ASTM E1131-98

(Test Method)Standard Test Method for Compositional Analysis by Thermogravimetry

Standard Test Method for Compositional Analysis by Thermogravimetry

SCOPE

1.1 This test method is intended to provide a general technique incorporating thermogravimetry to determine the amount of highly volatile matter, medium volatile matter, combustible material, and ash content of compounds. This test method will be useful in performing a compositional analysis in cases where agreed upon by interested parties.

1.2 This test method is applicable to solids and liquids.

1.3 The temperature range of test is typically room temperature to 1000°C. Composition between 1 and 100 weight% of individual components may be determined.

1.4 This test method utilizes an inert and reactive gas environment.

1.5 Computer or electronic-based instruments, techniques, or data treatment equivalent to this method may also be used. Users of this test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user of this test method to determine the necessary equivalency prior to use. In the case of dispute, only the manual procedures described in this test method are to be considered valid.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1131 – 98

Standard Test Method for

Compositional Analysis by Thermogravimetry

This standard is issued under the fixed designation E 1131; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method is intended to provide a general 3.1 Definitions:

technique incorporating thermogravimetry to determine the 3.1.1 Many of the technical terms used in this test method

amount of highly volatile matter, medium volatile matter, are defined in Terminologies E 473 and E 1142.

combustible material, and ash content of compounds. This test 3.2 Definitions of Terms Specific to This Standard:

method will be useful in performing a compositional analysis 3.2.1 highly volatile matter—moisture, plasticizer, residual

in cases where agreed upon by interested parties. solvent or other low boiling (200°C or less) components.

1.2 This test method is applicable to solids and liquids. 3.2.2 medium volatile matter—medium volatility materials

1.3 The temperature range of test is typically room tempera- such as oil and polymer degradation products. In general, these

ture to 1000°C. Composition between 1 and 100 weight % of materials degrade or volatilize in the temperature range 200 to

individual components may be determined. 750°C.

1.4 This test method utilizes an inert and reactive gas 3.2.3 combustible material—oxidizable material not vola-

environment. tile (in the unoxidized form) at 750°C, or some stipulated

1.5 Computer or electronic-based instruments, techniques, temperature dependent on material. Carbon is an example of

or data treatment equivalent to this test method may also be such a material.

used. 3.2.4 ash—nonvolatile residues in an oxidizing atmosphere

which may include metal components, filler content or inert

NOTE 1—Users of this test method are expressly advised that all such

reinforcing materials.

instruments or techniques may not be equivalent. It is the responsibility of

3.2.5 mass loss plateau—a region of a thermogravimetric

the user of this test method to determine the necessary equivalency prior

curve with a relatively constant mass.

to use.

1.6 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard.

4.1 This test method is an empirical technique using ther-

1.7 This standard does not purport to address all of the

mogravimetry in which the mass of a substance, heated at a

safety concerns, if any, associated with its use. It is the

controlled rate in an appropriate environment, is recorded as a

responsibility of the user of this standard to establish appro-

function of time or temperature. Mass loss over specific

priate safety and health practices and determine the applica-

temperature ranges and in a specific atmosphere provide a

bility of regulatory limitations prior to use.

compositional analysis of that substance.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 This test method is intended for use in quality control,

D 3172 Practice for Proximate Analysis of Coal and Coke

material screening, and related problem solving where a

E 473 Terminology Relating to Thermal Analysis

compositional analysis is desired or a comparison can be made

E 691 Practice for Conducting an Interlaboratory Study to

with a known material of the same type.

Determine the Precision of a Test Method

5.2 The parameters described should be considered as

E 1142 Terminology Relating to Thermophysical Proper-

guidelines. They may be altered to suit a particular analysis,

ties

provided the changes are noted in the report.

E 1582 Practice for Calibration of Temperature Scale for

5.3 The proportion of the determined components in a given

Thermogravimetry

mixture or blend may indicate specific quality or end use

performance characteristics. Particular examples include the

following:

This test method is under the jurisdiction of ASTM Committee E-37 on

Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on

5.3.1 Increasing soot (carbon) content of used diesel lubri-

Thermal Analysis Methods.

cating oils indicates decreasing effectiveness.

Current edition approved June 10, 1998. Published December 1998. Originally

5.3.2 Specific carbon-to-polymer ratio ranges are required

published as E 1131 – 86. Last previous edition E 1131 – 93.

Annual Book of ASTM Standards, Vol 05.05.

in some elastomeric and plastic parts in order to achieve

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1131

desired mechanical strength and stability. a Y-axis resolution of 5 μg and temperature or time with an

5.3.3 Some filled elastomeric and plastic products require X-axis resolution of1Kor0.1 min.

specific inert content (for example, ash, filler, reinforcing

NOTE 2—The capability to display the first derivative of the signal may

agent, etc.) to meet performance specifications.

be useful in the measurement of obscure thermostability ranges.

