ASTM D4446-08

(Test Method)Standard Test Method for Anti-Swelling Effectiveness of Water-Repellent Formulations and Differential Swelling of Untreated Wood When Exposed to Liquid Water Environments

Standard Test Method for Anti-Swelling Effectiveness of Water-Repellent Formulations and Differential Swelling of Untreated Wood When Exposed to Liquid Water Environments

SIGNIFICANCE AND USE

This test method is useful in determining the relative anti-swelling efficiency of various water-repellent formulations when applied to wood. It is the initial means of estimating the ability of water-repellent treated wood to perform satisfactorily when exposed to liquid water environments.

The swelling differences of untreated wood species when subjected to water immersion can also be determined by this test method.

This method is a basic screening test and thus provides an initial determination of the anti-swelling efficiency of water repellents. It is a qualitative method designed to provide a reproducible means of establishing: (1) the anti-swelling efficiency of water-repellent formulations, and (2) the relative swelling of untreated wood species when both are exposed to liquid water environments.

SCOPE

1.1 This test method is designed to evaluate the effectiveness of water-repellent compositions for retarding dimensional changes in coated wood submerged in water. It can also be used to measure the differential swelling of untreated wood when exposed to liquid water environments. The compositions tested are designed to be mixed until uniform and applied by brush, roller, dip or spray to an exterior wood surface.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4446 − 08

StandardTest Method for

Anti-Swelling Effectiveness of Water-Repellent Formulations

and Differential Swelling of Untreated Wood When Exposed

1

to Liquid Water Environments

This standard is issued under the fixed designation D4446; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope when applied to wood. It is the initial means of estimating the

ability of water-repellent treated wood to perform satisfactorily

1.1 This test method is designed to evaluate the effective-

when exposed to liquid water environments.

ness of water-repellent compositions for retarding dimensional

changesincoatedwoodsubmergedinwater.Itcanalsobeused 3.2 The swelling differences of untreated wood species

to measure the differential swelling of untreated wood when when subjected to water immersion can also be determined by

exposed to liquid water environments.The compositions tested this test method.

are designed to be mixed until uniform and applied by brush,

3.3 This method is a basic screening test and thus provides

roller, dip or spray to an exterior wood surface.

an initial determination of the anti-swelling efficiency of water

1.2 The values stated in SI units are to be regarded as the repellents. It is a qualitative method designed to provide a

standard. The values given in parentheses are for information reproducible means of establishing: (1) the anti-swelling effi-

only. ciency of water-repellent formulations, and (2) the relative

swelling of untreated wood species when both are exposed to

1.3 This standard does not purport to address all of the

liquid water environments.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Apparatus

priate safety and health practices and determine the applica-

4.1 Conditioning Room or Chamber, having a controlled

bility of regulatory limitations prior to use.

temperature of 23 6 2°C (73.5 6 3.5°F), and a controlled

2. Summary of Method relative humidity of 50 6 5 %. This room is used to establish

a uniform moisture content in the test specimens. In all studies

2.1 Wood samples in the form of elongated slats that

the temperature and relative humidity selected by the investi-

represent the timber species or product/treatment combination

gator must be stated and must remain constant throughout a

to be evaluated are exposed in soak containers. The elongated

given conditioning and test period.

