ASTM D5238-98(2003)

(Test Method)Standard Test Method for Smoldering Combustion Potential of Cotton-Based Batting

Standard Test Method for Smoldering Combustion Potential of Cotton-Based Batting

SIGNIFICANCE AND USE

This test method provides a means for evaluating the smoldering combustion potential of cotton-based batting for use in mattresses and upholstered furniture. The degree of correlation between the results of this test of a component material and actual end-use products has not been determined fully.

In this procedure, the specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it may not be possible by or from this test method to predict changes in the fire test response characteristics measured. The results are therefore valid only for the fire test exposure conditions described in this procedure.

In the case of a dispute arising from differences in the reported test results using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine whether a statistical bias exists between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student’t-test for unpaired data and an acceptable probability level chosen by the two parties before testing began. If a bias is found, either its cause must be determined and corrected, or the purchaser and supplier must agree to interpret future test results in light of the known bias.

SCOPE

1.1 This test method covers the determination of smoldering combustion potential within cotton-based batting intended for use in mattresses and upholstered furniture. This test method should not be used to evaluate batting containing less than 75 % cotton by weight, and it is intended to be used primarily as a quality control tool.

1.2 This test method should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or risk of materials, products, or assemblies under actual fire conditions. However, the results of this test may be used as elements of a fire risk assessment that takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.3 Inadequate consideration of a subsystem, such as cotton batting, to resist smoldering is frequently the reason that finish systems fail fire and smolder resistance tests in mattresses and upholstered furniture. This test method may be used to evaluate this smolder resistance in the subsystem of cotton batting used in such products. The purpose of this test method is to aid end users in better determining the potential of cotton batting components to resist smoldering. It is recommended that those using this test method be familiar with cotton batting production and the use of cotton batting in mattresses and upholstered furniture.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5238–98 (Reapproved 2003)

Standard Test Method for

Smoldering Combustion Potential of Cotton-Based Batting

This standard is issued under the fixed designation D5238; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 Thistestmethodcoversthedeterminationofsmoldering 2.1 ASTM Standards:

combustion potential within cotton-based batting intended for D123 Terminology Relating to Textiles

use in mattresses and upholstered furniture. This test method D1776 Practice for Conditioning and Testing Textiles

should not be used to evaluate batting containing less than D2258 Practice for Sampling Yarn for Testing

75 % cotton by weight, and it is intended to be used primarily D4391 Terminology Relating to The Burning Behavior of

as a quality control tool. Textiles

1.2 Thistestmethodshouldbeusedtomeasureanddescribe E176 Terminology of Fire Standards

the properties of materials, products, or assemblies in response 2.2 Government Standard:

to heat and flame under controlled laboratory conditions and 16 CFR Part 1632, Standard for the Flammability of Mat-

shouldnotbeusedtodescribeorappraisethefirehazardorrisk tresses and Mattress Pads (FF 4-72 Amended)

of materials, products, or assemblies under actual fire condi-

3. Terminology

tions. However, the results of this test may be used as elements

ofafireriskassessmentthattakesintoaccountallofthefactors 3.1 Definitions—For definitions of terms relating to burn-

ing behavior, refer to Terminology D4391. For definitions of

that are pertinent to an assessment of the fire hazard of a

particular end use. other textile terms, refer to Terminology D123.

3.2 Description of Term Specific to This Standard:

1.3 Inadequate consideration of a subsystem, such as cotton

batting, to resist smoldering is frequently the reason that finish 3.2.1 batting, n—a textile filling material consisting of a

continuous web of fibers formed by carding, garnetting, air

systems fail fire and smolder resistance tests in mattresses and

upholsteredfurniture.Thistestmethodmaybeusedtoevaluate layering, or other means.

3.2.1.1 Discussion—In the bedding, furniture, and futon

this smolder resistance in the subsystem of cotton batting used

industries, batting is made from a blend of fibers consisting

in such products. The purpose of this test method is to aid end

users in better determining the potential of cotton batting primarily of cotton.

