ASTM D6732-04(2015)

(Test Method)Standard Test Method for Determination of Copper in Jet Fuels by Graphite Furnace Atomic Absorption Spectrometry

Standard Test Method for Determination of Copper in Jet Fuels by Graphite Furnace Atomic Absorption Spectrometry

SIGNIFICANCE AND USE

5.1 At high temperatures aviation turbine fuels can oxidize and produce insoluble deposits that are detrimental to aircraft propulsion systems. Very low copper concentrations (in excess of 50 μg/kg) can significantly accelerate this thermal instability of aviation turbine fuel. Naval shipboard aviation fuel delivery systems contain copper-nickel piping, which can increase copper levels in the fuel. This test method may be used for quality checks of copper levels in aviation fuel samples taken on shipboard, in refineries, and at fuel storage depots.

SCOPE

1.1 This test method covers the determination of copper in jet fuels in the range of 5 μg/kg to 100 μg/kg using graphite furnace atomic absorption spectrometry. Copper contents above 100 μg/kg may be determined by sample dilution with kerosine to bring the copper level into the aforementioned method range. When sample dilution is used, the precision statements do not apply.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6732 − 04 (Reapproved 2015)

Standard Test Method for

Determination of Copper in Jet Fuels by Graphite Furnace

1

Atomic Absorption Spectrometry

This standard is issued under the fixed designation D6732; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 transmittance, T, n—the ratio of the radiant power

transmitted by a material to the radiant power incident upon it.

1.1 This test method covers the determination of copper in

jet fuels in the range of 5 µg⁄kg to 100 µg⁄kg using graphite 3.2 Definitions of Terms Specific to This Standard:

furnace atomic absorption spectrometry. Copper contents 3.2.1 absorbance, A, n—the logarithm to the base 10 of the

above 100 µg⁄kg may be determined by sample dilution with ratio of the reciprocal of the transmittance, T:

kerosine to bring the copper level into the aforementioned

A 5 log 1/T 52log T (1)

~ !

10 10

method range. When sample dilution is used, the precision

3.2.2 integrated absorbance, A,n—the integrated area un-

i

statements do not apply.

der the absorbance peak generated by the atomic absorption

1.2 The values stated in SI units are to be regarded as

spectrometer.

standard. No other units of measurement are included in this

standard.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

4.1 The graphite furnace is aligned in the light path of the

safety concerns, if any, associated with its use. It is the

atomic absorption spectrometer equipped with background

responsibility of the user of this standard to establish appro-

correction. An aliquot (typically 10 µL) of the sample is

priate safety and health practices and determine the applica-

pipetted onto a platform in the furnace. The furnace is heated

bility of regulatory limitations prior to use.

to low temperature to dry the sample completely without

spattering. The furnace is then heated to a moderate tempera-

2. Referenced Documents

ture to eliminate excess sample matrix. The furnace is further

2

heated very rapidly to a temperature high enough to volatilize

2.1 ASTM Standards:

the analyte of interest. It is during this step that the amount of

D4057 Practice for Manual Sampling of Petroleum and

light absorbed by the copper atoms is measured by the

Petroleum Products

spectrometer.

