ASTM E448-82(2002)

(Practice)Standard Practice for Scleroscope Hardness Testing of Metallic Materials

Standard Practice for Scleroscope Hardness Testing of Metallic Materials

SCOPE

1.1 This practice covers the determination of the Scleroscope hardness of metallic materials (Part A), the verification of Scleroscope hardness instruments (Part B), and the calibration of standardized hardness test blocks (Part C).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 448 – 82 (Reapproved 2002)

Standard Practice for

Scleroscope Hardness Testing of Metallic Materials

This standard is issued under the fixed designation E 448; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

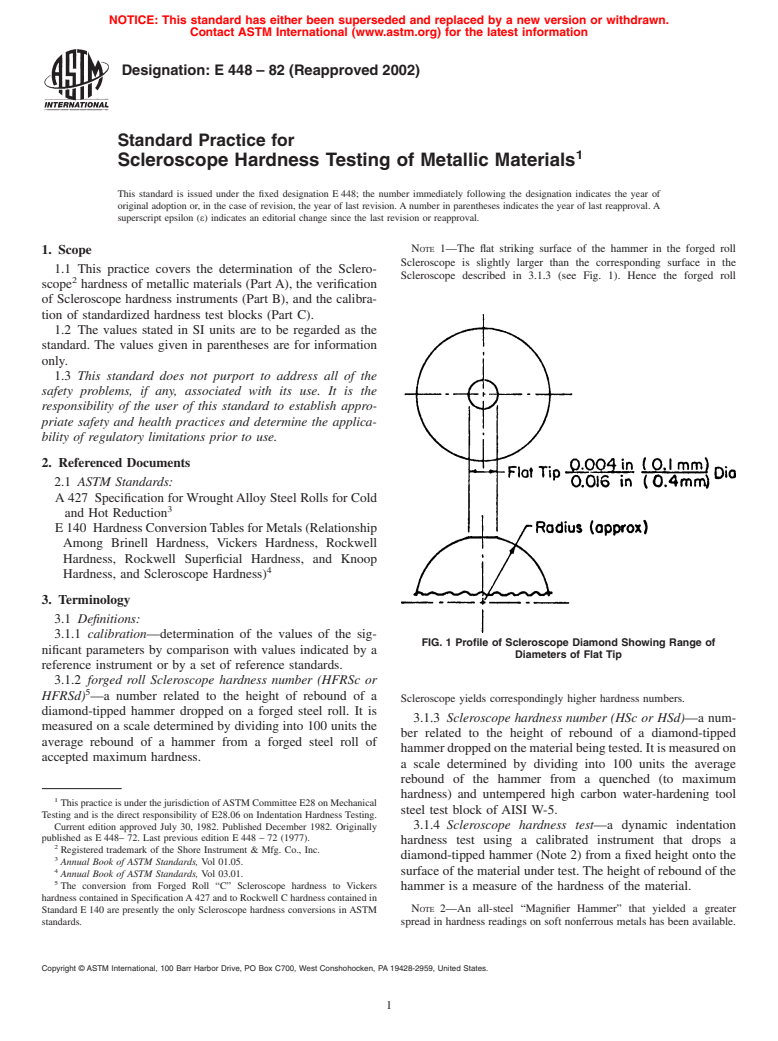

NOTE 1—The flat striking surface of the hammer in the forged roll

1. Scope

Scleroscope is slightly larger than the corresponding surface in the

1.1 This practice covers the determination of the Sclero-

Scleroscope described in 3.1.3 (see Fig. 1). Hence the forged roll

scope hardness of metallic materials (Part A), the verification

of Scleroscope hardness instruments (Part B), and the calibra-

tion of standardized hardness test blocks (Part C).

