ASTM E213-98

(Practice)Standard Practice for Ultrasonic Examination of Metal Pipe and Tubing

Standard Practice for Ultrasonic Examination of Metal Pipe and Tubing

SCOPE

1.1 This practice covers a procedure for detecting discontinuities in metal pipe and tubing using pulse-reflection ultrasonic contact or immersion angle beam techniques. Artificial discontinuities consisting of longitudinal reference notches are employed as the primary means of calibrating the ultrasonic system. If transverse as well as longitudinal examination is desired, a procedure for employing transverse notches is provided.

1.2 This practice is intended for use with tubular products having outside diameters approximately 1/2 in. (12.7 mm) and larger, provided that the examination parameters comply with and satisfy the requirements of Section 12. These procedures have been used successfully for smaller sizes, however, and may be specified upon contractural agreement between the using parties. Note 1-Exercise caution when examining pipe or tubes near or below the 1/2-in. specified limit. Certain combinations of search unit size, frequency, thin wall thicknesses, and small diameters could cause generation of unwanted sound waves that may produce erroneous test results.

1.3 This practice does not establish acceptance criteria; they must be specified by the using party or parties.

1.4 The values stated in inch-pound units are to be regarded as standard. The SI equivalents are in parentheses and may be approximate.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

Designation: E 213 – 98 An American National Standard

Standard Practice for

1

Ultrasonic Examination of Metal Pipe and Tubing

This standard is issued under the fixed designation E 213; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASNT Documents:

2

Recommended Practice SNT-TC-1A for Nondestructive

1.1 This practice covers a procedure for detecting discon-

4

Testing Personnel Qualification and Certification

tinuities in metal pipe and tubing using pulse-reflection ultra-

ANSI/ASNT CP-189 Standard for Qualification and Certi-

sonic contact or immersion angle beam techniques. Artificial

4

fication of Nondestructive Testing Personnel

discontinuities consisting of longitudinal reference notches are

2.3 Military Standards:

employed as the primary means of standardizing the ultrasonic

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

system. If transverse as well as longitudinal examination is

5

tion and Certification

desired, a procedure for employing transverse notches is

provided.

3. Terminology

1.2 This practice is intended for use with tubular products

3.1 Definitions—For definitions of terms used in this prac-

1

having outside diameters approximately ⁄2 in. (12.7 mm) and

tice, see Terminology E 1316.

