ASTM D7491-08(2015)

(Guide)Standard Guide for Management of Non-Conforming Coatings in Coating Service Level I Areas of Nuclear Power Plants

Standard Guide for Management of Non-Conforming Coatings in Coating Service Level I Areas of Nuclear Power Plants

SIGNIFICANCE AND USE

5.1 There are several methods for managing non-conforming coatings in an operating nuclear power plant. This guide outlines methods that have been determined to be acceptable to the nuclear industry.

5.2 Managing the amount of non-conforming coatings is key to ensuring the amount assumed, in the licensing bases is not exceeded.

5.3 EPRI Report 1003102 Revision 1 (formerly TR-109937) provides additional information on the selection, application, inspection and maintenance of nuclear plant safety-related protective coatings. This reference offers a detailed discussion of important considerations related to protective coatings and can be used to supplement this guide as deemed necessary.

SCOPE

1.1 This guide provides the user with guidance on developing a program for managing non-conforming coatings in Coating Service Level I areas of a nuclear power plant.

1.2 Non-conforming coatings include degraded previously DBA-qualified or acceptable coatings, unqualified coatings, unknown coatings, and unacceptable coatings.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7491 − 08 (Reapproved 2015)

Standard Guide for

Management of Non-Conforming Coatings in Coating

1

Service Level I Areas of Nuclear Power Plants

This standard is issued under the fixed designation D7491; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 non-conforming coatings, n—a coating or coating

system in a Coating Service Level I application that lacks or

1.1 This guide provides the user with guidance on develop-

has insufficient documentation to support or verify DBA

ing a program for managing non-conforming coatings in

qualification.

Coating Service Level I areas of a nuclear power plant.

3.2.1.1 Discussion—This would include coatings referred to

1.2 Non-conforming coatings include degraded previously

as unqualified, unacceptable, and degraded qualified coatings.

DBA-qualified or acceptable coatings, unqualified coatings,

3.2.2 unacceptable coating system, n—Asafetyrelatedcoat-

unknown coatings, and unacceptable coatings.

ing system for which no suitability for application review

1.3 This standard does not purport to address all of the

which meets the plant licensing requirements has been com-

safety concerns, if any, associated with its use. It is the

pleted.

responsibility of the user of this standard to establish appro-

3.2.2.1 Discussion—Therefore, no reasonable assurance ex-

priate safety and health practices and determine the applica-

ists that, when properly applied and maintained, the coating or

bility of regulatory limitations prior to use.

lining will not detach under normal or accident conditions.

This is applicable to “pre-ANSI” plants.

2. Referenced Documents

2

2.1 ASTM Standards:

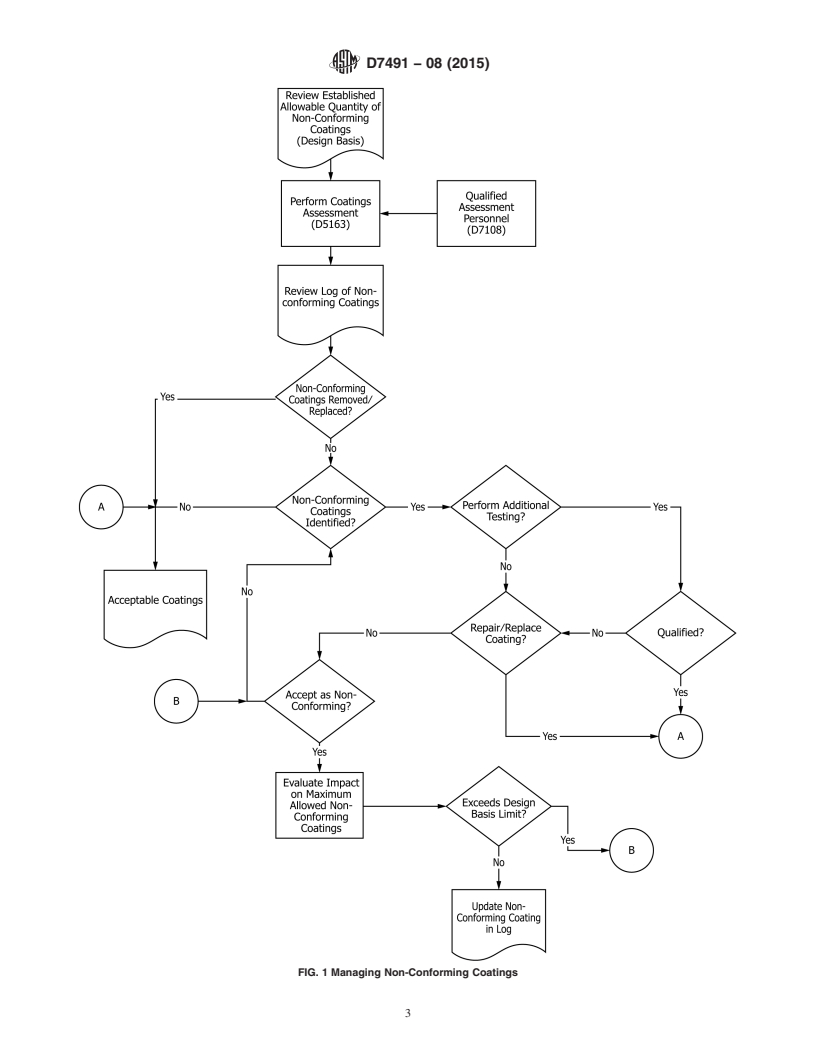

4. Summary of Practice

D4538 Terminology Relating to Protective Coating and

4.1 The process and use of this guide is summarized in

Lining Work for Power Generation Facilities

Fig. 1.

