ASTM D7408-12

(Specification)Standard Specification for Non Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams

Standard Specification for Non Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams

SCOPE

1.1 This specification covers the minimum values for seams fabricated into unreinforced PVC geomembranes in factory and field applications.

1.2 This specification covers PVC Geomembranes in thickness of .25 through 1.52 mm (0.010 through 0.060 in.)

1.3 In addition to structural characteristics, the specifier shall evaluate other characteristics beyond the scope of this specification that affect the final choice of construction. These include, but are not limited to, functional, legal, insurance and economic considerations.

1.4 This specification is not intended to exclude products or systems not covered by the referenced documents.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7408 −12

Standard Specification for

Non Reinforced PVC (Polyvinyl Chloride) Geomembrane

1

Seams

This standard is issued under the fixed designation D7408; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D882 Test Method for Tensile Properties of Thin Plastic

Sheeting

1.1 This specification covers the minimum values for seams

D4439 Terminology for Geosynthetics

fabricated into unreinforced PVC geomembranes in factory

D7176 Specification for Non-Reinforced Polyvinyl Chloride

and field applications.

(PVC) Geomembranes Used in Buried Applications

1.2 This specification covers PVC Geomembranes in thick-

3. Terminology

ness of .25 through 1.52 mm (0.010 through 0.060 in.).

3.1 Definitions:

1.3 In addition to structural characteristics, the specifier

3.1.1 chemical fusion seams, n—use of a chemical agent to

shall evaluate other characteristics beyond the scope of this

dissolve the surface of the geomembrane for bonding.

specification that affect the final choice of construction. These

include, but are not limited to, functional, legal, insurance and

3.1.2 adhesive or bodied solvent, n—these seams are typi-

economic considerations.

cally produced by applying an adhesive to both sides of the

sheet to be bonded and then pressure is applied to the top sheet

1.4 This specification is not intended to exclude products or

with the bottom sheet supported by flat a firm surface.

systems not covered by the referenced documents.

3.1.3 thermal fusion, n—alsoknownashotairorhotwedge,

1.5 The values stated in inch-pound units are to be regarded

this technique introduces high-temperature air or gas or a hot

as standard. The values given in parentheses are mathematical

wedge between two geomembrane surfaces to facilitate melt-

conversions to SI units that are provided for information only

ing. Pressure is applied to the top and/or bottom sheets of the

and are not considered standard.

geomembrane, forcing together the two surfaces to form a

1.6 This standard does not purport to address all of the

continuous bond.

safety concerns, if any, associated with its use. It is the

3.1.3.1 Discussion—Some seams of this kind are made with

responsibility of the user of this standard to establish appro-

dual bond tracks separated by a non-bonded gap. These seams

priate safety, health and environmental practices and deter-

are referred to as dual track seams or double-track seams.

mine the applicability of regulatory limitations prior to use.

3.1.4 hot air or knife, n—this technique melts the two

1.7 This international standard was developed in accor-

geomembrane surfaces to be seamed by running a hot metal

dance with internationally recognized principles on standard-

wedge or hot air between them. Pressure is applied to the top

ization established in the Decision on Principles for the

or bottom geomembrane, or both, to form a continuous bond.

Development of International Standards, Guides and Recom-

These seams are usually produced with a combination of a

mendations issued by the World Trade Organization Technical

hand held heat gun or hand held hot wedge along with a hand

Barriers to Trade (TBT) Committee.

roller.

2. Referenced Documents

3.2 For definitions of other terms, see Terminology D4439.

2

2.1 ASTM Standards:

4. Classification

D638 Test Method for Tensile Properties of Plastics

4.1 Types of seams covered in this specification:

4.1.1 Chemical Fusion,

1

This specification is under the jurisdiction of ASTM Committee D35 on

4.1.2 Adhesive or Bodied Solvent,

Geosynthetics and is the direct responsibility of Subcommittee D35.06 on Geosyn-

4.1.3 Dielectric, and

thetic Specifications.

