ASTM C1545-02(2020)

(Practice)Standard Practice for Dispersing Pigments and Other Materials Into Water-Based Suspensions With High Intensity Mixer

Standard Practice for Dispersing Pigments and Other Materials Into Water-Based Suspensions With High Intensity Mixer

SIGNIFICANCE AND USE

4.1 The traditional method of preparing glazes and slurries has been to add stains (pigments), stabilizers, viscosity control agents, bactericides, and so forth, to the pebble mill batch along with normal batch materials such as clay, frit, quartz, feldspar, whiting (calcium carbonate), zinc oxide, opacifier, and so forth. This method had the disadvantage of over grinding some of the materials of the batch and under grinding other materials. While part of the disadvantage could be alleviated by double or triple batching (where the pebble mill was stopped at one or two points in the cycle and one or more materials added), the practice was labor intensive and not always well controlled. Another disadvantage of the traditional method was that it was necessary to thoroughly wash out the mill between batches of different colors. An obvious advantage, however, was that small components of the batch (such as pigments) were thoroughly dispersed in the batch and even today it is necessary to use this procedure when small quantities of strongly colored pigments are to be used.

4.2 With the advent of high speed intensive mixers using a rotating shaft-mounted impeller, it is now the usual practice to add pigments, conditioners, and so forth, to the batch from the pebble mill and accomplish the same uniform dispersion as would be the case if the pigments were milled in rather than “stirred” in. In addition, the pigments tend to yield a stronger color in the glaze because they have not been over ground in the pebble mill. It is not uncommon to make a reduction in the amount of pigment needed to develop the desired color when the pigment is stirred in rather than milled in. An even greater benefit is using the “stirred in” technique is that a single large batch of a base glaze (for example, clear) can be made by milling, and individual colors developed by stirring appropriate pigments and conditioners into small amounts of the base glaze. In this way, a large pebble mill can be...

SCOPE

1.1 In preparing ceramic glazes and slurries for use, it is often necessary to add pigments to develop a desired fired color, to incorporate viscosity control agents for developing, or providing to develop the desired thickness of the glaze on the ware, to add materials which stabilize the suspension, control bacterial growth, and develop the desired hardness of the glaze on the ware to allow moving and handling before firing. While it is convenient to add these materials to the glaze or slurry in the dry form, it is often possible to use slurries where these materials are dispersed in a slurry and the slurry then added to the liquid glaze. Regardless of the state of the additions (dry or slurry), the dispersion can be done efficiently and effectively by the use of a high intensity mixer (sometimes referred to as a dissolver) and the procedure used is described here.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1545 − 02 (Reapproved 2020)

Standard Practice for

Dispersing Pigments and Other Materials Into Water-Based

Suspensions With High Intensity Mixer

This standard is issued under the fixed designation C1545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 In preparing ceramic glazes and slurries for use, it is 3.1 Definitions:

often necessary to add pigments to develop a desired fired 3.1.1 Standard terminology for ceramic whitewares and

color,toincorporateviscositycontrolagentsfordeveloping,or related products is given in Terminology C242.

providing to develop the desired thickness of the glaze on the

4. Significance and Use

ware, to add materials which stabilize the suspension, control

bacterialgrowth,anddevelopthedesiredhardnessoftheglaze

4.1 The traditional method of preparing glazes and slurries

on the ware to allow moving and handling before firing.While

has been to add stains (pigments), stabilizers, viscosity control

it is convenient to add these materials to the glaze or slurry in

agents, bactericides, and so forth, to the pebble mill batch

the dry form, it is often possible to use slurries where these

along with normal batch materials such as clay, frit, quartz,

materials are dispersed in a slurry and the slurry then added to

feldspar, whiting (calcium carbonate), zinc oxide, opacifier,

theliquidglaze.Regardlessofthestateoftheadditions(dryor

and so forth. This method had the disadvantage of over

slurry),thedispersioncanbedoneefficientlyandeffectivelyby

grinding some of the materials of the batch and under grinding

the use of a high intensity mixer (sometimes referred to as a

other materials. While part of the disadvantage could be

dissolver) and the procedure used is described here.

alleviated by double or triple batching (where the pebble mill

was stopped at one or two points in the cycle and one or more

1.2 The values stated in SI units are to be regarded as the

materials added), the practice was labor intensive and not

standard.

alwayswellcontrolled.Anotherdisadvantageofthetraditional

1.3 This standard does not purport to address all of the

method was that it was necessary to thoroughly wash out the

safety concerns, if any, associated with its use. It is the

mill between batches of different colors. An obvious

responsibility of the user of this standard to establish appro-

advantage, however, was that small components of the batch

priate safety, health, and environmental practices and deter-

(such as pigments) were thoroughly dispersed in the batch and

mine the applicability of regulatory limitations prior to use.

even today it is necessary to use this procedure when small

1.4 This international standard was developed in accor-

quantities of strongly colored pigments are to be used.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 4.2 With the advent of high speed intensive mixers using a

Development of International Standards, Guides and Recom- rotating shaft-mounted impeller, it is now the usual practice to

mendations issued by the World Trade Organization Technical add pigments, conditioners, and so forth, to the batch from the

pebble mill and accomplish the same uniform dispersion as

Barriers to Trade (TBT) Committee.

