ASTM C808-75(2005)

(Guide)Standard Guideline for Reporting Friction and Wear Test Results of Manufactured Carbon and Graphite Bearing and Seal Materials

Standard Guideline for Reporting Friction and Wear Test Results of Manufactured Carbon and Graphite Bearing and Seal Materials

SCOPE

1.1 This guideline covers the following areas for reporting friction and wear test results of manufactured carbon and graphite bearing and seal materials:

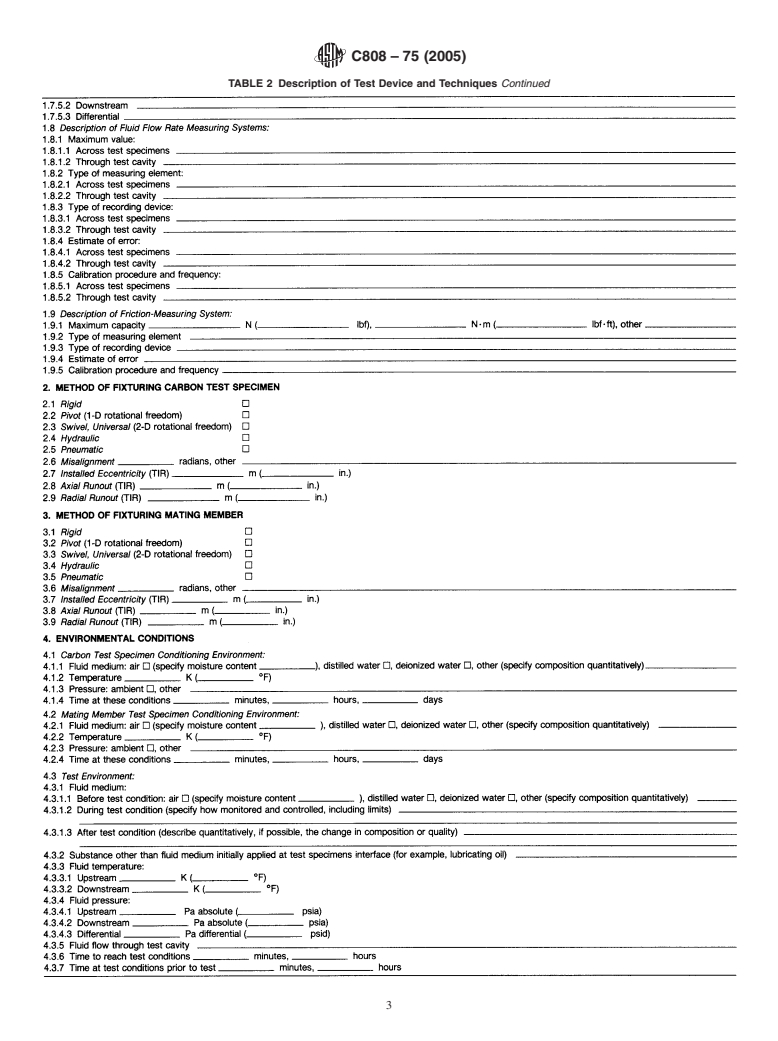

1.1.1 Description of test device and techniques (Table 1).

1.1.2 Description of carbon and graphite material test specimen (Table 2).

1.1.3 Description of mating member test specimen (Table 3).

1.1.4 Report of friction and wear test results (Table 4).

1.2 Many types of equipment and techniques will yield consistent data characterizing the friction and wear of carbon and graphite materials. However, the ranking of the materials by the various test methods used is not necessarily the same. This guideline is an initial effort to promote more complete description of the test methods, whatever they may be. It is the eventual intent to identify one or more specific standard test methods when sufficient information becomes available.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:C808–75 (Reapproved 2005)

Standard Guide for

Reporting Friction and Wear Test Results of Manufactured

Carbon and Graphite Bearing and Seal Materials

This standard is issued under the fixed designation C808; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and graphite materials. However, the ranking of the materials

by the various test methods used is not necessarily the same.

