ASTM B296-20

(Practice)Standard Practice for Temper Designations of Magnesium Alloys, Cast and Wrought

Standard Practice for Temper Designations of Magnesium Alloys, Cast and Wrought

ABSTRACT

This practice covers a system for designating the tempers of magnesium alloys, cast and wrought. The designations for temper are used for all forms of magnesium and magnesium-alloy products except ingots and are based on the sequence of basic treatments used to produce the various tempers. The temper designation follows the alloy designation, the two being separated by a dash.

SCOPE

1.1 This practice covers a system for designating the tempers of magnesium alloys, cast and wrought. The designations used in ASTM specifications under the jurisdiction of Committee B07 for magnesium alloy castings and wrought products conform to this practice.2

1.2 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B296 − 20

Standard Practice for

Temper Designations of Magnesium Alloys, Cast and

1

Wrought

This standard is issued under the fixed designation B296; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.3 Basic temper designations consist of letters. Subdivi-

sions of the basic tempers, where required, are indicated by a

1.1 This practice covers a system for designating the tem-

digit or digits following the letter. These designate specific

pers of magnesium alloys, cast and wrought. The designations

sequences of basic treatments, but only operations recognized

used in ASTM specifications under the jurisdiction of Com-

as significantly influencing the characteristics of the product

mitteeB07formagnesiumalloycastingsandwroughtproducts

2 are indicated. Should some other variation of the same se-

conform to this practice.

quence of basic operations be applied to the same alloy,

1.2 This international standard was developed in accor-

resulting in different characteristics, then additional digits are

dance with internationally recognized principles on standard-

added to the designation.

ization established in the Decision on Principles for the

NOTE 1—In material specifications containing reference to two or more

Development of International Standards, Guides and Recom-

tempers of the same alloy which result in identical mechanical properties,

mendations issued by the World Trade Organization Technical

the distinction between the tempers should be covered in suitable

Barriers to Trade (TBT) Committee.

explanatory notes.

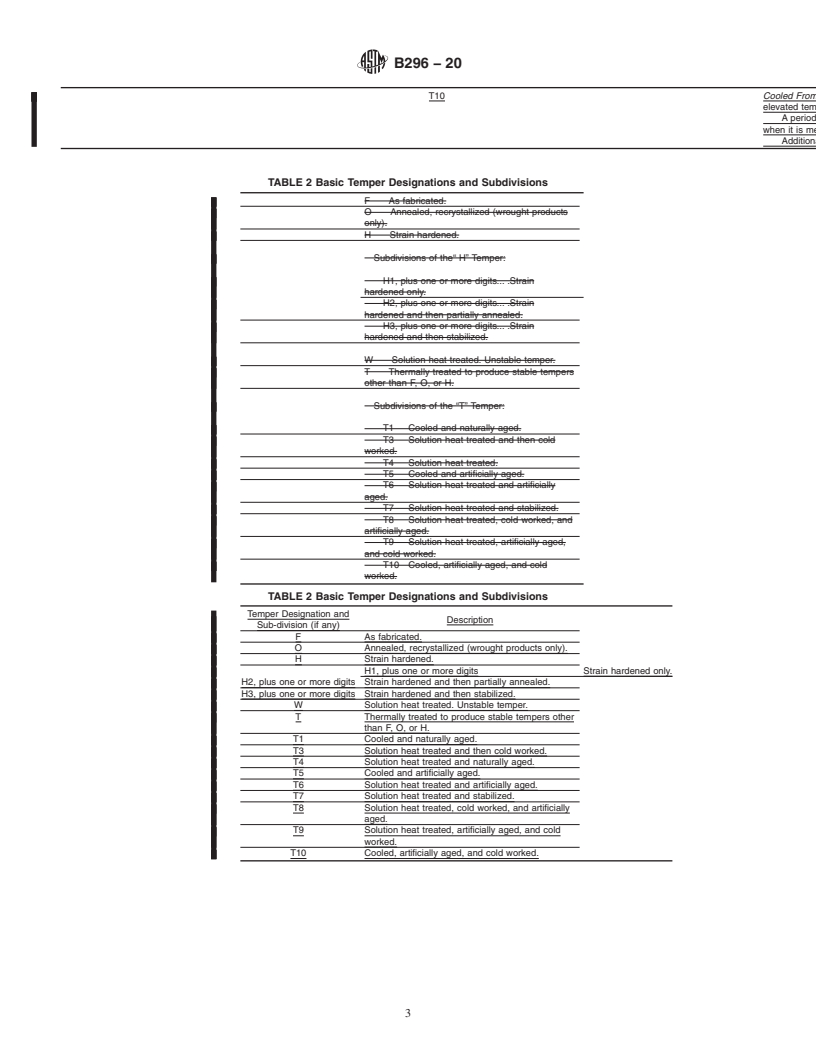

2. Basis of Codification 2.4 The temper designations and the subdivisions are fully

defined and explained in Table 1. A brief outline for quick

2.1 The designations for temper are used for all forms of

reference is given in Table 2.

magnesium and magnesium-alloy products except ingots and

are based on the sequence of basic treatments used to produce

3. Referenced Documents

the various tempers.