5.3.4 The volatile matter, fixed carbon, and ash content of

7.1.4 Containers (pans, crucibles, and so forth), which are

coal and coke are important parameters. The “ranking” of coal

inert to the specimen and which will remain dimensionally

increases with increasing carbon content and decreasing vola-

stable within the temperature limits of this method.

tile and hydrocarbon, (medium volatility) content.

7.2 Gas Flow Control Device, with the capability of switch-

ing between inert and reactive gases.

6. Interferences

6.1 This test method depends upon distinctive thermostabil-

8. Reagents and Materials

ity ranges of the determined components as a principle of the

8.1 An inert compressed gas such as argon or nitrogen and

test. For this reason, materials which have no well-defined

a reactive compressed gas such as air or oxygen are required

thermostable range, or whose thermostabilities are the same as

for this method.

other components, may create interferences. Particular ex-

8.2 Purity of Purge Gases:

amples include the following:

8.2.1 0.01 % maximum total impurity.

6.1.1 Oil-filled elastomers have such high molecular weight

8.2.2 1.0 μg/g water impurity maximum.

oils and such low molecular weight polymer content that the oil

8.2.3 1.0 μg/g hydrocarbon impurity maximum.

and polymer may not be separated based upon temperature

8.2.4 The inert purge gas must not contain more than 10

stability.

μg/g oxygen.

6.1.2 Ash content materials (metals) are slowly oxidized at

high temperatures and in an air atmosphere, so that their mass

9. Test Specimen

increases (or decreases) with time. Under such conditions, a

9.1 Specimens are ordinarily measured as received. If some

specific temperature or time region must be identified for the

heat or mechanical treatment is applied to the specimen prior to

measurement of that component.

test, this treatment shall be noted in the report.

6.1.3 Polymers, especially neoprene and acrylonitrile buta-

9.2 Since the applicable samples may be mixtures or blends,

diene rubber (NBR), carbonize to a considerable extent, giving

take care to ensure that the analyzed specimen is representative

low values for the polymer and high values for the carbon.

of the sample from which it is taken. If the sample is a liquid,

Approximate corrections can be made for this if the type of

mixing prior to taking the specimen is sufficient to ensure this

polymer is known.

consideration. If the sample is a solid, take several specimens

6.1.4 Certain pigments used in rubber lose weight on

from different areas of the sample and either combine for a

heating. For example, some pigments exhibit water loss in the

single determination, or each run separately with the final

range 500 to 600°C, resulting in high polymer values. Others,

analysis representing an average of the determinations. Note

such as calcium carbonate, release CO upon decomposition at

the number of determinations in the report.

825°C, that may result in high carbon values. The extent of

interference is dependent upon the type and quantity of

10. Calibration

pigment present.

10.1 Calibrate the mass signal from the apparatus according

to the manufacturer’s instructions.

7. Apparatus

10.2 Calibrate the temperature signal from the apparatus

7.1 The essential equipment required to provide the mini-

according to Practice E 1582.

mum thermogravimetric analyzer capability for this method

includes:

11. Procedure

7.1.1 A thermobalance, composed of (a) a furnace to

11.1 Establish the inert (nitrogen) and reactive (air or

provide uniform controlled heating or a specimen to a constant

oxygen) gases at the desired flow rates. For most analyses, this

temperature or at a constant rate within the 25 to 1000°C

rate will be in the range of 10 to 100 mL/min. Higher flow rates

temperature range of this test method; (b) a temperature sensor

may be used for some analyses, particularly when utilizing

to provide an indication of the specimen/furnace temperature to

high heating rates.

61°C; (c) an electrobalance to continuously measure the

11.2 Switch the purge gas to the inert (nitrogen) gas.

specimen mass with a minimum capacity of 30 mg and a

11.3 Zero the recorder and tare the balance. It is recom-

sensitivity of 61 μg; and (d) a means of sustaining the

mended that this be done in a range at least one recorder setting

specimen/container under atmosphere control with a purge rate

more sensitive than that to be used in the final ash weighing.

of 10 to 100 6 5 mL/min.

11.4 Open the apparatus to expose the specimen holder.

7.1.2 A temperature controller, capable of executing a

11.5 Prepare the specimen as outlined in 9.2 and carefully

specific temperature program by operating the furnace between

place it in the specimen holder. Typically, a sample mass of 10

selected temperature limits at a rate of temperature change

to 30 mg shall be used (see Table 1).

between 10 and 100°C/min constant to within 61 % for a

NOTE 3—Specimens smaller than 10 mg may be used if larger

minimum of 100 minutes.

specimens cause instrument fouling or poor reproducibility.

