ASTM D3809-01

(Test Method)Standard Method for Testing Synthetic Dielectric Fluids For Capacitors

Standard Method for Testing Synthetic Dielectric Fluids For Capacitors

SCOPE

1.1 These test methods cover testing synthetic dielectric fluids currently in use for capacitors. The methods are generally suitable for specification acceptance, factory control, referee testing, and research. Their applicability to future fluids has not been determined.

1.2 The scope of some of the test methods listed here apply to petroleum oils, but have been found suitable for synthetic fluids.

1.3 For methods relating to polybutene fluids refer to Specification D2296.

1.4 For methods relating to silicone fluids refer to Test Methods D2225.

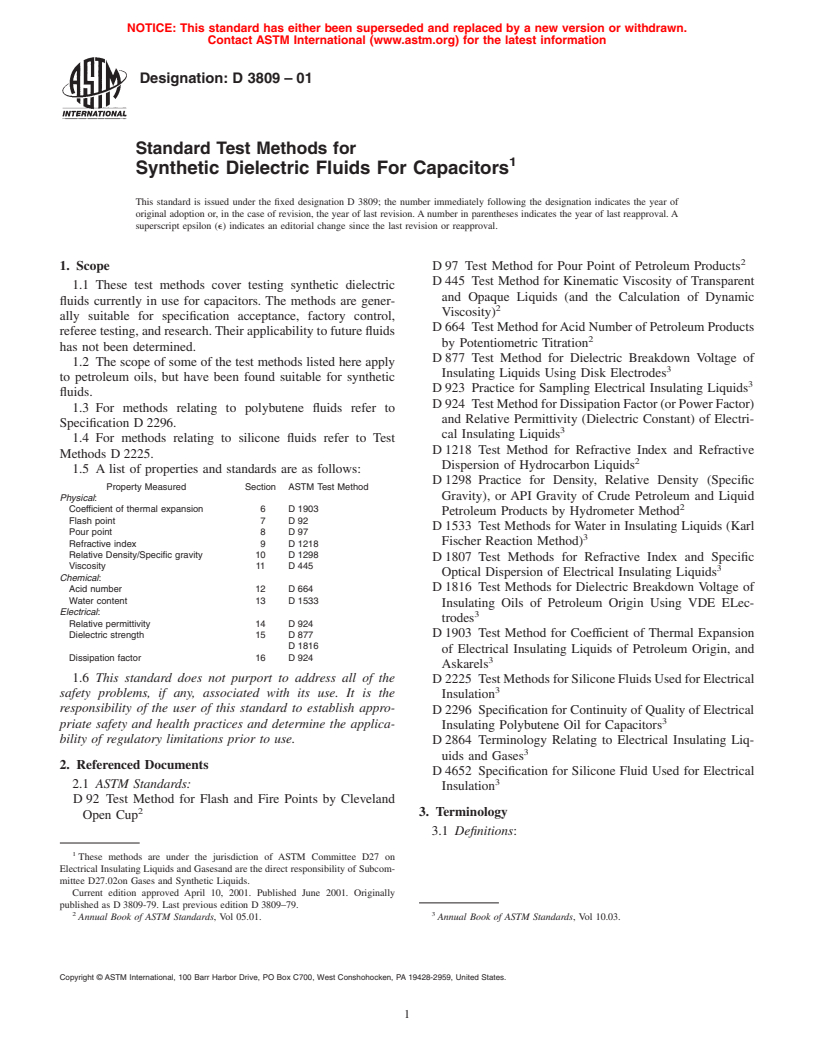

1.5 A list of properties and standards are as follows:Property MeasuredSectionASTM Test MethodPhysical:Coefficient of thermal expansion6D 1903Flash point7D 92Pour point8D 97Refractive index9 D 1218Relative Density/Specific gravity10 D 1298Viscosity11D 445Chemical:Acid number12D 664Water content13D 1533Electrical:Relative permittivity14 D 924Dielectric strength15D 877D 1816Dissipation factor16D 924

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 3809–01

Standard Test Methods for

1

Synthetic Dielectric Fluids For Capacitors

This standard is issued under the fixed designation D 3809; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

2

1. Scope D 97 Test Method for Pour Point of Petroleum Products

D 445 Test Method for Kinematic Viscosity of Transparent

1.1 These test methods cover testing synthetic dielectric

and Opaque Liquids (and the Calculation of Dynamic

fluids currently in use for capacitors. The methods are gener-

2

Viscosity)

ally suitable for specification acceptance, factory control,

D 664 Test Method forAcid Number of Petroleum Products

referee testing, and research.Their applicability to future fluids

2

by Potentiometric Titration

has not been determined.

