ASTM C1558-03(2007)

(Guide)Standard Guide for Development of Standard Data Records for Computerization of Thermal Transmission Test Data for Thermal Insulation

Standard Guide for Development of Standard Data Records for Computerization of Thermal Transmission Test Data for Thermal Insulation

SIGNIFICANCE AND USE

This guide defines the principal elements of information, which are considered important and worth recording and storing permanently in computerized databases. Sufficient information is provided in this guide to enable the user to construct a database structure suitable for the intended application involving thermal insulation.

Because of increased activity in building computerized materials databases and the desire to encourage uniformity and ease of data comparison and interchange, these recommended formats provide for the inclusion of specific elements of thermal transmission test data in databases.

This guide has no implication on data required for materials production or purchase. Reporting of actual test results shall be as described in the actual materials specification or as agreed upon between the vendor and purchaser.

The suggested set of units for the recommended standard format given in this guide is SI. This guide, however, does not preclude other sets of units, such as inch-pound (IP).

SCOPE

1.1 This guide provides recommended formats for the recording of thermal transmission test data for thermal insulation and similar materials for inclusion in computerized material property databases. From this information, the database designer should be able to construct the database dictionary preparatory for development of a database schema.

1.2 This guide is applicable to thermal transmission test data obtained from standard test methods that cover planar and radial specimen geometries.

1.3 This guide is not intended for thermal transmission data obtained for thermal insulation assemblies or systems (that is, heat transmission coefficients for walls, roofs, ceilings, and floors).

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1558 − 03(Reapproved 2007)

Standard Guide for

Development of Standard Data Records for Computerization

of Thermal Transmission Test Data for Thermal Insulation

This standard is issued under the fixed designation C1558; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C335 Test Method for Steady-State Heat Transfer Properties

of Pipe Insulation

1.1 This guide provides recommended formats for the

C449/C449M Specification for Mineral Fiber Hydraulic-

recording of thermal transmission test data for thermal insula-

Setting Thermal Insulating and Finishing Cement

tion and similar materials for inclusion in computerized mate-

C516 Specification for Vermiculite Loose Fill Thermal In-

rial property databases. From this information, the database

sulation

designer should be able to construct the database dictionary

C518 Test Method for Steady-State Thermal Transmission

preparatory for development of a database schema.

Properties by Means of the Heat Flow Meter Apparatus

1.2 Thisguideisapplicabletothermaltransmissiontestdata

C533 Specification for Calcium Silicate Block and Pipe

obtained from standard test methods that cover planar and

Thermal Insulation

radial specimen geometries.

C534 Specification for Preformed Flexible Elastomeric Cel-

lular Thermal Insulation in Sheet and Tubular Form

1.3 This guide is not intended for thermal transmission data

obtained for thermal insulation assemblies or systems (that is, C547 Specification for Mineral Fiber Pipe Insulation

C549 Specification for Perlite Loose Fill Insulation

heat transmission coefficients for walls, roofs, ceilings, and

floors). C552 Specification for Cellular Glass Thermal Insulation

C553 Specification for Mineral Fiber Blanket Thermal Insu-

1.4 This standard does not purport to address all of the

lation for Commercial and Industrial Applications

safety concerns, if any, associated with its use. It is the

C578 Specification for Rigid, Cellular Polystyrene Thermal

responsibility of the user of this standard to establish appro-

Insulation

priate safety and health practices and determine the applica-

C592 Specification for Mineral Fiber Blanket Insulation and

bility of regulatory requirements prior to use.

Blanket-Type Pipe Insulation (Metal-Mesh Covered) (In-

dustrial Type)

2. Referenced Documents

C610 Specification for Molded Expanded Perlite Block and

2.1 ASTM Standards:

Pipe Thermal Insulation

C168 Terminology Relating to Thermal Insulation

C612 Specification for Mineral Fiber Block and Board

C177 Test Method for Steady-State Heat Flux Measure-

Thermal Insulation

ments and Thermal Transmission Properties by Means of

C656 Specification for Structural Insulating Board, Calcium

the Guarded-Hot-Plate Apparatus

Silicate

C195 Specification for Mineral Fiber Thermal Insulating

C665 Specification for Mineral-Fiber Blanket Thermal Insu-

Cement

lation for Light Frame Construction and Manufactured

C196 Specification for Expanded or Exfoliated Vermiculite

Housing

Thermal Insulating Cement

C726 Specification for Mineral Wool Roof Insulation Board

C208 Specification for Cellulosic Fiber Insulating Board

C728 Specification for Perlite Thermal Insulation Board

C739 Specification for Cellulosic Fiber Loose-Fill Thermal

Insulation

This guide is under the jurisdiction of ASTM Committee C16 on Thermal

C745 Test Method for Heat Flux Through Evacuated Insu-

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

lations Using a Guarded Flat Plate Boiloff Calorimeter

Measurement.

