ASTM D910-99

(Specification)Standard Specification for Aviation Gasolines

Standard Specification for Aviation Gasolines

SCOPE

1.1 This specification is for the use of purchasing agencies in formulating specifications for purchases of aviation gasoline under contract.

1.2 This specification defines specific types of aviation gasolines for civil use. It does not include all gasolines satisfactory for reciprocating aviation engines. Certain equipment or conditions of use may permit a wider, or require a narrower, range of characteristics than is shown by this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 910 – 99 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Aviation Gasolines

This standard is issued under the fixed designation D 910; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 1266 Test Method for Sulfur in Petroleum Products

(Lamp Method)

1.1 This specification is intended primarily for use by

D 1298 Density, Relative Density (Specific Gravity), or API

purchasing agencies in formulating specifications for purchases

Gravity of Crude Petroleum and Liquid Petroleum Prod-

of aviation gasoline under contract.

ucts by Hydrometer Method

1.2 This specification defines specific types of aviation

D 2386 Test Method for Freezing Point of Aviation Fuels

gasolines for civil use. It does not include all gasolines

D 2392 Test Method for Color of Dyed Aviation Gasolines

satisfactory for reciprocating aviation engines. Certain equip-

D 2622 Test Method for Sulfur in Petroleum Products by

ment or conditions of use may permit a wider, or require a

X-Ray Spectrometry

narrower, range of characteristics than is shown by this

D 2624 Test Method for Electrical Conductivity of Aviation

specification.

and Distillate Fuels

2. Referenced Documents D 2700 Test Method for Knock Characteristics of Motor

and Aviation Fuels by the Motor Method

2.1 ASTM Standards:

D 3338 Test Method for Estimation of Heat of Combustion

D 86 Test Method for Distillation of Petroleum Products

of Aviation Fuels

D 93 Test Methods for Flash-Point by Pensky-Martens

D 3341 Test Method for Lead in Gasoline—Iodine

Closed Cup Tester

Monochloride Method

D 130 Test Method for Detection of Copper Corrosion from

D 4052 Test Method for Density and Relative Density of

Petroleum Products by the Copper Strip Tarnish Test

Liquids by Digital Density Meter

D 156 Test Method for Saybolt Color of Petroleum Prod-

D 4057 Practice for Manual Sampling of Petroleum and

ucts (Saybolt Chromometer Method)

Petroleum Products

D 323 Test Method for Vapor Pressure of Petroleum Prod-

D 4171 Specification for Fuel System Icing Inhibitors

ucts (Reid Method)

D 4306 Practice for Aviation Fuel Sampling Containers for

D 357 Method of Test for Knock Characteristics of Motor

Tests Affected by Trace Contamination

Fuels Below 100 Octane Number by the Motor Method

D 4529 Test Method for Estimation of Net Heat of Com-

D 381 Test Method for Existent Gum in Fuels by Jet

bustion of Aviation Fuels

Evaporation

D 4809 Test Method for Heat of Combustion of Liquid

D 614 Method of Test for Knock Characteristics of Aviation

Hydrocarbon Fuels by Bomb Calorimeter (Intermediate

Fuels by the Aviation Method

Precision Method)

D 873 Test Method for Oxidation Stability of Aviation Fuels

D 4865 Guide for the Generation and Dissipation of Static

(Potential Residue Method)

Electricity in Petroleum Fuel Systems

D 909 Test Method for Knock Characteristics of Aviation

D 5006 Test Method for Determination of Fuel System

Gasolines by the Supercharge Method

Icing Inhibitor (Ether Type) in Aviation Fuels

D 1094 Test Method for Water Reaction of Aviation Fuels

D 5059 Test Method for Lead in Gasoline by X-Ray Spec-

troscopy

D 5190 Test Method for Vapor Pressure of Petroleum Prod-

This specification is under the jurisdiction of ASTM Committee D-2 on 7

ucts (Automatic Method)

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D 5191 Test Method for Vapor Pressure of Petroleum Prod-

D02.J on Aviation Fuels.

ucts (Mini Method)

Current edition approved June 10, 1999. Published August 1999. Originally

published as D 910 – 47 T replacing former D 615. Last previous edition

E 29 Practice for Using Significant Digits in Test Data to

D 910 – 98.

Annual Book of ASTM Standards, Vol 05.01.

Discontinued 1969. Replaced by D 2700.

4 Annual Book of ASTM Standards, Vol 05.02.

Discontinued; see 1970 Annual Book of ASTM Standards.

5 Annual Book of ASTM Standards, Vol 05.03.

Annual Book of ASTM Standards, Vol 05.04.

