ASTM D8065/D8065M-16

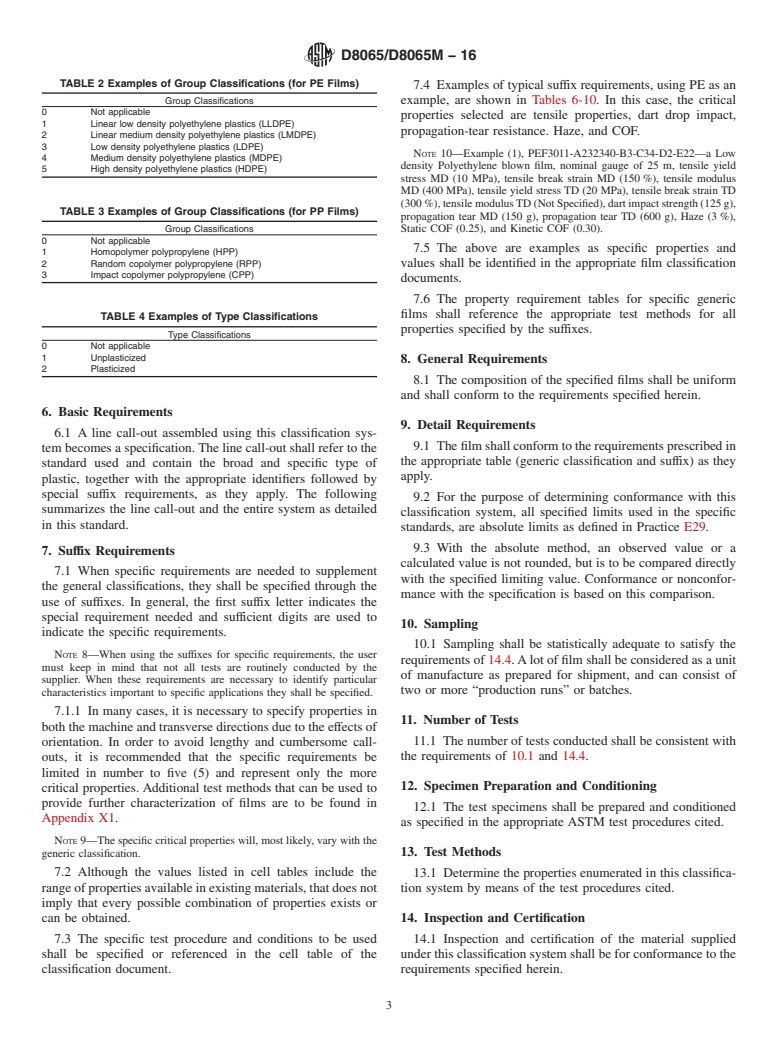

(Specification)Standard Classification System and Basis for Specification for Specifying Plastic Films

Standard Classification System and Basis for Specification for Specifying Plastic Films

SIGNIFICANCE AND USE

4.1 The purpose of this classification system is to provide a method of adequately identifying plastic films using a system that applies universally for plastic films. It further provides a means for specifying these films by the use of a simple line call-out designation.

