ASTM D5118/D5118M-12

(Practice)Standard Practice for Fabrication of Fiberboard Shipping Boxes

Standard Practice for Fabrication of Fiberboard Shipping Boxes

SIGNIFICANCE AND USE

Corrugated and solid fiberboard boxes, sleeves and liners are used to unitize products into packages of size and shape suitable for manual or mechanical handling and to protect the contents against environmental, handling, shipping, and storage conditions.

This practice covers some of the basic constructions and styles of commercially available fiberboard packaging used to unitize and protect contents.

Use of Other Specifications—Nothing in this practice shall be construed to prohibit the use of boxes of special design or of fiberboard packages identified by package number in the current Uniform Freight Classification and National Motor Freight Classification when in the experience and judgment of the purchaser, the nature of the articles or material to be shipped justifies such boxes or packages. Some commodities may require less protection while other commodities may require better boxes than are specified herein. Containers for explosives and dangerous articles must also comply with regulations for the Transport of Hazardous Materials (CFR Title 49).

FIG. 1 Fiberboard Box Dimensioning

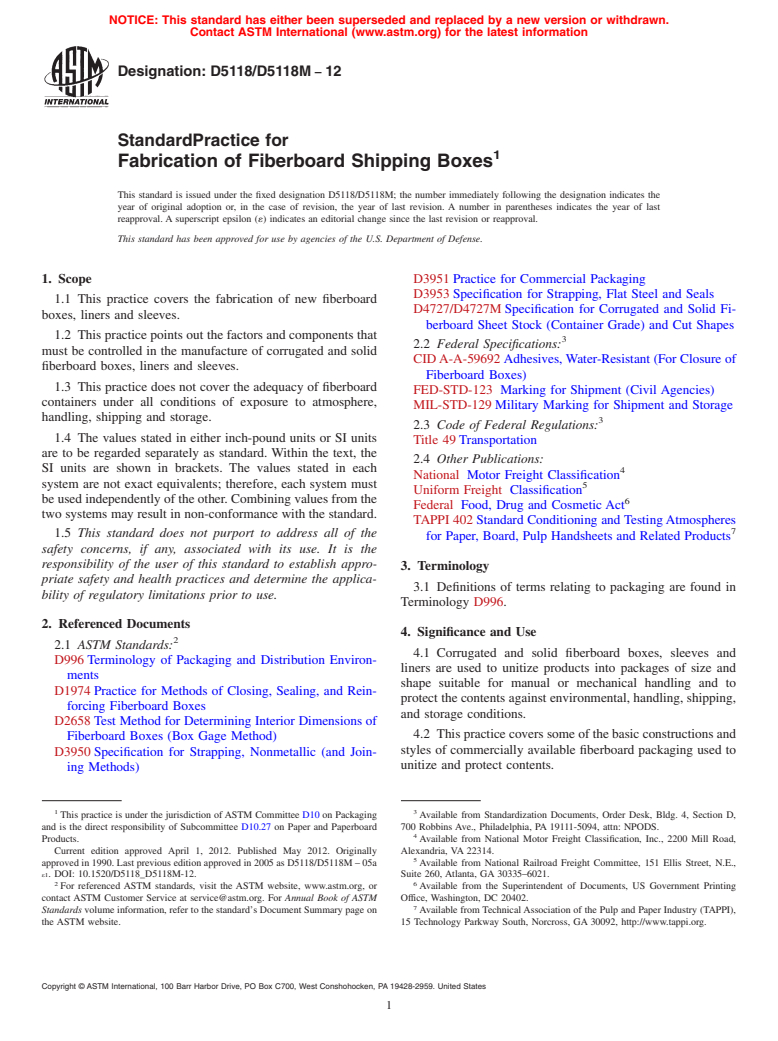

FIG. 2 Box, Fiberboard; Detail of Manufacturer's Joint Construction for Class Weather Resistant and WWVR Boxes

