ASTM F1930-00

(Test Method)Standard Test Method for Evaluation of Flame Resistant Clothing for Protection Against Flash Fire Simulations Using an Instrumented Manikin

Standard Test Method for Evaluation of Flame Resistant Clothing for Protection Against Flash Fire Simulations Using an Instrumented Manikin

SIGNIFICANCE AND USE

This test method can be used to measure and compare the thermal protection provided by different materials, garments, clothing ensembles, and systems.

This test method provides a measurement of garment and clothing ensemble performance on a stationary upright manikin.

5.2.1 This test method is not intended to be a quality assurance test.

5.2.2 The effects of body position and movement are not addressed in this test method.

The measurement of the thermal protection provided by clothing is complex and dependent on the apparatus and techniques used. It is not practical in a test method of this scope to establish details sufficient to cover all contingencies. Departures from the instructions in this test method may lead to significantly different test results. Technical knowledge concerning the theory of heat transfer and testing practices is needed to evaluate if, and which, departures from the instructions given in this test method are significant. Standardization of the test method reduces, but does not eliminate, the need for such technical knowledge. Any departures should be reported with the results.

SCOPE

1.1 This test method covers quantitative measurements and subjective observations that characterize the performance of single layer garments or protective clothing ensembles in a simulated flash fire environment having controlled heat flux, flame distribution, and duration. This test method is extremely complex and requires a high degree of technical expertise in both the test setup and operation.

1.1.1 Heat transmitted to each sensor location on the surface of an instrumented manikin is converted to show the corresponding predicted degree of burn injury to human tissue.

1.1.2 The sum of these values can then be converted to a percentage to show the total area of predicted burn injury.

1.1.2.1 Use of the predicted burn injury to evaluate the heat transferred to the manikin does not constitute a material's performance specification.

1.1.3 The visual and physical changes to the single layer garment or protective clothing ensemble are recorded to aid in understanding how the burn injury results can be interpreted.

1.2 The measurements obtained and observations noted can only apply to the particular garment(s) or ensemble(s) tested using the specified heat flux, duration, and flame distribution.

1.3 This standard should be used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions and should not be used to describe or appraise the fire-hazard or fire-risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire-hazard assessment or a fire-risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard or fire risk of a particular end use.

1.4 This test method is a fire-test-response test method.

1.5 The values stated in customary units are to be regarded as the standard. The values given in parentheses are for mathematical conversions to SI units.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1930–00

Standard Test Method for

Evaluation of Flame Resistant Clothing for Protection

Against Flash Fire Simulations Using an Instrumented

Manikin

This standard is issued under the fixed designation F 1930; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address the safety

concerns, if any, associated with its use. It is the responsibility

1.1 This test method covers quantitative measurements and

of the user of this standard to establish appropriate safety and

subjective observations that characterize the performance of

health practices and determine the applicability of regulatory

single layer garments or protective clothing ensembles in a

limitations prior to use.

simulated flash fire environment having controlled heat flux,

flame distribution, and duration. This test method is extremely

2. Referenced Documents

complex and requires a high degree of technical expertise in

2.1 ASTM Standards:

both the test setup and operation.

D 123 Terminology Relating to Textiles

1.1.1 Heattransmittedtoeachsensorlocationonthesurface

D 1835 Specification for Liquefied Petroleum (LP) Gases

of an instrumented manikin is converted to show the corre-

F 1494 Terminology Relating to Protective Clothing

sponding predicted degree of burn injury to human tissue.

2.2 AATCC Standard:

1.1.2 The sum of these values can then be converted to a

Test Method 135 Dimensional Changes inAutomatic Home

percentage to show the total area of predicted burn injury.

Laundering of Woven and Knit Fabrics

1.1.2.1 Use of the predicted burn injury to evaluate the heat

2.3 Canadian Standards:

transferred to the manikin does not constitute a material’s

CAN/CGSB-4.2 No. 58-M90 Textile Test Methods Colour-

performance specification.

fastness and Dimensional Change in Domestic Launder-

1.1.3 The visual and physical changes to the single layer

ing of Textiles

garment or protective clothing ensemble are recorded to aid in

CAN/CGSB-3.14 M88 Liquefied Petroleum Gas (Propane)

understanding how the burn injury results can be interpreted.

1.2 The measurements obtained and observations noted can

3. Terminology

only apply to the particular garment(s) or ensemble(s) tested

3.1 Definitions:

using the specified heat flux, duration, and flame distribution.