4.2 This classification system was developed to permit the addition of additional film products and property values.

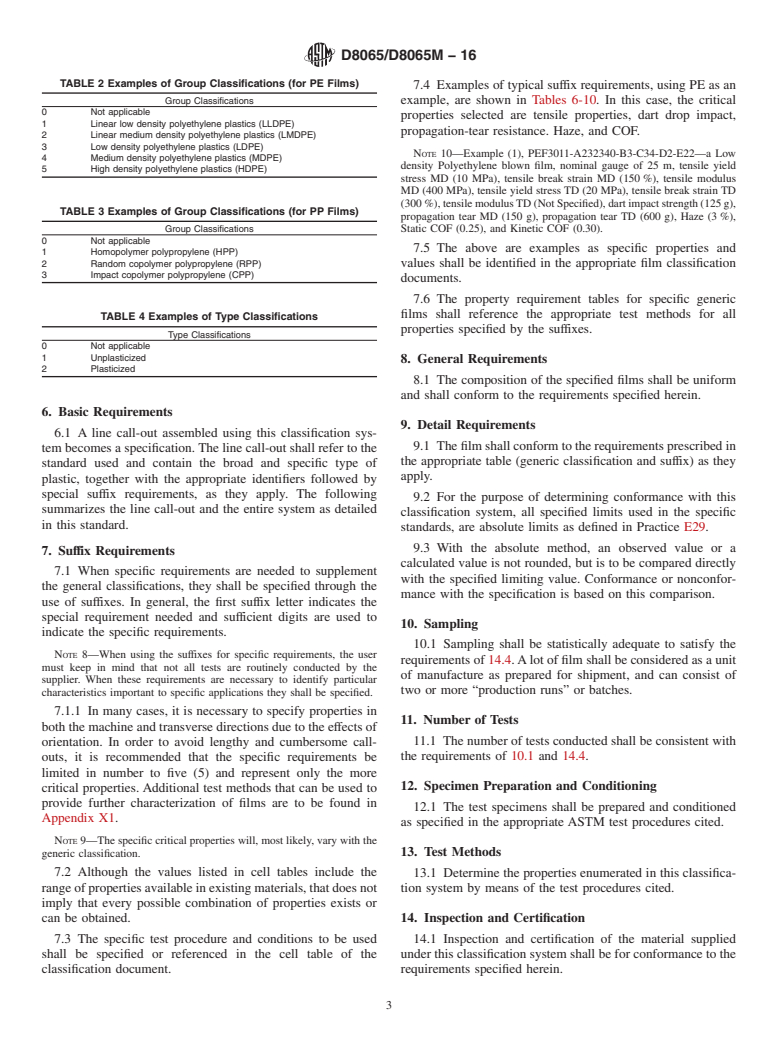

4.3 It is intended that the classification of plastic sheeting, >0.25 mm [0.010 in.] thickness, multi-layer structures, blends, and other variants will be addressed in related standards.

SCOPE

1.1 This standard provides a classification system for tabulating the properties of unfilled, single-layer plastic films.

Note 1: The classification system serves many of the needs of industries using plastic films. The standard is subject to revision as the need requires; therefore, the latest revision should always be used.

Note 2: Film is defined in Terminology D883 as an optional term for sheeting having a nominal thickness no greater than 0.25 mm [0.010 in.].

1.2 The classification system and subsequent line call-out (specification) is intended to be a means of identifying plastic films used for applications including industrial, packaging, construction, and agriculture. It is not intended for the selection of materials to be used in films. This selection should be made by those having expertise in the plastics field after careful consideration of the end-use requirements, the environment to which the films will be exposed, the fabrication process to be employed, the inherent properties of the material not covered in this document, and the economic factors.

1.3 This classification system is based on the premise that plastic films can be arranged into broad generic families based on materials with similar composition using basic film properties. A system is thus established which, together with values describing additional requirements, permits as complete a description as desired of the selected film.

1.4 In all cases where the provisions of this classification system would conflict with the referenced ASTM specification for a particular film product, the latter shall take precedence.

Note 3: It is strongly recommended that this classification system be used for all new applications and specifications and that the specification of films using existing standards be expeditiously withdrawn or converted to this classification system.

1.5 This classification system applies to commercial products and, as such, there is no control over the manufacturing parameters employed in producing the film. It shall be the responsibility of those developing the specification documents utilizing this classification system to identify the critical parameters and values to be used for the cell classifications and suffix requirements.

1.6 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 4: There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D8065/D8065M −16

Standard Classification System and Basis for Specification for

1

Specifying Plastic Films

This standard is issued under the fixed designation D8065/D8065M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 Units—The values stated in either SI units or inch-

pound units are to be regarded separately as standard. The

1.1 This standard provides a classification system for tabu-

values stated in each system may not be exact equivalents;

lating the properties of unfilled, single-layer plastic films.

therefore,eachsystemshallbeusedindependentlyoftheother.

NOTE 1—The classification system serves many of the needs of

Combining values from the two systems may result in non-

industries using plastic films. The standard is subject to revision as the

conformance with the standard.

need requires; therefore, the latest revision should always be used.

NOTE 2—Film is defined in Terminology D883 as an optional term for 1.7 This standard does not purport to address all of the

sheeting having a nominal thickness no greater than 0.25 mm [0.010 in.].

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1.2 The classification system and subsequent line call-out

priate safety and health practices and determine the applica-

(specification) is intended to be a means of identifying plastic

bility of regulatory limitations prior to use.

films used for applications including industrial, packaging,

construction,andagriculture.Itisnotintendedfortheselection

NOTE 4—There is no known ISO equivalent to this standard.

of materials to be used in films. This selection should be made

1.8 This international standard was developed in accor-

by those having expertise in the plastics field after careful

dance with internationally recognized principles on standard-

consideration of the end-use requirements, the environment to

ization established in the Decision on Principles for the

which the films will be exposed, the fabrication process to be

Development of International Standards, Guides and Recom-

employed, the inherent properties of the material not covered

mendations issued by the World Trade Organization Technical

in this document, and the economic factors.

Barriers to Trade (TBT) Committee.

1.3 This classification system is based on the premise that

plastic films can be arranged into broad generic families based

2. Referenced Documents

on materials with similar composition using basic film prop-

2.1 ASTM Standards:

erties.Asystem is thus established which, together with values

D149 Test Method for Dielectric Breakdown Voltage and

describing additional requirements, permits as complete a

DielectricStrengthofSolidElectricalInsulatingMaterials

description as desired of the selected film.

at Commercial Power Frequencies

1.4 In all cases where the provisions of this classification

D150 Test Methods forAC Loss Characteristics and Permit-

system would conflict with the referencedASTM specification

tivity (Dielectric Constant) of Solid Electrical Insulation

for a particular film product, the latter shall take precedence.

