ASTM B661-12(2020)

(Practice)Standard Practice for Heat Treatment of Magnesium Alloys

Standard Practice for Heat Treatment of Magnesium Alloys

ABSTRACT

This practice is intended as an aid for establishing a suitable procedure for the heat treatment of magnesium alloys to achieve the proper physical and mechanical properties. Air chamber furnaces that may be either electrically heated, or oil- or gas-fired, are usually used for the heat treatment process. Each furnace must be gas tight, have suitable equipment for protective atmosphere, be equipped with a high-velocity fan or any other comparable means for circulating the atmosphere, and designed so that no direct radiation from the heating elements or impingement of the flame on the magnesium. It is also important that the furnace be calibrated before it is used initially and after any change in the furnace. Likewise, temperature-measurement systems should be regularly checked for accuracy.

SCOPE

1.1 This practice is intended as an aid in establishing a suitable procedure for the heat treatment of magnesium alloys to assure proper physical and mechanical properties.

1.2 Times and temperatures are typical for various forms, sizes, and manufacturing methods and may not exactly describe the optimum heat treatment for a specific item. Consequently, it is not intended that this practice be used as a substitute for a detailed production process or procedure.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B661 − 12 (Reapproved 2020)

Standard Practice for

Heat Treatment of Magnesium Alloys

This standard is issued under the fixed designation B661; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope aging and age softening, it is the result of precipitation from a

solid solution of one or more compounds whose solubility

1.1 This practice is intended as an aid in establishing a

decreases with decreasing temperature; for each alloy suscep-

suitable procedure for the heat treatment of magnesium alloys

tible to aging, there is a unique range of time-temperature

to assure proper physical and mechanical properties.

combinations to which it will respond.

1.2 Times and temperatures are typical for various forms,

3.1.2 heat treatment—a combination of heating and cooling

sizes, and manufacturing methods and may not exactly de-

operationsappliedtoametaloralloyinthesolidstatetoobtain

scribe the optimum heat treatment for a specific item.

desiredconditionsofproperties;heatingforthesolepurposeof

Consequently, it is not intended that this practice be used as a

hot working is excluded from the meaning of this definition.

substitute for a detailed production process or procedure.

3.1.3 quenching—rapid cooling; when applicable, the fol-

1.3 This standard does not purport to address all of the

lowing more specific terms should be used: still air quenching,

safety concerns, if any, associated with its use. It is the

forced air quenching, hot water/polymer quenching.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.1.4 solution heat treatment—a treatment in which an alloy

mine the applicability of regulatory limitations prior to use.

is heated to a suitable temperature and held at this temperature

1.4 This international standard was developed in accor-

for a sufficient length of time to allow a desired constituent to

dance with internationally recognized principles on standard-

enter into solid solution, followed by rapid cooling to hold the

ization established in the Decision on Principles for the

constituent in solution; the material is then in a supersaturated,

Development of International Standards, Guides and Recom-

unstable state, and may subsequently exhibit Age Hardening.

mendations issued by the World Trade Organization Technical

3.1.5 T4—solution heat-treated and naturally aged to a

Barriers to Trade (TBT) Committee.

substantially stable condition.

2. Referenced Documents

3.1.6 T5—artificially aged only; applied to products which

2.1 ASTM Standards: are artificially aged after an elevated-temperature rapid-cool

fabrication process, such as casting or extrusion, to improve

B557 Test Methods for Tension Testing Wrought and Cast

Aluminum- and Magnesium-Alloy Products mechanical properties or dimensional stability, or both.

E21 TestMethodsforElevatedTemperatureTensionTestsof

3.1.7 T6—solution heat-treated and then artificially aged;

Metallic Materials

applies to products which are not cold worked after solution

heat-treatment.

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

4. Apparatus

3.1.1 aging—describes a time-temperature-dependent

4.1 Furnaces used for the heat treatment of magnesium are

change in the properties of certain alloys; except for strain

usually of the air chamber type and may be electrically heated

or oil- or gas-fired. Because of the atmospheres used for

This practice is under the jurisdiction of ASTM Committee B07 on Light

solution heat treatment, furnaces must be gas tight and contain

Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on

suitable equipment for the introduction of protective

Magnesium Alloy Cast and Wrought Products.

atmospheres, and means for control of those atmospheres. In

Current edition approved Nov. 1, 2020. Published December 2020. Originally

ordertopromoteuniformityoftemperature,furnacesshouldbe

approved in 1979. Last previous edition approved in 2012 as B661 – 12. DOI:

10.1520/B0661-12R20.

equipped with a high-velocity fan or comparable means for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

circulating the atmosphere. In the design of the furnace it is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

desirable that there be no direct radiation from the heating

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. elements or impingement of the flame on the magnesium.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B661 − 12 (2020)

4.2 Automatic recording and control equipment to control thermocouples located at front, center, and rear, or at top,

the temperature of the furnaces, which must be capable of center, and bottom of the furnace.

maintaining temperature in the working zone to within 610 °F

5.1.2.5 Perform the surveys in such manner as to reflect the

(66 °C) of the specified temperature.

normaloperatingcharacteristicsofthefurnace.Ifthefurnaceis

normally charged after being stabilized at the correct operating

4.3 There must be a separate manual reset safety cutout

temperature, similarly charge the temperature-sensing ele-

which will turn off the heat source in the event of any

ments. If the furnace is normally charged cold, charge the

malfunctioning or failure of the regular control equipment.

temperature-sensing elements cold. After insertion of the

Thesesafetycutoutsshallbesetascloselyaspracticableabove

temperature-sensing elements, readings should be taken fre-

the maximum temperature for the alloy being heat treated.This

quently enough to determine when the temperature of the

willbeabovethevariationexpected,butshallnotbemorethan

hottest region of the furnace approaches the bottom of the

10 °F (6 °C) above the maximum solution heat treating tem-

temperaturerangebeingsurveyed.Fromthattimeuntilthermal

perature for the alloy being heat treated. Protective devices

equilibrium is reached, the temperature of all test locations

shall also be installed to turn off the heat source in case of

should be determined at 2-min intervals in order to detect any

stoppage of circulation of air, and they shall be interconnected

overshooting. After thermal equilibrium is reached, readings

with a manual reset control.

should be taken at 5-min intervals for sufficient time to

4.4 The furnaces or ovens used for aging treatments may be

determine the recurrent temperature pattern, but for not less

heated by means of electricity, gas, or oil. The temperature at

than30min.Beforethermalequilibriumisreached,noneofthe

any point in the working zone, for any charge, shall be

temperature readings should exceed the maximum temperature

maintained within 610 °F (66 °C) of the desired aging tem-

of the range being surveyed. After thermal equilibrium is

perature after the furnace has been brought up to the aging

reached, the maximum temperature variation of all elements

temperature.

(both load and furnace thermocouples) shall not exceed 20 °F

4.5 Quenching:

(11 °C) and shall not vary outside the range being surveyed.

4.5.1 Normally magnesium work loads are cooled in air.

5.1.2.6 For furnaces used only for treatments other than

This should be by fan cooling the furnace charge after removal

solution heat treatment, after the initial temperature uniformity

from the furnace in such a way that the cooling is uniform on

survey as outlined in 5.1.2.5, surveys need not be made more

various parts of the furnace charge.

often than at each six-month interval, provided that (a) test

4.5.2 Some alloys (notably EV31A, EQ21A, and QE22A)

specimens from each lot are tested and meet applicable

arequenchedinwaterorothersuitablemediafromthesolution

material specifications requirements, (b) the furnace is

heat treating temperature. Quench facilities should be situated

equipped with a multipoint recorder, or (c) one or more

near the heat treatment furnaces. If required, means of heating

separate load thermocouples are employed to measure and

the quench medium should be provided. Handling equipment

record actual metal temperatures.

shall be such that it is possible to quench heat treatment loads

5.1.2.7 Monthly surveys for batch furnaces are not neces-

within 30 s after the opening of the furnace door.

sary when the furnace is equipped with a permanent multipoint

recording system with at least two sensing thermocouples in

5. Calibration and Standardization

each working zone, or when one or more separate load

thermocouples are employed to measure actual metal

5.1 Calibration of Equipment:

temperature, providing that uniformity surveys show a history

5.1.1 Surveys:

of satisfactory performance for a period of at least six months.

5.1.1.1 Perform a temperature survey, to ensure compliance

Thesensingthermocouplesshallbeinstalledsoastorecordthe

with the applicable recommendations presented herein for each

temperature of the heated air or actual metal temperatures.

furnace.

However, periodic surveys shall also be made at six-month

5.1.1.2 Make a new temperature survey after any changes

intervals in accordance with the procedures outlined for the

in the furnace that may affect operational characteristics.

monthly survey.