2.2 Other Documents:

Regulatory Guide 1.54 Service Level I, II, and III protective

3

5. Significance and Use

Coatings Applied to Nuclear Power Plants

EPRI Report 1003102 Guideline on Nuclear Safety-Related

5.1 There are several methods for managing non-

4

Coatings, Revision 1 (formerly TR-109937)

conforming coatings in an operating nuclear power plant. This

guide outlines methods that have been determined to be

3. Terminology

acceptable to the nuclear industry.

3.1 Definitions—Definitions for use with this guide are

5.2 Managing the amount of non-conforming coatings is

shown in Terminology D4538 or other applicable standards.

key to ensuring the amount assumed, in the licensing bases is

3.2 Definitions of Terms Specific to This Standard:

not exceeded.

5.3 EPRI Report 1003102 Revision 1 (formerly TR-

109937) provides additional information on the selection,

1

This guide is under the jurisdiction of ASTM Committee D33 on Protective

application, inspection and maintenance of nuclear plant

Coating and Lining Work for Power Generation Facilities and is the direct

safety-related protective coatings. This reference offers a

responsibility of Subcommittee D33.10 on Protective Coatings Maintenance Work

for Power Generation Facilities.

detailed discussion of important considerations related to

Current edition approved Dec. 1, 2015. Published January 2016. Originally

protective coatings and can be used to supplement this guide as

approved in 2008. Last previous edition approved in 2008 as D7491 – 08. DOI:

deemed necessary.

10.1520/D7491-08R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6. Establishing the Design Limit of Non-Conforming

Standards volume information, refer to the standard’s Document Summary page on

Coatings

the ASTM website.

3

Available from U. S. Nuclear Regulatory Commission, Distribution Services

6.1 Determine what coatings do not meet the licensing basis

Section, Washington, DC 20555–0001, http://www.nrc.gov.

4

for the plant. For plants that have commitments to meet

Available from EPRI Customer Fulfillment, 1355 Willow Way, Suite 278,

Concord, CA 94520. Regulatory Guide 1.54 (applicable revision) and/or related

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7491 − 08 (2015)

FIG. 1 Managing Non-Conforming Coatings

2

---------------------- Page: 2 ----------------------

D7491 − 08 (2015)

ANSI/ASTM standards typically require DBA testing of coat- 8. Guidance on Managing Non-Conforming Coatings

ings and extensive documentation associated with the applica-

8.1 Once an

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7491 − 08 D7491 − 08 (Reapproved 2015)

Standard Guide for

Management of Non-Conforming Coatings in Coating

1

Service Level I Areas of Nuclear Power Plants

This standard is issued under the fixed designation D7491; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide provides the user with guidance on developing a program for managing non-conforming coatings in Coating

Service Level I areas of a nuclear power plant.

1.2 Non-conforming coatings include degraded previously DBA-qualified or acceptable coatings, unqualified coatings,

unknown coatings, and unacceptable coatings.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4538 Terminology Relating to Protective Coating and Lining Work for Power Generation Facilities

2.2 Other Documents:

3

Regulatory Guide 1.54 Service Level I, II, and III protective Coatings Applied to Nuclear Power Plants

4

EPRI Report 1003102 Guideline on Nuclear Safety-Related Coatings, Revision 1 (formerly TR-109937)

3. Terminology

3.1 Definitions—Definitions for use with this guide are shown in Terminology D4538 or other applicable standards.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 non-conforming coatings, n—a coating or coating system in a Coating Service Level I application that lacks or has

insufficient documentation to support or verify DBA qualification.

1

This guide is under the jurisdiction of ASTM Committee D33 on Protective Coating and Lining Work for Power Generation Facilities and is the direct responsibility

of Subcommittee D33.10 on Protective Coatings Maintenance Work for Power Generation Facilities.

Current edition approved Nov. 1, 2008Dec. 1, 2015. Published December 2008January 2016. Originally approved in 2008. Last previous edition approved in 2008 as

D7491 – 08. DOI: 10.1520/D7491-08.10.1520/D7491-08R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

Available from U. S. Nuclear Regulatory Commission, Distribution Services Section, Washington, DC 20555–0001, http://www.nrc.gov.

4

Available from EPRI Customer Fulfillment, 1355 Willow Way, Suite 278, Concord, CA 94520.

3.2.1.1 Discussion—

This would include coatings referred to as unqualified, unacceptable, and degraded qualified coatings.

3.2.2 unacceptable coating system, n—A safety related coating system for which no suitability for application review which

meets the plant licensing requirements has been completed.

3.2.2.1 Discussion—

Therefore, no reasonable assurance exists that, when properly applied and maintained, the coating or lining will not detach under

normal or accident conditions. This is applicable to “pre-ANSI” plants.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7491 − 08 (2015)

4. Summary of Practice

4.1 The process and use of this guide is summarized in

Fig. 1.

5. Significance and Use

5.1 There are several methods for managing non-conforming coatings in an operating nuclear power plant. This guide outlines

methods that have been determined to be acceptable to the nuclear industry.

5.2 Managing the amount of non-conforming coatings is key to ensuring the amount assumed, in the licensing bases is not

exceeded.

5.3 EPRI Report 1003102 Revision 1 (formerly TR-109937) provides additional information on the selection, application,

inspection and maintenance of nuclear plant safety-related protective coatings. This reference offers a detailed discrussiondiscus-

sion of inportantimportant considerations related to protective coatings and can be used to supplement this guide as deemed

necessary.

6. Establishing the Design Limit of Non-Conforming Coatings

6.1 Determine what coatings do not meet the licensing basis for the plant. For plants that have commitments to meet Reg

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.