1.1 This guide covers the following areas for reporting

This guide is an initial effort to promote more complete

friction and wear test results of manufactured carbon and

description of the test methods, whatever they may be. It is the

graphite bearing and seal materials:

eventual intent to identify one or more specific standard test

1.1.1 Description of test device and techniques (Table 1 and

methods when sufficient information becomes available.

Table 2.)

1.1.2 Description of carbon and graphite material test speci-

2. Significance and Use

men (Table 3).

2.1 The purpose of this guide is twofold. First, it is a

1.1.3 Description of mating member test specimen (Table

research tool that will aid in the analysis and correlation of test

4).

results obtained on various test devices by different investiga-

1.1.4 Report of friction and wear test results (Table 5).

tors. Second, it serves to identify important considerations that

1.2 Many types of equipment and techniques will yield

must be made in testing to make the results easily understood

consistent data characterizing the friction and wear of carbon

and comparable with the results of other investigators.

3. Keywords

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

Products and Lubricants and is the direct responsibility of Subcommittee D02.F0 on

3.1 carbon; friction; graphite; reporting; wear

Manufactured Carbon and Graphite Products.

Curr

...

This May Also Interest You

SIGNIFICANCE AND USE

2.1 The purpose of this guide is twofold. First, it is a research tool that will aid in the analysis and correlation of test results obtained on various test devices by different investigators. Second, it serves to identify important considerations that must be made in testing to make the results easily understood and comparable with the results of other investigators.

SCOPE

1.1 This guide covers the following areas for reporting friction and wear test results of manufactured carbon and graphite bearing and seal materials:

1.1.1 Description of test device and techniques (Table 1 and Table 2.)

1.1.2 Description of carbon and graphite material test specimen (Table 3).

1.1.3 Description of mating member test specimen (Table 4).

1.1.4 Report of friction and wear test results (Table 5).

1.2 Many types of equipment and techniques will yield consistent data characterizing the friction and wear of carbon and graphite materials. However, the ranking of the materials by the various test methods used is not necessarily the same. This guide is an initial effort to promote more complete description of the test methods, whatever they may be. It is the eventual intent to identify one or more specific standard test methods when sufficient information becomes available.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 The term “surface texture” is used to describe the local deviations of a surface from an ideal shape. Surface texture usually consists of long wavelength repetitive features that occur as results of chatter, vibration, or heat treatments during the manufacture of implants. Short wavelength features superimposed on the long wavelength features of the surface, which may arise from polishing or etching of the implant, are referred to as roughness.

4.2 This guide provides an overview of techniques that are available for measuring the surface in terms of Cartesian coordinates and the parameters used to describe surface texture. It is important to appreciate that it is not possible to measure surface texture per se, but to derive values for parameters that can be used to describe it. ISO has published a series of standards on surface texture measurements that may be consulted for more information (ISO 3274, ISO 4287, ISO 4288, ISO 5436-2, ISO 10993-19, ISO 12179, ISO 13565-1, ISO 19606, ISO 21920-1, ISO 21920-2, ISO 21920-3, ISO 25178-1, ISO 25178-2, ISO 25178-3, ISO 25178-6, ISO 25178-70, ISO 25178-71, ISO 25178-72, ISO 25178-73, ISO 25178-600, ISO 25178-601, ISO 25178-602, ISO 25178-603, ISO 25178-604, ISO 25178-605, ISO 25178-606, ISO 25178-607, ISO 25178-700, ISO 25178-701).

SCOPE

1.1 This guide describes some of the more common methods that are available for measuring the topographical features of a surface and provides an overview of the parameters that are used to quantify them. Being able to reliably derive a set of parameters that describe the texture of biomaterial surfaces is a key aspect in the manufacture of safe and effective implantable medical devices that have the potential to trigger an adverse biological reaction in situ.

1.2 This guide is not intended to apply to porous structures with average pore dimensions in excess of approximately 50 nm (0.05 μm).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide10 pagesEnglish languagesale 15% off

- Guide10 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 As a base for calibration adjustment or accuracy verification of dry film coating thickness measuring instruments.

