ASTM F3324-19(2023)

(Test Method)Standard Test Method for Measurement of Cut Resistance to Chainsaw in Leg Protective Devices

Standard Test Method for Measurement of Cut Resistance to Chainsaw in Leg Protective Devices

SIGNIFICANCE AND USE

5.1 The purpose of this test method is to provide a measurable criterion of performance about the level of cut resistance provided by different types of protective garments and protective coverings worn by chainsaw operators.

5.2 This test method is intended to show to what level a protective garment can offer resistance to the cutting action of a chainsaw.

5.3 The protection that can be demonstrated by the garments and coverings tested in accordance with this test method is achieved by: (1) the cut resistance of the material to cutting when put in contact with saw chain; (2) pulling a part of the material or yarns in the material so that they are drawn into the chain and drive mechanism to block the chain movement; (3) the fibers of the materials used to demonstrate both high resistance to cutting and the capacity to absorb rotational energy, so that chain speed can be slowed down sufficiently to stop the movement of the saw chain; or (4) any combination of these.

5.4 This test method does not purport to evaluate comfort of lower body protective garments.

5.5 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should perform comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens from the same lot of components to be evaluated. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. If a bias is found, either its cause must be determined and corrected or the purchaser and the supplier must agree to interpret future test results in light of the known bias.

SCOPE

1.1 This test method2 measures cut resistance of garments and devices worn to protect the lower body (legs) when operating a chainsaw.

1.2 This test method may be used to test for compliance to minimum performance requirements in established safety standards.

1.3 The values stated in SI units are to be regarded as standard.

Note 1: The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3324 − 19 (Reapproved 2023)

Standard Test Method for

Measurement of Cut Resistance to Chainsaw in Leg

Protective Devices

This standard is issued under the fixed designation F3324; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F1494 Terminology Relating to Protective Clothing

2.2 Military Standard:

1.1 This test method measures cut resistance of garments

MIL-STD-105 Sampling Procedures and Tables for Inspec-

and devices worn to protect the lower body (legs) when

tion by Attributes

operating a chainsaw.

2.3 Federal Standard:

1.2 This test method may be used to test for compliance to

FS 5100-86 Type II, Cloth, Duck, Nylon, Polyurethane

minimum performance requirements in established safety stan-

Coated

dards.

1.3 The values stated in SI units are to be regarded as

3. Terminology

standard.

3.1 Definitions:

NOTE 1—The values stated in each system may not be exact equiva-

3.1.1 chainsaw, n—a portable, power-operated tool used for

lents; therefore, each system must be used independently of the other,

cutting wood that has cutters linked in a chain.

without combining values in any way.

3.1.2 chain speed, n—the speed of synchronized movement

1.4 This standard does not purport to address all of the

of linked cutters around a guide bar and sprocket.

safety concerns, if any, associated with its use. It is the

3.1.3 chain stop, n—the resulting action when a material

responsibility of the user of this standard to establish appro-

clogs (jams) the drive sprocket or slows the speed sufficiently

priate safety, health, and environmental practices and deter-

to prevent advancement of the saw chain.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor- 3.1.4 cut resistance, n—in chainsaw testing, the ability of a

material, while in contact with the linked cutters, to resist

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the cut-through of the cutters of a moving saw chain independent

Development of International Standards, Guides and Recom- of either jamming or chain stop.

mendations issued by the World Trade Organization Technical

3.1.5 cut-through, n—for chainsaw cut resistance, the action

Barriers to Trade (TBT) Committee.

of a running chainsaw after complete breakthrough of either a

protective garment or protective device.

2. Referenced Documents

3.1.5.1 Discussion—When a cut-through (0.64 cm) is

2.1 ASTM Standards:

effected, speed of the saw chain must be measured.

D123 Terminology Relating to Textiles

3.1.6 jamming, n—for chainsaw cut resistance, the clogging

D1056 Specification for Flexible Cellular Materials—

action manifested by a protective garment or a device that can

Sponge or Expanded Rubber

produce a chain stop.

