ASTM C915-79(1995)

(Specification)Standard Specification for Precast Reinforced Concrete Crib Wall Members

Standard Specification for Precast Reinforced Concrete Crib Wall Members

SCOPE

1.1 This specification covers open- and closed-face precast reinforced concrete crib walls intended to act as earth-retaining structures or as protection against stream encroachment. Note 1-This specification is a manufacturing and purchase specification only, with examples and suggestions for usage. Successful performance of this product depends on the proper selection and assembling of members, proper foundation and bearing material, and consideration of backfill heights, backfill material, drainage, and other engineering and construction considerations. The purchaser of the crib wall members specified herein is cautioned that he must properly correlate the field requirements with the members selected and provide adequate inspection at the construction site.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: C 915 – 79 (Reapproved 1995)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Precast Reinforced Concrete Crib Wall Members

This standard is issued under the fixed designation C 915; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 231 Test Method for Air Content of Freshly Mixed

Concrete by the Pressure Method

1.1 This specification covers open- and closed-face precast

C 260 Specification for Air-Entraining Admixtures for Con-

reinforced concrete crib walls intended to act as earth-retaining

crete

structures or as protection against stream encroachment.

C 309 Specification for Liquid Membrane-Forming Com-

NOTE 1—This specification is a manufacturing and purchase specifica- 4

pounds for Curing Concrete

tion only, with examples and suggestions for usage. Successful perfor-

C 330 Specification for Lightweight Aggregates for Struc-

mance of this product depends on the proper selection and assembling of

tural Concrete

members, proper foundation and bearing material, and consideration of

C 494 Specification for Chemical Admixtures for Concrete

backfill heights, backfill material, drainage, and other engineering and

C 595/C595M Specification for Blended Hydraulic Ce-

construction considerations. The purchaser of the crib wall members

specified herein is cautioned that he must properly correlate the field

ments

requirements with the members selected and provide adequate inspection

C 618 Specification for Fly Ash and Raw or Calcined

at the construction site.

Natural Pozzolan for Use as a Mineral Admixture in

1.2 The values stated in inch-pound units are to be regarded Portland Cement Concrete

as the standard. The values given in parentheses are for

3. Classification

information only.

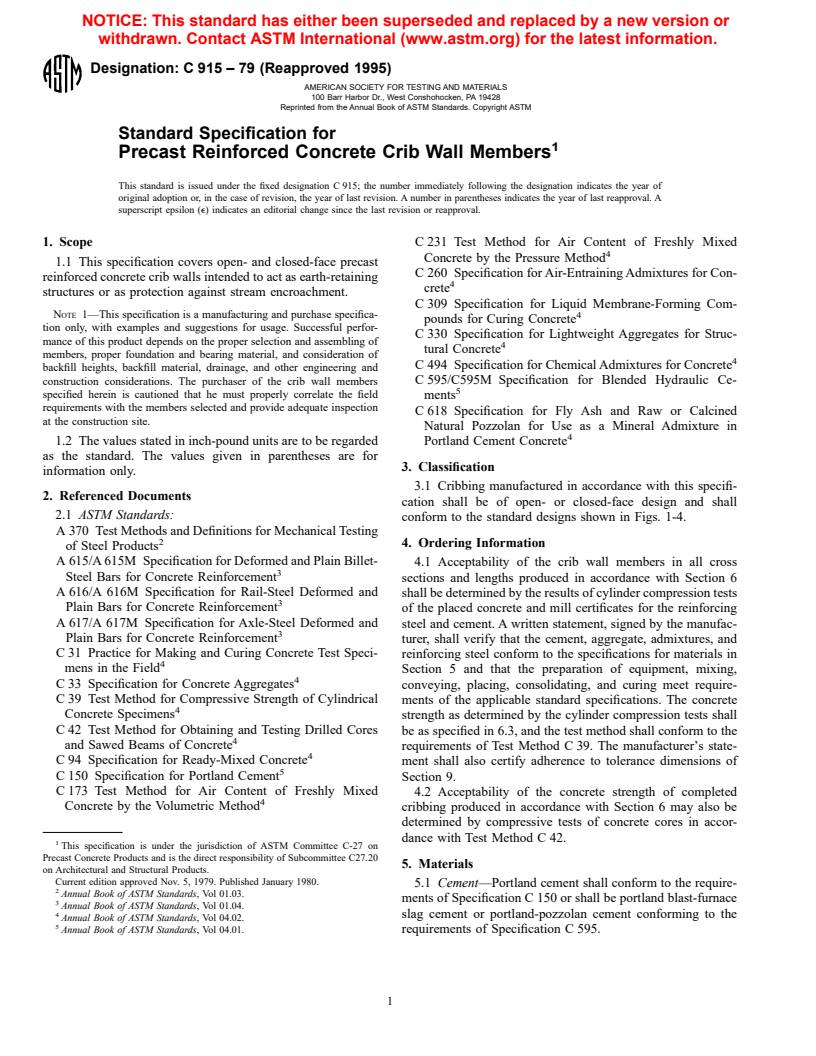

3.1 Cribbing manufactured in accordance with this specifi-

2. Referenced Documents

cation shall be of open- or closed-face design and shall

2.1 ASTM Standards:

conform to the standard designs shown in Figs. 1-4.