7.1.3 A recording device, either analog or digital, capable of

recording and displaying the change in mass (TGA curve) with 11.6 Position the specimen temperature sensor to the same

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1131

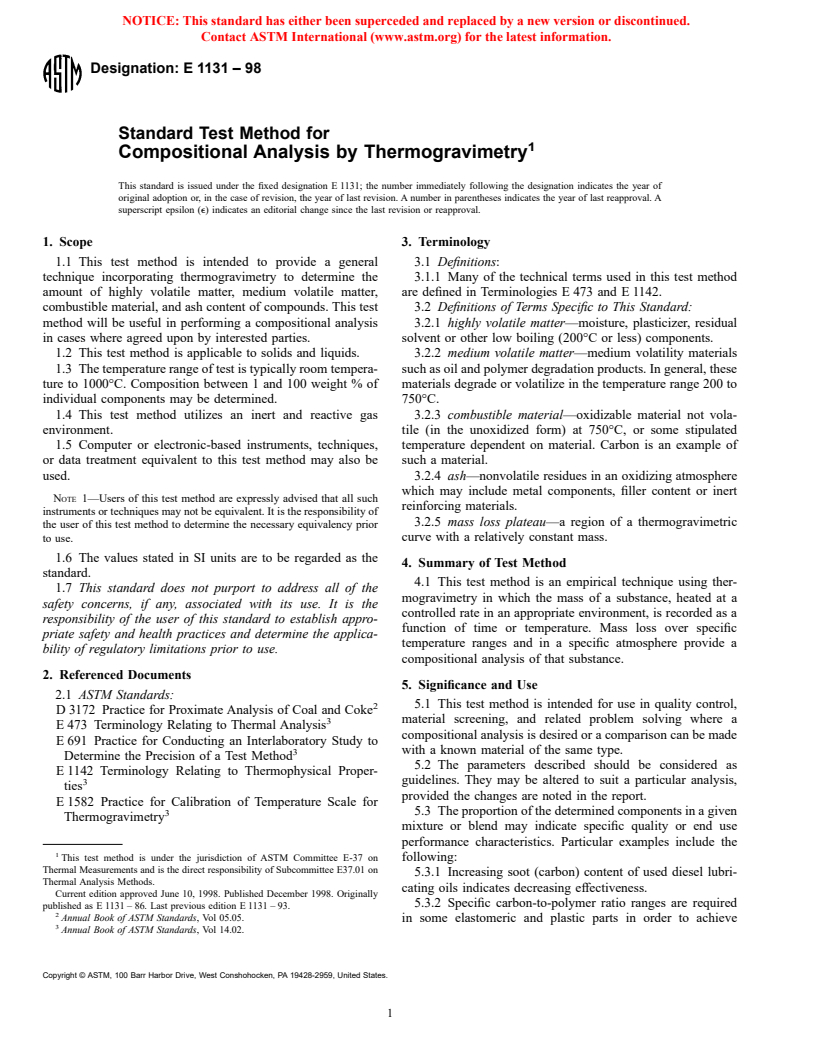

TABLE 1 Suggested Compositional Analysis Parameters

Purge Heating Gas

Temperature

Sample Flow Rate

Material Time Rate Switchover

A

Size mg mL/min B

Initial X Y Z

Min °C/min °C

coal 20 50 5 ambient 110 900 900 10 to 150 900

elastomers 20 50 2 ambient 325 550 750 10 600

thermoplastics 20 50 2 ambient 200 600 750 10 600

lubricants 20 40 to 500 1 50 150 600 750 10 to 100 600

thermosets 20 50 2 ambient 200 550 750 10 600

A

May differ depending upon instrument design.

B

Z is not necessarily the final temperature.

location used in calibration. (See Section 10.) by maintaining the specimen at constant temperature for

11.7 Enclose the specimen holder. several minutes after switching environments.

11.8 Record the initial mass. If the apparatus in use has

11.11 The analysis is complete upon the establishment of a

provisions for direct percentage measurements, adjust to read mass loss plateau following the introduction of the reactive

100 %. gas.

