ASTM G185-06(2012)

(Practice)Standard Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using the Rotating Cylinder Electrode

Standard Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using the Rotating Cylinder Electrode

SIGNIFICANCE AND USE

5.1 Selection of corrosion inhibitor for oil field and refinery applications involves qualification of corrosion inhibitors in the laboratory (see Guide G170). Field conditions should be simulated in the laboratory in a fast and cost-effective manner (1).4

5.2 Oil field corrosion inhibitors should provide protection over a range of flow conditions from stagnant to that found during typical production conditions. Not all inhibitors are equally effective over this range of conditions so that is important for a proper evaluation of inhibitors to test the inhibitors using a range of flow conditions.

5.3 The RCE is a compact and relatively inexpensive approach to obtaining varying hydrodynamic conditions in a laboratory apparatus. It allows electrochemical methods of estimating corrosion rates on the specimen and produces a uniform hydrodynamic state across the metal test surface. (2-21)

5.4 In this practice, a general procedure is presented to obtain reproducible results using RCE to simulate the effects of different types of coupon materials, inhibitor concentrations, oil, gas and brine compositions, temperature, pressure, and flow. Oil field fluids may often contain sand. This practice does not cover erosive effects that occur when sand is present.

SCOPE

1.1 This practice covers a generally accepted procedure to use the rotating cylinder electrode (RCE) for evaluating corrosion inhibitors for oil field and refinery applications in defined flow conditions.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G185 −06 (Reapproved 2012)

Standard Practice for

Evaluating and Qualifying Oil Field and Refinery Corrosion

1

Inhibitors Using the Rotating Cylinder Electrode

This standard is issued under the fixed designation G185; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G46 Guide for Examination and Evaluation of Pitting Cor-

rosion

1.1 This practice covers a generally accepted procedure to

G59 Test Method for Conducting Potentiodynamic Polariza-

use the rotating cylinder electrode (RCE) for evaluating

tion Resistance Measurements

corrosion inhibitors for oil field and refinery applications in

G96 Guide for Online Monitoring of Corrosion in Plant

defined flow conditions.

Equipment (Electrical and Electrochemical Methods)

1.2 The values stated in SI units are to be regarded as

G102 Practice for Calculation of Corrosion Rates and Re-

standard. The values given in parentheses are for information

lated Information from Electrochemical Measurements

only.

G106 Practice for Verification of Algorithm and Equipment

1.3 This standard does not purport to address all of the for Electrochemical Impedance Measurements

safety concerns, if any, associated with its use. It is the

G111 Guide for Corrosion Tests in High Temperature or

responsibility of the user of this standard to establish appro- High Pressure Environment, or Both

priate safety and health practices and determine the applica-

G170 Guide for Evaluating and Qualifying Oilfield and

bility of regulatory limitations prior to use. Refinery Corrosion Inhibitors in the Laboratory

2. Referenced Documents

3. Terminology

2

2.1 ASTM Standards:

3.1 The terminology used throughout shall be in accordance

D1141 Practice for the Preparation of Substitute Ocean

with Terminologies G15 and D4410 and Guide G170.