components to resist smoldering. It is recommended that those

4. Summary of Test Method

using this test method be familiar with cotton batting produc-

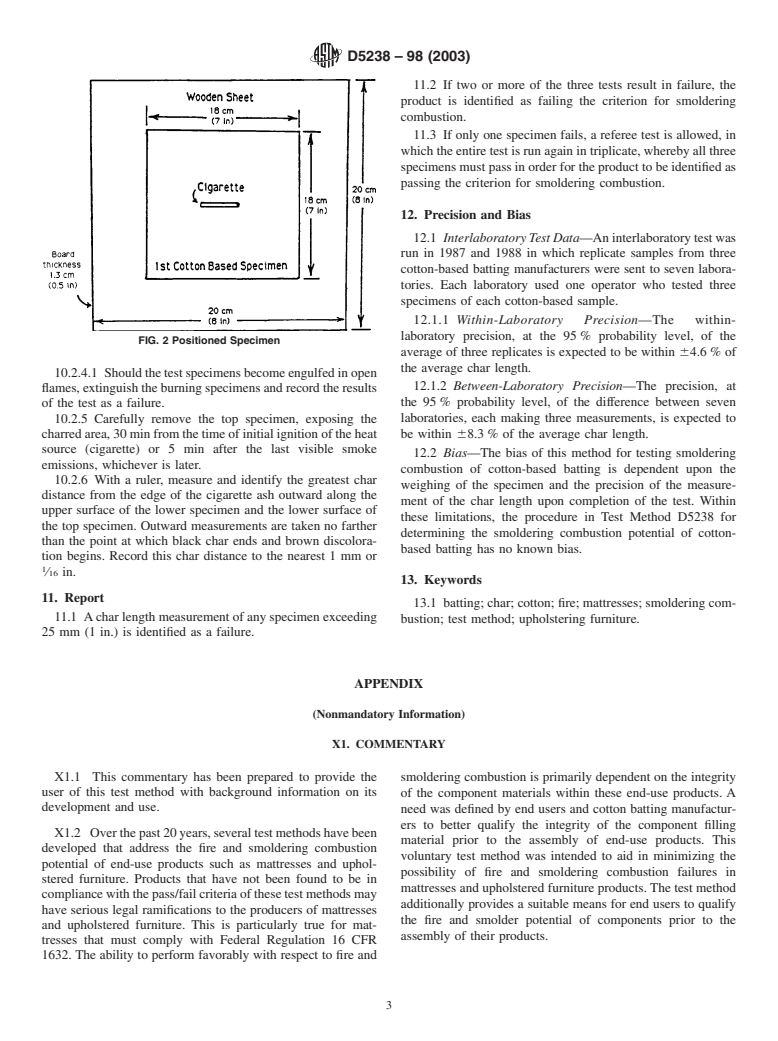

4.1 A controlled heat source is positioned between two

tion and the use of cotton batting in mattresses and upholstered

identical specimens of cotton batting. The heat source and

furniture.

specimens remain undisturbed until the specimens either are

1.4 The values stated in SI units are to be regarded as the

consumedorarenolongerundergoingsmolderingcombustion.

standard. The values given in parentheses are for information

Theresultingoutwardchardistancefromtheinitialheatsource

only.

is determined.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 This test method provides a means for evaluating the

priate safety and health practices and determine the applica-

smoldering combustion potential of cotton-based batting for

bility of regulatory limitations prior to use.

1 2

This test method is under the jurisdiction ofASTM Committee D13 onTextiles For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D13.52 on Flammability. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Sept. 10, 1998. Published December 1998. Originally Standards volume information, refer to the standard’s Document Summary page on

published as D5238 – 92. Last previous edition D5238 – 92. DOI: 10.1520/D5238- the ASTM website.

98R03. Federal Register, Vol 49, No. 197, Wednesday, October 10, 1984.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5238–98 (2003)

use in mattresses and upholstered furniture. The degree of

correlation between the results of this test of a component

material and actual end-use products has not been determined

fully.

5.2 In this procedure, the specimens are subjected to one or

more specific sets of laboratory test conditions. If different test

conditions are substituted or the end-use conditions are

changed, it may not be possible by or from this test method to

predict changes in the fire test response characteristics mea-

sured. The results are therefore valid only for the fire test

exposure conditions described in this procedure.

5.3 In the case of a dispute arising from differences in the

reported test results using this test method for acceptance

testing of commercial shipments, the purchaser and the sup-

plier should conduct comparative tests to determine whether a

statistical bias exists between their laboratories. Competent

statistical assistance is recommended for the investigation of

bias.As a minimum, the two parties should take a group of test

specimens that are as homogeneous as possible and that are

from a lot of material of the type in question. The test

specimens should then be randomly assigned in equal numbers

to each laboratory for testing.The average results from the two

laboratories should be compared using Student’s t-test for

unpaireddataandanacceptableprobabilitylevelchosenbythe

two parties before testing began. If a bias is found, either its

cause must be determined and corrected, or the purchaser and

FIG. 1 Draft Barrier

supplier must agree to interpret future test results in light of the

known bias.

8.2 Weigh and record the initial weights of each specimen.

6. Apparatus and Materials Each cotton-based specimen may weigh not less than 54 g (1.9

oz) and not more than 57 g (2 oz).

6.1 Balance, 200-g capacity open pan, with 0.1-g sensitiv-

ity.

9. Conditioning

6.2 Draft Barrier, as shown in Fig. 1.

9.1 If the as-received sample has a moisture content above

6.3 Test Room, draft-protected and equipped with a suitable

10 %, follow the preconditioning and conditioning procedures

system for exhausting combustion emissions produced during

as specified in Practice D1776 prior to testing.

testing.

9.2 Ithasbeenfoundthatsampleshavingamoisturecontent

6.4 Heat Source—Pall Mall cigarettes without filters or

of 10 % and below do not materially affect the results of this

equal, each measuring 85 6 2 mm (3.4 6 0.1 in.) in length and

test method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.