5.1.2 Furnace Calibration:

5.1.2.8 Do not use furnace control temperature-measuring

5.1.2.1 Make the initial temperature survey at the maxi-

instruments to read the temperature of the test temperature-

mum and minimum temperature of solution heat treatments

sensing elements.

and aging heat treatment for which each furnace is to be used.

3 3

There shall be at least one test location for each 25 ft (0.7 m )

5.1.3 Temperature-measuring System Check—Check the ac-

of air furnace volume up to a maximum of 40 test locations

curacy of temperature-measuring system under operating con-

with a minimum of nine test locations.

ditions weekly. Check should be made by inserting a calibrated

5.1.2.2 After the initial survey, survey each furnace

test temperature-sensing element adjacent to the furnace

monthly, except as provided in 5.1.2.7. The monthly survey

temperature-sensing element and reading the test temperature-

shall be at one operating temperature for solution heat treat-

sensing element with a calibrated test potentiometer. When the

ment and one for aging heat treatment.

furnace is equipped with dual potentiometer measuring

5.1.2.3 For the monthly surveys there shall be at least one

systems, which are checked daily against each other, the above

3 3

test location for each 40 ft (1.13 m ) load volume. checks may be conducted every three months rather than every

3 3

5.1.2.4 For furnaces of 10 ft (0.28 m ) or less the week. Calibrate the test temperature-sensing element,

temperature survey may be made with a minimum of three potentiometer, and cold junction compensation combination

B661 − 12 (2020)

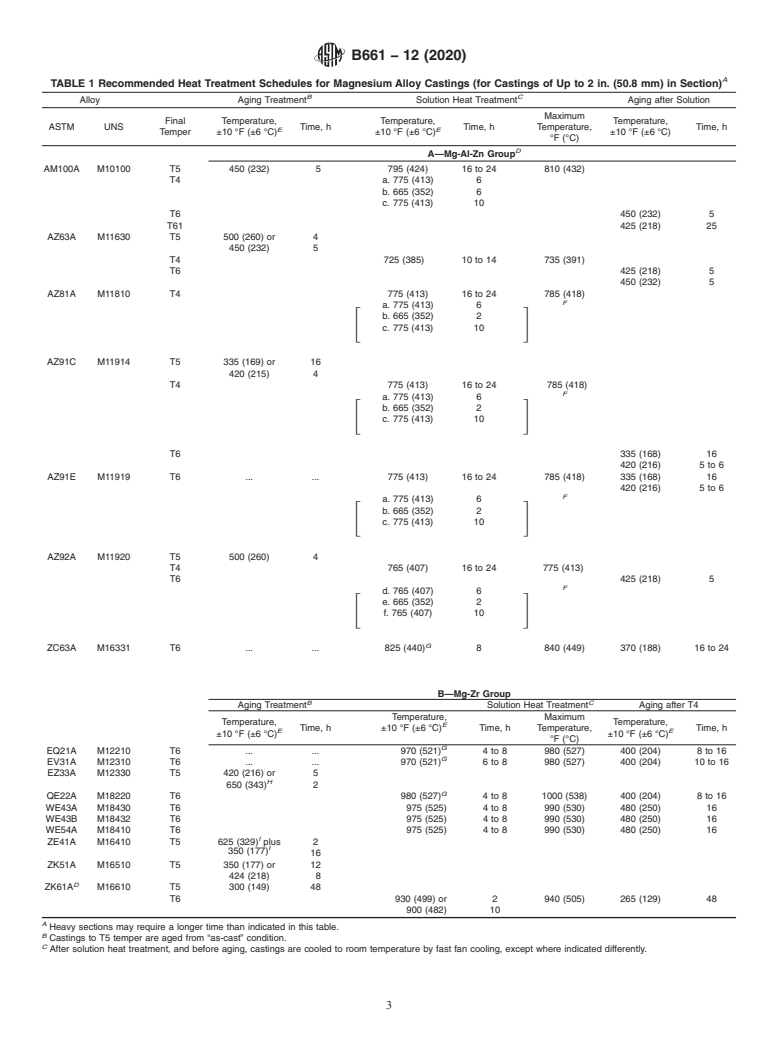

A

TABLE 1 Recommended Heat Treatment Schedules for Magnesium Alloy Castings (for Castings of Up to 2 in. (50.8 mm) in Section)

