ASTM D4124-09(2018)

(Test Method)Standard Test Method for Separation of Asphalt into Four Fractions

Standard Test Method for Separation of Asphalt into Four Fractions

SIGNIFICANCE AND USE

5.1 This test method separates asphalts into four well-defined fractions. Analysis of these fractions can be used to evaluate asphalt composition (1, 2).4 For example, one can compare the ratios of the fractions with other asphalt systems to evaluate processing and aging parameters that relate to performance properties of the asphalt.

SCOPE

1.1 This test method covers the separation of four defined fractions from petroleum asphalts. The four fractions are defined as saturates, naphthene aromatics, polar aromatics, and iso-octane insoluble asphaltenes. This method can also be used to isolate saturates, naphthene aromatics, and polar aromatics from distillate products such as vacuum gas oils, lubricating oils, and cycle stocks. These distillate products usually do not contain asphaltenes.

1.2 The values stated in SI units are to be regarded as standard.

1.3 Since a precision estimate for this standard has not been developed, this test method is to be used for research or informational purposes only. Therefore, this standard should not be used for acceptance or rejection of a material for purchasing purposes.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4124 − 09 (Reapproved 2018)

Standard Test Method for

Separation of Asphalt into Four Fractions

This standard is issued under the fixed designation D4124; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Documents:

Manual on Hydrocarbon Analysis

1.1 This test method covers the separation of four defined

fractions from petroleum asphalts. The four fractions are

3. Terminology

defined as saturates, naphthene aromatics, polar aromatics, and

iso-octane insoluble asphaltenes.This method can also be used 3.1 Definitions of Terms Specific to This Standard:

3.1.1 asphaltenes or alkane insolubles—insoluble matter

to isolate saturates, naphthene aromatics, and polar aromatics

from distillate products such as vacuum gas oils, lubricating that can be separated from asphalt following digestion of the

asphalt in n-alkane (and in some cases, branched alkanes)

oils, and cycle stocks. These distillate products usually do not

contain asphaltenes. under the specified conditions in this test method.

3.1.2 naphthene—any of a group of hydrocarbon ring com-

1.2 The values stated in SI units are to be regarded as

pounds of the general formula, C H , derivatives of cyclopen-

standard.

n 2n

tane and cyclohexane, found in certain petroleum stocks.

1.3 Since a precision estimate for this standard has not been

3.1.3 naphthene aromatics—material that is adsorbed on

developed, this test method is to be used for research or

calcined CG-20 alumina in the presence of n-heptane, and

informational purposes only. Therefore, this standard should

desorbed by toluene, after removal of saturates under the

not be used for acceptance or rejection of a material for

conditions specified.

purchasing purposes.

3.1.4 petrolenes (also referred to as maltenes)—(1) any of

1.4 This standard does not purport to address all of the

the constituents of a bitumen, as asphalt, that are soluble in

safety concerns, if any, associated with its use. It is the

n-alkanes (and in some cases, branched alkanes), which

responsibility of the user of this standard to establish appro-

generally range in carbon number between n-C to n-C

5 10

priate safety, health, and environmental practices and deter-

alkanes, n-heptane being the most common solvent used; (2)

mine the applicability of regulatory limitations prior to use.

the low molecular weight alkane-soluble matter recovered

Specific precautionary statements are given in Section 8.

following separation of asphaltenes from the digested mixture

1.5 This international standard was developed in accor-

under the specified conditions described in this and similar test

dance with internationally recognized principles on standard-

methods.

ization established in the Decision on Principles for the

3.1.5 polar aromatics (resins)—material desorbed from cal-

Development of International Standards, Guides and Recom-

cinedCG-20aluminaabsorbent,afterthesaturatesfractionand

mendations issued by the World Trade Organization Technical

naphthenic aromatics fraction have been removed, using tolu-

Barriers to Trade (TBT) Committee.

ene:methanol (50:50, vol:vol) and trichloroethylene eluate

under the conditions specified.

2. Referenced Documents

3.1.6 saturates—material that, on percolation in an alkane

2.1 ASTM Standards:

eluate, is not absorbed on calcined CG-20 alumina absorbent

D140 Practice for Sampling Bituminous Materials

under the conditions specified.

