ASTM D4927-20

(Test Method)Standard Test Methods for Elemental Analysis of Lubricant and Additive Components—Barium, Calcium, Phosphorus, Sulfur, and Zinc by Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

Standard Test Methods for Elemental Analysis of Lubricant and Additive Components—Barium, Calcium, Phosphorus, Sulfur, and Zinc by Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

SIGNIFICANCE AND USE

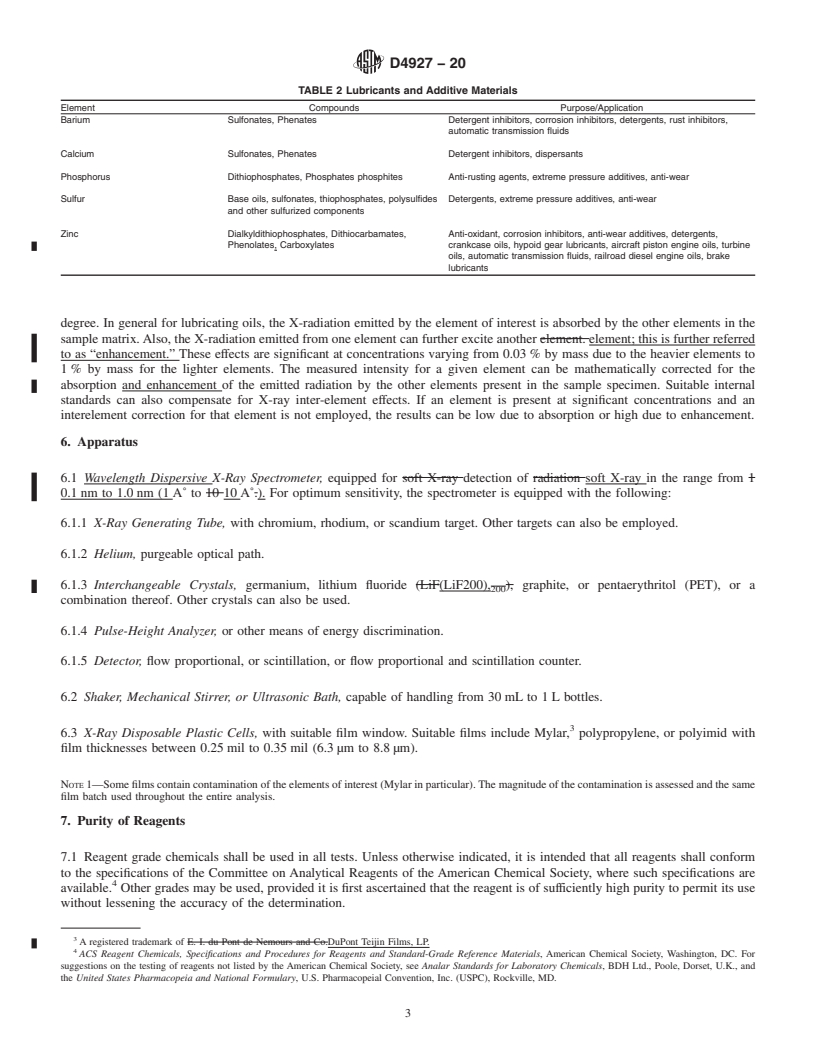

4.1 Some oils are formulated with organo-metallic additives which act as detergents, antioxidants, antiwear agents, and so forth. Some of these additives contain one or more of these elements: barium, calcium, phosphorus, sulfur, and zinc. These test methods provide a means of determining the concentration of these elements which in turn provides an indication of the additive content of these oils.

4.2 Several additive elements and their compounds are added to the lubricating oils to give beneficial performance (see Table 2).

SCOPE

1.1 These test methods cover the determination of barium, calcium, phosphorus, sulfur, and zinc in unused lubricating oils at element concentration ranges shown in Table 1. The range can be extended to higher concentrations by dilution of sample specimens. Additives can also be determined after dilution. Two different methods are presented in these test methods.

1.2 Test Method A (Internal Standard Procedure)—Internal standards are used to compensate for interelement effects of X-ray excitation and fluorescence (see Sections 8 through 13).

1.3 Test Method B (Mathematical Correction Procedure)—The measured X-ray fluorescence intensity for a given element is mathematically corrected for potential interference from other elements present in the sample (see Sections 14 through 19).

1.4 The preferred concentration units are mass % barium, calcium, phosphorus, sulfur, or zinc.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4927 − 20

Standard Test Methods for

Elemental Analysis of Lubricant and Additive Components—

Barium, Calcium, Phosphorus, Sulfur, and Zinc by

1

Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

This standard is issued under the fixed designation D4927; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 These test methods cover the determination of barium,

D6299 Practice for Applying Statistical Quality Assurance

calcium,phosphorus,sulfur,andzincinunusedlubricatingoils

and Control Charting Techniques to Evaluate Analytical

at element concentration ranges shown in Table 1. The range

Measurement System Performance

can be extended to higher concentrations by dilution of sample

specimens. Additives can also be determined after dilution.

