ASTM E405-89(1996)e1

(Test Method)Standard Test Methods for Wear Testing Rotary Operators for Windows

Standard Test Methods for Wear Testing Rotary Operators for Windows

SCOPE

1.1 These test methods describe the wear testing of gear-type rotary operating devices used for opening and closing windows (Note 1).

1.2 These test methods do not directly determine the effects of varying environmental conditions but may be employed after environmental exposure to evaluate the effect of such exposure.

1.3 These test methods are not intended to evaluate the structural adequacy of the operator in resisting the maximum force to which it may be subjected.

Note 1-Certain types of rotary window operators, such as torque-bar operators and telescopic operators cannot be tested by these test methods.

1.4 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Note 3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: E 405 – 89 (Reapproved 1996)

Standard Test Methods for

Wear Testing Rotary Operators

for Windows

This standard is issued under the fixed designation E 405; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in September 1996.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 closing torque, n—a constant torque applied to the

1.1 These test methods describe the wear testing of gear-

input shaft when the operator is in the fully closed position,

type rotary operating devices used for opening and closing

simulating the forces applied by a person tightly closing the

windows (Note 1).

window and shall be expressed in pound-force-inches (or

1.2 These test methods do not directly determine the effects

newton metres).

of varying environmental conditions but may be employed

3.2.2 fully closed position of the operator, n—the position

after environmental exposure to evaluate the effect of such

of the operator with the window in a fully closed position.

exposure.

3.2.3 fully opened position of the operator, n—the position

1.3 These test methods are not intended to evaluate the

of the arm from 2 to 5° short of locking the mechanism with the

structural adequacy of the operator in resisting the maximum

window in an open position.

force to which it may be subjected.

3.2.4 gear-type rotary operator, n—a mechanical operating

NOTE 1—Certain types of rotary window operators, such as torque-bar

device for opening and closing windows. It consists basically

operators and telescopic operators cannot be tested by these test methods.

of an operating handle turning an input shaft which drives a

1.4 The values stated in inch-pound units are to be regarded

gear mechanism that causes an arm or arms to pivot, operating

as the standard. The metric equivalents of inch-pound units

the window.

may be approximate.

3.2.5 operating moment, n—the product of the applied force

1.5 This standard does not purport to address all of the

and the length of the output lever arm from the point of load

safety concerns, if any, associated with its use. It is the

application to the pivot axis. It shall be expressed in pound-

responsibility of the user of this standard to establish appro-

force-inches (or newton metres). During a test cycle, the

priate safety and health practices and determine the applica-

operating moment varies from a maximum value with the arm

bility of regulatory limitations prior to use. For a specific

in a centered position (peak operating moment) to some lesser

hazard statement, see Note 3.

value as the arm is moved away from the centered position.

3.2.6 operator test specimen, n—an entire, assembled gear-

2. Referenced Documents

type rotary operator, including the operating handle.

2.1 ASTM Standards:

3.2.7 test cycle, n:

E 631 Terminology of Building Constructions

3.2.7.1 Test Method A—fully opening and fully closing the

operator.

3. Terminology

3.2.7.2 Test Method B—the number of rotations of the

3.1 Definitions—Definitions are in accordance with Termi-

handle to open and close the operator fully.

nology E 631 unless otherwise indicated.

3.2.8 test force, n, for Test Method A—the force applied to

the operator arm at the point of attachment. The required test

1 force in pounds-force (or newtons) is equal to the specified

These test methods are under the jurisdiction of ASTM Committee E-6 on

Performance of Buildings and are the direct responsibility of Subcommittee E06.51 peak operating moment in pound-force-inches (or newton

on Component Performance of Windows, Curtain Walls, and Doors.

metres) divided by the distance in inches (or metres) measured

Current edition approved Feb. 24, 1989. Published April 1989. Originally

perpendicular to the line of action of the force from the pivot

e1

published as E 405 – 70. Last previous edition E 405 – 70 (1981) .

axis to the point of attachment.

Annual Book of ASTM Standards, Vol 04.11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 405

4. Summary of Test Methods

4.1 These test methods consist of subjecting the rotary

operator to an operating moment against which the operator

shall work in a cyclic function of opening and closing. Test

Method A evaluates the operator for its ability to resist wear

through a given number of cycles against the test moment with

a specified torque applied to the input shaft. Test Method B

evaluates only the rotating fingergrip portion of handle assem-

blies having rotating fingergrips.

5. Significance and Use

5.1 These tests provide standard methods for evaluating the

mechanical performance of the rotary-type window operators,

while the operators are subjected to cyclic wear in opening and

closing against the operating moment.

6. Apparatus

6.1 The apparatus described is general in nature and any

arrrangement of equipment capable of performing the test

procedure within the allowable tolerances is permitted.