D 910

Determine Conformance with Specifications lead and sufficient ethylene dibromide to provide two bromine

atoms per atom of lead. The balance shall contain no added

3. Terminology

ingredients other than kerosine, an approved oxidation inhibi-

tor and blue dye, as specified herein. The maximum concen-

3.1 Definitions:

tration limit for each grade of gasoline is specified in Table 1.

3.1.1 aviation gasoline, n—gasoline possessing specific

6.2.1.1 If mutually agreed upon by the fuel producer and

properties suitable for fueling aircraft powered by reciprocat-

additive vendor, tetraethyl lead antiknock mixture may be

ing spark ignition engines.

diluted with 20m%ofa mixed aromatic solvent having a

3.1.1.1 Discussion—Principal properties include volatility

minimum flash point of 60°C according to Test Method D 93

limits, stability, detonation-free performance in the engine for

when the product is to be handled in cold climates. The TEL

which it is intended and suitability for low temperature

content of the dilute product is reduced to 49 m%, so that the

performance.

amount of antiknock additive must be adjusted to achieve the

4. General

necessary lead level. The dilute product still delivers two

bromine atoms per atom of lead.

4.1 This specification, unless otherwise provided, prescribes

6.2.2 Dyes—The maximum concentration limits in each

the required properties of aviation gasoline at the time and

grade of gasoline are specified in Table 1.

place of delivery.

6.2.2.1 The only blue dye which shall be present in the

5. Classification

finished gasoline shall be essentially 1,4-

dialkylaminoanthraquinone.

5.1 Three grades of aviation gasoline are provided, known

6.2.2.2 The only yellow dyes which shall be present in the

as:

finished gasoline shall be essentially

Grade 80

p-diethylaminoazobenzene (Color Index No. 11021) or 1,3-

Grade 100

Grade 100LL

benzenediol 2,4-bis [(alkylphenyl)azo-].

6.2.2.3 The only red dye which shall be present in the

NOTE 1—The above grade names are based on their octane/

performance numbers as measured by the now obsolete Test Method

finished gasoline shall be essentially alkyl derivatives of

D 614 Knock Characteristics of Aviation Fuels by the Aviation Method

azobenzene-4-azo-2-naphthol.

(Discontinued 1970). A table for converting octane/performance numbers

6.3 Additives—Optional, may be added to each grade of

obtained by the Test Method D 2700 Motor Method into aviation ratings

aviation gasoline in the amount and of the composition

was last published in Specification D 910 – 94 in the 1995 Annual Book of

specified in the following list of approved materials. The

ASTM Standards, Vol 05.01.

quantities and types must be declared by the manufacturer and

5.2 Grades 100 and 100LL represent two aviation gasolines

agreed to by the purchaser.

identical in anti-knock quality but differing in maximum lead

6.3.1 Antioxidants—The following oxidation inhibitors may

content and color. The color identifies the difference for

be added to the gasoline separately or in combination in total

engines that have a low tolerance to lead.

concentration not to exceed 12 mg of inhibitor (not including

NOTE 2—Listing of and requirements for Avgas Grades 91/96, 108/135 weight of solvent) per litre of fuel.

and 115/145 appeared in the 1967 version of this specification. US

6.3.1.1 2,6-ditertiary butyl-4-methylphenol.

Military Specification MIL-G-5572F, dated January 24, 1978 (withdrawn

6.3.1.2 2,4-dimethyl-6-tertiary butylphenol.

March 22, 1988), also covers grade 115/145 aviation gasoline and is

6.3.1.3 2,6-ditertiary butylphenol.

available as a research report from ASTM Headquarters: Request

6.3.1.4 75 % min 2,6-ditertiary butylphenol plus 25 % max

RR:D02-1255.

mixed tertiary and tritertiary butylphenols.

5.3 Although the grade designations show only a single

6.3.1.5 75 % min di- and tri-isopropyl phenols plus 25 %

octane rating for each grade, each grade must meet a minimum

max di- and tri-tertiary butylphenols.

lean mixture motor rating and a minimum rich mixture

6.3.1.6 72 % min 2,4-dimethyl-6-tertiary butylphenol plus

super-charge rating (see X1.2.2).

28 % max monomethyl and dimethyl tertiary butylphenols.