D1776/D1776M Practice for Conditioning and Testing Tex-

3.1.7 lower body, n—that part of the human body which

tiles

includes all portions between the waist and feet, not to include

1 the feet.

This test method is under the jurisdiction of ASTM Committee F23 on Personal

Protective Clothing and Equipment and is the direct responsibility of Subcommittee

3.1.8 protective clothing, n—an item of clothing that is

F23.20 on Physical.

specifically designed and constructed for the intended purpose

Current edition approved Nov. 1, 2023. Published November 2023. Originally

of isolating all or part of the body from a potential hazard, or

approved in 2018. Last previous edition approved in 2019 as F3324 – 19. DOI:

10.1520/F3324-19R23.

isolating the external environment from contamination by the

This standard was developed as a replacement for the archived CAN/BNQ

clothing.

1923-450.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3324 − 19 (2023)

3.1.8.1 Discussion—For chainsaw cut-resistant protective resistance to cutting and the capacity to absorb rotational

clothing, the potential hazard is exposure to a running power energy, so that chain speed can be slowed down sufficiently to

saw chain. stop the movement of the saw chain; or (4) any combination of

these.

3.1.9 saw chain, n—a closed loop of cutters linked together

for use in a portable, power-operated tool.

5.4 This test method does not purport to evaluate comfort of

lower body protective garments.

3.1.10 threshold stopping speed, n—chain speed that results

in a ⁄4 in. cut in the bottom layer of the protective pad liner in

5.5 In case of a dispute arising from differences in reported

a chainsaw leg protective device.

test results when using this test method for acceptance testing

3.1.10.1 Discussion—This value establishes the relationship

of commercial shipments, the purchaser and the supplier

between the probability of cutting through the protective

should perform comparative tests to determine if there is a

clothing (or foot protective device) and the speed of the saw

statistical bias between their laboratories. Competent statistical

chain. For lower chain speeds, the probability of cut-through

assistance is recommended for the investigation of bias. As a

approaches zero, while for higher chain speeds, the probability

minimum, the two parties should take a group of test speci-

of cut-through approaches one.

mens from the same lot of components to be evaluated. The test

specimens should then be randomly assigned in equal numbers

3.2 For definitions of other textile terms used in this test

to each laboratory for testing. If a bias is found, either its cause

method, refer to Terminology D123.

must be determined and corrected or the purchaser and the

3.3 For definitions of other protective clothing terms used in

supplier must agree to interpret future test results in light of the

this test method, refer to Terminology F1494.

known bias.

3.4 Pass/fail is a threshold stopping speed value measured in

meters per second (feet per minute) of chain travel speed that

6. Apparatus

results in the stated 6 mm ( ⁄4 in.) cut in the bottom of the lining

6.1 Apparatus consists of three main components:

of the performance pad of a chainsaw protective device. (See

6.2 Specimen Holder:

3.1.10.)

