ASTM D4680-98(2004)

(Test Method)Standard Test Method for Creep and Time to Failure of Adhesives in Static Shear by Compression Loading (Wood-to-Wood)

Standard Test Method for Creep and Time to Failure of Adhesives in Static Shear by Compression Loading (Wood-to-Wood)

SIGNIFICANCE AND USE

Creep data that are obtained over a relatively short period of time in this test method can provide a measure of an adhesive bond’ability to withstand static loading in shear over a relatively long period of time. Creep measurements are made over a range of expected service conditions, including level of stress, temperature, relative humidity, and duration of load. Creep rate, creep strain, and creep modulus are calculated at the various service conditions.

Creep data can be used to (1) predict performance of an adhesive under long-term loading, (2) characterize an adhesive, (3) compare adhesives with each other and against specifications, and ( 4) design structural members fabricated with an adhesive.

Time-to-failure data provide a measure of the ultimate load-carrying ability of an adhesive bond as a function of time at various levels of stress, temperature, and relative humidity.

With proper caution, time-to-failure data derived from relatively short loading periods can be extrapolated to estimate the useful service life of an adhesive at working levels of static stress. This property may also be used with creep data to accomplish purposes listed in 4.2.

This test method is a research tool intended for development or evaluation of new adhesives and new product designs. The researcher may select from suggested tests those that are appropriate. However, creep and time-to-failure tests are nonroutine and can be time-consuming and expensive, so tests must be selected with care.

The apparatus and procedures may be suitable for measuring creep properties of adhesives on substrates other than wood, such as metal, plastic, and glass, but such considerations are not within the scope of this test method.

FIG. 1 Creep Test Apparatus

SCOPE

1.1 This test method covers the determination of time-dependent properties of structural adhesives in wood-to-wood bonds when specimens are subjected to shearing stresses at various levels of static load, constant temperature, and relative humidity. Apparatus and procedures are provided for direct measurement of time-dependent shear deformation (creep) and time to failure of adhesive bonds under static load. Guidelines for selecting test conditions, methods for calculating creep rate, creep strain, creep modulus, and extrapolation of time to failure, are given along with methods of presenting these data.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units are given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4680–98(Reapproved2004)

Standard Test Method for

Creep and Time to Failure of Adhesives in Static Shear by

Compression Loading (Wood-to-Wood)

This standard is issued under the fixed designation D4680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Compression-Shear Creep Test Apparatus

1.1 This test method covers the determination of time-

3. Terminology

dependent properties of structural adhesives in wood-to-wood

3.1 Definitions—Many terms in these test methods are

bonds when specimens are subjected to shearing stresses at

defined in Terminology D907.

various levels of static load, constant temperature, and relative

3.1.1 creep—the dimensional change with time of a mate-

humidity. Apparatus and procedures are provided for direct

rial under load, following the initial instantaneous elastic or

measurementoftime-dependentsheardeformation(creep)and

rapid deformation. Creep at room temperature is sometimes

time to failure of adhesive bonds under static load. Guidelines

called cold flow.

forselectingtestconditions,methodsforcalculatingcreeprate,

3.1.2 creep modulus—the ratio of initial applied stress to

creep strain, creep modulus, and extrapolation of time to

creep strain.

failure, are given along with methods of presenting these data.

3.1.3 creep strain—the total strain, at any given time,

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

produced by the applied stress during a creep test.

as the standard. The SI units are given in parentheses are for

3.1.3.1 Discussion—In this test method, creep strain is

information only.

calculated by dividing displacement at any given time by the

1.3 This standard does not purport to address all of the

estimated apparent thickness of the adhesive bondline.

safety concerns, if any, associated with its use. It is the

3.1.4 rate of creep—the slope of the creep-time curve at a

responsibility of the user of this standard to establish appro-

given time.

priate safety and health practices and determine the applica-

3.1.5 shear stress—the stress component tangential to the

bility of regulatory limitations prior to use.

plane on which the forces act, that is, in the plane of the bond

2. Referenced Documents line.

2 3.1.6 strain—the unit change, due to stress, in the size or

2.1 ASTM Standards:

shape of a body referred to its original size or shape.

D143 Test Methods for Small Clear Specimens of Timber

3.1.7 stress, n—the force exerted per unit area at a point

D905 Test Method for Strength Properties of Adhesive

within the plane.