5.2 The dry film thickness of coatings on wood or wood-based products is specified in written product warranties for proper decorative and protective performance of coatings on wood or wood-based products.

5.3 The minimum and maximum dry film thickness of coatings is recommended by coating companies for satisfactory decorative and protective performance on wood or wood-based products.

5.4 The average dry film thickness of coatings on wood or wood-based material may be used by manufacturing companies to estimate the theoretical cost of applied coatings.

5.5 The ratio of minimum to maximum dry film thickness on textured products is used as an indication of coating uniformity.

5.6 Specific coated product requirements may dictate certain film thickness determinations to be made. Agreement between buyer and seller may be advisable to accommodate product needs relative to dry film thickness.

SCOPE

1.1 This test method covers the measurement of dry film thickness of coatings applied to a smooth, textured or curved rigid substrate of wood or a wood-based product.

1.2 This test method covers the preparation of wood or wood-based specimens for the purpose of microscopic measurement of dry film thickness.

1.3 This test method suggests an analysis of dry film thickness of coatings on wood or wood-based products using a microscopic measurement.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard10 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Many physical and appearance properties of the finished coating are affected by the film thickness. Film thickness can affect the color, gloss, surface profile, adhesion, flexibility, impact resistance and hardness of the coating. The fit of pieces assembled after coating can be affected when film thickness is not within tolerance. Therefore coatings must be applied within certain minimum and maximum film thickness specifications to optimize their intended use.

5.2 All procedures involve taking measurements of applied coating powders in the pre-cured, pre-gelled state to help insure correct cured film thickness. This enables the application system to be set up and fine-tuned prior to the curing process. In turn, this will reduce the amount of scrap and over-spray. Accurate predictions help avoid stripping and re-coating which can cause problems with adhesion and coating integrity.

5.3 Measurements of cured powder coating thickness can be made using different methods depending upon the substrate. Non-destructive measurements over metal substrates can be made with magnetic and eddy current coating thickness gauges (see Practice D7091). Non-destructive measurements over non-metal substrates can be made with ultrasonic coating thickness gauges (see Test Method D6132). Destructive measurements over rigid substrates can be made with cross-sectioning instruments (see Practices D4138).

SCOPE

1.1 This practice describes the thickness measurement of dry coating powders applied to a variety of rigid substrates. Use of some of these procedures may require repair of the coating powder. This practice covers the use of portable instruments. It is intended to supplement the manufacturers’ instructions for their operation of the gauges and is not intended to replace them. It includes definitions of key terms, reference documents, the significance and use of the practice, and the advantages and limitations of the instruments.

1.2 Three procedures are provided for measuring dry coating powder thickness:

1.2.1 Procedure A—Using rigid metal notched (comb) gauges.

1.2.2 Procedure B—Using magnetic or eddy current coating thickness gauges.

1.2.3 Procedure C—Using non-contact ultrasonic powder thickness instruments.

1.3 Coating powders generally diminish in thickness during the curing process. Some of these procedures therefore require a reduction factor be established to predict cured film thickness of powder coatings.

1.4 Procedure A and Procedure B

measure the thickness (height or depth) of the applied coating powders in the pre-cured, pre-gelled state. By comparing results to the measured cured powder thickness in the same location, a reduction factor can be determined and applied to future thickness measurements of the same coating powder.

1.5 Procedure C

results in a predicted thickness value of the cured state based on a calibration for typical coating powders. If the powder in question is not typical then an adjustment can be made to align gauge readings with the actual cured values as determined by other measurement methods.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method is designed to rank material couples in their resistance to the failure mode caused by galling and not merely to classify the surface appearance of sliding surfaces.

5.2 This test method should be considered when damaged (galled) surfaces render components non-serviceable. Experience has shown that galling is most prevalent in sliding systems that are slow moving and operate intermittently. The galling and seizure of threaded components is a classic example which this test method most closely simulates.

5.3 Other galling-prone examples include: sealing surfaces of value trim which may leak excessively due to galling; and pump wear rings that may function ineffectively due to galling.