11.9 Initiate the heating program within the desired tem- 11.12 Switch to the inert purge gas.

perature range. See Table 1 for suggested heating rates and

11.13 Calculate and report the sample composition.

temperature ranges. Record the specimen mass change con-

tinuously over the temperature interval. 12. Calculation

11.9.1 The mass loss profile may be expressed in either

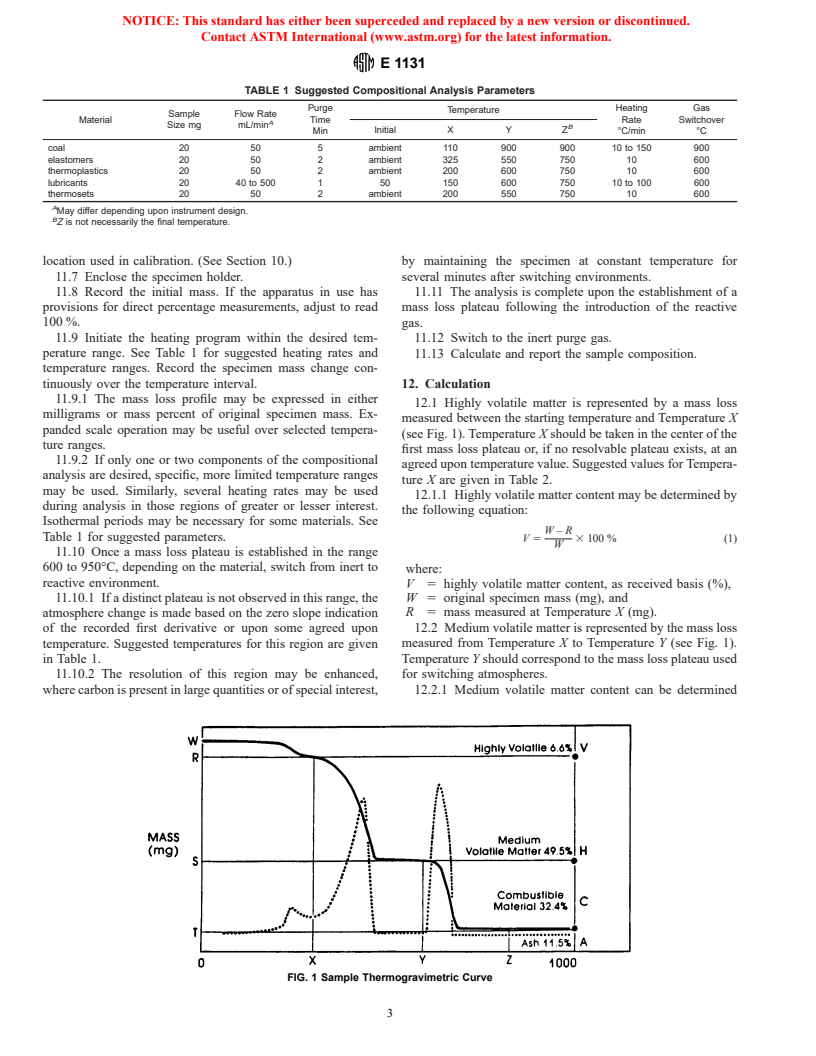

12.1 Highly volatile matter is represented by a mass loss

milligrams or mass percent of original specimen mass. Ex-

measured between the starting temperature and Temperature X

panded scale operation may be useful over selected tempera-

(see Fig. 1). Temperature X should be taken in the center of the

ture ranges.

first mass loss plateau or, if no resolvable plateau exists, at an

11.9.2 If only one or two components of the compositional

agreed upon temperature value. Suggested values for Tempera-

analysis are desired, specific, more limited temperature ranges

ture X are given in Table 2.

may be used. Similarly, several heating rates may be used

12.1.1 Highly volatile matter content may be determined by

during analysis in those regions of greater or lesser interest.

the following equation:

Isothermal periods may be necessary for some materials. See

W – R

Table 1 for suggested parameters.

V 5 3 100 % (1)

W

11.10 Once a mass loss plateau is established in the range

600 to 950°C, depending on the material, switch from inert to

where:

reactive environment.

V 5 highly volatile matter content, as received basis (%),

11.10.1 If a distinct plateau is not observed in this range, the W 5 original specimen mass (mg), and

atmosphere change is made based on the zero slope indication R 5 mass measured at Temperature X (mg).

of the recorded first derivative or upon some agreed upon 12.2 Medium volatile matter is represented by the mass loss

temperature. Suggested temperatures for this region are given measured from Temperature X to Temperature Y (see Fig. 1).

in Table 1. Temperature Y should correspond to the mass loss plateau used

11.10.2 The resolution of this region may be enhanced, for switching atmospheres.

where carbon is present in large quantities or of special interest, 12.2.1 Medium volatile matter content can be determined

FIG. 1 Sample Thermogravimetric Curve

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1131

TABLE 2 Compositional Analysis Interlaboratory Test

the oxidation of carbon to carbon dioxide.

Parameters

12.3.1 Combustible material content may be calculated by

Test Parameters by Material

the following equation:

Sample Purge Gas Preanalysis

S – T

A

Material Mass Flow Purge

C 5 3 100 % (3)

W

(mg) (mL/min) (min)

Coal 20 50 1

where:

Lubricant 10 100 1

C 5 combustible material content, as-received basis, (%),

Polyethylene 20 50 1

S 5 mass me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.