Bonds in Shear by Compression Loading

D907 Terminology of Adhesives

4. Significance and Use

D2016 Test Methods for Moisture Content of Wood

4.1 Creep data that are obtained over a relatively short

2.2 ASTM Adjuncts:

period of time in this test method can provide a measure of an

adhesivebond’sabilitytowithstandstaticloadinginshearover

This test method is under the jurisdiction of ASTM Committee D14 on

arelativelylongperiodoftime.Creepmeasurementsaremade

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

over a range of expected service conditions, including level of

Adhesives.

stress, temperature, relative humidity, and duration of load.

Current edition approved April 1, 2004. Published April 2004. Originally

approved in 1987. Last previous edition approved in 1998 as D4680–98. DOI:

Creep rate, creep strain, and creep modulus are calculated at

10.1520/D4680-98R04.

the various service conditions.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Withdrawn. The last approved version of this historical standard is referenced Available from ASTM International Headquarters. Order Adjunct No.

on www.astm.org. ADJD4680. Original adjunct produced in 1987.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4680–98 (2004)

4.2 Creep data can be used to (1) predict performance of an The preheated apparatus must be wrapped with a piece of

adhesiveunderlong-termloading,(2)characterizeanadhesive, flexible thermal insulation material while the test load is

(3) compare adhesives with each other and against specifica-

applied to the specimen. After loading and measurements,

tions, and ( 4) design structural members fabricated with an

returntheloadedapparatustothetestenvironment.Sincethere

adhesive.

are no significant changes in temperature before or after

4.3 Time-to-failure data provide a measure of the ultimate

loading, no adjustments are needed in the spring.

load-carrying ability of an adhesive bond as a function of time

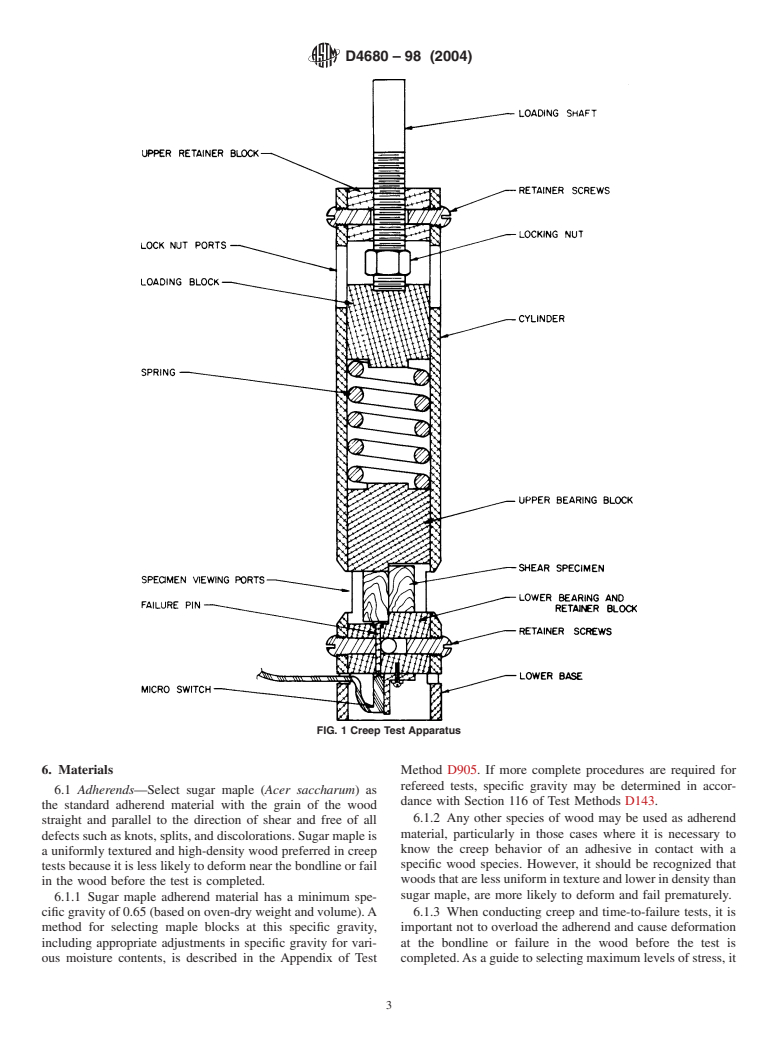

5.3.2 Thecreep-testapparatusismadeofcorrosion-resistant

at various levels of stress, temperature, and relative humidity.

