ASTM D4697-95(2001)

(Guide)Standard Guide for Maintaining Test Methods in the User's Laboratory (Withdrawn 2009)

Standard Guide for Maintaining Test Methods in the User's Laboratory (Withdrawn 2009)

SIGNIFICANCE AND USE

Following this guide will aid the user in maintaining control of both the bias and the precision of any test method.

4.1.1 It is necessary to control bias so that, if a change in level of an unknown material under test occurs, the user can be confident that the change was not due to the execution of the test method.

4.1.2 It is also necessary to control precision so that the established confidence limits and critical differences will be maintained.

Should the use of the test method be out of control, this guide will detect it, and may give an indication of where the problem lies.

SCOPE

1.1 This guide is intended to assist laboratories in maintaining precision and controlling bias in testing. It includes statistical procedures for detecting lack of control, changes in calibration constants, and in operator technique. Suggestions are given for the correction of some out of control situations.

1.2 This guide includes the following topics: Topic Title SectionNumberScope1Referenced Documents2Terminology3Significance and Use4Calibration Control5Test Performance Control6

Annexes:

Calibration ControlAnnex A1Test Performance ControlAnnex A2

1.3 This standard does not give all of the details for preparing statistical quality control charts or the statistical tests used to interpret them, but such information may be found easily in a number of publications.

WITHDRAWN RATIONALE

This guide is intended to assist laboratories in maintaining precision and controlling bias in testing.

Formerly under the jurisdiction of Committee D13 on Textiles, , this guide was withdrawn in March 2009 because D13 no longer has the expertise to maintain and statistical standards are being maintained by committee E11.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4697–95 (Reapproved 2001)

Standard Guide for

Maintaining Test Methods in the User’s Laboratory

This standard is issued under the fixed designation D 4697; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

throughASTM Headquarters, 100 Barr Harbor Drive, Conshohocken, PA

1. Scope

19428,USA.Thecontrolchartparametersdescribedintheannexesofthis

1.1 This guide is intended to assist laboratories in maintain-

guide can be calculated with one of these programs and the control charts

ing precision and controlling bias in testing. It includes

screen plotted.

statistical procedures for detecting lack of control, changes in

3. Terminology

calibration constants, and in operator technique. Suggestions

are given for the correction of some out of control situations.

3.1 Definitions:

1.2 This guide includes the following topics:

3.1.1 accuracy, n—of a test method, the degree of agree-

Section

ment between the true value of the property being tested (or an

Topic Title Number

accepted standard value) and the average of many observations

Scope 1

made according to the test method, preferably by many

Referenced Documents 2

Terminology 3

observers. (See also bias and precision.)

Significance and Use 4

3.1.2 attribute data, n—observed values or determinations

Calibration Control 5

which indicate the presence or absence of specific character-

Test Performance Control 6

istics.

Annexes:

3.1.3 bias, n—in statistics, a constant or systematic error in

test results.

Calibration Control Annex A1

Test Performance Control Annex A2

3.1.3.1 Discussion—Bias can exist between the true value

andatestresultobtainedfromonemethod;betweentestresults

1.3 This standard does not give all of the details for

from two methods; or between two test results obtained from a

preparing statistical quality control charts or the statistical tests

single method, for example, between operators or between

used to interpret them, but such information may be found

laboratories.

easily in a number of publications.

3.1.4 calibrate, vt—to determine and record the relationship

2. Referenced Documents

between a set of standard units of measure and the output of an

instrument or test procedure.

2.1 ASTM Standards:

3.1.5 calibration, n—the act or process of calibrating; the

D 123 Terminology Relating to Textiles

recorded relationship resulting from calibrating.

D 1578 Test Method for Breaking Strength ofYarn in Skein

3.1.6 measurement value, n—the numerical result of quan-

Form

tifying a particular property or dimension. (Syn. measurement,

E 456 Terminology Relating to Quality and Statistics

measurement datum.)

2.2 ASTM Adjuncts:

3.1.7 moving range, MR, n—the difference without regard

TEX-PAC

to sign between two successive observations.

NOTE 1—Tex-Pac is a group of PC programs on floppy disks, available

3.1.8 precision, n—the degree of agreement within a set of

observations or test results obtained as directed in a test

This guide is under the jurisdiction of ASTM Committee D13 on Textiles and

method.

is the direct responsibility of Subcommittee D13.93 on Statistics.

3.1.8.1 Discussion—The term “precision” delimited in vari-

Current edition approved May 15, 1995. Published July 1995. Originally

ouswaysisusedtodescribedifferentaspectsofprecision.This

published as D 4697 – 87. Last previous edition D 4697 – 91.

usage was chosen in preference to the use of “repeatability”

For information see: Juran, J. M., ed., Quality Control Handbook, McGraw

Hill, New York, 4th ed., 1988; Manual on Presentation of Data and Control Chart

and “reproducibility” which have been assigned conflicting

Analysis, ASTM STP 15D,ASTM, 1976; and Statistical Quality Control Handbook,

meanings by various authors and standardizing bodies.

Western Electric Co., Inc., 2nd ed., 1985 (Inquiries may be made to: AT& T

3.1.9 test method, n—a definitive procedure for the identi-

Technologies, Commercial Sales Clerk, Select Code 700-444, P.O. Box 19901,

Indianapolis, IN 44219). fication, measurement, and evaluation of one or more qualities,

Annual Book of ASTM Standards, Vol 07.01.

characteristics, or properties of a material, product, system, or

Annual Book of ASTM Standards, Vol 14.02.

service that produces a test result.