6.2.1 A stationary wooden cylinder having a diameter of

4. Summary of Test Method

152 mm (6 in.) and a minimum length of 356 mm (14 in.) (see

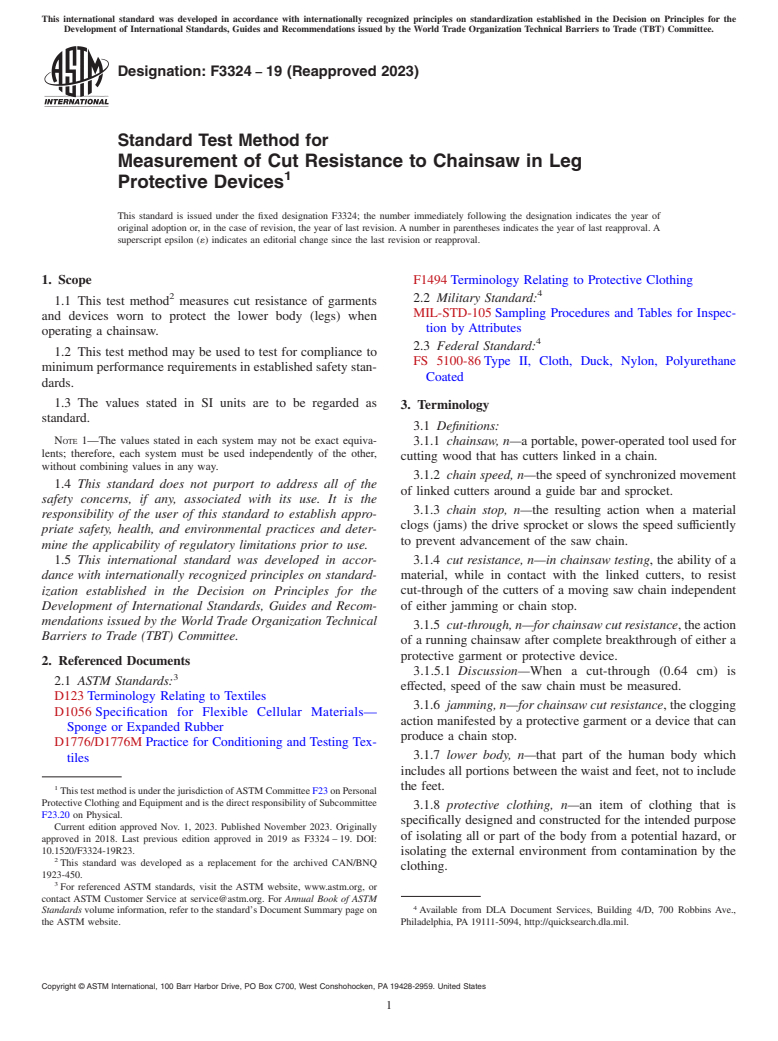

Figs. 1 and 2).

4.1 Test specimens are securely mounted on a test apparatus

6.2.1.1 The cylinder is covered with a vinyl nitrile foam

that simulates a human leg.

having a thickness of 18 mm (0.71 in.) (see Figs. 1 and 2). This

4.2 A chainsaw of specific characteristic and operating at a 2

covering shall have a density between 55 and 80 kg ⁄m and its

designated speed is brought into contact with the test specimen.

resistance to a 25 % compression shall be between 10 and

4.2.1 The cutting action of the saw chain will achieve one of

20 kPa, measured in accordance with the testing procedure in

the following results: (1) complete cut-through with chain stop,

Specification D1056.

(2) complete cut-through without chain stop, (3) no cut-

NOTE 3—Ensolite M, a synthetic foam rubber made of PVC and NBR,

through with a chain stop, or (4) no cut-through without a chain

meets the requirements stipulated in Specification D1056.

stop.

6.2.1.2 Two specimen attachment plates, each secured by

4.3 Chain speed is measured electronically just prior to

two screws to the wooden cylinder parallel to the axis of that

contact with test specimen. Chain speed is adjusted and

cylinder. Each plate is 75 by 25 mm (3 by 1 in.) (see Figs. 1

reported based on these measurements.

and 2).

NOTE 2—Materials may be characterized by repeated testing at different

6.2.1.3 The stationary wooden cylinder shall be attached to

speeds; for quality control, results may be reported as “pass” or “fail” at

a swivel mechanism that allows the mandrel to be moved to an

one pre-selected chain speed.

angle of either 45° or 90° to the vertical plane of the guide bar.

5. Significance and Use Specimen must be securely attached to mandrel to prevent

movement of specimen.

5.1 The purpose of this test method is to provide a measur-

6,7

able criterion of performance about the level of cut resistance 6.3 Chainsaw and Related Equipment:

provided by different types of protective garments and protec- 6.3.1 Saw:

tive coverings worn by chainsaw operators.

6.3.1.1 A gas-powered chainsaw, having an idle speed of

2250 6 250 rpm and a maximum power of 3.3 6 0.3 kW at

5.2 This test method is intended to show to what level a

8500 rpm that meets the following specifications: (1) minimum

protective garment can offer resistance to the cutting action of

3 3

66.7 cm or 4.0 in. ; (2) bore 50 mm; (3) stroke 34 mm; (4)

a chainsaw.