components so that it can be used in high-temperature and

4.4 With proper caution, time-to-failure data derived from

humidenvironmentsforprolongedperiodswithoutconcernfor

relativelyshortloadingperiodscanbeextrapolatedtoestimate

damaging the apparatus or interfering with the effectiveness of

theusefulservicelifeofanadhesiveatworkinglevelsofstatic

the test.

stress. This property may also be used with creep data to

5.3.3 Thecreep-testapparatushasbeencompactlydesigned

accomplish purposes listed in 4.2.

withitsload-applyingmechanismbuilt-in.Thus,severalofthe

4.5 This test method is a research tool intended for devel-

units may be stacked on racks in a small environmental

opment or evaluation of new adhesives and new product

chamber such as an oven, incubator, or humidity cabinet. The

designs. The researcher may select from suggested tests those

apparatus may be transferred from one exposure chamber to

that are appropriate. However, creep and time-to-failure tests

another, or may be removed from an exposure chamber for

are nonroutine and can be time-consuming and expensive, so

measurements without disturbing the specimen under static

tests must be selected with care.

load.

4.6 The apparatus and procedures may be suitable for

measuring creep properties of adhesives on substrates other 5.3.4 The creep-test apparatus shown in Fig. 1 has a

than wood, such as metal, plastic, and glass, but such consid-

microswitch mounted at its base which is activated when the

erations are not within the scope of this test method.

creep specimen fails. A small pin is located in the lower

specimen seat which is driven against the microswitch when

5. Apparatus

the failed specimen strikes it. The microswitch must be

5.1 Testing Machine— A testing machine, or other suitable

connected to an automatic timer-recorder.

loading machine, capable of applying compression loads from

5.4 Automatic Timer-Recorder—If creep or time-to-failure

0 to 5000 lbf (22 kN) and cross-head speeds from 0.01 to 0.40

measurements are to be made, an automatic and multi-channel

in./min (0.3 to 10.2 mm/min) is sufficient for this test method.

timer-recorder is connected to the microswitch on each creep-

A minimum vertical space of 20 in. (508 mm) is required to

test apparatus. The timer-recorder is capable of automatically

compress the loading spring in the creep-test apparatus.

scanning the several connected circuits at selected intervals of

5.2 Compression Shearing Tool—The testing machine is

time. When the creep specimen fails and activates the mi-

equipped with a shearing tool capable of applying a uniformly

croswitch, the timer-recorder automatically records the time at

distributed compression load to the loading ledges of the

which the circuit is broken.

block-shear specimen. A shearing tool equipped with a self-

5.5 Microscope—A microscope is required to measure dis-

aligning seat in the shearing blade ensures uniform loading.

placement of scribe marks across the two adherends of a

5.3 Creep-TestApparatus—Staticloadsshallbeappliedand

specimen as creep occurs. Accurate measurements are also

maintained on block-shear specimens by means of the

5,4

required for bondline thicknesses. Make measurements to the

compression-loadedcreep-testcylindershowninFig.1. The

nearest 0.001 mm (0.0004 in.). A linear traveling binocular

apparatus is spring-loaded and can sustain any load up to the

microscope is ideally suited to creep measurements; however,

design capacity of the spring. This particular spring has a

a microscope fitted with an appropriately graduated scale is

design load of 2300 lbf (10 kN); however, others of greater or

less capacity may be substituted. Varying spring capacities satisfactory. An objective lens of at least 73 magnification is

required.

with outside diameters no greater than the cylinder inside

diameter are available.

5.6 Environmental Chambers—Control of temperature and

5.3.1 For creep tests above room temperature, it is not

relative humidity is required in creep tests of adhesive bonds

necessary to adjust the spring or load to compensate for the

on wood substrates. Temperature has a profound effect on

effects of changing temperature. It is only necessary that the

creep properties of adhesives. Humidity also affects creep of

apparatus, with included specimen, be preconditioned to the

certain adhesives, but it can also affect dimensional change in

test temperature before the test load is applied to the spring.

woodadherends.Conditioningequipmentshouldbecapableof

maintainingaconstanttemperaturewithin 63.0°F(61.7°C)of

theset-pointandconstantrelativehumiditywithin 65%ofthe

Thiscreep-testapparatusmaybepurchasedfromHullMachineShop,P.O.373,

Hull, GA 30646, or other suitable suppliers. set-point at a given temperature.