slats are immersed in the water-repellent formulation, condi-

4.2 Balance, sensitive to at least 0.01 g.

tioned with appropriate weighing, then subjected to immersion

in distilled water for a prescribed period. The untreated slats

4.3 Treating Tank (Fig. 1).

omit the immersion in the water-repellent formulation. The

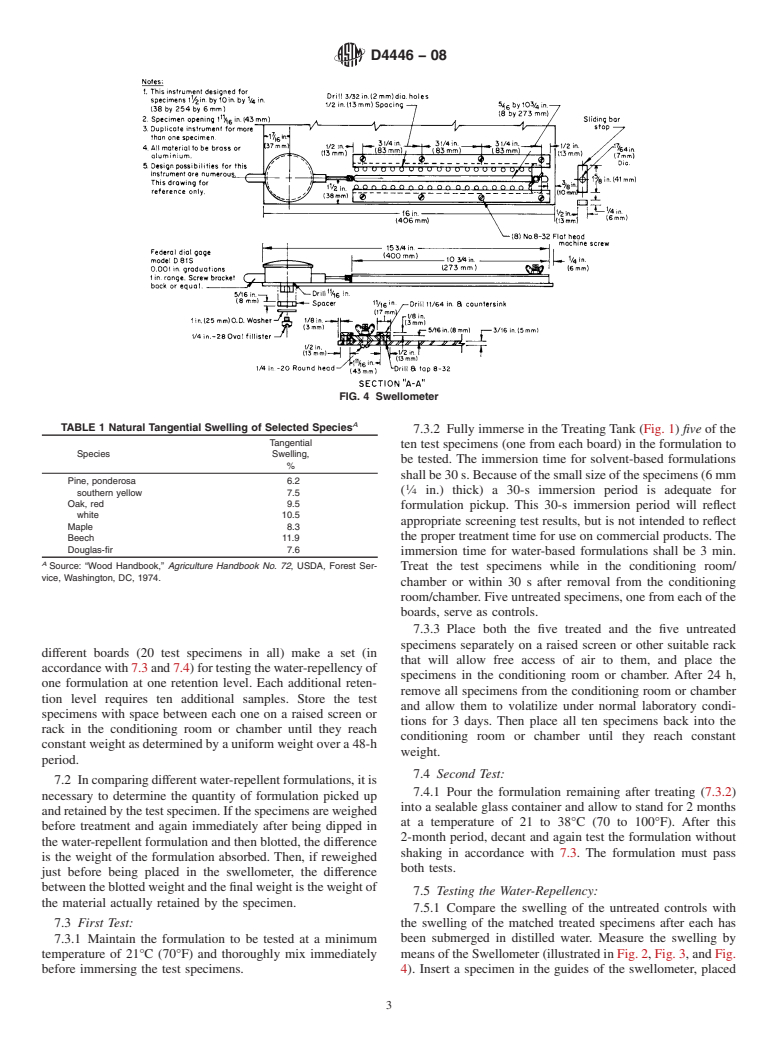

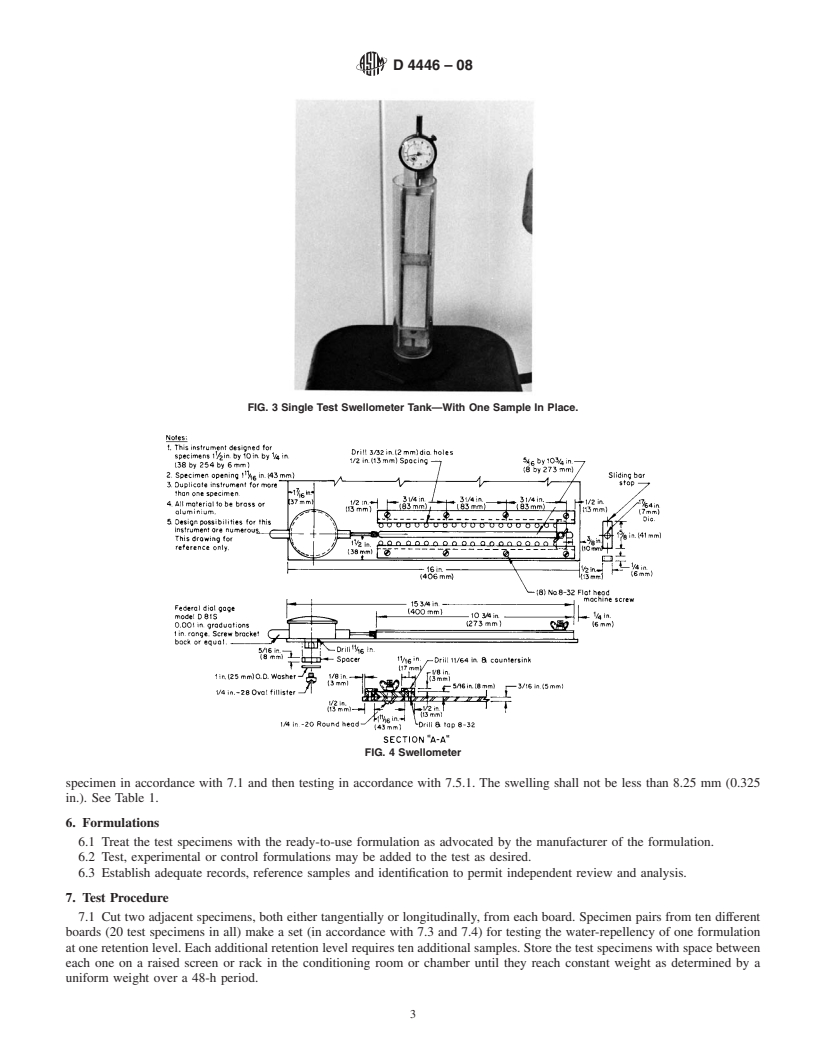

4.4 Swellometer, as illustrated in Fig. 2, Fig. 3, and Fig. 4.

swelling resulting from immersion for the selected time period

is determined by reading a dial gage calibrated in increments of

5. Test Specimens

0.025 mm (0.001 in.).

