ASTM D5946-04

(Test Method)Standard Test Method for Corona-Treated Polymer Films Using Water Contact Angle Measurements

Standard Test Method for Corona-Treated Polymer Films Using Water Contact Angle Measurements

SCOPE

1.1 This test method covers measurement of the contact angle of water droplets on corona-treated polymer film surfaces.

Note 1—There is no similar or equivalent ISO standard.

1.2 The values stated in SI units are to be regarded as the standard. The values given in brackets are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5946–04

Standard Test Method for

Corona-Treated Polymer Films Using Water Contact Angle

1

Measurements

This standard is issued under the fixed designation D 5946; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

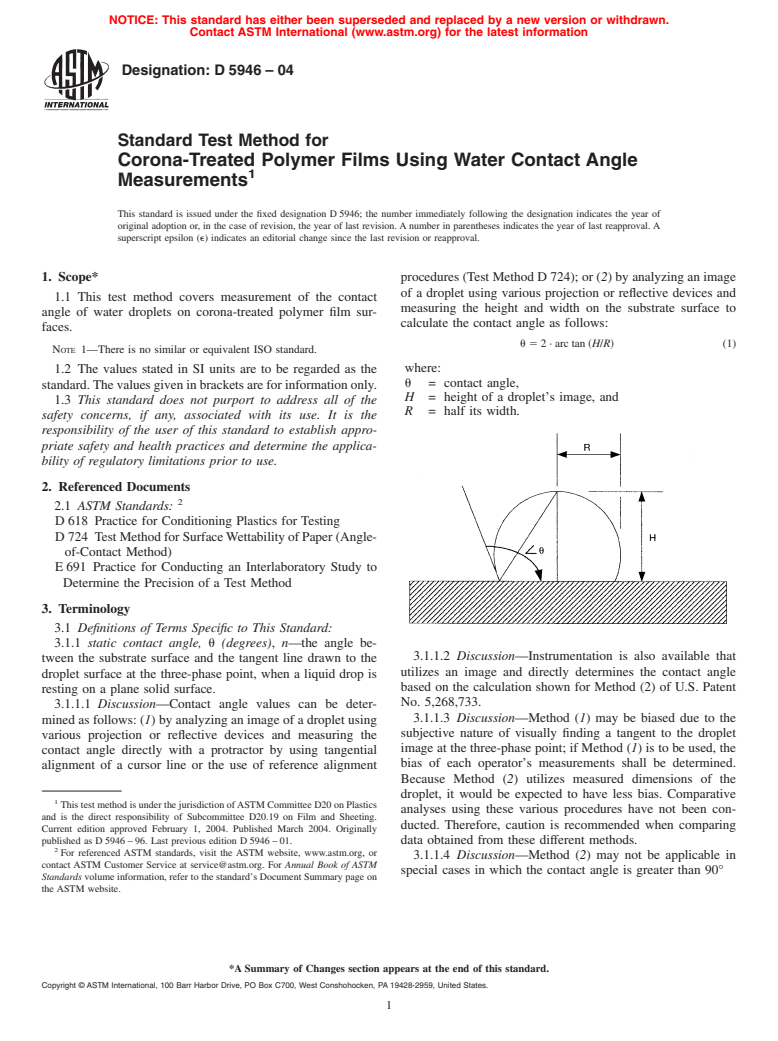

1. Scope* procedures (Test Method D 724); or (2) by analyzing an image

of a droplet using various projection or reflective devices and

1.1 This test method covers measurement of the contact

measuring the height and width on the substrate surface to

angle of water droplets on corona-treated polymer film sur-

calculate the contact angle as follows:

faces.

u5 2 · arc tan ~H/R! (1)

NOTE 1—There is no similar or equivalent ISO standard.

where:

1.2 The values stated in SI units are to be regarded as the

u = contact angle,

standard.Thevaluesgiveninbracketsareforinformationonly.

H = height of a droplet’s image, and

1.3 This standard does not purport to address all of the

R = half its width.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

D 724 TestMethodforSurfaceWettabilityofPaper(Angle-

of-Contact Method)

E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 static contact angle, u (degrees), n—the angle be-

3.1.1.2 Discussion—Instrumentation is also available that

tween the substrate surface and the tangent line drawn to the

utilizes an image and directly determines the contact angle

droplet surface at the three-phase point, when a liquid drop is

based on the calculation shown for Method (2) of U.S. Patent

resting on a plane solid surface.

No. 5,268,733.