4. Summary of Test Method

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.47 in 4.1 The sample containing the four defined fractions is first

Miscellaneous Asphalt Tests.

separated into alkane-insoluble asphaltenes and alkane-soluble

Current edition approved Jan. 1, 2018. Published January 2018. Originally

petrolenes. Petrolenes are then adsorbed onto calcined CG-20

approved in 1982. Last previous edition approved in 2009 as D4124 – 09. DOI:

alumina and further fractionated into saturate, naphthene

10.1520/D4124-09R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from ASTM as MNL3-6TH-EB.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4124 − 09 (2018)

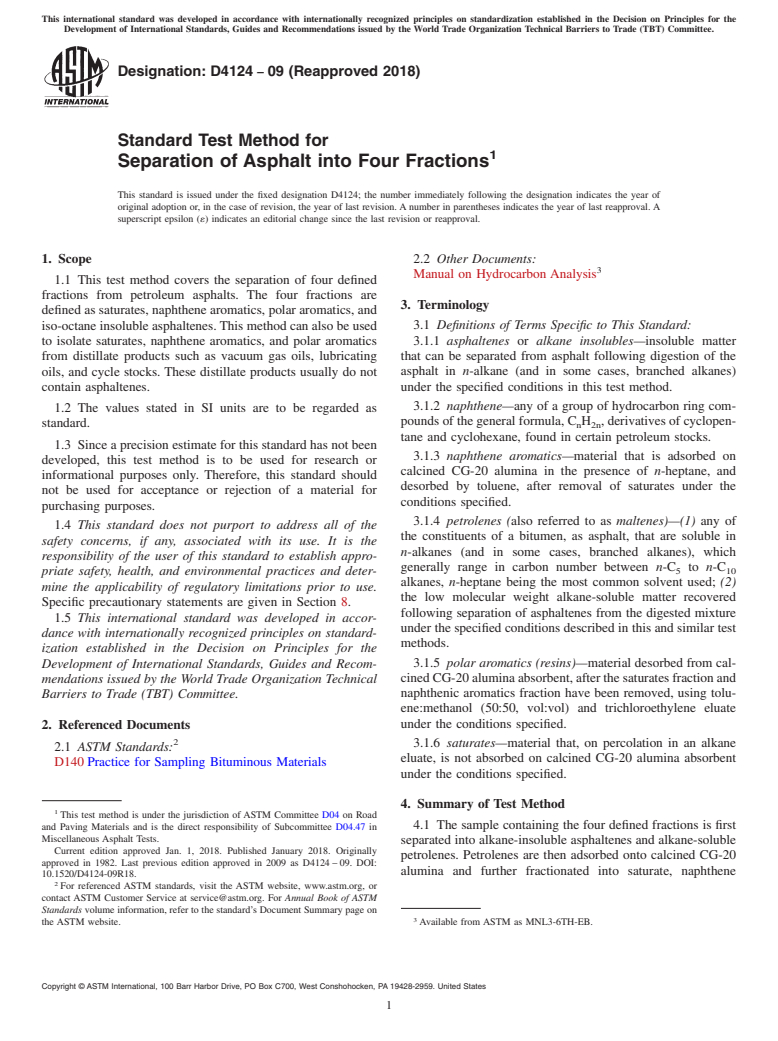

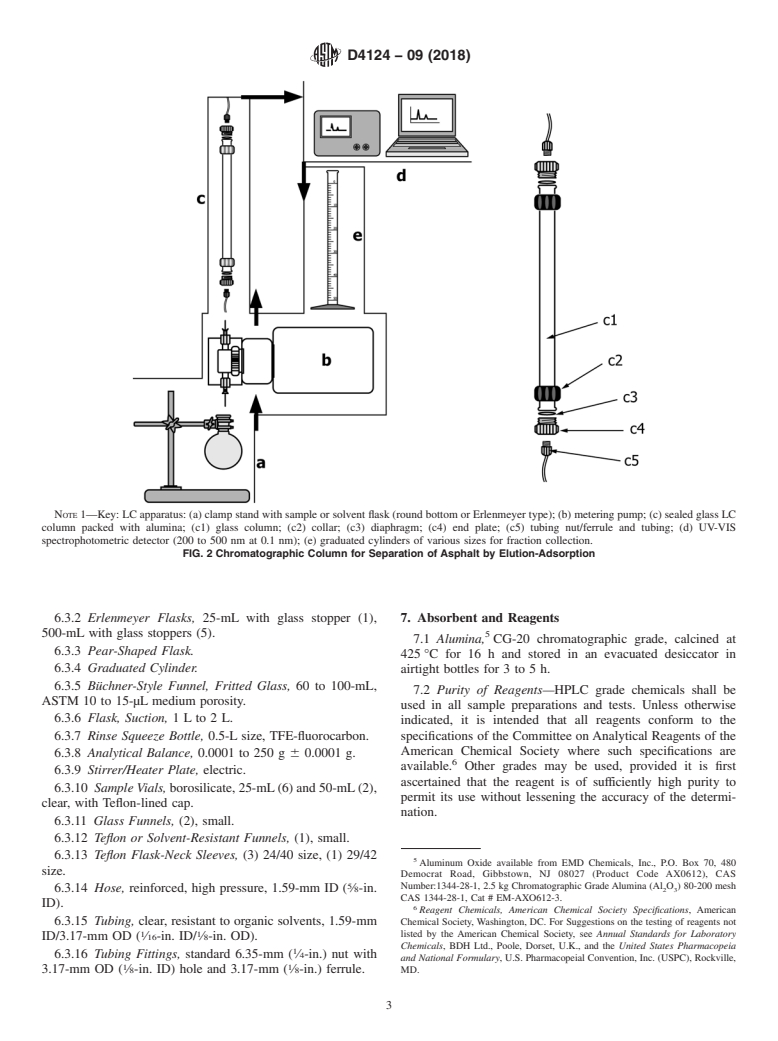

aromatic, and polar aromatic fractions by pumping an eluo- 6.2.1 LC Apparatus (Fig. 2)—(a) ring stand with clamp,

tropic series of elution solvents upwards through a glass flask (25-mL round bottom or Erlenmeyer flask); (b) metering

chromatographiccolumnpackedwithcalcinedalumina.Eluted pump; (c) sealed glass LC column; (d) UV detector with data

fractions are recovered by solvent removal prior to final acquisition system (wavelength range 200 to 500 nm at

weighing. The three eluted fractions plus the alkane- 0.1 nm); (e) graduated cylinder (Fig. 2).

precipitated asphaltenes comprise the four fractions as defined 6.2.2 UVDetectorwithDataAcquisitionSystem(Fig.2)—A

in Section 3.

UV detector with data acquisition system suitable for use with

liquid chromatography or HPLC used to detect the occurrence

5. Significance and Use