5.3 The protection that can be demonstrated by the garments

and coverings tested in accordance with this test method is 5

See Appendix X1 to review maintenance checklist.

achieved by: (1) the cut resistance of the material to cutting

Husqvarna Model 570 XP with an eight-tooth drive sprocket, available from

Husqvarna, http://www.husqvarna.com.

when put in contact with saw chain; (2) pulling a part of the

This is the sole source of supply known to the committee at this time. If you are

material or yarns in the material so that they are drawn into the

aware of alternative suppliers, please provide this information to ASTM Headquar-

chain and drive mechanism to block the chain movement; (3)

ters. Your comments will receive careful consideration at a meeting of the

the fibers of the materials used to demonstrate both high responsible technical committee, which you may attend.

F3324 − 19 (2023)

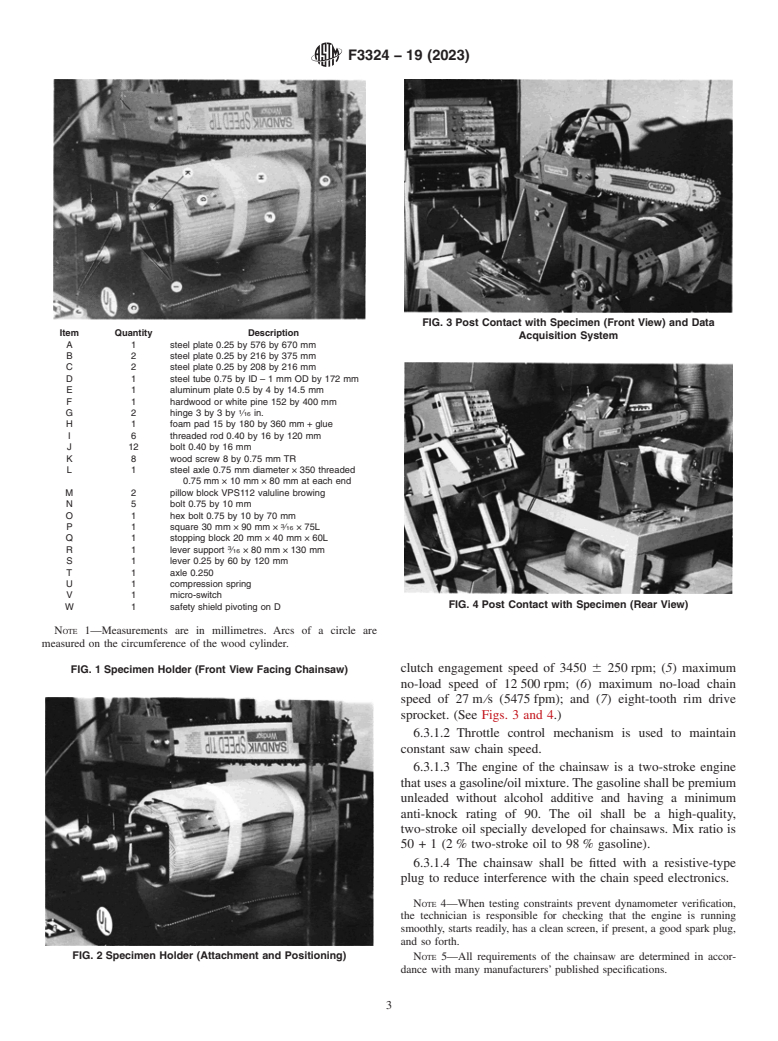

FIG. 3 Post Contact with Specimen (Front View) and Data

Item Quantity Description

Acquisition System

A 1 steel plate 0.25 by 576 by 670 mm

B 2 steel plate 0.25 by 216 by 375 mm

C 2 steel plate 0.25 by 208 by 216 mm

D 1 steel tube 0.75 by ID – 1 mm OD by 172 mm

E 1 aluminum plate 0.5 by 4 by 14.5 mm

F 1 hardwood or white pine 152 by 400 mm

G 2 hinge 3 by 3 by ⁄16 in.