(Withdrawn 2008)

Current edition approved Sept. 1, 2007. Published September 2007. Originally

approved in 2003. Last previous edition approved in 2003 as C1558–03. DOI: C764 Specification for Mineral Fiber Loose-Fill Thermal

10.1520/C1558-03R07.

Insulation

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1558 − 03 (2007)

C991 Specification for Flexible Fibrous Glass Insulation for 3.2.2 data element, n—an individual piece of information

Metal Buildings used to describe a material or to record test results; for

C1014 Specification for Spray-Applied Mineral Fiber Ther- example, a variable name or a test parameter.

mal and Sound Absorbing Insulation 3.2.2.1 Discussion—The term is synonymous with data

C1029 Specification for Spray-Applied Rigid Cellular Poly- item.

urethane Thermal Insulation

3.2.3 essential field, n—a field in a record that must be

C1033 Test Method for Steady-State Heat Transfer Proper-

completed in order to make the record meaningful in accor-

ties of Pipe Insulation Installed Vertically (Withdrawn

dance with the pertinent guidelines or standard.

2003)

3.2.3.1 Discussion—Fields are considered essential if re-

C1044 Practice for Using a Guarded-Hot-PlateApparatus or

quired to make a comparison of property data from different

Thin-Heater Apparatus in the Single-Sided Mode

sources meaningful. A comparison of data from different

C1045 Practice for Calculating Thermal Transmission Prop-

sourcesmaystillbepossibleifessentialinformationisomitted,

erties Under Steady-State Conditions

but the value of the comparison may be greatly reduced.

C1071 Specification for Fibrous Glass Duct Lining Insula-

3.2.4 field, n—an elementary unit of a record that may

tion (Thermal and Sound Absorbing Material)

contain a data item, a data aggregate, a pointer, or a link.

C1086 Specification for Glass Fiber Mechanically Bonded

3.2.5 field name, n—a name or code associated with a field

Felt Thermal Insulation

and used for identification.

C1114 Test Method for Steady-State Thermal Transmission

Properties by Means of the Thin-Heater Apparatus 3.2.6 form, n—the material form, for example, blanket,

C1126 Specification for Faced or Unfaced Rigid Cellular

board, or roll.

Phenolic Thermal Insulation

3.2.7 value set, n—an open listing of representative accept-

C1149 Specification for Self-Supported Spray Applied Cel-

able text which could be included in a particular field of a

lulosic Thermal Insulation

record.

C1289 Specification for Faced Rigid Cellular Polyisocyanu-

rate Thermal Insulation Board

4. Significance and Use

C1290 Specification for Flexible Fibrous Glass Blanket

4.1 This guide defines the principal elements of

Insulation Used to Externally Insulate HVAC Ducts

information, which are considered important and worth record-

C1363 Test Method for Thermal Performance of Building

ing and storing permanently in computerized databases. Suffi-

Materials and Envelope Assemblies by Means of a Hot

cient information is provided in this guide to enable the user to

Box Apparatus

construct a database structure suitable for the intended appli-

C1410 Specification for Cellular Melamine Thermal and

cation involving thermal insulation.

Sound-Absorbing Insulation

4.2 Because of increased activity in building computerized

C1427 Specification for Extruded Preformed Flexible Cel-

materials databases and the desire to encourage uniformity and

lular Polyolefin Thermal Insulation in Sheet and Tubular

ease of data comparison and interchange, these recommended

Form

formats provide for the inclusion of specific elements of

2.2 ISO Standards:

thermal transmission test data in databases.

ISO 8301 Thermal Insulation, Determination of Steady-

State Thermal Resistance and Related Properties—Heat

4.3 This guide has no implication on data required for

Flow Meter Apparatus

materials production or purchase. Reporting of actual test

ISO 8302 Thermal Insulation—Determination of Steady-

resultsshallbeasdescribedintheactualmaterialsspecification

State Thermal Resistance and Related Properties—

or as agreed upon between the vendor and purchaser.