3.1.1 burn injury, n—burn damage that occurs at various

1.3 This standard should be used to measure and describe

levels of depth within human tissue.

the response of materials, products, or assemblies to heat and

3.1.1.1 Discussion—burn injury in human tissue occurs

flame under controlled conditions and should not be used to

when the tissue is heated and kept at an elevated temperature

describe or appraise the fire-hazard or fire-risk of materials,

for a critical period of time. The amount of burn injury, first,

products, or assemblies under actual fire conditions. However,

second, or third-degree, depends upon both the level of the

results of this test may be used as elements of a fire-hazard

elevated temperature and the duration of time.

assessment or a fire-risk assessment which takes into account

3.1.2 flame distribution, n—in the flash fire testing of

allofthefactorswhicharepertinenttoanassessmentofthefire

clothing, a spatial distribution of incident flames from test

hazard or fire risk of a particular end use.

facility burners to provide a controlled heat flux over the

1.4 This test method is a fire-test-response test method.

manikin surface.

1.5 The values stated in customary units are to be regarded

as standard. The values given in parentheses are mathematical

conversions to SI units.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This test method is under the jurisdiction of ASTM Committee F23 on the ASTM website.

Protective Clothing and is the direct responsibility of Subcommittee F23.80 on Available from American Association of Textile Chemists and Colorists, PO

Instrumented Manikin Test. Box 12215, Research Triangle Park, NC 27709.

Current edition approved June 10, 2000. Published August 2000. Originally Available from Standards Council of Canada, Suite 1200, 45 O’Connor St.,

published as F 1930 – 99. Last previous edition F 1930 – 99. Ottawa, Ontario, K1P 6N7.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1930–00

3.1.3 instrumented manikin, n—a model representing an the flash fire exposure. Identification of the test specimen, test

adult-size human and fitted with sensors on the surface for use conditions, comments and remarks about the test purpose, and

in testing. response of the test specimen to the exposure are recorded and

3.1.3.1 Discussion—The instrumented manikin used in are included as part of the report. The performance of the test

flash fire testing of clothing is fitted with at least 100 heat specimenisindicatedbythecalculatedburninjuryareaandthe

sensors, excluding hands and feet. way the specimen responds to the test exposure.

3.1.4 predicted total area of burn injury, n—in the flash fire

5. Significance and Use

testing of clothing, the sum of areas represented by the sensors

5.1 This test method can be used to measure and compare

that calculate at least a second degree burn injury.

the thermal protection provided by different materials, gar-

3.1.5 second-degree burn injury, n—irreversible burn dam-

ments, clothing ensembles, and systems.

age at the epidermis/dermis interface in human tissue. (Syn-

5.2 This test method provides a measurement of garment

onym second-degree burn)

and clothing ensemble performance on a stationary upright

3.1.6 second-degree burn injury area, n—in the flash fire

manikin.

testing of clothing, the sum of the areas represented by sensors

5.2.1 This test method is not intended to be a quality

that calculate a burn injury at the epidermis/dermis interface in

human tissue. (Synonym second-degree burn area) assurance test.

5.2.2 The effects of body position and movement are not

3.1.7 heat sensor, n—a device capable of measuring inci-

dent heat to the manikin’s surface under test conditions and addressed in this test method.

5.3 The measurement of the thermal protection provided by

creating data that can be processed by a computer program to

assess burn injury. clothing is complex and dependent on the apparatus and

techniquesused.Itisnotpracticalinatestmethodofthisscope

3.1.8 thermal protection, n—the property that characterizes

the overall performance of a garment or protective clothing to establish details sufficient to cover all contingencies. Depar-

tures from the instructions in this test method may lead to

ensemble relative to how it prevents the transfer of heat that is

significantly different test results. Technical knowledge con-

sufficient enough to cause burn injury.

cerning the theory of heat transfer and testing practices is

3.1.8.1 Discussion—In flash fire testing of clothing, thermal

needed to evaluate if, and which, departures from the instruc-

protection of a garment or ensemble and the consequential

tions given in this test method are significant. Standardization

predicted burn injury (second-degree or third-degree), can be

of the test method reduces, but does not eliminate, the need for

quantified by the measured sensor response that indicates how

such technical knowledge. Any departures should be reported

well the garment or protective clothing ensemble blocks heat

with the results.

from the manikin surface. In addition to the measured sensor

response, the physical response and degradation is an observ-

6. Apparatus

able phenomenon that can be correlated to the sensor calcula-

6.1 Instrumented Manikin—An upright manikin that is in

tions and is useful in understanding garment or protective

the shape and size of an adult male human form shall be used.

clothing ensemble thermal protection.