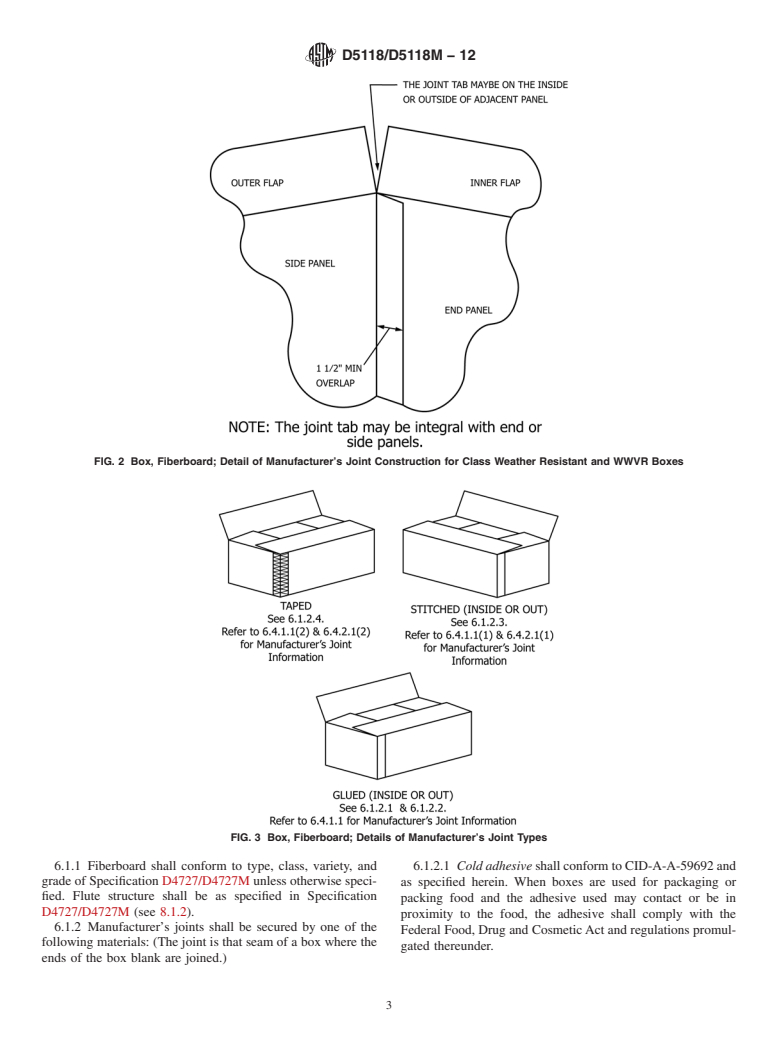

FIG. 3 Box, Fiberboard; Details of Manufacturer's Joint Types

Note 1—Dimension and cube can be boxmaker's certificate, round or rectangular as applicable and may be located on the box where it is customarily placed.

Note 2—Dimensions and cube other than specified in MIL-STD-129 shall be printed only on government procured boxes. FIG. 4 Compliance Marking for Class Weather-Resistant and WWVR Boxes

FIG. 5 Cover Assembly

FIG. 6 Box, Fiberboard; SLSleeve

FIG. 7 Box, Fiberboard; LLiner

FIG. 8 Box, Fiberboard; RSCRegular Slotted Box (0201)

FIG. 9 Box, Fiberboard; OSCOverlap Slotted Box (0202)

FIG. 10 Box, Fiberboard; FOLFull Overlap Slotted Box (0203)

FIG. 11 Box, Fiberboard; SFFSpecial Full Flap Slotted Box (0206)

FIG. 12...

SCOPE

1.1 This practice covers the fabrication of new fiberboard boxes, liners and sleeves.

1.2 This practice points out the factors and components that must be controlled in the manufacture of corrugated and solid fiberboard boxes, liners and sleeves.

1.3 This practice does not cover the adequacy of fiberboard containers under all conditions of exposure to atmosphere, handling, shipping and storage.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5118/D5118M − 12

StandardPractice for

1

Fabrication of Fiberboard Shipping Boxes

This standard is issued under the fixed designation D5118/D5118M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D3951 Practice for Commercial Packaging

D3953 Specification for Strapping, Flat Steel and Seals

1.1 This practice covers the fabrication of new fiberboard

D4727/D4727M Specification for Corrugated and Solid Fi-

boxes, liners and sleeves.

berboard Sheet Stock (Container Grade) and Cut Shapes

1.2 This practice points out the factors and components that

3

2.2 Federal Specifications:

must be controlled in the manufacture of corrugated and solid

CIDA-A-59692 Adhesives, Water-Resistant (For Closure of

fiberboard boxes, liners and sleeves.

Fiberboard Boxes)

1.3 This practice does not cover the adequacy of fiberboard

FED-STD-123 Marking for Shipment (Civil Agencies)

containers under all conditions of exposure to atmosphere,

MIL-STD-129 Military Marking for Shipment and Storage

handling, shipping and storage.