6.3.1.7 N,N8-di-isopropyl-para-phenylenediamine.

6. Materials and Manufacture

6.3.1.8 N,N8-di-secondary-butyl-para-phenylenediamine.

6.1 Aviation gasoline, except as otherwise specified in this

6.3.2 Fuel System Icing Inhibitor (FSII)— One of the

specification, shall consist of blends of refined hydrocarbons

following may be used.

derived from crude petroleum, natural gasoline, or blends,

6.3.2.1 Isopropyl Alcohol (IPA, propan-2-ol), conforming to

thereof, with synthetic hydrocarbons or aromatic hydrocar-

the requirements of Specification D 4171 (Type II). May be

bons, or both.

used in concentrations recommended by the aircraft manufac-

6.2 Additives—Mandatory, shall be added to each grade of

turer when required by the aircraft owner/operator.

aviation gasoline in the amount and of the composition

NOTE 3—Addition of isopropyl alcohol (IPA) may reduce knock ratings

specified in the following list of approved materials.

below minimum specification values (see Appendix X1.2.4).

6.2.1 Tetraethyl Lead, shall be added in the form of an

6.3.2.2 Di-Ethylene Glycol Monomethyl Ether (Di-EGME),

antiknock mixture containing not less than 61m%of tetraethyl

Guidelines for the approval or disapproval of additives are available from

Annual Book of ASTM Standards, Vol 14.02. ASTM Headquarters. Request RR:D02-1125.

D 910

A

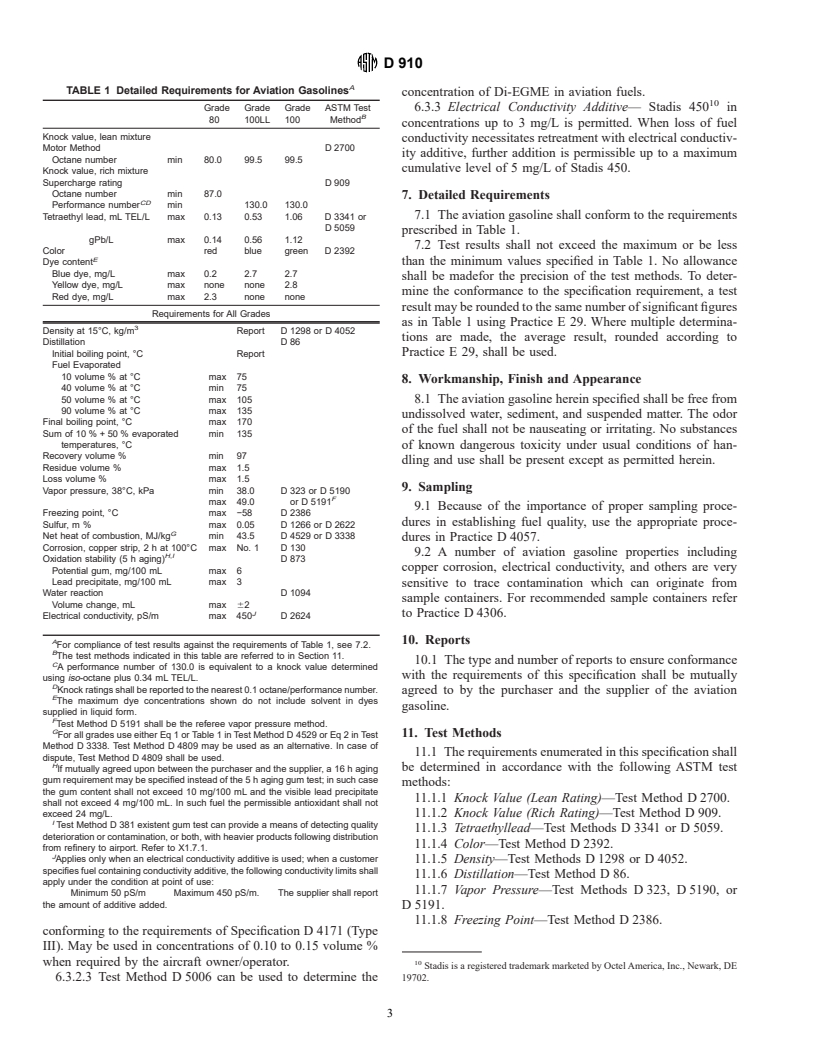

TABLE 1 Detailed Requirements for Aviation Gasolines

concentration of Di-EGME in aviation fuels.

Grade Grade Grade ASTM Test 6.3.3 Electrical Conductivity Additive— Stadis 450 in

B

80 100LL 100 Method

concentrations up to 3 mg/L is permitted. When loss of fuel

Knock value, lean mixture

conductivity necessitates retreatment with electrical conductiv-

Motor Method D 2700

ity additive, further addition is permissible up to a maximum

Octane number min 80.0 99.5 99.5

cumulative level of 5 mg/L of Stadis 450.