D4680–98 (2004)

FIG. 1 Creep Test Apparatus

6. Materials Method D905. If more complete procedures are required for

refereed tests, specific gravity may be determined in accor-

6.1 Adherends—Select sugar maple (Acer saccharum)as

dance with Section 116 of Test Methods D143.

the standard adherend material with the grain of the wood

6.1.2 Any other species of wood may be used as adherend

straight and parallel to the direction of shear and free of all

material, particularly in those cases where it is necessary to

defectssuchasknots,splits,anddiscolorations.Sugarmapleis

know the creep behavior of an adhesive in contact with a

a uniformly textured and high-density wood preferred in creep

specific wood species. However, it should be recognized that

testsbecauseitislesslikelytodeformnearthebondlineorfail

woodsthatarelessuniformintextureandlowerindensitythan

in the wood before the test is completed.

sugar maple, are more likely to deform and fail prematurely.

6.1.1 Sugar maple adherend material has a minimum spe-

cificgravityof0.65(basedonoven-dryweightandvolume).A 6.1.3 When conducting creep and time-to-failure tests, it is

method for selecting maple blocks at this specific gravity, important not to overload the adherend and cause deformation

including appropriate adjustments in specific gravity for vari- at the bondline or failure in the wood before the test is

ous moisture contents, is described in the Appendix of Test completed.Asaguidetoselectingmaximumlevelsofstress,it

D4680–98 (2004)

FIG. 2 Block-Shear Specimen for Creep and Time To Failure Tests

is recommended that the load not exceed the average shear 7. Test Specimens

strength parallel-to-grain for the species of wood when ad-

7.1 The standard specimen for both creep and time-to-

justed for any change in moisture content from 12%.Average

failure tests shall be the block-shear specimen illustrated in

shear strengths at 12% moisture content for sugar maple and

Fig. 2. Use the test adhesive to bond the two hard maple

other species of wood are presented in Table4-2 of the Wood

adherends together.The shear area is 1.00 by 1.00 in. (2.54 by

2 2

Handbook. For moisture contents other than 12%, it will be

2.54 cm), equalling 1.00 in. (6.45 cm ).

necessary to adjust shear strengths by the formula described in

7.2 The finished specimen for creep tests has well-defined

pp. 4-32 and 4-33 of the Wood Handbook.

scribe marks on each side of the specimen for measuring

6.1.4 Should premature failures occur in the wood after

displacement of the two adherends as creep takes place.

mean strength values have been adjusted for moisture content,

7.3 Scribe marks are not necessary for specimens intended

then the 5% exclusion limit may be used to select the

for the time-to-failure tests.

maximum level of stress for a particular species of wood. The

7.4 Number of Specimens:

maximum level of stress S is determined by the

max0.05

7.4.1 Test at least ten specimens at each set of test condi-

following equation:

tions,thatis,eachcombinationofstresslevel,temperature,and

S 5 S 21.645~0.14S ! (1) relative humidity, for either creep test or time-to-failure test. It

max0.05 m m

is suggested that at least one test joint assembly (contains

where S is the mean shear strength parallel-to-grain as

m

6 twelve specimens) be prepared for each combination of test

presented in Table4-2 of the Wood Handbook.

conditions.

6.2 Adhesives—Creep properties of any adhesive can be

7.4.2 Randomlyassignthetenspecimensforeachsetoftest

measured on any species of wood as long as the level of shear

conditions to that set from the entire lot of specimens prepared

stress does not exceed the shear strength of the wood in the

for testing of a given adhesive.

specimen.

7.4.3 For many adhesives, measured creep properties will

be highly variable, and ten specimens may not be a large

enoughsampletogiveahighdegreeofconfidencetothemean

Wood Handbook: Wood As An Engineering Material, USDA Agriculture

of a measured property. Creep tests generally are expensive

Handbook 72,rev.,U.S.ForestProductsLab.,1974,Table4-2andp.4-32and4-33.

and time-consuming, and a specimen count of ten represents a

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,732

N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401. practical compromise.

D4680–98 (2004)

7.4.4 If it is determined from experimental evidence that a givenin8.1.Conditionthemtherefor7daystoensurethatthe

reasonable degree of confidence can be given to a mean by moisture content has stabilized before creep tests begin. If

using a lesser number of specimens, then it is permissible to creep tests are to be conducted at equilibrium moisture

use the lesser number. conditions other than those in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.