Current edition approved July 15, 2012. Published September 2012. Last 4.1.4 Thermal Fusion.

previous edition published 2008 as D7408–08. DOI: 10.1520/D7408-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5. Significance and Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 Significance—The increased use of geomembranes as

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. barrier materials to restrict fluid migration from one location to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

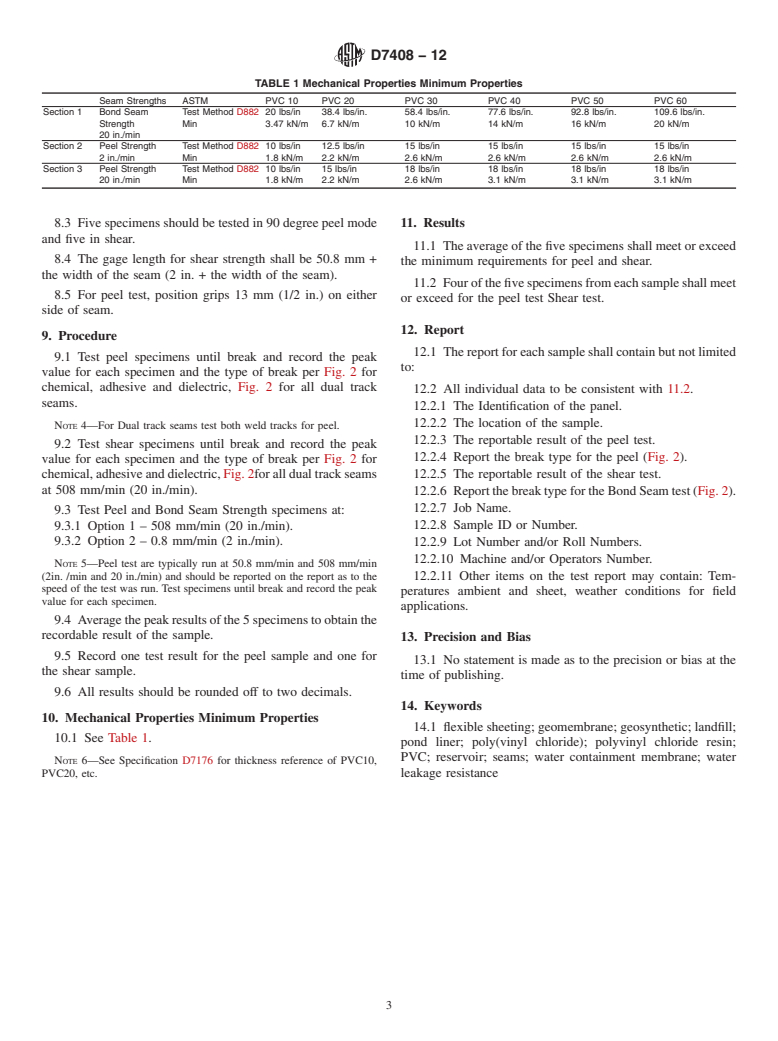

D7408−12

NOTE 1—Larger samples sizes may be required on site specific or

another in various applications, and the various types of

project specific or requirements for the purpose of archiving or third party

seaming methods used in joining g

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7408 − 08 D7408 − 12

Standard Specification for

Non Reinforced PVC (Polyvinyl Chloride) Geomembrane

1

Seams

This standard is issued under the fixed designation D7408; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the minimum values for seams fabricated into unreinforced PVC geomembranes in factory and

field applications.

1.2 This specification covers PVC Geomembranes in thickness of .25 through 1.52 mm (0.010 through 0.060 in.)

1.3 In addition to structural characteristics, the specifier shall evaluate other characteristics beyond the scope of this

specification that affect the final choice of construction. These include, but are not limited to, functional, legal, insurance and

economic considerations.

1.4 This specification is not intended to exclude products or systems not covered by the referenced documents.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D882 Test Method for Tensile Properties of Thin Plastic Sheeting

D4439 Terminology for Geosynthetics

D7176 Specification for Non-Reinforced Polyvinyl Chloride (PVC) Geomembranes Used in Buried Applications

3. Terminology

3.1 Definitions:

3.1.1 chemical fusion seams, n—use of a chemical agent to dissolve the surface of the geomembrane for bonding.

3.1.2 adhesive or bodied solvent, n—these seams are typically produced by applying an adhesive to both sides of the sheet to

be bonded and then pressure is applied to the top sheet with the bottom sheet supported by flat a firm surface

3.1.3 thermal fusion, n— also known as hot air or hot wedge, this technique introduces high-temperature air or gas or a hot

wedge between two geomembrane surfaces to facilitate melting. Pressure is applied to the top and/or bottom sheets of the

geomembrane, forcing together the two surfaces to form a continuous bond.