H 1 foam pad 15 by 180 by 360 mm + glue

I 6 threaded rod 0.40 by 16 by 120 mm

J 12 bolt 0.40 by 16 mm

K 8 wood screw 8 by 0.75 mm TR

L 1 steel axle 0.75 mm diameter × 350 threaded

0.75 mm × 10 mm × 80 mm at each end

M 2 pillow block VPS112 valuline browing

N 5 bolt 0.75 by 10 mm

O 1 hex bolt 0.75 by 10 by 70 mm

P 1 square 30 mm × 90 mm × ⁄16 × 75L

Q 1 stopping block 20 mm × 40 mm × 60L

R 1 lever support ⁄16 × 80 mm × 130 mm

S 1 lever 0.25 by 60 by 120 mm

T 1 axle 0.250

U 1 compression spring

V 1 micro-switch

FIG. 4 Post Contact with Specimen (Rear View)

W 1 safety shield pivoting on D

NOTE 1—Measurements are in millimetres. Arcs of a circle are

measured on the circumference of the wood cylinder.

clutch engagement speed of 3450 6 250 rpm; (5) maximum

FIG. 1 Specimen Holder (Front View Facing Chainsaw)

no-load speed of 12 500 rpm; (6) maximum no-load chain

speed of 27 m ⁄s (5475 fpm); and (7) eight-tooth rim drive

sprocket. (See Figs. 3 and 4.)

6.3.1.2 Throttle control mechanism is used to maintain

constant saw chain speed.

6.3.1.3 The engine of the chainsaw is a two-stroke engine

that uses a gasoline/oil mixture. The gasoline shall be premium

unleaded without alcohol additive and having a minimum

anti-knock rating of 90. The oil shall be a high-quality,

two-stroke oil specially developed for chainsaws. Mix ratio is

50 + 1 (2 % two-stroke oil to 98 % gasoline).

6.3.1.4 The chainsaw shall be fitted with a resistive-type

plug to reduce interference with the chain speed electronics.

NOTE 4—When testing constraints prevent dynamometer verification,

the technician is responsible for checking that the engine is running

smoothly, starts readily, has a clean screen, if present, a good spark plug,

and so forth.

FIG. 2 Specimen Holder (Attachment and Positioning) NOTE 5—All requirements of the chainsaw are determined in accor-

dance with many manufacturers’ published specifications.

F3324 − 19 (2023)

8,7

6.3.2 Chain: 7. Hazards

6.3.2.1 A chain with a pitch of 10 mm ( ⁄8 in.), a 0.058 in.

7.1 Warning—The chainsaw equipment used in this test

gage, and a round ground full chisel cutter.

method can pose a potential danger to the technician if specific

6.3.2.2 New chain may be used without sharpening, or the

safety cautions are not followed.

chain must be sharpened using the sharpening procedure noted

7.2 As a minimum safety precaution, it is suggested that the

in Annex A1 before testing.

spark plug wire be disengaged until the engine needs to be

6.3.3 Guide Bar:

started.

6.3.3.1 A guide bar having a length of 500 mm (20 in.), with

an eleven-tooth roller-nose sprocket, designed to accommodate

7.3 As a further safety precaution, it is suggested that the

a 10 mm ( ⁄8 in.) pitch, 0.058 in. gage saw chain.

spark plug wire be grounded by circuitry after cutting the lower

6.3.3.2 The roller nose on the guide bar will need to be

wire of the data collection system. If the chain stops before this

cleaned at periodic intervals. To facilitate repeated cleanings,

wire is cut or if the chain slides over the specimen, a timer

the rivets attaching the roller nose to the bar should be

should limit the test and stop the engine by grounding the

replaced. Modification requires that rivets be removed and

electric circuitry of the chainsaw.

holes be enlarged by drilling, so that aircraft-quality bolts and

7.4 The technician performing this test method should use

locking nuts can be used.

ear protection to avoid potential hearing injury.

6.3.4 Chain Guidance and Lubrication:

6.3.4.1 The saw chain shall be able to turn freely around the 7.5 The technician performing this test method should use

drive sprocket and roller nose. The system shall be adequately eye protection to avoid potential eye injury.

lubricated. Chain tension shall be adjustable so that application

7.6 The chainsaw motor should be vented to prevent poten-

of a force of 15 N on the middle of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.