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A 427 Specification for WroughtAlloy Steel Rolls for Cold

and Hot Reduction

E 140 HardnessConversionTablesforMetals(Relationship

Among Brinell Hardness, Vickers Hardness, Rockwell

Hardness, Rockwell Superficial Hardness, and Knoop

Hardness, and Scleroscope Hardness)

3. Terminology

3.1 Definitions:

3.1.1 calibration—determination of the values of the sig-

FIG. 1 Profile of Scleroscope Diamond Showing Range of

nificant parameters by comparison with values indicated by a

Diameters of Flat Tip

reference instrument or by a set of reference standards.

3.1.2 forged roll Scleroscope hardness number (HFRSc or

HFRSd) —a number related to the height of rebound of a

Scleroscope yields correspondingly higher hardness numbers.

diamond-tipped hammer dropped on a forged steel roll. It is

3.1.3 Scleroscope hardness number (HSc or HSd)—a num-

measured on a scale determined by dividing into 100 units the

ber related to the height of rebound of a diamond-tipped

average rebound of a hammer from a forged steel roll of

hammerdroppedonthematerialbeingtested.Itismeasuredon

accepted maximum hardness.

a scale determined by dividing into 100 units the average

rebound of the hammer from a quenched (to maximum

hardness) and untempered high carbon water-hardening tool

This practice is under the jurisdiction ofASTM Committee E28 on Mechanical

steel test block of AISI W-5.

Testing and is the direct responsibility of E28.06 on Indentation Hardness Testing.

Current edition approved July 30, 1982. Published December 1982. Originally 3.1.4 Scleroscope hardness test—a dynamic indentation

published as E 448– 72. Last previous edition E 448 – 72 (1977).

hardness test using a calibrated instrument that drops a

Registered trademark of the Shore Instrument & Mfg. Co., Inc.

diamond-tipped hammer (Note 2) from a fixed height onto the

Annual Book of ASTM Standards, Vol 01.05.

surface of the material under test. The height of rebound of the

Annual Book of ASTM Standards, Vol 03.01.

The conversion from Forged Roll “C” Scleroscope hardness to Vickers

hammer is a measure of the hardness of the material.

hardness contained in SpecificationA 427 and to Rockwell C hardness contained in

NOTE 2—An all-steel “Magnifier Hammer” that yielded a greater

Standard E 140 are presently the only Scleroscope hardness conversions in ASTM

standards. spread in hardness readings on soft nonferrous metals has been available.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 448 – 82 (2002)

This hammer has become obsolete and, hence, is not considered in this

practice.

3.1.5 verification—checking or testing the instrument to

assure conformance with the specification.

GENERAL DESCRIPTION OF INSTRUMENTS AND TEST PROCEDURE FOR SCLEROSCOPE

HARDNESS TEST

4. Apparatus be shaped to produce a correct reading on reference bars of

knownhardness.IntheforgedrollScleroscopethediamondtip

4.1 The instrument used for determining Scleroscope hard-

is specifically dimensioned to produce a correct reading on a

ness numbers is supplied in two models designated Model C

forged-steel roll of known hardness. In profile, the diamond is

and Model D.

convex, having an approximate radius terminated by a flat

4.2 Scleroscope Model C—This model consists of a verti-

striking surface, as shown in Fig. 1. The flat striking surface is

cally disposed barrel containing a precision bore glass tube. A

approximately circular and from 0.004 to 0.016 in. (0.1 to 0.4

scale, graduated from 0 to 140, is set behind and is visible

mm) in diameter, depending on the type of instrument and the

through the glass tube. A pneumatic actuating head, affixed to

hardness and other physical characteristics of the diamond.

the top of the barrel, is manually operated by a rubber bulb and

4.5 Supporting Devices—The three supporting devices used

tube. A hammer drops from a specified height and rebounds

most frequently with the Scleroscope are (a) the clamping

within the glass tube.

stand, (b) the swing arm and post, and (c) the roll-testing stand.

