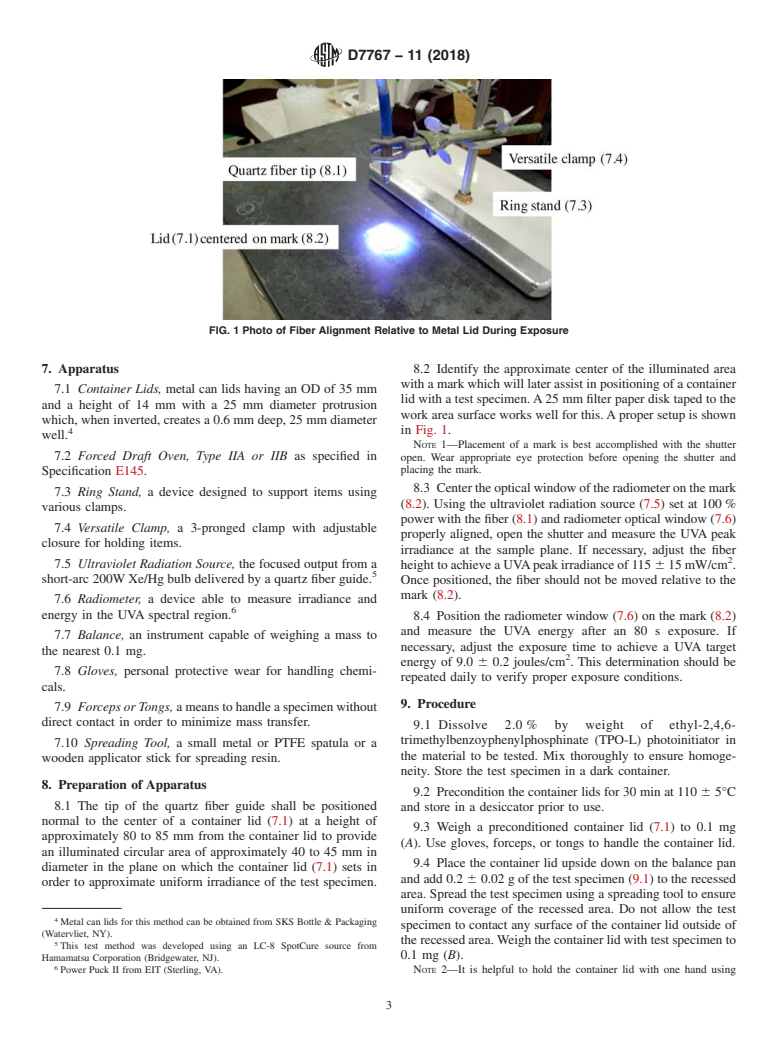

ASTM D7767-11(2018)

(Test Method)Standard Test Method to Measure Volatiles from Radiation Curable Acrylate Monomers, Oligomers, and Blends and Thin Coatings Made from Them

Standard Test Method to Measure Volatiles from Radiation Curable Acrylate Monomers, Oligomers, and Blends and Thin Coatings Made from Them

SIGNIFICANCE AND USE

5.1 This test method is an extension of Test Method D5403. While Test Method D5403 specifies that a test specimen be cured by exposure to UV or EB as prescribed by the supplier of the material, most radiation curable monomers and oligomers provided as raw materials to formulators are not designed to be used alone but rather as blends of monomers and oligomers so that there are no “supplier prescribed” exposure conditions. Test Method D5403 is not appropriate for the measurement of volatiles from thin radiation-curable coatings because supplier prescribed cure conditions include both a thickness and an exposure specification which are difficult or impossible to achieve in a test lab. Furthermore, inks form a special class of thin radiation curable coatings because they are formulated with known interferences (for example, pigments). As a result, Test Method D5403 does not provide a method for measuring volatiles from monomers and oligomers used as raw materials in the formulation of radiation curable coatings nor does it provide a method for measuring volatiles from thin radiation curable coatings such as inks.