PC programs on floppy disks are available throughASTM. For a 3 ⁄2 inch disk

1 3.1.10 verification, n—the act or process of verifying.

request PCN:12-429040-18, for a 5 ⁄4 inch disk request PCN:12-429041-18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

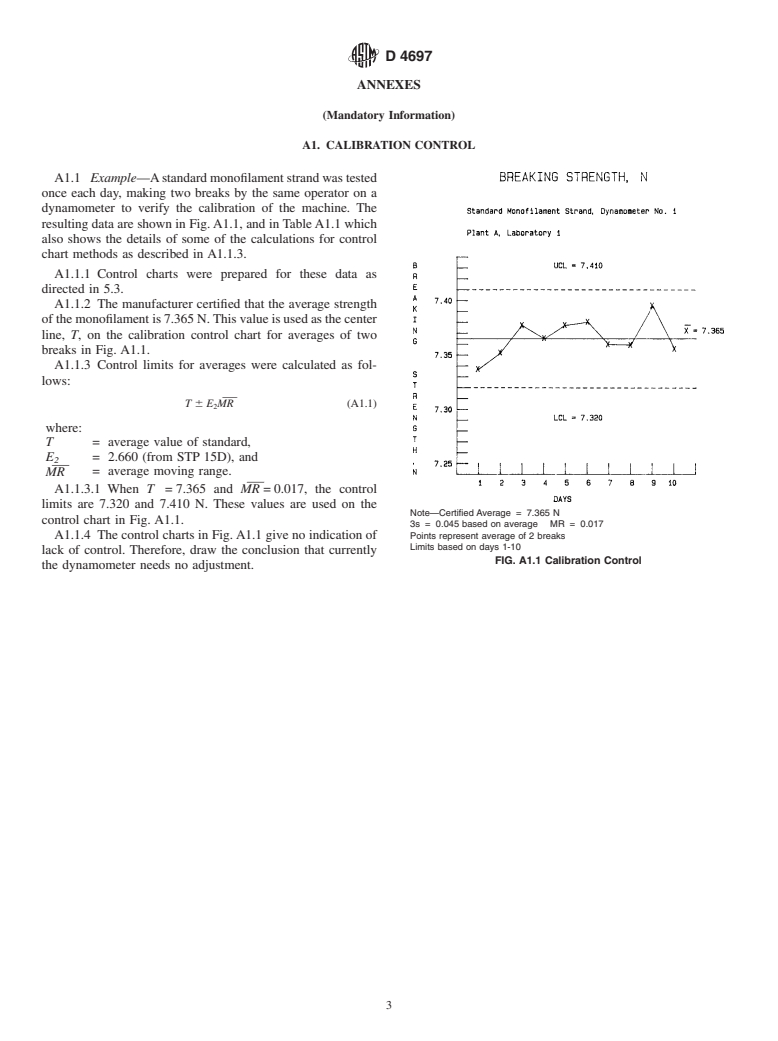

D4697

3.1.11 verify, vt—(1) to determine whether a previously 5.3.2 In the case of calibration control, it is seldom neces-

calibrated instrument, standard solution, or other standard is sary to plot a control chart for the range of specimens. This

still properly calibrated; (2) to establish that an operation has aspect of test method maintenance will usually be well

been completed correctly. controlledwhenthedirectionsin6.1,6.2,and6.5arefollowed.

3.1.12 For definitions of textile terms in this standard, refer

to Terminology D 123. For definitions of statistical terms in 6. Test Performance Control

this standard, refer to Terminology D 123 or Terminology

6.1 Standard Sample—Reserve an adequate supply of a

E 456.

stable standard sample of material for maintaining test perfor-

3.2 Definitions of Terms Specific to This Standard:

mance (Note 2). Each day, before making a test on unknown

3.2.1 maintain—to monitor the usage of test methods and to

laboratory samples, have each analyst run an analysis on the

take remedial steps when necessary.

standard sample. Have the analyst use the machine he will use

later to test the unknown samples.

4. Significance and Use

4.1 Following this guide will aid the user in maintaining NOTE 2—It is essential to obtain a new supply of a standard material

well before the old supply is exhausted, and to run the old supply and the

control of both the bias and the precision of any test method.

new supply in parallel for a short length of time.

4.1.1 It is necessary to control bias so that, if a change in

level of an unknown material under test occurs, the user can be

6.1.1 If a supply of a stable standard sample cannot be

confident that the change was not due to the execution of the

obtained, there are techniques available for overcoming this

test method.

problem. For example, two analysts could analyze a specimen

4.1.2 It is also necessary to control precision so that the

from the same sample at the same time, and the difference

established confidence limits and critical differences will be

between the two results could be plotted. For problems of this

maintained.

kind, competent statistical help is required in the planning of

4.2 Should the use of the test method be out of control, this

the program, the presentation, and analysis of the data.

guide will detect it, and may give an indication of where the

6.2 Quality Control Chart—Using the standard sample test

problem lies.

data, establish statistical quality control charts for the test

results produced by each analyst-instrument pair. If there is

5. Calibration Control

more than one analyst-instrument pair, plot a separate average

5.1 Calibration Procedure—To be completely useful, the

and range chart for each pair, using the same control lines (for

test method must contain a calibration procedure if it makes

an example, see Annex A2).

useofareagent,apparatus,orstandardthatissubjecttochange

6.3 Average Center Line—Use the established expected test

withageoruse.Ifitdoesnothaveacalibrationprocedure,then

value of the standard sample as the center line on the chart for

one should be obtained or written and incorporated in the

averages. This value may have been obtained with a standard

method.

material procured from an ou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.