Guarded Hot Plate Apparatus

4.4 The suggested set of units for the recommended stan-

ISO 8497 Thermal Insulation—Determination of Steady-

dardformatgiveninthisguideisSI.Thisguide,however,does

State Thermal Transmission Properties of Thermal Insu-

not preclude other sets of units, such as inch-pound (IP).

lation for Circular Pipes

ISO 8990 Thermal Insulation—Determination of Steady-

5. Recording of Test Data

State Thermal Transmission Properties—Calibrated and

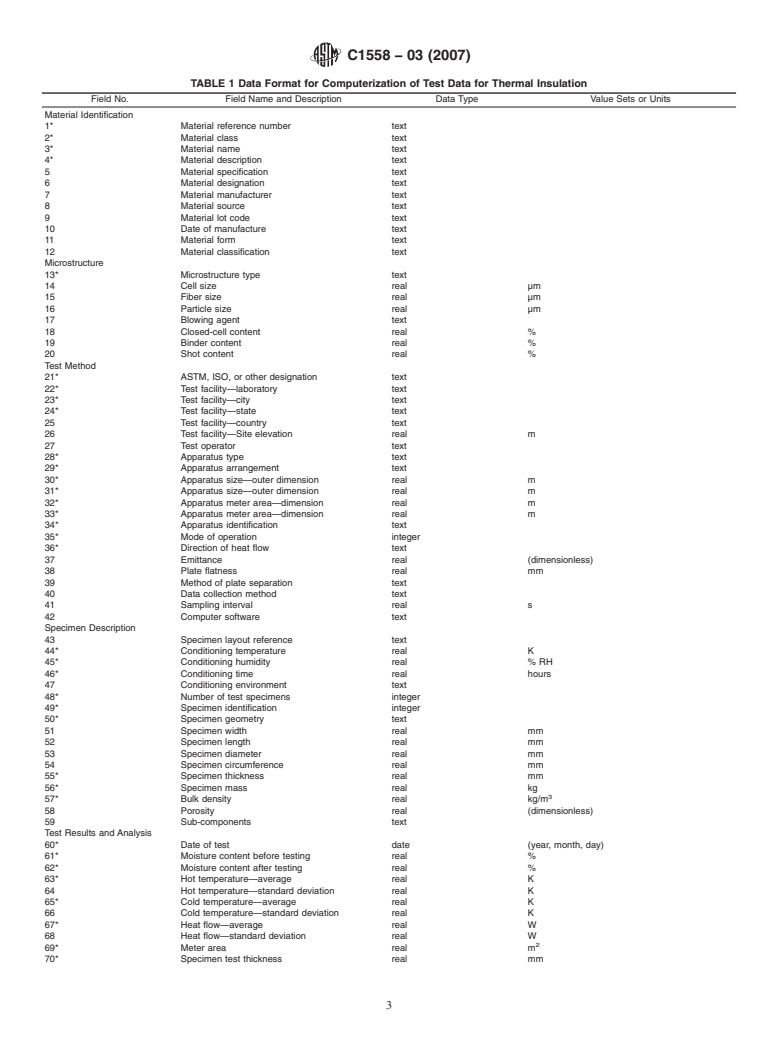

5.1 Table 1 is a recommended standard format for the

Guarded Hot Box

computerization of thermal transmission data for thermal

3. Terminology

insulation materials. The headings for each field are:

5.1.1 Field Number—A reference number assigned to an

3.1 Definitions—For definitions of some terms applicable to

individual data field that has no permanent value and does not

this guide, see Terminology C168

become part of the database.

3.2 Definitions of Terms Specific to This Standard:

5.1.2 Field Name and Description—The complete name of

3.2.1 class, n—amajormaterialclass,forexample,ceramic,

the field, descriptive of the data element of information of

insulation, polymer, etc.

interest.

5.1.3 Data Type—Type of data to be included in the field,

such as the type of number, character text, logical values

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. (yes/no), and date.