of material fractions (peak response) as they are eluted from

5.1 This test method separates asphalts into four well- the column.

defined fractions. Analysis of these fractions can be used to 6.2.3 Metering Pump (Fig. 2)—Piston and piston chamber

evaluate asphalt composition (1, 2). For example, one can

will be constructed of materials resistant to deterioration by

compare the ratios of the fractions with other asphalt systems solvents that will be used to perform the method. Flow rate

to evaluate processing and aging parameters that relate to

range of the pump will be 0.1 to 5.0 mL/min 6 0.1 mL/min

performance properties of the asphalt. flow rate stability.

6.2.4 LC Column with Water Jacket—Closed glass liquid

6. Apparatus and Materials

chromatography column, 70 cm long and 1.5 cm inside

6.1 Reflux Apparatus for Asphaltene/Maltene Separation, diameter (volume, 124 cc). The LC column will be a closed

with features as specified in Fig. 1. (See 6.1.1.)

column with end plates containing solvent-permeable dia-

6.1.1 Apparatus (Fig. 1)—(a) ring stand with clamp; (b) phragms and fitting ports for 6.35-mm ( ⁄4-in.) tubing fittings.

heater stirring plate; (c) 500-mL Erlenmeyer flask with 29/42

6.2.5 Refrigerated/Heating Circulator—A refrigerated/

sintered glass neck; (d) reducer, 29/42 to 24/40 sintered glass

heating circulator, temperature range between 0 and 100 °C 6

necks; (e) Allihn-type reflux condenser with 24/40 sintered

0.1 °C stability, with water circulation through the LC column

glass neck.

water jacket via high-pressure hose 15.9-mm ( ⁄8-in. ID).