3. Summary of the Test Methods

Two different methods are presented in these test methods.

3.1 Asample specimen is placed in the X-ray beam and the

1.2 Test Method A (Internal Standard Procedure)—Internal

intensity of the appropriate fluorescence lines of barium,

standards are used to compensate for interelement effects of

calcium,phosphorus,sulfur,andzincaremeasured.Instrument

X-ray excitation and fluorescence (see Sections 8 through 13).

response factors related to the concentration of standards

1.3 Test Method B (Mathematical Correction Procedure)—

enable the determination of the concentration of elements in

The measured X-ray fluorescence intensity for a given element

thetestedsamplespecimens.Enhancementorabsorptionofthe

is mathematically corrected for potential interference from

X-ray fluorescence of a given element by an interfering

other elements present in the sample (see Sections 14 through

element in the sample may occur. Two test methods (A and B)

19).

are described for compensating any interference effect.

1.4 The preferred concentration units are mass % barium,

3.2 Test Method A (Internal Standard Procedure)—Internal

calcium, phosphorus, sulfur, or zinc.

standards are used with the standards and sample specimens to

compensate for the potential interelement effects.

1.5 This standard does not purport to address all of the

3.2.1 Barium, Calcium, Phosphorus, and Zinc—A sample

safety concerns, if any, associated with its use. It is the

that has been blended with a single internal standard solution

responsibility of the user of this standard to establish appro-

(containing tin or titanium for barium and calcium, zirconium

priate safety, health, and environmental practices and deter-

for phosphorus, and nickel for zinc) is poured into an X-ray

mine the applicability of regulatory limitations prior to use.

cell. Total net counts (peak intensity – background) for each

1.6 This international standard was developed in accor-

element and its respective internal standard are collected at

dance with internationally recognized principles on standard-

their appropriate wavelengths. The ratios between elemental

ization established in the Decision on Principles for the

and internal standard counts are calculated and converted into

Development of International Standards, Guides and Recom-

barium, calcium, phosphorus, or zinc concentrations, or a

mendations issued by the World Trade Organization Technical

combination thereof, from calibration curves.

Barriers to Trade (TBT) Committee.

3.2.2 Sulfur—A sample is mixed with a lead internal stan-

dard solution and analyzed as described in 3.2.1.

1

These test methods are under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and are the direct responsibility

2

of Subcommittee D02.03 on Elemental Analysis. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2020. Published January 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1989. Last previous edition approved in 2020 as D4927 – 15 (2020). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D4927-20. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4927 − 20

TABLE 1 Range of A

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4927 − 15 (Reapproved 2020) D4927 − 20

Standard Test Methods for

Elemental Analysis of Lubricant and Additive Components—

Barium, Calcium, Phosphorus, Sulfur, and Zinc by

1

Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

This standard is issued under the fixed designation D4927; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 These test methods cover the determination of barium, calcium, phosphorus, sulfur, and zinc in unused lubricating oils at

element concentration ranges shown in Table 1. The range can be extended to higher concentrations by dilution of sample

specimens. Additives can also be determined after dilution. Two different methods are presented in these test methods.

1.2 Test Method A (Internal Standard Procedure)—Internal standards are used to compensate for interelement effects of X-ray

excitation and fluorescence (see Sections 8 through 13).

1.3 Test Method B (Mathematical Correction Procedure)—The measured X-ray fluorescence intensity for a given element is

mathematically corrected for potential interference from other elements present in the sample (see Sections 14 through 19).

1.4 The preferred concentration units are mass % barium, calcium, phosphorus, sulfur, or zinc.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

3. Summary of the Test Methods

3.1 A sample specimen is placed in the X-ray beam and the intensity of the appropriate fluorescence lines of barium, calcium,

1

These test methods are under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and are the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

Current edition approved May 1, 2020Dec. 1, 2020. Published June 2020January 2021. Originally approved in 1989. Last previous edition approved in 20152020 as

D4927 – 15.D4927 – 15 (2020). DOI: 10.1520/D4927-15R20.10.1520/D4927-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4927 − 20

TABLE 1 Range of Applicability

Element Range, Mass %

Barium 0.04-8.5

Calcium 0.01-1.0

Phosphorus 0.01-0.5

Sulfur 0.1-4.0

Zinc 0.01-0.6

phosphorus, sulfur, and zinc are measured. Instrument response factors related to the concentration of standards enable the

determination of the concentration of elements in the tested sample specimens. Enhancement or depressionabsorption of the X-ray

fluorescence of a given element by an interfering element in the sample may occur. Two test methods (A and B) are described for

compensating any interference effect.

3.2 Test Method A (Internal Standard Procedure)—Internal standards are used with the standards and sample specimens to

compensate for the potential interelement effects.

3.2.1 Barium, Calcium, Phosphorus, and Zinc—A sample specimen that has been blended with a single internal standard solution

(containing tin or titanium for barium and calcium, zirconium for phosphorus, and nickel for zinc) is poured into an X-ray cell.

Total net counts (peak intensity—background) intensity – background) for each element and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.