3

2.3 Code of Federal Regulations:

1.4 The values stated in either inch-pound units or SI units

Title 49 Transportation

are to be regarded separately as standard. Within the text, the

2.4 Other Publications:

SI units are shown in brackets. The values stated in each

4

National Motor Freight Classification

system are not exact equivalents; therefore, each system must 5

Uniform Freight Classification

be used independently of the other. Combining values from the

6

Federal Food, Drug and Cosmetic Act

two systems may result in non-conformance with the standard.

TAPPI 402 Standard Conditioning and TestingAtmospheres

7

1.5 This standard does not purport to address all of the

for Paper, Board, Pulp Handsheets and Related Products

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions of terms relating to packaging are found in

bility of regulatory limitations prior to use.

Terminology D996.

2. Referenced Documents

4. Significance and Use

2

2.1 ASTM Standards:

4.1 Corrugated and solid fiberboard boxes, sleeves and

D996 Terminology of Packaging and Distribution Environ-

liners are used to unitize products into packages of size and

ments

shape suitable for manual or mechanical handling and to

D1974 Practice for Methods of Closing, Sealing, and Rein-

protect the contents against environmental, handling, shipping,

forcing Fiberboard Boxes

and storage conditions.

D2658 Test Method for Determining Interior Dimensions of

4.2 This practice covers some of the basic constructions and

Fiberboard Boxes (Box Gage Method)

styles of commercially available fiberboard packaging used to

D3950 Specification for Strapping, Nonmetallic (and Join-

unitize and protect contents.

ing Methods)

1 3

This practice is under the jurisdiction ofASTM Committee D10 on Packaging Available from Standardization Documents, Order Desk, Bldg. 4, Section D,

and is the direct responsibility of Subcommittee D10.27 on Paper and Paperboard 700 Robbins Ave., Philadelphia, PA 19111-5094, attn: NPODS.

4

Products. Available from National Motor Freight Classification, Inc., 2200 Mill Road,

Current edition approved April 1, 2012. Published May 2012. Originally Alexandria, VA 22314.

5

approved in 1990. Last previous edition approved in 2005 as D5118/D5118M – 05a Available from National Railroad Freight Committee, 151 Ellis Street, N.E.,

ε1. DOI: 10.1520/D5118_D5118M-12. Suite 260, Atlanta, GA 30335–6021.

2 6

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from the Superintendent of Documents, US Government Printing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Office, Washington, DC 20402.

7

Standards volume information, refer to the standard’s Document Summary page on Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

the ASTM website. 15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5118/D5118M − 12