A 370 Test Methods and Definitions for Mechanical Testing

4. Ordering Information

of Steel Products

A 615/A 615M Specification for Deformed and Plain Billet- 4.1 Acceptability of the crib wall members in all cross

Steel Bars for Concrete Reinforcement

sections and lengths produced in accordance with Section 6

A 616/A 616M Specification for Rail-Steel Deformed and

shall be determined by the results of cylinder compression tests

Plain Bars for Concrete Reinforcement

of the placed concrete and mill certificates for the reinforcing

A 617/A 617M Specification for Axle-Steel Deformed and

steel and cement. A written statement, signed by the manufac-

Plain Bars for Concrete Reinforcement

turer, shall verify that the cement, aggregate, admixtures, and

C 31 Practice for Making and Curing Concrete Test Speci-

reinforcing steel conform to the specifications for materials in

mens in the Field

Section 5 and that the preparation of equipment, mixing,

C 33 Specification for Concrete Aggregates

conveying, placing, consolidating, and curing meet require-

C 39 Test Method for Compressive Strength of Cylindrical

ments of the applicable standard specifications. The concrete

Concrete Specimens

strength as determined by the cylinder compression tests shall

C 42 Test Method for Obtaining and Testing Drilled Cores

be as specified in 6.3, and the test method shall conform to the

and Sawed Beams of Concrete

requirements of Test Method C 39. The manufacturer’s state-

C 94 Specification for Ready-Mixed Concrete ment shall also certify adherence to tolerance dimensions of

C 150 Specification for Portland Cement

Section 9.

C 173 Test Method for Air Content of Freshly Mixed 4.2 Acceptability of the concrete strength of completed

Concrete by the Volumetric Method

cribbing produced in accordance with Section 6 may also be

determined by compressive tests of concrete cores in accor-

dance with Test Method C 42.

This specification is under the jurisdiction of ASTM Committee C-27 on

Precast Concrete Products and is the direct responsibility of Subcommittee C27.20

5. Materials

on Architectural and Structural Products.

Current edition approved Nov. 5, 1979. Published January 1980.

5.1 Cement—Portland cement shall conform to the require-

Annual Book of ASTM Standards, Vol 01.03.

ments of Specification C 150 or shall be portland blast-furnace

Annual Book of ASTM Standards, Vol 01.04.

slag cement or portland-pozzolan cement conforming to the

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 04.01. requirements of Specification C 595.

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

C 915

NOTE 1—Surface drainage should not be permitted to flow directly against the face of the cribbing.

NOTE 2—Walls should be separated into 96-ft sections by the provision of double rows of headers.

NOTE 3—In using these typical sections for designing walls of intermediate height, the drawing should be read from the top down until the desired

height is reached. Base details are repeated for intermediate heights.

NOTE 4—In areas of aggressive environment, Type II cement or protective coatings, or both, may need to be used to avoid deterioration of the walls.

3 3

NOTE 5—Metric Conversion: 1 ft 5 304.8 1 in. 5 25.4 mm 1 lb 5 0.453592 kg 1 ft 5 0.028317 m

FIG. 1 Open-Faced Concrete Crib Wall

5.2 Aggregates—Aggregates shall conform to Specification 6. Design

C 33 or C 330. The nominal maximum size aggregate shall not

6.1 Precast concrete crib wall members shall conform to

be greater than ⁄4 in. (19.0 mm).

details and dimensions prescribed in Figs. 1-4, subject to the

5.3 Admixtures—Air-entraining admixtures shall conform

provisions of this section and Section 10.