D 877 Test Method for Dielectric Breakdown Voltage of

1.2 The scope of some of the test methods listed here apply

3

Insulating Liquids Using Disk Electrodes

to petroleum oils, but have been found suitable for synthetic

3

D 923 Practice for Sampling Electrical Insulating Liquids

fluids.

D 924 TestMethodforDissipationFactor(orPowerFactor)

1.3 For methods relating to polybutene fluids refer to

and Relative Permittivity (Dielectric Constant) of Electri-

Specification D 2296.

3

cal Insulating Liquids

1.4 For methods relating to silicone fluids refer to Test

D 1218 Test Method for Refractive Index and Refractive

Methods D 2225.

2

Dispersion of Hydrocarbon Liquids

1.5 A list of properties and standards are as follows:

D 1298 Practice for Density, Relative Density (Specific

Property Measured Section ASTM Test Method

Gravity), or API Gravity of Crude Petroleum and Liquid

Physical:

2

Coefficient of thermal expansion 6 D 1903

Petroleum Products by Hydrometer Method

Flash point 7 D 92

D 1533 Test Methods for Water in Insulating Liquids (Karl

Pour point 8 D 97

3

Refractive index 9 D 1218 Fischer Reaction Method)

Relative Density/Specific gravity 10 D 1298

D 1807 Test Methods for Refractive Index and Specific

Viscosity 11 D 445

3

Optical Dispersion of Electrical Insulating Liquids

Chemical:

D 1816 Test Methods for Dielectric Breakdown Voltage of

Acid number 12 D 664

Water content 13 D 1533

Insulating Oils of Petroleum Origin Using VDE ELec-

Electrical:

3

trodes

Relative permittivity 14 D 924

D 1903 Test Method for Coefficient of Thermal Expansion

Dielectric strength 15 D 877

D 1816

of Electrical Insulating Liquids of Petroleum Origin, and

Dissipation factor 16 D 924

3

Askarels

1.6 This standard does not purport to address all of the

D 2225 TestMethodsforSiliconeFluidsUsedforElectrical

3

safety problems, if any, associated with its use. It is the

Insulation

responsibility of the user of this standard to establish appro-

D 2296 Specification for Continuity of Quality of Electrical

3

priate safety and health practices and determine the applica-

Insulating Polybutene Oil for Capacitors

bility of regulatory limitations prior to use.

D 2864 Terminology Relating to Electrical Insulating Liq-

3

uids and Gases

2. Referenced Documents

D 4652 Specification for Silicone Fluid Used for Electrical

3

2.1 ASTM Standards:

Insulation

D 92 Test Method for Flash and Fire Points by Cleveland

2

3. Terminology

Open Cup

3.1 Definitions:

1

These methods are under the jurisdiction of ASTM Committee D27 on

Electrical Insulating Liquids and Gasesand are the direct responsibility of Subcom-

mittee D27.02on Gases and Synthetic Liquids.

Current edition approved April 10, 2001. Published June 2001. Originally

published as D 3809-79. Last previous edition D 3809–79.

2 3

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 10.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3809

3.1.1 coeffıcient of thermal expansion—the increase in vol- 8.1.1 The pour point is important as an index of the lowest

ume per unit volume per degree change in temperature. It is temperature to which the material may be cooled without

commonly stated as the average coefficient over a given seriously limiting the degree of circulation of the fluid.

temperature range. 8.2 Procedure—Determine the pour point in accordance

3.1.2 total acid number—the quantity of base, expressed in with Test Method D 97.

milligrams of potassium hydroxide (KOH) that is required to

9. Refractive Index

titrate all acidic constituents present in 1 g of sample.

3.2 For additional terms refer to Terminology D 2864.

9.1 Significance—The refractive index is useful in the

detection of various types of contamination or in the iden

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.