D4306 Practice for Aviation Fuel Sample Containers for

Tests Affected by Trace Contamination

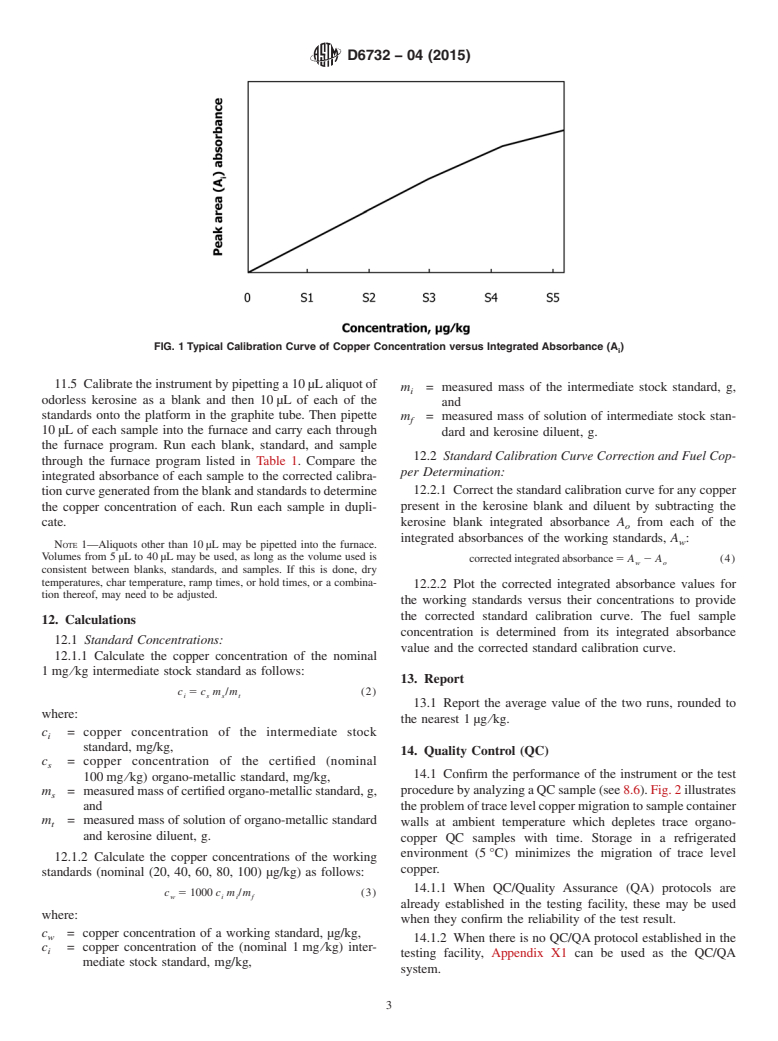

4.2 The light absorbed is measured over a specified period.

D6299 Practice for Applying Statistical Quality Assurance

The integrated absorbance A produced by the copper in the

i

and Control Charting Techniques to Evaluate Analytical

samples is compared to a calibration curve constructed from

Measurement System Performance

measured A values for organo-metallic standards.

i

3. Terminology 5. Significance and Use

3.1 Definitions:

5.1 At high temperatures aviation turbine fuels can oxidize

3.1.1 radiant power, P, n—the rate at which energy is

and produce insoluble deposits that are detrimental to aircraft

transported in a beam of radiant energy.

propulsion systems. Very low copper concentrations (in excess

of 50 µg⁄kg) can significantly accelerate this thermal instabil-

ity of aviation turbine fuel. Naval shipboard aviation fuel

1 delivery systems contain copper-nickel piping, which can

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

increasecopperlevelsinthefuel.Thistestmethodmaybeused

Subcommittee D02.03 on Elemental Analysis.

for quality checks of copper levels in aviation fuel samples

Current edition approved April 1, 2015. Published May 2015. Originally

taken on shipboard, in refineries, and at fuel storage depots.

approved in 2001. Last previous edition approved in 2010 as D6732 – 04 (2010).

DOI: 10.1520/D6732-04R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Interferences

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Interferences most commonly occur due to light that is

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. absorbed by species other than the atomic species of interest.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6732 − 04 (2015)

Generally, this is due to undissociated molecular particles from 9. Sampling

thesamplematrix.Thecharstepinthefurnaceprogramisused

9.1 Samples shall be taken in accordance with procedures

to eliminat

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6732 − 04 (Reapproved 2010) D6732 − 04 (Reapproved 2015)

Standard Test Method for

Determination of Copper in Jet Fuels by Graphite Furnace

1

Atomic Absorption Spectrometry

This standard is issued under the fixed designation D6732; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of copper in jet fuels in the range of 55 μg ⁄kg to 100100 μg ⁄ μg/kg kg using

graphite furnace atomic absorption spectrometry. Copper contents above 100100 μg ⁄ μg/kg kg may be determined by sample

dilution with kerosine to bring the copper level into the aforementioned method range. When sample dilution is used, the precision

statements do not apply.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4306 Practice for Aviation Fuel Sample Containers for Tests Affected by Trace Contamination

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

3. Terminology

3.1 Definitions:

3.1.1 radiant power, P, n—the rate at which energy is transported in a beam of radiant energy.

3.1.2 transmittance, T, n—the ratio of the radiant power transmitted by a material to the radiant power incident upon it.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 absorbance, A, n—the logarithm to the base 10 of the ratio of the reciprocal of the transmittance, T:

A 5 log ~1/T! 52log T (1)

10 10

3.2.2 integrated absorbance, A , n—the integrated area under the absorbance peak generated by the atomic absorption

i

spectrometer.