6.2 Chromatographic Column Apparatus, with features as

6.3 Materials:

specified in Fig. 2 (see 6.2.1 – 6.2.5).

6.3.1 Utilities—Fume hood, vacuum source, nitrogen gas

source, cold water source, nitrogen gas-purged vacuum drying

oven, rotary solvent evaporator (water bath and oil bath type),

The boldface numbers in parentheses refer to a list of references at the end of

nitrogen gas stream evaporator with heater water bath.

this standard.

NOTE 1—Key: (a) ring stand with large test tube clamp; (b) heater/stirring plate; (c) 500-mL Erlenmeyer flask with 29/42 sintered glass neck; (d)

reducer 29/42 to 24/40 sintered glass spout to neck; (e) Allihn-type reflux condenser with 24/40 sintered glass spout.

FIG. 1 Asphaltene/Maltene Separation Apparatus

D4124 − 09 (2018)

NOTE 1—Key: LC apparatus: (a) clamp stand with sample or solvent flask (round bottom or Erlenmeyer type); (b) metering pump; (c) sealed glass LC

column packed with alumina; (c1) glass column; (c2) collar; (c3) diaphragm; (c4) end plate; (c5) tubing nut/ferrule and tubing; (d) UV-VIS

spectrophotometric detector (200 to 500 nm at 0.1 nm); (e) graduated cylinders of various sizes for fraction collection.

FIG. 2 Chromatographic Column for Separation of Asphalt by Elution-Adsorption

6.3.2 Erlenmeyer Flasks, 25-mL with glass stopper (1), 7. Absorbent and Reagents

500-mL with glass stoppers (5). 5

7.1 Alumina, CG-20 chromatographic grade, calcined at

6.3.3 Pear-Shaped Flask.

425 °C for 16 h and stored in an evacuated desiccator in

6.3.4 Graduated Cylinder.

airtight bottles for 3 to 5 h.

6.3.5 Büchner-Style Funnel, Fritted Glass, 60 to 100-mL,

7.2 Purity of Reagents—HPLC grade chemicals shall be

ASTM 10 to 15-µL medium porosity.

used in all sample preparations and tests. Unless otherwise

6.3.6 Flask, Suction,1Lto2L.

indicated, it is intended that all reagents conform to the

6.3.7 Rinse Squeeze Bottle, 0.5-L size, TFE-fluorocarbon. specifications of the Committee on Analytical Reagents of the

American Chemical Society where such specifications are

6.3.8 Analytical Balance, 0.0001 to 250 g 6 0.0001 g.

available. Other grades may be used, provided it is first

6.3.9 Stirrer/Heater Plate, electric.

ascertained that the reagent is of sufficiently high purity to

6.3.10 Sample Vials, borosilicate, 25-mL(6) and 50-mL(2),

permit its use without lessening the accuracy of the determi-

clear, with Teflon-lined cap.

nation.

6.3.11 Glass Funnels, (2), small.

6.3.12 Teflon or Solvent-Resistant Funnels, (1), small.

6.3.13 Teflon Flask-Neck Sleeves, (3) 24/40 size, (1) 29/42

Aluminum Oxide available from EMD Chemicals, Inc., P.O. Box 70, 480

size.

Democrat Road, Gibbstown, NJ 08027 (Product Code AX0612), CAS

5 Number:1344-28-1, 2.5 kg Chromatographic Grade Alumina (Al O ) 80-200 mesh

6.3.14 Hose, reinforced, high pressure, 1.59-mm ID ( ⁄8-in. 2 3

CAS 1344-28-1, Cat # EM-AXO612-3.

ID).

Reagent Chemicals, American Chemical Society Specifications, American

6.3.15 Tubing, clear, resistant to organic solvents, 1.59-mm Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

1 1 listed by the American Chemical Society, see Annual Standards for Laboratory

ID/3.17-mm OD ( ⁄16-in. ID/ ⁄8-in. OD).

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

6.3.16 Tubing Fittings, standard 6.35-mm ( ⁄4-in.) nut with

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

1 1

3.17-mm OD ( ⁄8-in. ID) hole and 3.17-mm ( ⁄8-in.) ferrule. MD.