3.1.1.1 Discussion—Contact angle values can be deter-

3.1.1.3 Discussion—Method (1) may be biased due to the

mined as follows: (1) by analyzing an image of a droplet using

subjective nature of visually finding a tangent to the droplet

various projection or reflective devices and measuring the

image at the three-phase point; if Method (1) is to be used, the

contact angle directly with a protractor by using tangential

bias of each operator’s measurements shall be determined.

alignment of a cursor line or the use of reference alignment

Because Method (2) utilizes measured dimensions of the

droplet, it would be expected to have less bias. Comparative

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

analyses using these various procedures have not been con-

and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

ducted. Therefore, caution is recommended when comparing

Current edition approved February 1, 2004. Published March 2004. Originally

published as D 5946 – 96. Last previous edition D 5946 – 01. data obtained from these different methods.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.1.4 Discussion—Method (2) may not be applicable in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

special cases in which the contact angle is greater than 90°

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5946–04

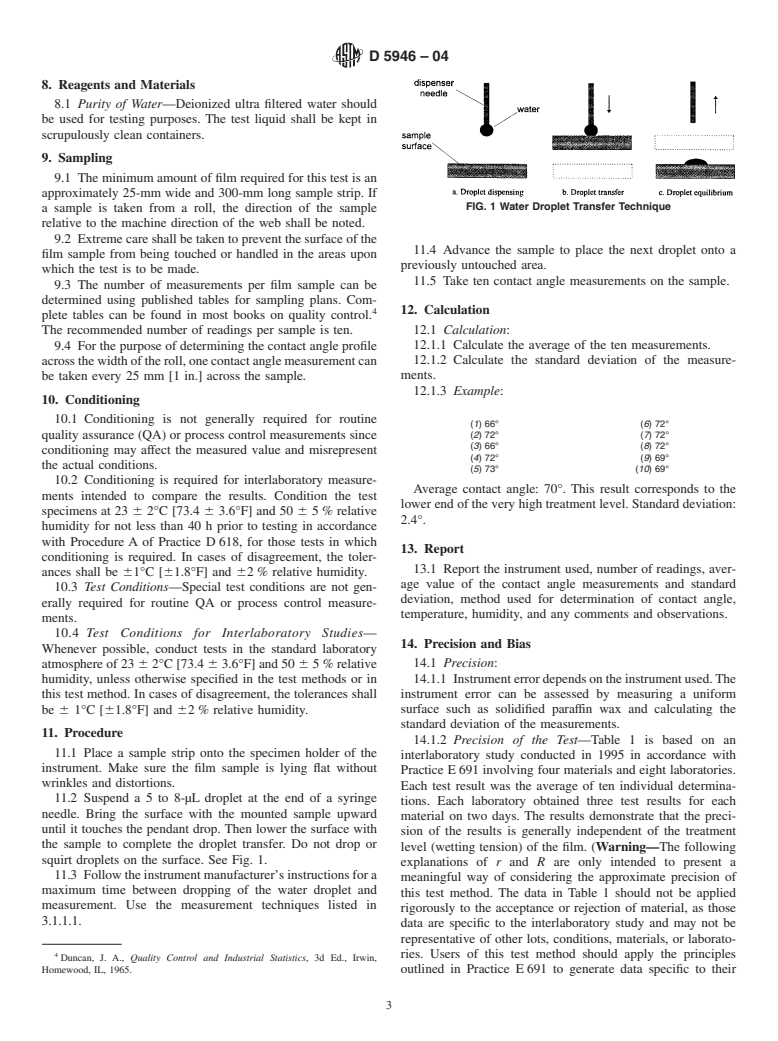

4. Summary of Test Method film may affect the results. It is therefore important that the

portion of the film surface to be tested not be touched or

4.1 In this test method, drops of water are placed on the

rubbed, that all equipment be scrupulously clean, and that

surface of a film sample, and the contact angle values are

water purity be guarded carefully. Glass apparatus, in particu-

measured and then averaged.

lar, is likely to be contaminated with detergents having very

5. Significance and Use low surface tension, unless specific precautions are taken to

ensure their absence, such as cleaning with chromic sulfuric

5.1 The ability of polymer films to retain inks, coatings,

acid and rinsing with distilled water.

adhesives, etc. is primarily dependent on the character of their

surfaces and can be improved by one of several surface- 6.2 The presence of slip, antistatic, or antiblocking and

treating techniques. The electrical discharge treatment, such as other ad

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.