5.1 Wood used for these tests must be straight-grained,

2.2 A water repellent efficiency of 60 % is required to pass

flat-sawn, clear, kiln-dried Ponderosa pine sapwood or other

this test.

suitable species. Cut the parent boards in a manner to give

1 1

specimens 6 mm ( ⁄4 in.) in the longitudinal dimension, 1 ⁄2 in.

3. Significance and Use

(38 mm) in the radial dimension, and 254 mm (10 in.) in the

3.1 This test method is useful in determining the relative

tangential dimension. Cut with a sharp, fine-toothed saw to

anti-swelling efficiency of various water-repellent formulations

obtain as smooth a surface as possible without sanding.

Number each specimen for identification and reference.

1

5.1.1 Selection of Ponderosa pine sapwood can be assured

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

by the following quick chemical test: (1) prepare a solution of

Subcommittee D01.42 on Architectural Coatings.

5 g of benzidine in 25 g of hydrochloric acid and 970 g of

CurrenteditionapprovedJune1,2008.PublishedJuly2008.Originallyapproved

water, and (2) prepare a second solution consisting of a 10 %

in 1995. Last previous edition approved in 2005 as D4446 – 05. DOI: 10.1520/

D4446-08. concentration of sodium nitrite in water. When the test is to be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4446 − 08

FIG. 1 Treating Tank—Five Samples

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4446–05 Designation:D4446–08

Standard Test Method for

Anti-Swelling Effectiveness of Water-Repellent Formulations

and Differential Swelling of Untreated Wood When Exposed

1

to Liquid Water Environments

This standard is issued under the fixed designation D 4446; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is designed to evaluate the effectiveness of water-repellent compositions for retarding dimensional changes

in coated wood submerged in water. It can also be used to measure the differential swelling of untreated wood when exposed to

liquid water environments. The compositions tested are designed to be mixed until uniform and applied by brush, roller, dip or

spray to an exterior wood surface.

1.2

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Summary of Method

2.1 Wood samples in the form of elongated slats that represent the timber species or product/treatment combination to be

evaluated are exposed in soak containers. The elongated slats are immersed in the water-repellent formulation, conditioned with

appropriateweighing,thensubjectedtoimmersionindistilledwaterforaprescribedperiod.Theuntreatedslatsomittheimmersion

in the water-repellent formulation. The swelling resulting from immersion for the selected time period is determined by reading

a dial gage calibrated in increments of 0.025 mm (0.001 in.).

2.2 A water repellent efficiency of 60 % is required to pass this test.

3. Significance and Use

3.1 This test method is useful in determining the relative anti-swelling efficiency of various water-repellent formulations when

applied to wood. It is the initial means of estimating the ability of water-repellent treated wood to perform satisfactorily when

exposed to liquid water environments.

3.2 The swelling differences of untreated wood species when subjected to water immersion can also be determined by this test

method.

3.3 This method is a basic screening test and thus provides an initial determination of the anti-swelling efficiency of water

repellents. It is a qualitative method designed to provide a reproducible means of establishing: (1) the anti-swelling efficiency of

water-repellent formulations, and (2) the relative swelling of untreated wood species when both are exposed to liquid water

environments.

4. Apparatus

4.1 Conditioning Room or Chamber , having a controlled temperature of 23 6 2°C (73.5 6 3.5°F), and a controlled relative

humidity of 50 6 5 %. This room is used to establish a uniform moisture content in the test specimens. In all studies the

temperature and relative humidity selected by the investigator must be stated and must remain constant throughout a given

conditioning and test period.

4.2 Balance, sensitive to at least 0.01 g.

4.3 Treating Tank (Fig. 1).

4.4 Swellometer, as illustrated in Fig. 2, Fig. 3, and Fig. 4.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

Current edition approved May 15, 2005. Published June 2005. Originally approved in 1995. Last previous edition approved in 2002 as D4446–02.

Current edition approved June 1, 2008. Published July 2008. Originally approved in 1995. Last previous edition approved in 2005 as D 4446 – 05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4446–08

FIG. 1 Treating Tank—Five Samples Tested Simultaneously

FIG. 2 Single Test Swellometer Tank and One Sample

5. Test Specimens

5.1 Wood used for these tests must be straight-grained, flat-sawn, clear, kiln-dried Ponderosa pine sapwood or other suitable

1 1

species. Cut the parent boards in a manner to give specimens 6 mm ( ⁄4 in.) in the longitudinal dimension, 1 ⁄2 in. (38 mm) in the

radial dimension, and 254 mm (10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.