8

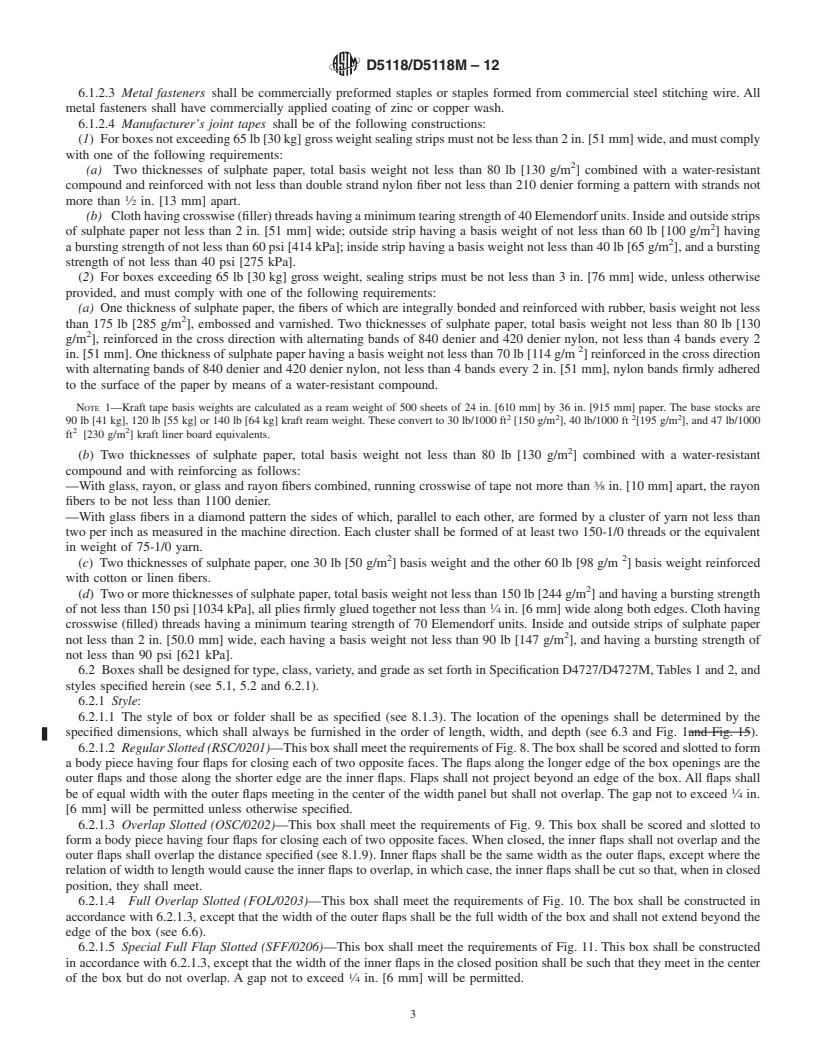

4.3 Use of Other Specifications—Nothing in this practice 5.1.2 OSC/0202 —Overlap slotted box (Fig. 9).

8

shall be construed to prohibit the use of boxes of special design 5.1.3 FOL/0203 —Full overlap slotted box (Fig. 10).

8

or of fiberboar

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D5118/D5118M–05a Designation:D5118/D5118M–12

Standard Practice for

1

Fabrication of Fiberboard Shipping Boxes

This standard is issued under the fixed designation D5118/D5118M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Section references in subsection 6.2.1.11(2) and 6.4.2.1(1) were editorially corrected in January 2007.

1. Scope

1.1 This practice covers the fabrication of new fiberboard boxes, liners and sleeves.

1.2 This practice points out the factors and components that must be controlled in the manufacture of corrugated and solid

fiberboard boxes, liners and sleeves.

1.3 Thispracticedoesnotcovertheadequacyoffiberboardcontainersunderallconditionsofexposuretoatmosphere,handling,

shipping and storage.

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

2

D685Practice for Conditioning Paper and Paper Products for Testing ASTM Standards:

D996 Terminology of Packaging and Distribution Environments

D1974 Practice for Methods of Closing, Sealing, and Reinforcing Fiberboard Boxes

D2658 Test Method for Determining Interior Dimensions of Fiberboard Boxes (Box Gage Method)

D3950 Specification for Strapping, Nonmetallic (and Joining Methods)

D3951 Practice for Commercial Packaging

D3953 Specification for Strapping, Flat Steel and Seals

D4727/D4727M Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes

3

2.2 Federal Specifications:

CID A-A-59692 Adhesives, Water-Resistant (For Closure of Fiberboard Boxes)

FED-STD-123 Marking for Shipment (Civil Agencies)

MIL-STD-129 Military Marking for Shipment and Storage

3

2.3 Code of Federal Regulations:

Title 49 Title 49 Transportation

2.4 Other Publications:

4

National Motor Freight Classification

5

Uniform Freight ClassificationUniform Freight Classification

Federal Food, Drug and Cosmetic Act

1

ThispracticeisunderthejurisdictionofASTMCommitteeD10onPackagingandisthedirectresponsibilityofSubcommitteeD10.27onPaperandPaperboardProducts.

Current edition approved Oct. 1, 2005. Published November 2005. Originally approved in 1990. Last previous edition approved in 2005 as D5118/D5118M–05. DOI:

10.1520/D5118_D5118M-05AE01.

´1

Current edition approved April 1, 2012. Published May 2012. Originally approved in 1990. Last previous edition approved in 2005 as D5118/D5118M – 05a . DOI:

10.1520/D5118_D5118M-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents, Order Desk, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, attn: NPODS.

4

Available from National Motor Freight Classification, Inc., 2200 Mill Road, Alexandria, VA 22314.

5

Available from National Railroad Freight Committee, 151 Ellis Street, N.E., Suite 260, Atlanta, GA 30335–6021.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5118/D5118M–12

6

Federal Food, Drug and Cosmetic Act

7

TAPPI 402 Standard Conditioning and Testing Atmospheres for Paper, Board, Pulp Handsheets and Related Products

3. Terminology

3.1 Definitions of terms relating to packaging are found in Terminology D996.

4. Significance and Use

4.1 Corrugated and solid fiberboard boxes, sleeves and liners are used to unitize products into packages of size and shape

suitable for manual or mechanical handling and to protect the contents against environmental, han

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.