5.4 If the equipment continues to operate satisfactorily and loses dimension gradually, then mechanical wear should be evaluated by a different test such as the crossed cylinder Test Method (see Test Method G83). Chain belt pins and bushings are examples of this type of problem.

5.5 This test method should not be used for quantitative or final design purposes since many environmental factors influence the galling performance of materials in service. Lubrication, alignment, stiffness and geometry are only some of the factors that can affect how materials perform. This test method has proven valuable in screening materials for prototypical testing that more closely simulates actual service conditions.

SCOPE

1.1 This test method covers a laboratory test which ranks the galling resistance of material couples. Most galling studies have been conducted on bare metals and alloys; however, non-metallics, coatings, and surface modified alloys may also be evaluated by this test method.

1.2 This test method is not designed for evaluating the galling resistance of material couples sliding under lubricated conditions because galling usually will not occur under lubricated sliding conditions using this test method.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The amount of wear in any system will, in general, depend upon the number of system factors such as the applied load, machine characteristics, sliding speed, sliding distance, the environment, and the material properties. The value of any wear test method lies in predicting the relative ranking of material combinations. Since the pin-on-disk test method does not attempt to duplicate all the conditions that may be experienced in service (for example, lubrication, load, pressure, contact geometry, removal of wear debris, and presence of corrosive environment), there is no insurance that the test will predict the wear rate of a given material under conditions differing from those in the test.

5.2 The use of this test method will fall in one of two categories: (1) the test(s) will follow all particulars of the standard, and the results will have been compared to the ILS data (Table 2), or (2) the test(s) will have followed the procedures/methodology of Test Method G99 but applied to other materials or using other parameters such as load, speed, materials, etc., or both. In this latter case, the results cannot be compared to the ILS data (Table 2). Further, it must be clearly stated what choices of test parameters/materials were chosen.

SCOPE

1.1 This test method covers a laboratory procedure for determining the wear of materials and friction during sliding using a pin-on-disk apparatus. Materials are tested in pairs under nominally non-abrasive conditions. The principal areas of experimental attention in using this type of apparatus to measure wear are described.

1.2 This test method standard uses a specific set of test parameters (load, sliding speed, materials, etc.) that were then used in an interlaboratory study (ILS), the results of which are given here (Tables 1 and 2). (This satisfies the ASTM form in that “The directions for performing the test should include all of the essential details as to apparatus, test specimen, procedure, and calculations needed to achieve satisfactory precision and bias.”) Any user should report that they “followed the requirements of ASTM G99,” where that is true.

1.3 Now it is often found in practice that users may follow all instructions given here, but choose other test parameters, such as load, speed, materials, environment, etc., and thereby obtain different test results. Such a use of this standard is encouraged as a means to improve wear testing methodology. However, it must be clearly stated in any report that, while the directions and protocol in Test Method G99 were followed (if true), the choices of test parameters were different from Test Method G99 values, and the test results were therefore also different from the Test Method G99 results. This use should be described as having “followed the procedure of ASTM G99.” All test parameters that were used in such case must be stated.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method is designed to rank material couples, surface treatments, and lubricants by CFT and in their resistance to adhesive wear. Since adhesive wear is a complex phenomenon and stochastic in nature, it is essential to evaluate surfaces to confirm the presence of adhesion.

5.2 This test method should be considered when evaluating the impact of changes in a process or application that is prone to adhesive wear, including any combination of scoring, galling, and plowing. These modes of failure commonly occur under sliding contact, at high contact stress, and, when applicable, at lubricant starvation.

5.3 The TCT is often used to evaluate the ability of material couples, surface treatments, coatings, and lubricants to prevent or reduce adhesive wear in metalworking operations including deep drawing, extrusion, and pipe bending. Other applications in which the test may be effective are loader bucket bushings, gear teeth at startup, and low-clearance pumps.

5.4 This test method is best used as a comparative screening tool. The ranking of performance produced by the TCT correlates well with the ranking in many applications.3 However, since the test is a bench test and not directly reproducing any specific application, TCT results should be only used as an indicator of the tendency for adhesive wear to occur. TCT is a useful screening test for comparing the effectiveness of material couples, surface treatments, coatings, and lubricant formulations before process testing and field trials.