C1558 − 03 (2007)

TABLE 1 Data Format for Computerization of Test Data for Thermal Insulation

Field No. Field Name and Description Data Type Value Sets or Units

Material Identification

1* Material reference number text

2* Material class text

3* Material name text

4* Material description text

5 Material specification text

6 Material designation text

7 Material manufacturer text

8 Material source text

9 Material lot code text

10 Date of manufacture text

11 Material form text

12 Material classification text

Microstructure

13* Microstructure type text

14 Cell size real µm

15 Fiber size real µm

16 Particle size real µm

17 Blowing agent text

18 Closed-cell content real %

19 Binder content real %

20 Shot content real %

Test Method

21* ASTM, ISO, or other designation text

22* Test facility—laboratory text

23* Test facility—city text

24* Test facility—state text

25 Test facility—country text

26 Test facility—Site elevation real m

27 Test operator text

28* Apparatus type text

29* Apparatus arrangement text

30* Apparatus size—outer dimension real m

31* Apparatus size—outer dimension real m

32* Apparatus meter area—dimension real m

33* Apparatus meter area—dimension real m

34* Apparatus identification text

35* Mode of operation integer

36* Direction of heat flow text

37 Emittance real (dimensionless)

38 Plate flatness real mm

39 Method of plate separation text

40 Data collection method text

41 Sampling interval real s

42 Computer software text

Specimen Description

43 Specimen layout reference text

44* Conditioning temperature real K

45* Conditioning humidity real % RH

46* Conditioning time real hours

47 Conditioning environment text

48* Number of test specimens integer

49* Specimen identification integer

50* Specimen geometry text

51 Specimen width real mm

52 Specimen length real mm

53 Specimen diameter real mm

54 Specimen circumference real mm

55* Specimen thickness real mm

56* Specimen mass real kg

57* Bulk density real kg/m

58 Porosity real (dimensionless)

59 Sub-components text

Test Results and Analysis

60* Date of test date (year, month, day)

61* Moisture content before testing real %

62* Moisture content after testing real %

63* Hot temperature—average real K

64 Hot temperature—standard deviation real K

65* Cold temperature—average real K

66 Cold temperature—standard deviation real K

67* Heat flow—average real W

68 Heat flow—standard deviation real W

69* Meter area real m

70* Specimen test thickness real mm

C1558 − 03 (2007)

TABLE 1 Continued

Field No. Field Name and Description Data Type Value Sets or Units

71 Clamping pressure real kPa

72 Mean temperature real K

73 Temperature difference real K

74* Ambient temperature—average real K

75 Ambient temperature—standard deviation real K

76 Ambient humidity—average real %

77 Ambient humidity—standard deviation real %

78 Ambient barometric pressure—average real kPa

79 Ambient barometric pressure—standard real kPa

deviation

80* Thermal conductance—average real W/(m ·K)

81 Thermal conductance—standard deviation real W/(m ·K)

82* Thermal resistance—average real m ·K/W

83 Thermal resistance—standard deviation real m ·K/W

84 Thermal conductivity—average real W/(m·K)

85 Thermal conductivity—standard deviation real W/(m·K)

86 Thermal resistivity—average real m·K/W

87 Thermal resistivity—standard deviation real m·K/W

88* Is the test valid? logical

89* Standard uncertainty of test result real %

90* Footnotes text

* Essential field

5.1.4 Value Sets or Units—A listing of the types of infor- 6.1.3 Material Name (3*)—A (generic) name for the par-

mation which would be included in the field or, in the case of ticular material. A value set of typical responses is given in

properties or the numeric fields, the SI units in which the Table 2.

numbers are expressed. 6.1.4 Material Description (4*)—Descriptive name of ma-

terial tested, for example, E-type fibrous glass with phenolic

5.2 The presentation of the recommended standard format

binder.

does not require that every element of information be included

6.1.5 Material Specification (5)—Specification and year of

in every database. There is, however, a minimum number of

issue for material name in field (3). A value set of typical

fields considered essential to any database and these fields are

responses is given in Table 2.

marked with an asterisk (*).

6.1.6 Material Designation (6)—Trade name, trademark,

NOTE 1—Many databases are prepared for specific applications and,

brand name, etc., of material.

therefore,somedatabasebuildersmayomitcertainelementsconsideredto

6.1.7 MaterialManufacturer(7)—Manufacturerofmaterial.

beofnovalueforthatspecificapplication.Conversely,insomeindividual

6.1.8 Material Source (8)—Source of material, if different

cases, additional data elements are needed and the database builder is

from manufacturer.

encouraged to include these elements along with the elements in the

recommended standard format. It is important to note that not all of the

6.1.9 Material Lot Code (9)—Manufacturer identification

elements considered essential will be available for eve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.