ASTM A752-93(2003)

(Specification)Standard Specification for General Requirements for Wire Rods and Coarse Round Wire, Alloy Steel

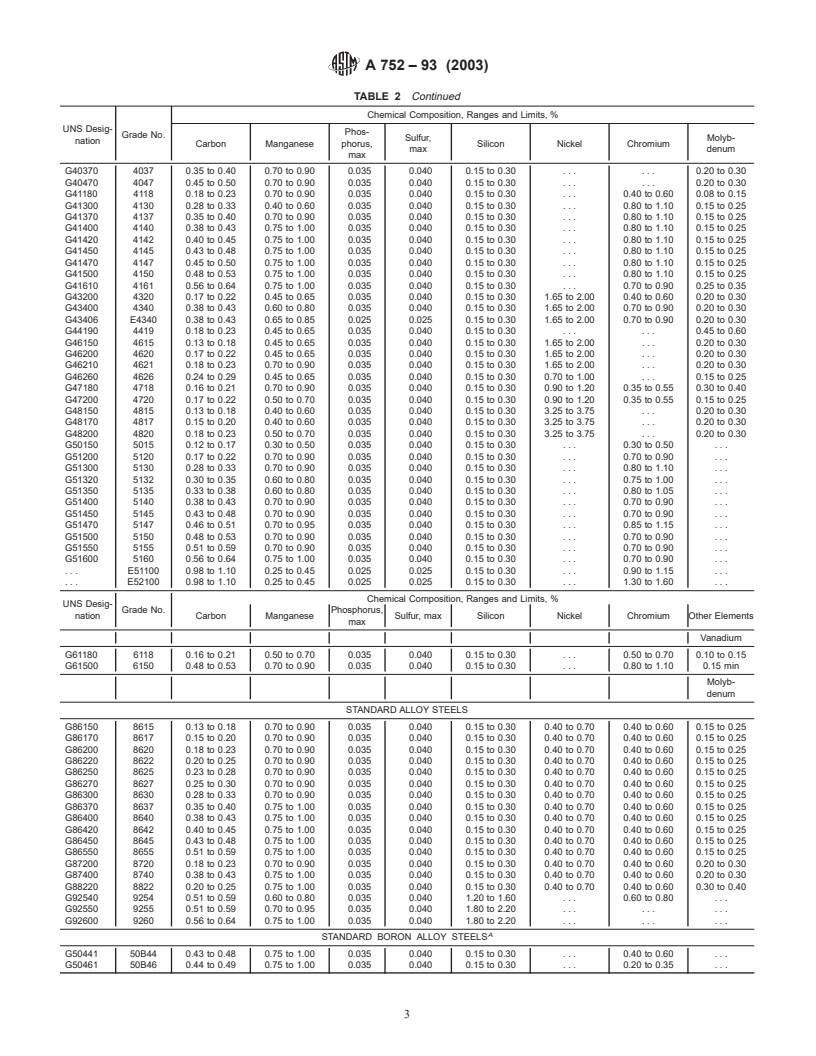

Standard Specification for General Requirements for Wire Rods and Coarse Round Wire, Alloy Steel

SCOPE

1.1 This specification covers general requirements for alloy steel rods and uncoated coarse round alloy wire in coils that are not required to meet hardenability band limits.

1.2 In case of conflict, the requirements in the purchase order, on the drawing, in the individual specification, and in this general specification shall prevail in the sequence named.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 752 – 93 (Reapproved 2003)

Standard Specification for

General Requirements for Wire Rods and Coarse Round

1

Wire, Alloy Steel

This standard is issued under the fixed designation A 752; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers general requirements for alloy 3.1 Description of Terms Specific to This Standard:

steel rods and uncoated coarse round alloy wire in coils that are 3.1.1 alloy steel— steel is considered to be alloy steel when

not required to meet hardenability band limits. the maximum of the range given for the content of alloying