SCOPE

1.1 This test method covers laboratory procedures for determining the coefficient of friction (COF) and resistance of materials to adhesion under flat sliding using the twist compression test (TCT). This test method ranks material couples, surface treatments, coatings, and lubricant combinations by COF and their resistance to adhesion.

1.2 The time until adhesion for the materials under the test conditions are reported and used to quantify the tribocouple’s adhesion resistance and susceptibility to galling or scuffing. Systems of higher adhesion resistance will give longer time until failure.

1.3 The coefficient of friction values averaged between the test reaching full test pressure and the time of the onset of adhesion or the end of tests run for a predetermined time period are recorded. Systems are ranked by their average coefficients of friction before adhesion occurs.

1.4 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard except psi and pounds in Table 1.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard9 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The gloss of metallic finishes is important commercially on metals for automotive, architectural, and other uses where these metals undergo special finishing processes to produce the appearances desired. It is important for the end-products, which use such finished metals that parts placed together have the same glossy appearance.

5.2 It is also important that automotive finishes and other high-gloss nonmetallic surfaces possess the desired finished appearance. The present method identifies by measurements important aspects of finishes. Those having identical sets of numbers normally have the same gloss characteristics. It usually requires more than one measurement to identify properly the glossy appearance of any finish (see Refs 3 and 4).

SCOPE

1.1 These test methods cover the measurement of the reflection characteristics responsible for the glossy appearance of high-gloss surfaces. Two test methods, A and B, are provided for evaluating such surface characteristics at specular angles of 20° and 30°, respectively. These test methods are not suitable for diffuse finish surfaces nor do they measure color, another appearance attribute.

1.2 As originally developed by Tingle and others (see Refs 1 and 2),2 the test methods were applied only to bright metals. Recently they have been applied to high-gloss automotive finishes and other nonmetallic surfaces.

1.3 The DOI of a glossy surface is generally independent of its curvature. The DOI measurement by this test method is limited to flat or flattenable surfaces.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard10 pagesEnglish languagesale 15% off

- Standard10 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 Measurement of the thickness of a coating is essential to assessing its utility and cost.

4.2 The coulometric method destroys the coating over a very small (about 0.1 cm2) test area. Therefore its use is limited to applications where a bare spot at the test area is acceptable or the test piece may be destroyed.

SCOPE

1.1 This test method covers the determination of the thickness of metallic coatings by the coulometric method, also known as the anodic solution or electrochemical stripping method.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers infrared thermometers, which are electronic instruments intended for the intermittent measurement and monitoring of patient temperatures by means of detecting the intensity of thermal radiation between the subject of measurement and the sensor. The specification addresses the assessment of the subject's internal body temperature through measurement of thermal emission from the ear canal. Though, performance requirements for noncontact temperature measurement of skin are also provided. Limits are set for laboratory accuracy, and determination and disclosure of clinical accuracy of the covered instruments are required. Performance and storage limits under various environmental conditions, requirements for labeling, and test procedures are all established herein.

SCOPE

1.1 This specification covers electronic instruments intended for intermittent measuring and monitoring of patient temperatures by means of detecting the intensity of thermal radiation between the subject of measurement and the sensor.

1.2 The specification addresses assessing subject’s body internal temperature through measurement of thermal emission from the ear canal. Performance requirements for noncontact temperature measurement of skin are also provided.

1.3 The specification sets limits for laboratory accuracy and requires determination and disclosure of clinical accuracy of the covered instruments.

1.4 Performance and storage limits under various environmental conditions, requirements for labeling, and test procedures are established.

Note 1: For electrical safety, consult Underwriters Laboratory Standards.2

Note 2: For electromagnetic emission requirements and tests, refer to CISPR 11: 1990 Lists of Methods of Measurement of Electromagnetic Disturbance Characteristics of Industrial, Scientific, and Medical (ISM) Radiofrequency Equipment.3

1.5 The values of quantities stated in SI units are to be regarded as the standard. The values of quantities in parentheses are not in SI and are optional.

1.6 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification17 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.