4.3 Scleroscope Model D—This model is known as the Dial

Recording Scleroscope. It consists of a vertically disposed

5. Test Specimens

barrel containing a clutch to arrest the hammer at maximum

5.1 Form—Specimens used in Scleroscope testing vary

height of rebound. This is made possible by using a hammer

greatly with respect to size and shape. Smaller specimens may

which is longer and heavier than the hammer in the Model C

be tested in the clamping stand which has a jaw capacity of 3

Scleroscope, and which develops the same striking energy in

in. (76 mm) high by 2 ⁄2 in. (64 mm) deep. Large specimens,

dropping through a shorter distance. A number of supporting

beyond the jaw capacity of the clamping stand, may be tested

devices are available with this instrument and it is recom-

with the instrument mounted on the swing arm and post or the

mended that one of these be used (see section 4.5).

roll-testing stand. The swing arm and post has a height and

4.4 Diamond-Tipped Hammers:

reach capacity of 9 in. (230 mm) and 14 in. (360 mm),

4.4.1 There are two sizes of diamond-tipped hammers

respectively. The roll-testing stand may be used for mounting

commonly used in the Scleroscope hardness instruments.

the instrument on cylindrical specimens with a diameter of 2 ⁄2

These are the small hammer used in the Model C instrument

in. (64 mm) and upward without limit. The roll-testing stand

and the larger hammer used in the Model D instrument.

may also be used for mounting the instrument on flat, horizon-

4.4.2 The following dimensions are applicable to the

tal surfaces with a minimum perimetric dimension of 3 by 5 in.

diamond-tipped hammers:

(76 by 130 mm). The Model C Scleroscope may be used free

Model C

hand for testing specimens with a minimum mass of 5 lb (2.3

Diameter 0.234 in. (5.94 mm)

Mass 2.3006 0.500 g

kg). It is not recommended that the Model D Scleroscope be

Over-all length 0.815 to 0.840 in. (20.7 to 21.3 mm)

used free hand.

Distance hammer 9.890 + 0.005, −0.015 in. (251.2 + 0.1,

falls −0.4 mm) 5.2 Thickness—Thin strips or sheets may be tested, with

some limitations, but only when the Scleroscope is mounted in

Model D

theclampingstand.Ideally,thesheetshouldbeflatandwithout

Diameter 0.3125 in. (7.94 mm)

Mass 36.06 2.0 g undulation. If the sheet material is bowed, the concave side

Over-all length 3.990 to 4.010 in. (101.33 to 104.10 mm)

should be up to preclude any possibility of erroneous readings

Distance hammer 0.704 + 0.017, −0.021 in. (17.9 + 0.4, −0.5

due to spring effect. The minimum thicknesses of sheet in

falls mm)

various categories that may be tested are as follows:

4.4.3 The geometry of the diamond tip is of significance

Thickness

onlyatitsultimateextremitybecauseofthelimitedpenetration

Material in. mm

Hard steel 0.005 to 0.006 0.13 to 0.15

of the diamond into the material being tested. Such penetration

Half-hard brass strip 0.010 0.25

is about 0.001 in. (0.025 mm) on mild steel and about 0.0005

Cold-rolled steel 0.010 0.25

in. (0.013 mm) on hardened tool steel. Further, the variation in

Annealed-brass sheet 0.015 0.38

hardness of commercially available industrial diamonds has a

5.3 Finish—The degree of test-surface finish is important.

significant effect on the readings of a rebound-type hardness

An excessively coarse finish will yield low and erratic read-

instrument. Consequently, the geometry of the diamond must

ings. Hence, when necessary, the surface shall be filed,

machined, ground, or polished to permit accurate, consistent

readings to be obtained. Care should be taken to avoid

Model C and D Scleroscopes are manufactured by the Shore Instrument and

Manufacturing Co., Inc., Jamaica, NY. overheating or excessively cold working the surface. The

E 448 – 82 (2002)

surface finish required to obtain reproducible results varies tions at least 0.020 in. (0.51 mm) apart and make only once at

with the hardness of the test specimen. In proceeding from soft the same spot. Flat specimens with parallel surfaces may be

metalstohardenedsteeltherequiredsurfacefinishrangedfrom testedwithin ⁄4in.(6mm)oftheedgewhenprope

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.