ASTM D5045-14(2022)

(Test Method)Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials

Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials

SIGNIFICANCE AND USE

5.1 The property KIc (GIc) determined by these test methods characterizes the resistance of a material to fracture in a neutral environment in the presence of a sharp crack under severe tensile constraint, such that the state of stress near the crack front approaches plane strain, and the crack-tip plastic (or non-linear viscoelastic) region is small compared with the crack size and specimen dimensions in the constraint direction. A KIc value is believed to represent a lower limiting value of fracture toughness. This value has been used to estimate the relation between failure stress and defect size for a material in service wherein the conditions of high constraint described above would be expected. Background information concerning the basis for development of these test methods in terms of linear elastic fracture mechanics can be found in Refs (1-5).3

5.1.1 The KIc (GIc) value of a given material is a function of testing speed and temperature. Furthermore, cyclic loads have been found to cause crack extension at K values less than KIc (GIc). Crack extension under cyclic or sustained load will be increased by the presence of an aggressive environment. Therefore, application of KIc (GIc) in the design of service components should be made considering differences that may exist between laboratory tests and field conditions.

5.1.2 Plane-strain fracture toughness testing is unusual in that sometimes there is no advance assurance that a valid KIc (GIc) will be determined in a particular test. Therefore it is essential that all of the criteria concerning validity of results be carefully considered as described herein.

5.1.3 Clearly, it will not be possible to determine KIc (GIc) if any dimension of the available stock of a material is insufficient to provide a specimen of the required size.

5.2 Inasmuch as the fracture toughness of plastics is often dependent on specimen process history, that is, injection molded, extruded, compression molded, etc., the spe...

SCOPE

1.1 These test methods are designed to characterize the toughness of plastics in terms of the critical-stress-intensity factor, KIc, and the energy per unit area of crack surface or critical strain energy release rate, GIc, at fracture initiation.

1.2 Two testing geometries are covered by these test methods, single-edge-notch bending (SENB) and compact tension (CT).

1.3 The scheme used assumes linear elastic behavior of the cracked specimen, so certain restrictions on linearity of the load-displacement diagram are imposed.

1.4 A state-of-plane strain at the crack tip is required. Specimen thickness must be sufficient to ensure this stress state.

1.5 The crack must be sufficiently sharp to ensure that a minimum value of toughness is obtained.

1.6 The significance of these test methods and many conditions of testing are identical to those of Test Method E399, and, therefore, in most cases, appear here with many similarities to the metals standard. However, certain conditions and specifications not covered in Test Method E399, but important for plastics, are included.

1.7 This protocol covers the determination of GIc as well, which is of particular importance for plastics.

1.8 These test methods give general information concerning the requirements for KIc and GIc testing. As with Test Method E399, two annexes are provided which give the specific requirements for testing of the SENB and CT geometries.

1.9 Test data obtained by these test methods are relevant and appropriate for use in engineering design.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: This standard and ISO 13586 address the same subject matter, but differ in technical con...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5045 − 14 (Reapproved 2022)

Standard Test Methods for

Plane-Strain Fracture Toughness and Strain Energy Release

1

Rate of Plastic Materials

This standard is issued under the fixed designation D5045; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 These test methods are designed to characterize the

toughness of plastics in terms of the critical-stress-intensity

NOTE1—ThisstandardandISO13586addressthesamesubjectmatter,

but differ in technical content.

factor, K , and the energy per unit area of crack surface or

Ic

critical strain energy release rate, G , at fracture initiation.