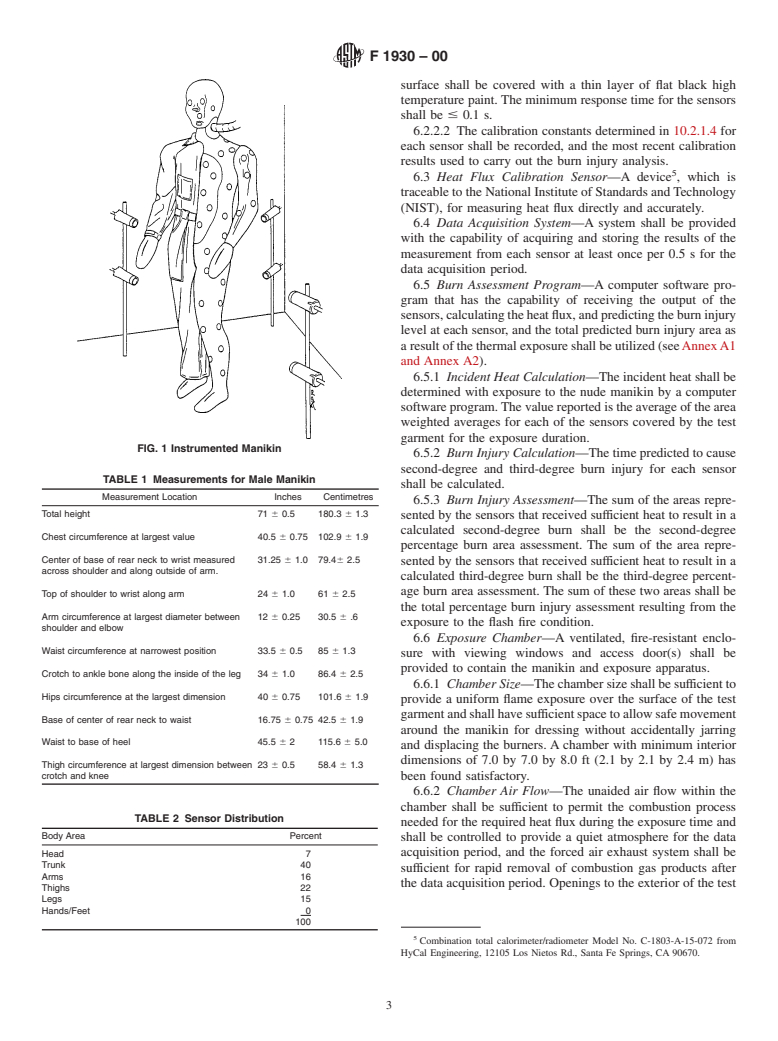

(see Fig. 1)

3.1.9 third-degree burn injury, n—the irreversible burn

6.1.1 Size and Shape—The manikin shall be constructed

damage at the dermis/subcutaneous interface in human tissue

with a head, chest/back, abdomen/buttocks, arms, hands, legs,

(Synonym third-degree burn).

and feet.The manikin’s dimensions should correspond to those

3.1.10 third-degree burn injury area, n—in the flash fire

requiredforstandardsizesofgarmentsbecausedeviationsinfit

testing of clothing, the sum of the areas represented by sensors

will affect the results. A male manikin consisting of the sizes

that calculate a burn injury at the dermis/subcutaneous inter-

given in Table 1 has been found satisfactory to evaluate

face in human tissue. (Synonym third-degree burn area)

garments or protective ensembles.

3.1.11 For definitions of other protective clothing related

6.1.2 The manikin should be constructed of flame resistant,

terms used in this test method, refer to Terminology F 1494.

thermally stable, nonmetallic materials.

For definitions for other textile related terms used in this test

6.2 Apparatus for Burn Injury Assessment:

method, refer to Terminology D 123.