6.2 Test Method A:

6.2.1 The test apparatus for Test Method A shall consist of

a frame for mounting the rotary operator with the operator

arm(s) centered (approximately the center of travel); test

weights accurate to within 6 0.5 %, attached by flexible cable

to the arm(s) to provide the required test forces; an attachment

bolt fastening the cable to the arm; a torque-limiting clutch,

whose output is within 6 15 % of the specified closing torque,

attached to the handle drive mechanism in line with the

operator input shaft and driven by a reversible air or electric

motor; and limit switching devices to effect reversal of rotation

at the fully open and fully closed operator positions (see Fig.

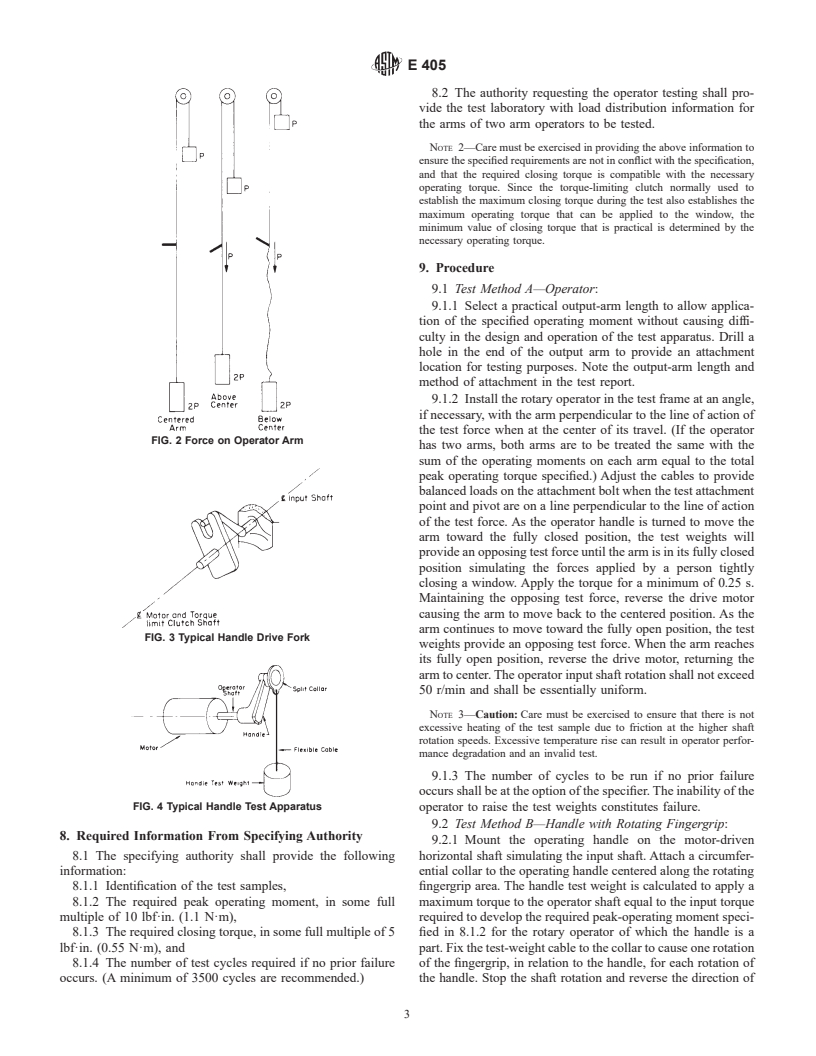

FIG. 1 Typical Operator Test Apparatus

1).

6.2.2 The arm or the test attachment bolt through the arm

shall bear against the test frame, if necessary, to prevent the

which the test handle is attached. The shaft shall be obtained by

arm from closing beyond the nominal fully closed position.

removing the input shaft from an operator or as an additionally

The cables shall be adjustable to provide an equal tension force

supplied part. The handle end of the shaft shall be identical to

in both the cables when the test attachment point and pivot are

the input shafts of the test operators. The timing device effects

centered.

a reversal of the motor at required intervals. The split collar

6.2.3 Fig. 2 shows how, if a vertical arrangement were used,

carries the test weight and attaches to the rotating fingergrip of

to test a single-arm operator, a system of two test weights, an

the handle causing one revolution of the fingergrip with respect

upper weight equal to the test force and a lower weight of twice

to the handle for each revolution of the handle (see Fig. 4).

the test force, would act to provide the required downward

force when the arm is above the center position of its travel and

7. Test Specimens

the same force upward when the arm is below the center of its

7.1 The operator test specimens shall be representative in all

travel. For operators with two arms, sum of the test weight on

respects of the operators to be qualified under these test

each arm should equal the total test weight with neither arm

methods. Unless otherwise specified, the specimens shall

seeing less than 25 % of the total test weight. The test weight

consist of six identical pro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.