B C

Alloy Aging Treatment Solution Heat Treatment Aging after Solution

Maximum

Final Temperature, Temperature, Temperature,

ASTM UNS Time, h Time, h Temperature, Time, h

E E

Temper ±10 °F (±6 °C) ±10 °F (±6 °C) ±10 °F (±6 °C)

°F (°C)

D

A—Mg-Al-Zn Group

AM100A M10100 T5 450 (232) 5 795 (424) 16 to 24 810 (432)

T4 a. 775 (413) 6

b. 665 (352) 6

c. 775 (413) 10

T6 450 (232) 5

T61 425 (218) 25

AZ63A M11630 T5 500 (260) or 4

450 (232) 5

T4 725 (385) 10 to 14 735 (391)

T6 425 (218) 5

450 (232) 5

AZ81A M11810 T4 775 (413) 16 to 24 785 (418)

F

a. 775 (413) 6

b. 665 (352) 2

c. 775 (413) 10

F G

AZ91C M11914 T5 335 (169) or 16

420 (215) 4

T4 775 (413) 16 to 24 785 (418)

F

a. 775 (413) 6

b. 665 (352) 2

c. 775 (413) 10

F G

T6 335 (168) 16

420 (216) 5to6

AZ91E M11919 T6 . . 775 (413) 16 to 24 785 (418) 335 (168) 16

420 (216) 5to6

F

a. 775 (413) 6

b. 665 (352) 2

c. 775 (413) 10

F G

AZ92A M11920 T5 500 (260) 4

T4 765 (407) 16 to 24 775 (413)

T6 425 (218) 5

F

d. 765 (407) 6

e. 665 (352) 2

f. 765 (407) 10

F G

G

ZC63A M16331 T6 . . 825 (440) 8 840 (449) 370 (188) 16 to 24

B—Mg-Zr Group

B C

Aging Treatment Solution Heat Treatment Aging after T4

Temperature, Maximum

Temperature, Temperature,

E

Time, h ±10 °F (±6 °C) Time, h Temperature, Time, h

E E

±10 °F (±6 °C) ±10 °F (±6 °C)

°F (°C)

G

EQ21A M12210 T6 . . 970 (521) 4 to 8 980 (527) 400 (204) 8 to 16

G

EV31A M12310 T6 . . 970 (521) 6 to 8 980 (527) 400 (204) 10 to 16

EZ33A M12330 T5 420 (216) or 5

H

650 (343) 2

G

QE22A M18220 T6 980 (527) 4 to 8 1000 (538) 400 (204) 8 to 16

WE43A M18430 T6 975 (525) 4 to 8 990 (530) 480 (250) 16

WE43B M18432 T6 975 (525) 4 to 8 990 (530) 480 (250) 16

WE54A M18410 T6 975 (525) 4 to 8 990 (530) 480 (250) 16

I

ZE41A M16410 T5 625 (329) plus 2

I

350 (177)

ZK51A M16510 T5 350 (177) or 12

424 (218) 8

D

ZK61A M16610 T5 300 (149) 48

T6 930 (499) or 2 940 (505) 265 (129) 48

900 (482) 10

A

Heavy sections may require a longer time than indicated in this table.

B

Castings to T5 temper are aged from “as-cast” condition.

C

After solution heat treatment, and before aging, castings are cooled to room temperature by fast fan cooling, except where indicated differently.

B661 − 12 (2020)

D

Thealloysshowninthistablesection(Mg-Al-ZnGroupandZK61A)areloadedintothefurnaceat500 °F(260 °C)andbroughttoholdingovera2-hperiodatauniform

rate of temperature rise. This does not apply to ZC63A which has zinc and copper.

E

Except where quoted differently.

F

Analternativeheattreatment,ifrequiredtominimizegraingrowth,consistsofasequentialtreatmentasindicatedforalloysAM100A,AZ81A,AZ91C,AZ91E,andAZ92A.

G

Quench from solution heat treatment temperature either in water heated to 150 °F (66 °C) or in other suitable quench media.

H

This alternative aging treatment for EZ33A alloy can be used where maximum resistance to creep at elevated temperature is not of prime importance.

I

The2hat625°F(329°C)isadequatetoobtainsatisfactoryproperties.The16hat350 °F(177 °C)isoptionaltogiveaveryslightimprovementinmechanicalproperties.

againstNationalInstituteofStandardsandTechnologyprimary 5.3.1 Test specimens prepared in accordance with 5.2.1 and

orsecondarycertifiedtemperature-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.