D257 Test Methods for DC Resistance or Conductance of

Insulating Materials

NOTE 3—It is strongly recommended that this classification system be

D774/D774M Test Method for Bursting Strength of Paper

used for all new applications and specifications and that the specification

2

of films using existing standards be expeditiously withdrawn or converted

(Withdrawn 2010)

to this classification system.

D882 Test Method for Tensile Properties of Thin Plastic

1.5 This classification system applies to commercial prod- Sheeting

ucts and, as such, there is no control over the manufacturing D883 Terminology Relating to Plastics

parameters employed in producing the film. It shall be the

D1003 Test Method for Haze and Luminous Transmittance

responsibility of those developing the specification documents of Transparent Plastics

utilizing this classification system to identify the critical

D1004 Test Method for Tear Resistance (Graves Tear) of

parametersandvalues to be used for the cell classificationsand Plastic Film and Sheeting

suffix requirements.

D1203 Test Methods for Volatile Loss From Plastics Using

Activated Carbon Methods

1

This standard is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

Molded Products.

2

Current

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8065/D8065M − 16

Standard Classification System and Basis for Specification for

1

Specifying Plastic Films

This standard is issued under the fixed designation D8065/D8065M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 Units—The values stated in either SI units or inch-

pound units are to be regarded separately as standard. The

1.1 This standard provides a classification system for tabu-

values stated in each system may not be exact equivalents;

lating the properties of unfilled, single-layer plastic films.

therefore, each system shall be used independently of the other.

NOTE 1—The classification system serves many of the needs of

Combining values from the two systems may result in non-

industries using plastic films. The standard is subject to revision as the

conformance with the standard.

need requires; therefore, the latest revision should always be used.

NOTE 2—Film is defined in Terminology D883 as an optional term for 1.7 This standard does not purport to address all of the

sheeting having a nominal thickness no greater than 0.25 mm [0.010 in.].

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1.2 The classification system and subsequent line call-out

priate safety and health practices and determine the applica-

(specification) is intended to be a means of identifying plastic

bility of regulatory limitations prior to use.

films used for applications including industrial, packaging,

construction, and agriculture. It is not intended for the selection

NOTE 4—There is no known ISO equivalent to this standard.

of materials to be used in films. This selection should be made

1.8 This international standard was developed in accor-

by those having expertise in the plastics field after careful

dance with internationally recognized principles on standard-

consideration of the end-use requirements, the environment to

ization established in the Decision on Principles for the

which the films will be exposed, the fabrication process to be

Development of International Standards, Guides and Recom-

employed, the inherent properties of the material not covered

mendations issued by the World Trade Organization Technical

in this document, and the economic factors.

Barriers to Trade (TBT) Committee.

1.3 This classification system is based on the premise that

plastic films can be arranged into broad generic families based

2. Referenced Documents

on materials with similar composition using basic film prop-

2.1 ASTM Standards:

erties. A system is thus established which, together with values

D149 Test Method for Dielectric Breakdown Voltage and

describing additional requirements, permits as complete a

Dielectric Strength of Solid Electrical Insulating Materials

description as desired of the selected film.

at Commercial Power Frequencies

1.4 In all cases where the provisions of this classification

D150 Test Methods for AC Loss Characteristics and Permit-

system would conflict with the referenced ASTM specification

tivity (Dielectric Constant) of Solid Electrical Insulation

for a particular film product, the latter shall take precedence.

D257 Test Methods for DC Resistance or Conductance of

Insulating Materials

NOTE 3—It is strongly recommended that this classification system be

D774/D774M Test Method for Bursting Strength of Paper

used for all new applications and specifications and that the specification

2

of films using existing standards be expeditiously withdrawn or converted

(Withdrawn 2010)

to this classification system.

D882 Test Method for Tensile Properties of Thin Plastic

1.5 This classification system applies to commercial prod- Sheeting

ucts and, as such, there is no control over the manufacturing

D883 Terminology Relating to Plastics

parameters employed in producing the film. It shall be the D1003 Test Method for Haze and Luminous Transmittance

responsibility of those developing the specification documents

of Transparent Plastics

utilizing this classification system to identify the critical D1004 Test Method for Tear Resistance (Graves Tear) of

parameters and values to be used for the cell classifications and

Plastic Film and Sheeting

suffix requirements. D1203 Test Methods for Volatile Loss From Plastics Using

Activated Carbon Methods

1

This standard is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

Molded Products.

2

Current edition approved Sept. 1, 2016. Published September 2016. DOI: The last approved version o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.