would be the case if the pigments were milled in rather than

2. Referenced Documents

“stirred” in. In addition, the pigments tend to yield a stronger

2.1 ASTM Standards:

color in the glaze because they have not been over ground in

C242Terminology of Ceramic Whitewares and Related the pebble mill. It is not uncommon to make a reduction in the

Products

amount of pigment needed to develop the desired color when

the pigment is stirred in rather than milled in.An even greater

This practice is under the jurisdiction of Committee C21 on Ceramic White-

benefit is using the “stirred in” technique is that a single large

waresandRelatedProductsandisthedirectresponsibilityofSubcommitteeC21.03

batch of a base glaze (for example, clear) can be made by

on Methods for Whitewares and Environmental Concerns.

milling,andindividualcolorsdevelopedbystirringappropriate

Current edition approved Nov. 1, 2020. Published December 2020. Originally

pigments and conditioners into small amounts of the base

approved in 2002. Last previous edition approved in 2016 as C1545–02(2016).

DOI: 10.1520/C1545-02R20.

glaze. In this way, a large pebble mill can be dedicated to clear

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

baseglazeandcleaningthemillbetweenbatchesisnotneeded.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Glaze stains frequently are treated with proprietary materials

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. which assist in dispersing the stain into the glaze.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1545 − 02 (2020)

5. Apparatus

5.1 There are two types of high intensity mixers

(dissolvers), those designed for laboratory use, where capacity

is approximately 10 to 15 litres of liquid, and those designed

for production use, where capacity can be 1200 litres or more.

Typical characteristics of both types of mixer are shown in

Table 1.

5.2 Essentialinstallationandoperating“tips”forthemixers

are:

5.2.1 The motor power must be sufficient to maintain

desired speed with specified load.

5.2.2 The floor mounted model must be rigidly secured to

the floor.

5.2.3 A cylindrical container can be used for the glaze

whether it is laboratory or production equipment. Production

equipment must be fitted with a guide which centers and holds

in place the container on the same center as the impeller. A

rectangular container can be used, provided that the side and

bottom corners are well-rounded to avoid “dead” areas in the

mixture, just as is necessary with the bottom corner of the

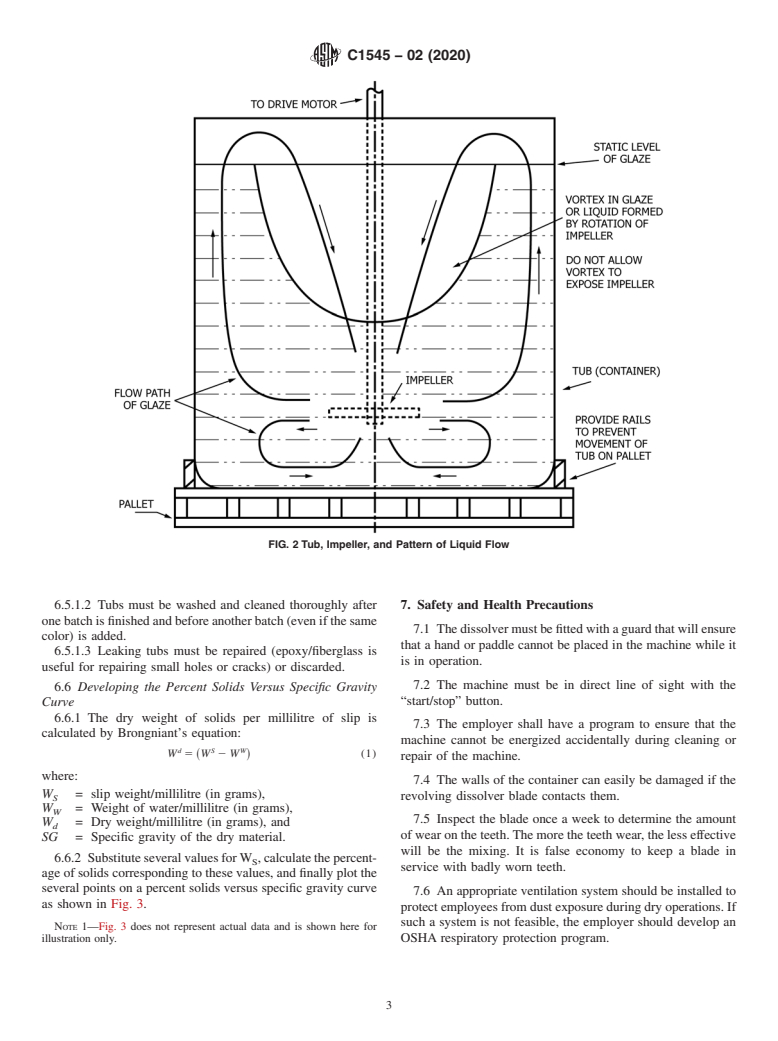

FIG. 1 Round Tub

round tub. A rectangular container has an advantage over the

round one in that there is less “spinning” of the glaze during

mixing. See Fig. 1 for details of a round tub.

6. Procedure

5.2.4 There must be a guard for the impeller (production

6.1 It is convenient to standardize on one size of container

machine) when the machine is not being used. This can be a

(for example, 1200 mm diameter × 1200 mm height).

split disk of plywood slightly larger in diameter than the

6.2 Add the desired amount of base glaze to th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.