Water

D4410 Terminology for Fluvial Sediment

4. Summary of Practice

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

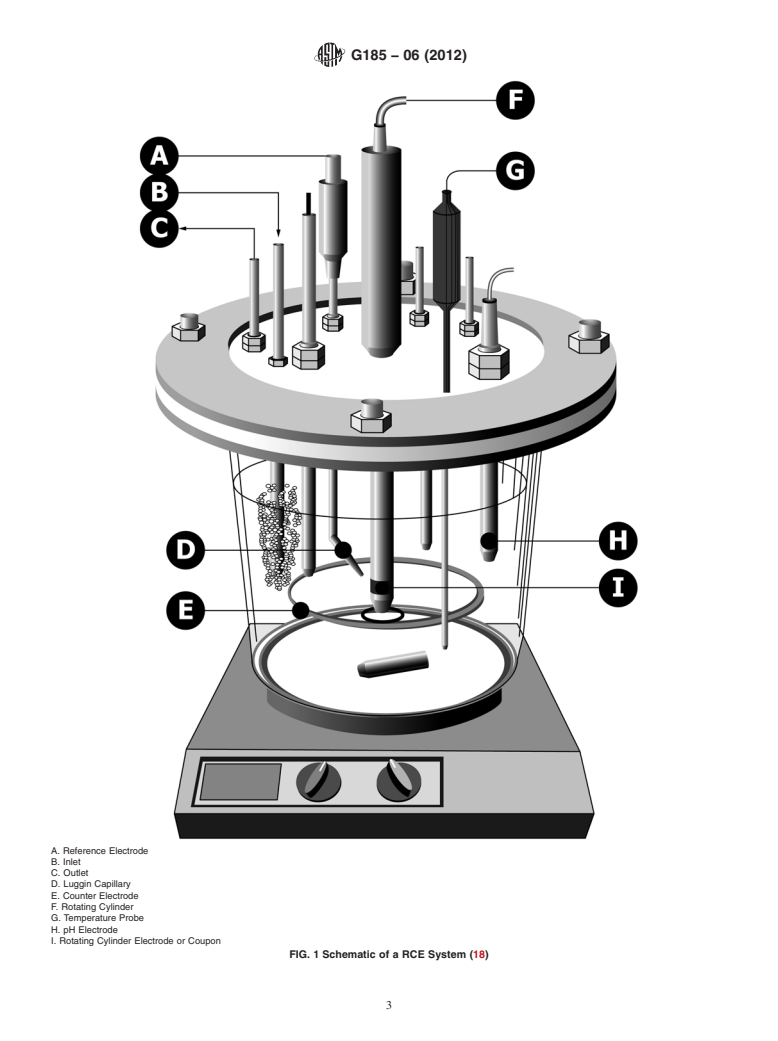

4.1 This practice provides a method of evaluating corrosion

sion Test Specimens

inhibitor efficiency in a RCE apparatus. The method uses a

G3 Practice for Conventions Applicable to Electrochemical

well-defined rotating specimen set up and mass loss or elec-

Measurements in Corrosion Testing

trochemical measurements to determine corrosion rates in a

G5 Reference Test Method for Making Potentiodynamic

laboratory apparatus. Measurements are made at a number of

Anodic Polarization Measurements

rotating rates to evaluate the inhibitor performance under

G15 Terminology Relating to Corrosion and CorrosionTest-

increasingly severe hydrodynamic conditions.

3

ing (Withdrawn 2010)

G16 Guide for Applying Statistics to Analysis of Corrosion

5. Significance and Use

Data

5.1 Selection of corrosion inhibitor for oil field and refinery

G31 Guide for Laboratory Immersion Corrosion Testing of

applicationsinvolvesqualificationofcorrosioninhibitorsinthe

Metals

laboratory (see Guide G170). Field conditions should be

simulated in the laboratory in a fast and cost-effective manner

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

4

(1).

of Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory

Corrosion Tests.

5.2 Oil field corrosion inhibitors should provide protection

Current edition approved Nov. 1, 2012. Published November 2012. Originally

over a range of flow conditions from stagnant to that found

approved in 2006. Last previous edition approved in 2006 as G185 – 06. DOI:

during typical production conditions. Not all inhibitors are

10.1520/G0185-06R12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

equally effective over this range of conditions so that is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

4

3

The last approved version of this historical standard is referenced on The boldface numbers in parentheses refer to the list of references at the end of

www.astm.org. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G185−06 (2012)

important for a proper evaluation of inhibitors to test the electrode can be attached. The other end of the rod is attached

inhibitors using a range of flow conditions. directly to the rotating unit, through which the electrical

connection is made.

5.3 The RCE is a compact and relatively inexpensive

approach to obtaining varying hydrodynamic conditions in a 6.6 After attaching the specimen to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.