5.2 This test method provides a means to measure the volatile content of individual acrylate monomers, oligomers, and blends commonly used to formulate radiation curable coatings such as printing inks. Such coatings comprise liquid or solid reactants that cure by polymerizing, crosslinking, or a combination of both and are designed to be applied as thin coatings in the absence of water or solvent and to be cured by exposing to ultraviolet radiation. There is currently no direct method for measuring the volatiles from the individual materials used or thin coatings made from them.

5.3 This test method also provides a means to measure the volatiles from acrylate monomers, oligomers, and blends cured using ultraviolet radiation from which an estimate for the volatiles from a thin coating cured using ultraviolet radiation comprising these acrylate monomers, o...

SCOPE

1.1 This test method describes a means to determine the percentage of processing, potential, and total volatiles from radiation curable acrylate monomers, oligomers, and blends. The results can be used to estimate the volatiles from thin radiation curable coatings that cannot otherwise be measured with the restriction that those coatings are not subjected to a pre-exposure water or solvent drying step. It also provides a means to determine the volatiles of thin radiation curable coatings in the absence of known interferences such as pigments in inks.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7767 − 11 (Reapproved 2018)

Standard Test Method to

Measure Volatiles from Radiation Curable Acrylate

Monomers, Oligomers, and Blends and Thin Coatings Made

1

from Them

This standard is issued under the fixed designation D7767; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method describes a means to determine the 2.1 ASTM Standards:

percentage of processing, potential, and total volatiles from D5403 Test Methods for Volatile Content of Radiation Cur-

radiation curable acrylate monomers, oligomers, and blends. able Materials

The results can be used to estimate the volatiles from thin E145 Specification for Gravity-Convection and Forced-

radiation curable coatings that cannot otherwise be measured Ventilation Ovens

with the restriction that those coatings are not subjected to a E177 Practice for Use of the Terms Precision and Bias in

pre-exposure water or solvent drying step. It also provides a ASTM Test Methods

means to determine the volatiles of thin radiation curable E691 Practice for Conducting an Interlaboratory Study to

coatings in the absence of known interferences such as Determine the Precision of a Test Method

3

pigments in inks. 2.2 Other Document:

EPA Method 24 Determination of Volatile Matter Content,

1.2 The values stated in SI units are to be regarded as

WaterContent,Density,VolumeSolids,andWeightSolids

standard. No other units of measurement are included in this

of Surface Coatings

standard.

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions:

responsibility of the user of this standard to establish appro-

3.1.1 cure, n—conversion of a coating from its application

priate safety and health practices and determine the applica-

state to its final use state measured by tests generally related to

bility of regulatory limitations prior to use.This standard does

end use performance and mutually agreeable to supplier and

not purport to address all of the safety concerns, if any,

purchaser.

associated with its use. It is the responsibility of the user of this

3.1.2 electron beam (EB) curing, n—conversionofacoating

standard to establish appropriate safety, health, and environ-

from its application state to its final use state by means of a

mental practices and determine the applicability of regulatory

mechanism initiated by electron impingement generated by

limitations prior to use.

equipment designed for that purpose.

1.4 This international standard was developed in accor-

3.1.3 pigment, n—an insoluble substance added to a formu-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the lation to modify the visual appearance of a coating made from

the formulation.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3.1.4 potential volatiles, n—the percentage loss in specimen

Barriers to Trade (TBT) Committee.

weightuponheatingat110°Cfor60minafterradiationcuring.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Related Coatings, Materials, andApplications and is the direct responsibility of Standards volume information, refer to the standard’s Document Summary page on

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. the ASTM website.

3

Current edition approved June 1, 2018. Published June 2018. Originally AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

approved in 2011. Last previous edition approved in 2011 as D7767 – 11. DOI: 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

10.1520/D7767-11R18. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7767 − 11 (2018)

3.1.5 processing volatiles, n—the percentage loss in speci- combination of both and are designed to be applied as thin

men weight under process conditions that are designed to coatings in the absence of water or solvent and to be cured by

simulate actual industrial cure processing conditions. exposing to ultraviolet ra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.