larger, provided that the examination parameters comply with

and satisfy the requirements of Section 12. These procedures

4. Summary of Practice

have been used successfully for smaller sizes, however, and

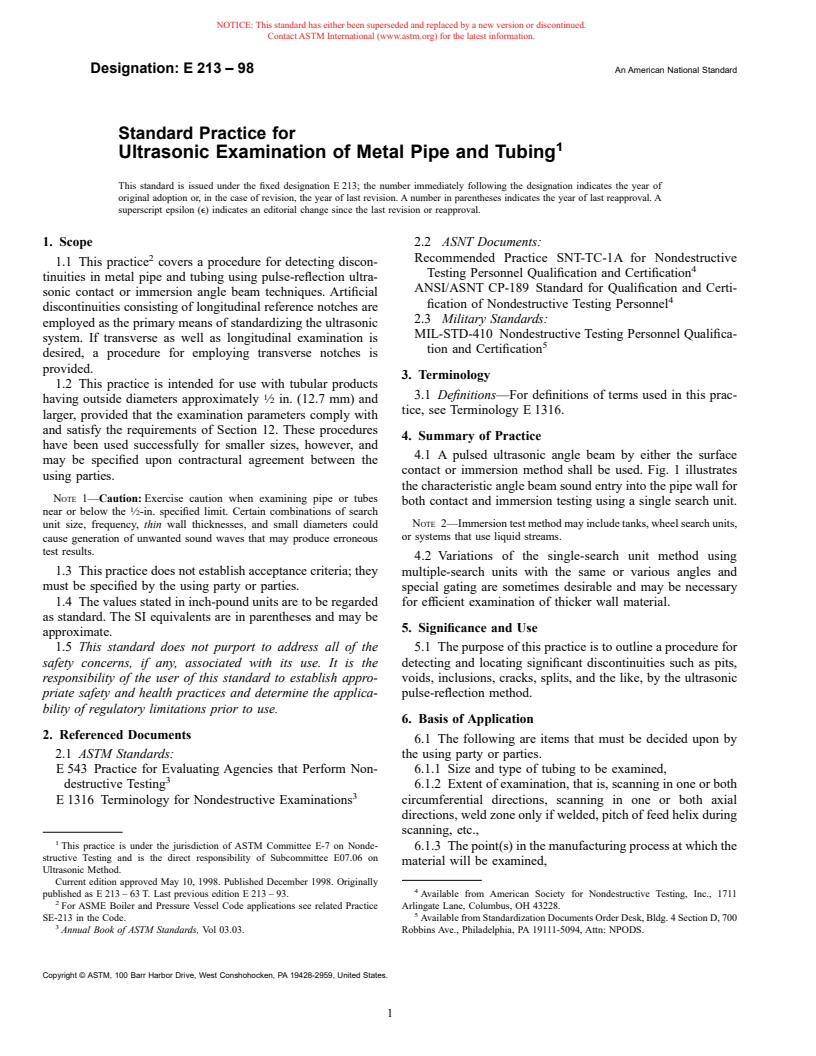

4.1 A pulsed ultrasonic angle beam by either the surface

may be specified upon contractural agreement between the

contact or immersion method shall be used. Fig. 1 illustrates

using parties.

the characteristic angle beam sound entry into the pipe wall for

NOTE 1—Caution: Exercise caution when examining pipe or tubes

both contact and immersion testing using a single search unit.

1

near or below the ⁄2-in. specified limit. Certain combinations of search

NOTE 2—Immersion test method may include tanks, wheel search units,

unit size, frequency, thin wall thicknesses, and small diameters could

or systems that use liquid streams.

cause generation of unwanted sound waves that may produce erroneous

test results.

4.2 Variations of the single-search unit method using

1.3 This practice does not establish acceptance criteria; they multiple-search units with the same or various angles and

must be specified by the using party or parties.

special gating are sometimes desirable and may be necessary

1.4 The values stated in inch-pound units are to be regarded for efficient examination of thicker wall material.

as standard. The SI equivalents are in parentheses and may be

5. Significance and Use

approximate.

1.5 This standard does not purport to address all of the 5.1 The purpose of this practice is to outline a procedure for

safety concerns, if any, associated with its use. It is the detecting and locating significant discontinuities such as pits,

responsibility of the user of this standard to establish appro- voids, inclusions, cracks, splits, and the like, by the ultrasonic

priate safety and health practices and determine the applica- pulse-reflection method.

bility of regulatory limitations prior to use.

6. Basis of Application

2. Referenced Documents

6.1 The following are items that must be decided upon by

2.1 ASTM Standards: the using party or parties.

E 543 Practice for Evaluating Agencies that Perform Non- 6.1.1 Size and type of tubing to be examined,

3

destructive Testing 6.1.2 Extent of examination, that is, scanning in one or both

3

E 1316 Terminology for Nondestructive Examinations circumferential directions, scanning in one or both axial

directions, weld zone only if welded, pitch of feed helix during

scanning, etc.,

1

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde-

6.1.3 The point(s) in the manufacturing process at which the

structive Testing and is the direct responsibility of Subcommittee E07.06 on

material will be examined,

Ultrasonic Method.

Current edition approved May 10, 1998. Published December 1998. Originally

4

published as E 213 – 63 T. Last previous edition E 213 – 93. Available from American Society for Nondestructive Testing, Inc., 1711

2

For ASME Boiler and Pressure Vessel Code applications see related Practice Arlingate Lane, Columbus, OH 43228.

5

SE-213 in the Code. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

3

Annual Book of ASTM Standards, Vol 03.03. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 213

FIG. 1 Circumferential Propagation of Sound in Tube Wall

6.1.4 Surface condition, fied by the employer or certifying agency, as appl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.