to Specification C 260. Chemical admixtures shall conform to

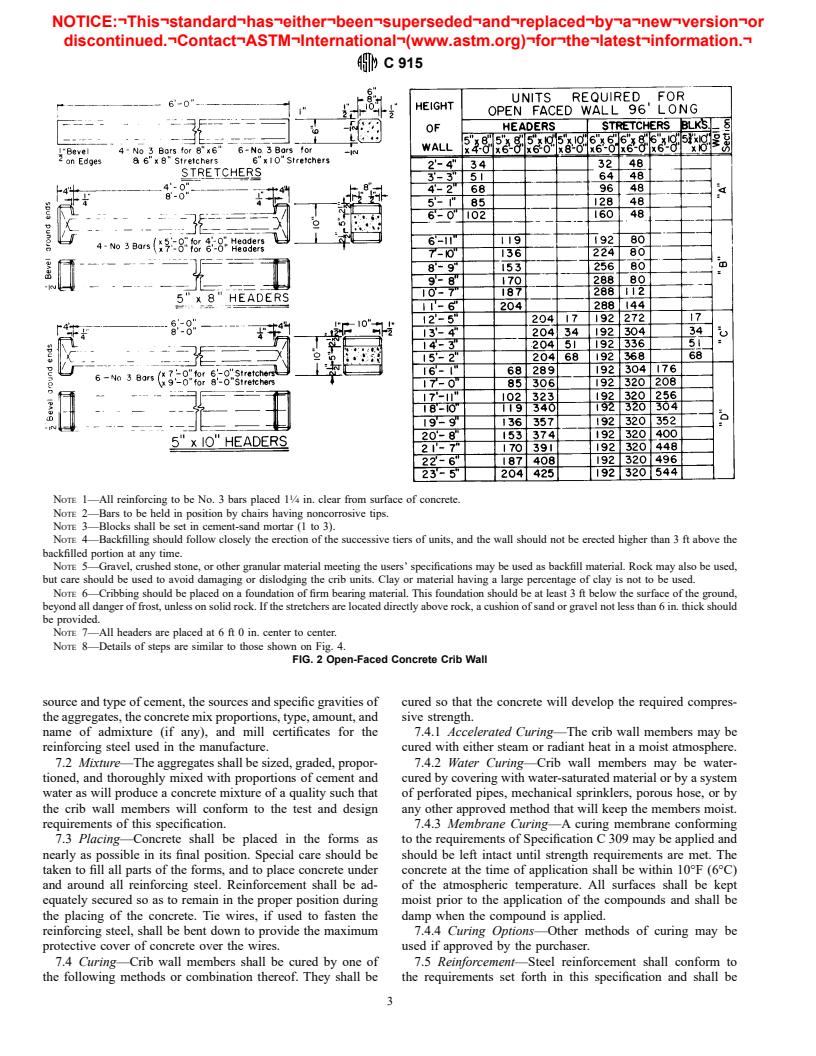

6.2 Reinforcement—Minimum reinforcement shall be as

Specification C 494. Fly ash or other pozzolanic admixtures

shown in Fig. 2 and Fig. 4 and shall be Grade 40 or 60.

shall conform to the requirements of Specification C 618.

6.3 Concrete—Concrete shall have a minimum design com-

5.4 Water—Water used for curing, washing aggregates, and pressive strength of 4000 psi (28 MPa) in 28 days.

mixing concrete shall be free of oils, organic materials, and 6.4 Concrete Cover—The minimum concrete cover over the

other substances that may be deleterious to concrete or steel; it

reinforcement shall be 1 ⁄4 in. (32 mm).

should not contain concentrations of chlorides in excess of 6.5 Air Entrainment—Unless otherwise specified by the

1 1

1000 ppm or sulfates in excess of 1000 ppm.

purchaser, all concrete shall have an air content of 6 ⁄2 6 1 ⁄2 %

as measured by Test Method C 173 or C 231.

5.4.1 If water of higher chloride content is used by reason of

nonavailability of water of recommended quality, the manu-

7. Manufacture

facturer must obtain approval from the user.

5.5 Steel Reinforcement—Steel reinforcement shall consist 7.1 Certification—At the request of the purchaser, the

of bars conforming to Specifications A 615/A 615M, A 616/ manufacturer shall, prior to the actual delivery of the crib wall

A 616M, or A 617/A 617M. members, furnish a statement to the purchaser giving the

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

C 915

NOTE 1—All reinforcing to be No. 3 bars placed 1 ⁄4 in. clear from surface of concrete.

NOTE 2—Bars to be held in position by chairs having noncorrosive tips.

NOTE 3—Blocks shall be set in cement-sand mortar (1 to 3).

NOTE 4—Backfilling should follow closely the erection of the successive tiers of units, and the wall should not be erected higher than 3 ft above the

backfilled portion at any time.

NOTE 5—Gravel, crushed stone, or other granular material meeting the users’ specifications may be used as backfill material. Rock may also be used,

but care should be used to avoid damaging or dislodging the crib units. Clay or material having a large percentage of clay is not to be used.

NOTE 6—Cribbing should be placed on a foundation of firm bearing material. This foundation should be at least 3 ft below the surface of the ground,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.