D4124 − 09 (2018)

7.3 Reagents: sidesoftheflask.Oncethesamplehasbeenobservedtogointo

7.3.1 iso-Octane (2,2,4-trimethyl pentane), HPLC grade, solution, stir the solution with refluxing for an additional 1 h

0.01 % water. (Note 2).

7.3.2 n-Heptane, HPLC grade, 0.01 % water.

NOTE2—Normally2hisasufficientamountoftimetodissolve(digest)

7.3.3 Methanol, anhydrous, HPLC grade, 0.01 % water.

straight reduced asphalts, but for air-blown or chemically modified

7.3.4 Toluene, HPLC grade, 0.001 % water.

asphalts, the dissolution time may need to be extended to 3 h.

7.3.5 Trichloroethylene, ACS grade, 0.02 % water, boiling

9.5 After the 2 to 3-h period of time required for refluxing

point 86.5 to 87.5 °C.

with stirring, turn off the heater element of the stirrer/heater

plate and allow the sample solution to cool with stirring.

8. Safety Precautions

Continue to stir the cooled sample solution for an additional

8.1 Most organic solvents used in these methods are flam-

2 h after cooling, at which time discontinue stirring, remove

mable and to some degree toxic. Reference should be made to

the Allihn-type reflux condenser, stopper the flask, and allow

Material Safety Data Sheets available from the supplier. These

the sample solution to settle for 2 h prior to filtering (Note 3).

solvents should be handled with care and only in well-

NOTE 3—At some time during the stirring process, after heating has

ventilated areas such as a fume hood.All working areas should

been discontinued, rinse down the reflux assembly with 10 to 20 mL of

be kept free of sparks, flames, or other sources of high

iso-octane by dispensing solvent from the top of the Allihn-type reflux

temperature.

condenser into the flask using a squeeze bottle.

9.6 Set up a Büchner-style fritted-glass funnel (60-mL,

9. Separation of Asphalt into Asphaltenes and Petrolenes

ASTM 10 to 15-µLmedium porosity) by placing the funnel on

(Maltenes)

a 1-Lsuction flask with a filter ring.Attach the suction flask to

9.1 Representative asphalt samples free of foreign sub-

a cold-trapped vacuum source with high-pressure hose and

stances will be collected in accordance with Practice D140.

hose clamps and secure the suction flask to a ring stand or

Samples for testing can be transferred by chilling to facilitate

mount rack with a clamp. Prior to filtration, tare the Büchner-

fracturing the sample or by heating the sample until it becomes

style fritted-glass funnel.

sufficiently fluid to pour. Warning—In no case shall the

9.7 Filter the sample solution prepared in 9.2 – 9.5,by

samples be heated more than 50 °C above the expected

quantitatively decanting the liquid contents of the sample

softeningpointofthematerial,whichisapproximately100 °C.

solution from the 500-mL Erlenmeyer flask directly into the

9.2 Transfer to the nearest 0.001 g, 2.000 g of the asphalt

Büchner-style fritted-glass funnel while applying suction to the

into a tared 500-mL Erlenmeyer flask and record the mass of

1-L suction flask.

the asphalt, M .Allow the sample to cool if transferred by

asphalt

9.8 Quantitatively transfer the filtered decant, using a glass

heating and pouring prior to adding the iso-octane in the ratio

funnel, to a 1-Lpear-shaped flask clamped to a ring stand, (this

of 100 mL of solvent per1gof sample.Add 200 6 0.1 mL of

decant represents the first portion of petrolenes dissolved in

HPLC grade iso-octane to the sample asphalt in the 500-mL

iso-octane). Transfer the 1-L pear-shaped flask to a rotary

Erlenmeyer flask.

evaporator and distill the iso-octane off of the petrolene

9.3 In a fume hood of sufficient size to accommodate all

fraction. Return the Büchner-style fritted-glass funnel to the

required components of the apparatus and supplies used to

suction flask.

perform this procedure, assemble a reflux apparatus in accor-

9.9 Wash the asphaltenes which remain in the 500-mL

dance with the setup shown in Fig. 1. Place a stir bar into the

Erlenmeyer flask with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.