1.2 In case of conflict, the requirements in the purchase elements exceeds one or more of the following limits: manga-

order, on the drawing, in the individual specification, and in nese 1.65 %, silicon 0.60 %, copper 0.60 %; or in which a

this general specification shall prevail in the sequence named. definite range or a definite minimum quantity of any of the

1.3 The values stated in inch-pound units are to be regarded following elements is specified or required within the limits of

as the standard. the recognized field of constructional alloy steels: aluminum,

chromium up to 3.99 %, cobalt, columbium, molybdenum,

2. Referenced Documents

nickel, titanium, tungsten, vanadium, zirconium, or any other

2.1 ASTM Standards: alloying elements added to obtain a desired alloying effect.

A 370 Test Methods and Definitions for Mechanical Testing

Note that aluminum, columbium, and vanadium may also be

2

of Steel Products used for grain refinement purposes.

A 700 Practices for Packaging, Marking, and Loading

3.1.1.1 Boron treatment of alloy steels, which are fine grain,

3

Methods for Steel Products for Domestic Shipment may be specified to improve hardenability.

4

A 919 Terminology Relating to Heat Treatment of Metals

3.1.1.2 Other elements, such as lead, selenium, tellurium, or

E 29 Practice for Using Significant Digits in Test Data to bismuth, may be specified to improve machinability.

5

Determine Conformance with Specifications

3.1.2 coarse round wire—from 0.035 to 0.999 in. (0.89 to

E 30 Test Methods for Chemical Analysis of Steel, Cast

25.4 mm) in diameter, inclusive, wire produced from hot-rolled

6

Iron, Open-Hearth Iron, and Wrought Iron wire rods or hot-rolled coiled bars by one or more cold

7

E 112 Test Methods for Determining Average Grain Size

reductions primarily for the purpose of obtaining a desired size

2.2 AIAG Standard: with dimensional accuracy, surface finish, and mechanical

AIAGB-5 02.00 Primary Metals Identification Tag Applica-

properties. By varying the amount of cold reduction and other

8

tion Standard wire mill practices, including thermal treatment, a wide diver-

sity of mechanical properties and finishes are made available.

3.1.2.1 Coarse round wire is designated by common frac-

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

tions or decimal parts of an inch, or millimetres.

Stainless Steel and Related Alloys, and is the direct responsibility of Subcommittee

3.1.3 wire rods—rods that are hot rolled from billets into an

A01.03 on Steel Rod and Wire.

Current edition approved April 10, 2003. Published June 2003. Originally approximate round cross section and into coils of one continu-

approved in 1977. Last previous edition approved in 1998 as A 752 – 93 (1998).

ous length. Rods are not comparable to hot-rolled bars in

2

Annual Book of ASTM Standards, Vol 01.03.

accuracy of cross section or surface finish and as a semi-

3

Annual Book of ASTM Standards, Vol 01.05.

4

finished product are primarily for the manufacture of wire.

Discontinued; see 1998 Annual Book of ASTM Standards, Vol 01.01. Replaced

7 47

by A 941.

3.1.3.1 Rod sizes from ⁄32 to ⁄64 in. (5.6 to 18.7 mm) in

5

Annual Book of ASTM Standards, Vol 14.02.

diameter, inclusive, are designated by fractions or decimal

6

Discontinued; see 1994 Annual Book of ASTM Standards, Vol 03.05.

7 parts of an inch as shown in Table 1.

Annual Book of ASTM Standards, Vol 03.01.

8

Available from the Automotive Industry Action Group, 26200 Lahser, Suite

200, Southfield, MI 48034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 752 – 93 (2003)

TABLE 1 Sizes of Alloy Steel Wire Rods

Inch Decimal Metric Inch Decimal Metric

Fraction Equivalent, Equivalent, Fraction Equivalent, Equivalent,

in. mm in. mm

7 31

⁄32 0.219 5.6 ⁄64 0.484 12.3

15 1

⁄64 0.234 6.0 ⁄2 0.500 12.7

1 33

⁄4 0.250 6.4 ⁄64 0.516 13.1

17 17

⁄6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.