4. Summary of Test Method

4.1 The graphite furnace is aligned in the light path of the atomic absorption spectrometer equipped with background correction.

An aliquot (typically 10 μL) 10 μL) of the sample is pipetted onto a platform in the furnace. The furnace is heated to low

temperature to dry the sample completely without spattering. The furnace is then heated to a moderate temperature to eliminate

excess sample matrix. The furnace is further heated very rapidly to a temperature high enough to volatilize the analyte of interest.

It is during this step that the amount of light absorbed by the copper atoms is measured by the spectrometer.

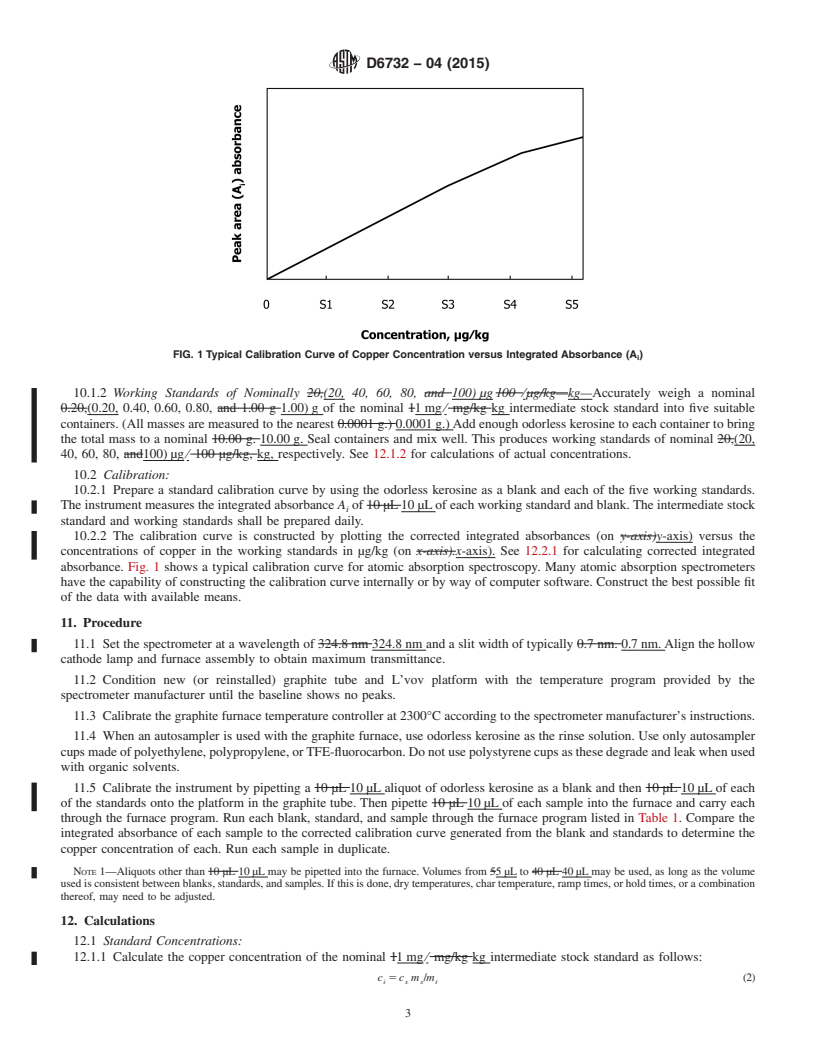

4.2 The light absorbed is measured over a specified period. The integrated absorbance A produced by the copper in the samples

i

is compared to a calibration curve constructed from measured A values for organo-metallic standards.

i

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

Current edition approved May 1, 2010April 1, 2015. Published May 2010May 2015. Originally approved in 2001. Last previous edition approved in 20042010 as

D6732D6732 – 04 (2010).–04. DOI: 10.1520/D6732-04R10.10.1520/D6732-04R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6732 − 04 (2015)

5. Significance and Use

5.1 At high temperatures aviation turbine fuels can oxidize and produce insoluble deposits that are detrimental to aircraft

propulsion systems. Very low copper concentrations (in excess of 5050 μg ⁄ μg/kg) kg) can significantly accelerate this thermal

instability of aviation turbine fuel. Naval shipboard aviation fuel delivery systems contain copper-nickel piping, which can increase

copper levels in the fuel. This test method may be used for quality checks of copper levels in aviatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.