1.11 This international standard was developed in accor-

Ic

dance with internationally recognized principles on standard-

1.2 Two testing geometries are covered by these test

ization established in the Decision on Principles for the

methods, single-edge-notch bending (SENB) and compact

Development of International Standards, Guides and Recom-

tension (CT).

mendations issued by the World Trade Organization Technical

1.3 The scheme used assumes linear elastic behavior of the

Barriers to Trade (TBT) Committee.

cracked specimen, so certain restrictions on linearity of the

load-displacement diagram are imposed. 2. Referenced Documents

2

1.4 A state-of-plane strain at the crack tip is required. 2.1 ASTM Standards:

Specimen thickness must be sufficient to ensure this stress D638Test Method for Tensile Properties of Plastics

state. D4000Classification System for Specifying Plastic Materi-

als

1.5 The crack must be sufficiently sharp to ensure that a

E399Test Method for Linear-Elastic Plane-Strain Fracture

minimum value of toughness is obtained.

Toughness of Metallic Materials

1.6 The significance of these test methods and many con-

E691Practice for Conducting an Interlaboratory Study to

ditions of testing are identical to those of Test Method E399,

Determine the Precision of a Test Method

and, therefore, in most cases, appear here with many similari-

3. Terminology

ties to the metals standard. However, certain conditions and

specifications not covered in Test Method E399, but important

3.1 Definitions:

for plastics, are included.