6.2.1 Manikin Construction—Atleast100heatsensorsshall

4. Summary of Test Method

be distributed as uniformly as possible in each area on the

4.1 The test method evaluates the protective performance of manikin as given in Table 2.

the materials of construction and design of the test specimen, 6.2.2 Heat sensor construction—Each heat sensor shall

which is either a garment or an ensemble. The test specimen is havethecapacitytomeasuretheincidentheatfluxoverarange

2 2

placed on an adult-size manikin at ambient atmospheric from 0.0 to 4.0 cal/cm ·s (167 kW/m ). This range permits the

conditions and exposed to a laboratory flash fire simulation useofthesensorstosettheexposurelevelbydirectlyexposing

with controlled heat flux, duration, and flame distribution. The the manikin to the flames in a test without the garment and also

testprocedure,dataacquisition,resultscalculations,andprepa- having the capability to measure the heat transfer to the

ration of the test report are performed with computer hardware manikin with exposure of the test garment or protective

and software programs. Heat, which is transferred through the clothing ensemble.

test specimen during and after the exposure, is measured by 6.2.2.1 The sensors shall be constructed of a material with

sensors. These measurements are used to calculate the second- known thermal characteristics that can be used to indicate heat

degree, third-degree, and total burn injury areas resulting from flux and temporal variation received by the sensors. The outer

F1930–00

surface shall be covered with a thin layer of flat black high

temperature paint. The minimum response time for the sensors

shall be# 0.1 s.

6.2.2.2 The calibration constants determined in 10.2.1.4 for

each sensor shall be recorded, and the most recent calibration

results used to carry out the burn injury analysis.

6.3 Heat Flux Calibration Sensor—A device , which is

traceable to the National Institute of Standards andTechnology

(NIST), for measuring heat flux directly and accurately.

6.4 Data Acquisition System—A system shall be provided

with the capability of acquiring and storing the results of the

measurement from each sensor at least once per 0.5 s for the

data acquisition period.

6.5 Burn Assessment Program—A computer software pro-

gram that has the capability of receiving the output of the

sensors,calculatingtheheatflux,andpredictingtheburninjury

level at each sensor, and the total predicted burn injury area as

aresultofthethermalexposureshallbeutilized(seeAnnexA1

and Annex A2).

6.5.1 Incident Heat Calculation—The incident heat shall be

determined with exposure to the nude manikin by a computer

softwareprogram.Thevaluereportedistheaverageofthearea

weighted averages for each of the sensors covered by the test

garment for the exposure duration.

FIG. 1 Instrumented Manikin

6.5.2 Burn Injury Calculation—The time predicted to cause

second-degree and third-degree burn injury for each sensor

TABLE 1 Measurements for Male Manikin

shall be calculated.

Measurement Location Inches Centimetres

6.5.3 Burn Injury Assessment—The sum of the areas repre-

Total height 71 6 0.5 180.3 6 1.3

sented by the sensors that received sufficient heat to result in a

calculated second-degree burn shall be the second-degree

Chest circumference at largest value 40.5 6 0.75 102.9 6 1.9

percentage burn area assessment. The sum of the area repre-

Center of base of rear neck to wrist measured 31.25 6 1.0 79.46 2.5

sented by the sensors that received sufficient heat to result in a

across shoulder and along outside of arm.

calculated third-degree burn shall be the third-degree percent-

age burn area assessment. The sum of these two areas shall be

Top of shoulder to wrist along arm 24 6 1.0 61 6 2.5

the total percentage burn injury assessment resulting from the

Arm circumference at largest diameter between 12 6 0.25 30.5 6 .6

exposure to the flash fire condition.

shoulder and elbow

6.6 Exposure Chamber—A ventilated, fire-resistant enclo-

Waist circumference at narrowest position 33.5 6 0.5 85 6 1.3

sure with viewing windows and access door(s) shall be

provided to contain the manikin and exposure apparatus.

Crotch to ankle bone along the inside of the leg 34 6 1.0 86.4 6 2.5

6.6.1 Chamber Size—Thechambersizeshallbesufficientto

Hips circumference at the largest dimension 40 6 0.75 101.6 6 1.9

provide a uniform flame exposure over the surface of the test

garmentandshallhavesufficientspacetoallowsafemovement

Base of center of rear neck to waist 16.75 6 0.75 42.5 6 1.9

around the manikin for dressing without accidentally jarring

Waist to base of heel 45.5 6 2 115.6 6 5.0

and displacing the burners. A chamber with minimum interior

dimensions of 7.0 by 7.0 by 8.0 ft (2.1 by 2.1 by 2.4 m) has

Thigh circumference at largest dimension between 23 6 0.5 58.4 6 1.3

crotch and knee been found satisfactory.

6.6.2 Chamber Air Flow—The unaided air flow within the

chamber shall be sufficient to permit the combustion process

TABLE 2 Sensor Distribution

needed for the required heat flux during the exposure time and

Body Area Percent

shall be controlled to provide a quiet atmosphere for the data

acquisition period, and the forced air exhaust system shall be

Head 7

Trunk 40

sufficient for rapid removal of combustion gas products after

Arms 16

the data acquisition period. Openings to the exterior of the test

Thi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.