Knock value, rich mixture

Supercharge rating D 909

Octane number min 87.0

7. Detailed Requirements

CD

Performance number min 130.0 130.0

Tetraethyl lead, mL TEL/L max 0.13 0.53 1.06 D 3341 or 7.1 The aviation gasoline shall conform to the requirements

D 5059

prescribed in Table 1.

gPb/L max 0.14 0.56 1.12

7.2 Test results shall not exceed the maximum or be less

Color red blue green D 2392

E

than the minimum values specified in Table 1. No allowance

Dye content

Blue dye, mg/L max 0.2 2.7 2.7

shall be madefor the precision of the test methods. To deter-

Yellow dye, mg/L max none none 2.8

mine the conformance to the specification requirement, a test

Red dye, mg/L max 2.3 none none

result may be rounded to the same number of significant figures

Requirements for All Grades

as in Table 1 using Practice E 29. Where multiple determina-

Density at 15°C, kg/m Report D 1298 or D 4052

tions are made, the average result, rounded according to

Distillation D 86

Initial boiling point, °C Report Practice E 29, shall be used.

Fuel Evaporated

10 volume % at °C max 75

8. Workmanship, Finish and Appearance

40 volume % at °C min 75

50 volume % at °C max 105

8.1 The aviation gasoline herein specified shall be free from

90 volume % at °C max 135

undissolved water, sediment, and suspended matter. The odor

Final boiling point, °C max 170

of the fuel shall not be nauseating or irritating. No substances

Sum of 10%+50% evaporated min 135

temperatures, °C of known dangerous toxicity under usual conditions of han-

Recovery volume % min 97

dling and use shall be present except as permitted herein.

Residue volume % max 1.5

Loss volume % max 1.5

9. Sampling

Vapor pressure, 38°C, kPa min 38.0 D 323 or D 5190

F

max 49.0 or D 5191

9.1 Because of the importance of proper sampling proce-

Freezing point, °C max −58 D 2386

dures in establishing fuel quality, use the appropriate proce-

Sulfur, m % max 0.05 D 1266 or D 2622

G

Net heat of combustion, MJ/kg min 43.5 D 4529 or D 3338

dures in Practice D 4057.

Corrosion, copper strip,2hat 100°C max No. 1 D 130

9.2 A number of aviation gasoline properties including

H,I

Oxidation stability (5 h aging) D 873

copper corrosion, electrical conductivity, and others are very

Potential gum, mg/100 mL max 6

Lead precipitate, mg/100 mL max 3

sensitive to trace contamination which can originate from

Water reaction D 1094

sample containers. For recommended sample containers refer

Volume change, mL max 62

J

to Practice D 4306.

Electrical conductivity, pS/m max 450 D 2624

A

10. Reports

For compliance of test results against the requirements of Table 1, see 7.2.

B

The test methods indicated in this table are referred to in Section 11.

10.1 The type and number of reports to ensure conformance

C

A performance number of 130.0 is equivalent to a knock value determined

with the requirements of this specification shall be mutually

using iso-octane plus 0.34 mL TEL/L.

D

Knock ratings shall be reported to the nearest 0.1 octane/performance number.

agreed to by the purchaser and the supplier of the aviation

E

The maximum dye concentrations shown do not include solvent in dyes

gasoline.

supplied in liquid form.

F

Test Method D 5191 shall be the referee vapor pressure method.

G

11. Test Methods

For all grades use either Eq 1 or Table 1 in Test Method D 4529 or Eq 2 in Test

Method D 3338. Test Method D 4809 may be used as an alternative. In case of

11.1 The requirements enumerated in this specification shall

dispute, Test Method D 4809 shall be used.

H

If mutually agreed upon between the purchaser and the supplier, a 16 h aging be determined in accordance with the following ASTM test

gum requirement may be specified instead of the 5 h aging gum test; in such case

methods:

the gum content shall not exceed 10 mg/100 mL and the visible lead precipitate

11.1.1 Knock Value (Lean Rating)—Test Method D 2700.

shall not exceed 4 mg/100 mL. In such fuel the permissible antioxidant shall not

exceed 24 mg/L. 11.1.2 Knock Value (Rich Rating)—Test Method D 909.

I

Test Method D 381 existent gum test can provide a means of detecting quality

11.1.3 Tetraethyllead—Test Methods D 3341 or D 5059.

deterioration or contamination, or both, with heavier products following distribution

11.1.4 Color—Test Method D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.