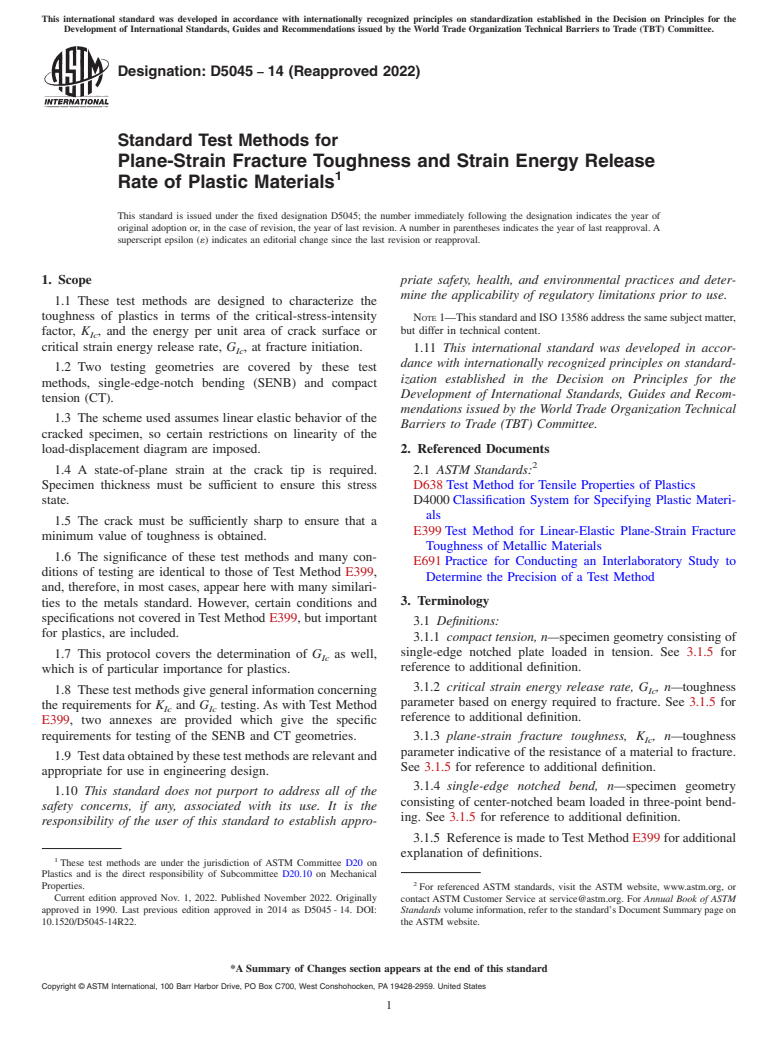

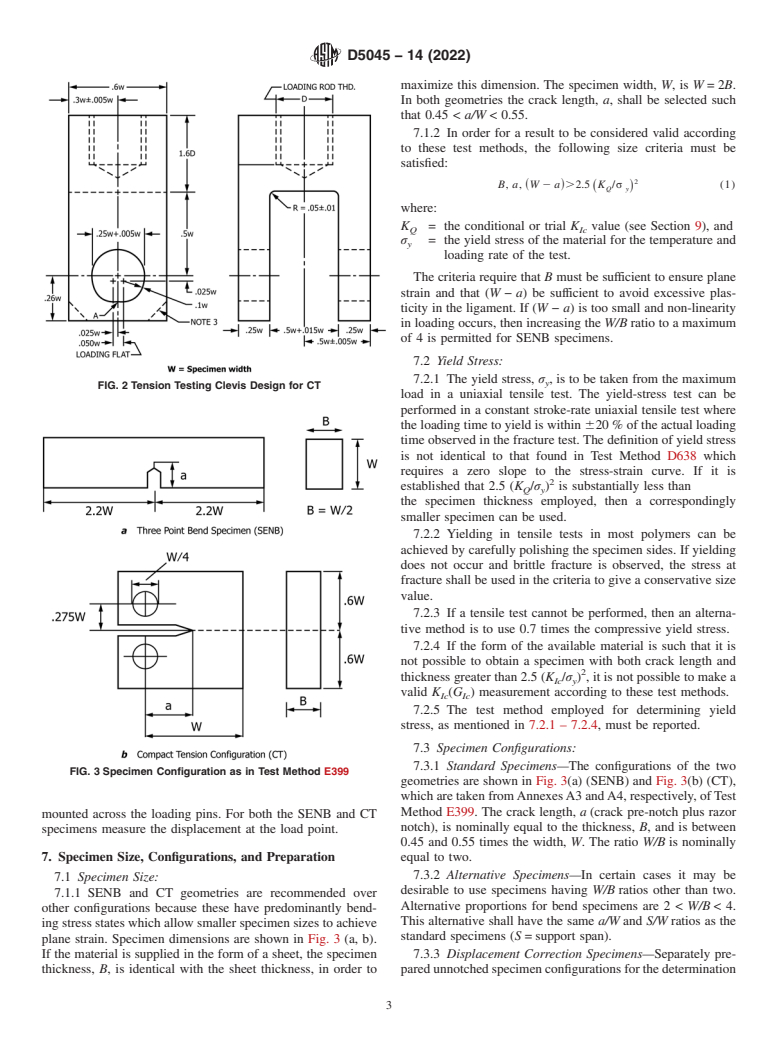

3.1.1 compact tension, n—specimen geometry consisting of

single-edge notched plate loaded in tension. See 3.1.5 for

1.7 This protocol covers the determination of G as well,

Ic

reference to additional definition.

which is of particular importance for plastics.

3.1.2 critical strain energy release rate, G ,n—toughness

1.8 Thesetestmethodsgivegeneralinformationconcerning Ic

parameter based on energy required to fracture. See 3.1.5 for

the requirements for K and G testing. As with Test Method

Ic Ic

reference to additional definition.

E399, two annexes are provided which give the specific

requirements for testing of the SENB and CT geometries. 3.1.3 plane-strain fracture toughness, K ,n—toughness

Ic

parameter indicative of the resistance of a material to fracture.

1.9 Testdataobtainedbythesetestmethodsarerelevantand

See 3.1.5 for reference to additional definition.

appropriate for use in engineering design.

3.1.4 single-edge notched bend, n—specimen geometry

1.10 This standard does not purport to address all of the

consisting of center-notched beam loaded in three-point bend-

safety concerns, if any, associated with its use. It is the

ing. See 3.1.5 for reference to additional definition.

responsibility of the user of this standard to establish appro-

3.1.5 Reference is made toTest Method E399 for additional

explanation of definitions.

1

These test methods are under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.10 on Mechanical

2

Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2022. Published November 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1990. Last previous edition approved in 2014 as D5045-14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5045-14R22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.