1

This specification is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

Current edition approved May 1, 2008July 15, 2012. Published June 2008September 2012. Last previous edition published 2008 as D7408–08. DOI: 10.1520/D7408-

08.10.1520/D7408-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

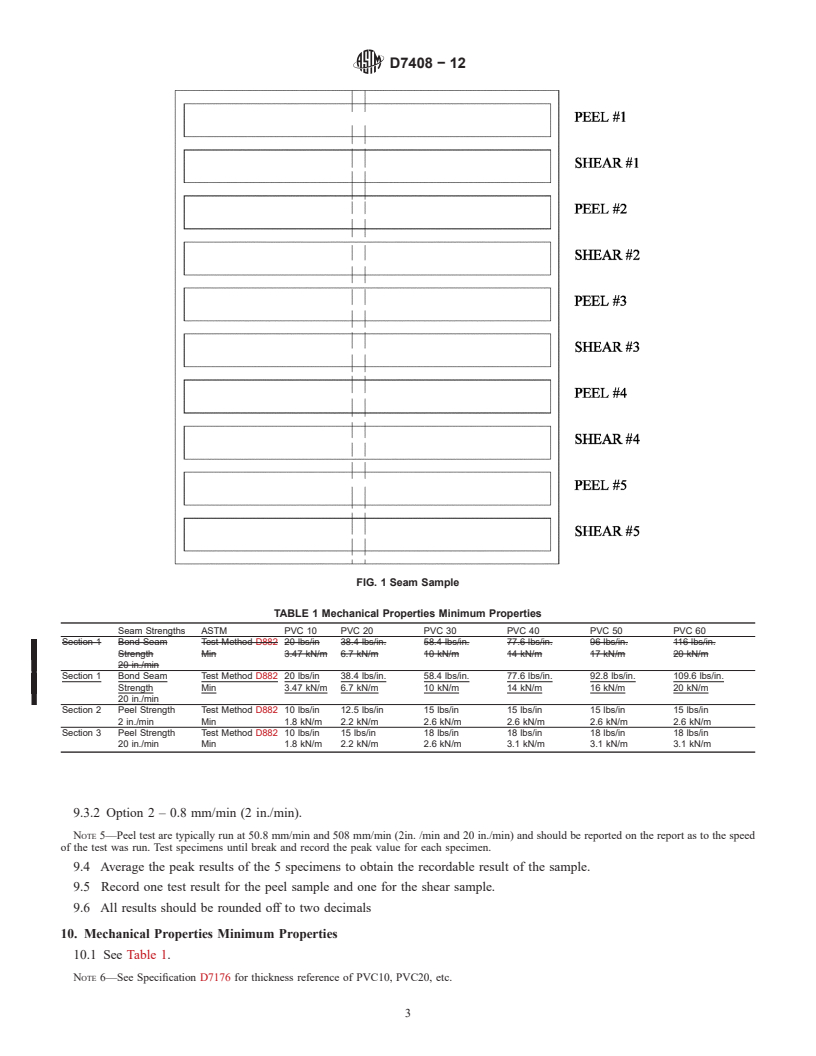

3.1.3.1 Discussion—

Some seams of this kind are made with dual bond tracks separated by a non-bonded gap. These seams are referred to as dual track

seams or double-track seams

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7408 − 12

3.1.4 hot air or knife, n— this technique melts the two geomembrane surfaces to be seamed by running a hot metal wedge or

hot air between them. Pressure is applied to the top or bottom geomembrane, or both, to form a continuous bond. These seams

are usually produced with a combination of a hand held heat gun or hand held hot wedge along with a hand roller.

3.2 For definitions of other terms, see Terminology D4439.

4. Classification

4.1 Types of seams covered in this specification:

4.1.1 Chemical Fusion,

4.1.2 Adhesive or Bodied Solvent,

4.1.3 Dielectric, and

4.1.4 Thermal Fusion.

5. Significance and Use

5.1 Significance— the increased use of geomembranes as barrier materials to restrict fluid migration from one location to

another in various applications, and the various types of seaming methods used in joining geomembrane sheets, has created a need

to standardize minimum seam strength requirements.

5.2 Use—Standard seam specification provides information as to the status of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.