3

3.1 ANSI Standard:

2.2 The temper designation follows the alloy designation,

ANSI H35.1/H35.1M American National Standard Alloy

the two being separated by a dash.

and Temper Designation Systems for Aluminum

1

This practice is under the jurisdiction of the ASTM Committee B07 on Light

4. Keywords

Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on

Magnesium Alloy Cast and Wrought Products.

4.1 cast and wrought alloys; magnesium alloys; temper

Current edition approved May 1, 2020. Published June 2020. Originally

designations

approved in 1954. Last previous edition approved in 2014 as B296 – 03 (2014).

DOI: 10.1520/B0296-20.

2

The designations used in ASTM Committee B07 specifications for aluminum-

3

alloy wrought and cast products conform to the American National Standard Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

H35.1/H35.1M. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B296 − 20

TABLE 1 Temper Designations

Temper Designation and

Description

Sub-division (if any)

F As Fabricated —Applies to products that acquire some temper from shaping processes not having special control over the amount of

strain hardening or thermal treatment.

O Annealed, Recrystallized—Applies to the softest temper of wrought products.

H Strain Hardened (Wrought Products Only)—Applies to products that have their strength increased by strain hardening with or without

supplementary thermal treatments to produce partial softening. Two or more digits always follow the H.

H1 Strain Hardened Only—Applies to products that are strain hardened to obtain the desired mechanical properties without supplementary

thermal treatment. The number following this designation indicates the final degree of strain hardening.

H2 Strain Hardened and Then Partially Annealed—Applies to products that are strain hardened more than the desired final amount and then

reduced in strength to the desired final amount by partial annealing.

The number following this designation indicates the final degree of strain hardening remaining after the product has been partially

annealed.

H3 Strain Hardened and Then Stabilized—Applies to products that are strain hardened and then stabilize

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B296 − 03 (Reapproved 2014) B296 − 20

Standard Practice for

Temper Designations of Magnesium Alloys, Cast and

1

Wrought

This standard is issued under the fixed designation B296; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This practice covers a system for designating the tempers of magnesium alloys, cast and wrought. The designations used

in ASTM specifications under the jurisdiction of Committee B07 for magnesium alloy castings and wrought products conform to

2

this practice.

1.2 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Basis of Codification

2.1 The designations for temper are used for all forms of magnesium and magnesium-alloy products except ingots and are based

on the sequence of basic treatments used to produce the various tempers.

2.2 The temper designation follows the alloy designation, the two being separated by a dash.

2.3 Basic temper designations consist of letters. Subdivisions of the basic tempers, where required, are indicated by a digit or

digits following the letter. These designate specific sequences of basic treatments, but only operations recognized as significantly

influencing the characteristics of the product are indicated. Should some other variation of the same sequence of basic operations

be applied to the same alloy, resulting in different characteristics, then additional digits are added to the designation.

NOTE 1—In material specifications containing reference to two or more tempers of the same alloy which result in identical mechanical properties, the

distinction between the tempers should be covered in suitable explanatory notes.

2.4 The temper designations and the subdivisions are fully defined and explained in Table 1. A brief outline for quick reference

is given in Table 2.

3. Referenced Documents

3

3.1 ANSI Standard:

ANSI H35.1/H35.1M American National Standard Alloy and Temper Designation Systems for Aluminum

4. Keywords

4.1 cast and wrought alloys; magnesium alloys; temper designations

1

This practice is under the jurisdiction of the ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on Magnesium

Alloy Cast and Wrought Products.

Current edition approved May 1, 2014May 1, 2020. Published June 2014June 2020. Originally approved in 1954. Last previous edition approved in 20082014 as B296 – 03

(2008).(2014). DOI: 10.1520/B0296-03R14.10.1520/B0296-20.

2

The designations used in ASTM Committee B07 specifications for aluminum-alloy wrought and cast products conform to the American National Standard

H 35.1H35.1/H35.1M.⁄H 35.1(M).

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B296 − 20

TABLE 1 Temper Designations

Temper

Designation

and Sub- Description

division (if

any)

F As Fabricated

treatment.

O Annealed, Recrystallized

H Strain Hardened

treatments to

Subdivisions of the 9H9 Temper:

H1 Strain Hardened

number following

H2 Strain Hardened

desired final amount

The number

H3 Strain Hardened

and increase

The number

stabilized.

The number following this designation indicates the degree of strain hardening remaining after the product has been strain hardened a specific

amount and then stabilized.

Subdivisions of the 9H1,9 9H2,9 and 9H39 Tempers:

The digit following the designations 9H1,9 9H2,9 and 9H39 indicates the final degree of strain hardening. Tempers between 0 (annealed) and 8 (full hard)

Subdivisions The digit following the designations “H1,” “H2,” and “H3” indicates the final degree of strain hardening. Tempers between 0 (annealed) and 8 (full hard)

of H1, H2, are designated by numerals 1 through 7. Material having a strength about midway between that of the 0 temper and that of the 8 temper is designated

and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.