ASTM D1531-95

(Test Method)Standard Test Methods for Relative Permittivity (Dielectric Constant) and Dissipation Factor by Fluid Displacement Procedures

Standard Test Methods for Relative Permittivity (Dielectric Constant) and Dissipation Factor by Fluid Displacement Procedures

SCOPE

1.1 These test methods provide techniques for the determination of the relative (Note 1) permittivity and the dissipation factor of solid insulating materials by fluid (Note 1) displacement.

Note 1--In common usage, the word "relative" is frequently dropped.

Note 2--The word "fluid" is a commonly used synonym for "liquid'' and yet a gas is also a fluid. In these test methods the words fluid and liquid appear as synonyms, but the word fluid is also used to show that liquid is not all that is meant.

1.2 Test Method A is especially suited to the precise measurements on polyethylene sheeting at 23oC and at frequencies between 1 kHz and 1 MHz. It may also be used at other frequencies and temperatures to make measurements on other materials in sheet form.

1.3 Test Method B is limited to the frequency range of available guarded bridges. It is especially suited to measurements on very thin films since it does not require determination of the thickness of the specimen. The test method provides an estimate of the thickness of thin films which is more accurate and precise than thickness measurements obtained by other means.

1.4 Test Method B is also useful for measurements of polymer sheeting up to 2 mm thickness.

1.5 These test methods permit calculation of the dissipation factor of the specimens tested.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precautionary statement, see Note 3.

1.7 The values stated in SI units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1531 – 95 An American National Standard

Standard Test Methods for

Relative Permittivity (Dielectric Constant) and Dissipation

Factor by Fluid Displacement Procedures

This standard is issued under the fixed designation D 1531; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods provide techniques for the determi- 2.1 ASTM Standards:

nation of the relative (Note 1) permittivity and the dissipation D 150 Test Methods for AC Loss Characteristics and Per-

factor of solid insulating materials by fluid (Note 2) displace- mittivity (Dielectric Constant) of Solid Electrical Insulat-

ment. ing Materials

D 374 Test Methods for Thickness of Solid Electrical Insu-

NOTE 1—In common usage, the word “relative” is frequently dropped.

lation

NOTE 2—The word “fluid” is a commonly used synonym for “liquid’’

D 618 Practice for Conditioning Plastics and Electrical

and yet a gas is also a fluid. In these test methods the words fluid and

liquid appear as synonyms, but the word fluid is also used to show that Insulating Materials for Testing

liquid is not all that is meant.

D 831 Test Method for Gas Content of Cable and Capacitor

Oils

1.2 Test Method A is especially suited to the precise

D 924 Test Method for Dissipation Factor (or Power Factor)

measurements on polyethylene sheeting at 23°C and at fre-

and Relative Permittivity (Dielectric Constant) of Electri-

quencies between 1 kHz and 1 MHz. It may also be used at

cal Insulating Liquids

other frequencies and temperatures to make measurements on

D 1711 Terminology Relating to Electrical Insulation

other materials in sheet form.

E 1 Specification for ASTM Thermometers

1.3 Test Method B is limited to the frequency range of

available guarded bridges. It is especially suited to measure-

3. Terminology

ments on very thin films since it does not require determination

3.1 Definitions—Definitions are in accordance with Termi-

of the thickness of the specimen. The test method provides an

nology D 1711.

estimate of the thickness of thin films which is more accurate

3.2 Description of a Term Specific to This Standard:

and precise than thickness measurements obtained by other

3.2.1 compatibility, n—A fluid is considered compatible

means.

with a test specimen if, during the time required to complete a

1.4 Test Method B is also useful for measurements of

test of the specimen in the fluid at the specified temperature and

polymer sheeting up to 2 mm thickness.

frequency, the calculated permittivity of the specimen does not

1.5 These test methods permit calculation of the dissipation

change by more than 0.1 %, and the dissipation factor change

factor of the specimens tested.

is less than 0.0001.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Methods

responsibility of the user of this standard to establish appro-

4.1 Test Method A— The single fluid technique:

priate safety and health practices and determine the applica-

4.1.1 Measurements are made with a fixed-plate, two-

bility of regulatory limitations prior to use. For a specific

terminal self-shielded test cell assembly. By two measure-

precautionary statement, see Note 3.

ments, one with the cell filled with the fluid (which in this case

1.7 The values stated in SI units are to be regarded as the

is a liquid) only and the second one with the solid specimen

standard.

immersed in the liquid, a change in capacitance is determined.

This capacitance difference is used with the approximate

thickness of the specimen, the plate spacing, and the precisely

These test methods are under the jurisdiction of ASTM Committee D-9 on

known permittivity of the liquid to calculate the permittivity of

Electrical and Electronic Insulating Materials and are the direct responsibility of

Subcommittee D09.12 on Electrical Tests.

Current edition approved July 15, 1995. Published September 1995. Originally

e1 3

published as D 1531 – 58 T. Last previous edition D 1531 – 90 . Annual Book of ASTM Standards, Vol. 10.01.

2 4

Coutlee, K. G., “Liquid Displacement Test Cell for Dielectric Constant and Annual Book of ASTM Standards, Vol. 08.01.

Dissipation Factor up to 100 Mc,” 1959 Annual Report, Conference on Electrical Annual Book of ASTM Standards, Vol. 10.03.

Insulation, National Research Council, Publication 756, Washington, DC. Annual Book of ASTM Standards, Vol. 14.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1531

the specimen. The dissipation factor of the test specimen is 5.2 Dissipation Factor—Normally, polyethylene has a very

calculated from measurements of the cell with the liquid alone low dissipation factor, and a test specimen exhibiting an

and with the specimen immersed in it. Precision and accuracy abnormally high dissipation factor would be suspected of

are made high by limiting the proportion of fluid to solid, containing impurities or being contaminated. The reproducibil-

limiting the difference in permittivity between the fluid and the ity of dissipation factor by this test method is somewhat better

solid, and designing the cell so that both the stray capacitance than that obtainable with the more conventional methods, but is

and the sensitivity limit of the measuring instrument are very limited by the sensitivity of commercially available measuring

small relative to that part of the capacitance due to the apparatus.

specimen. Also, due to its bulk, the measuring system is

6. Apparatus

insensitive to mechanical and thermal disturbances. Since it is

6.1 Measuring Circuits—Any low-voltage bridge or

not necessary to know the thickness of the specimen accurately

resonant-circuit method conforming to the requirements of Test

and it is not necessary to apply electrodes, there is an overall

Methods D 150 is suitable when the parallel substitution

saving in testing time.

method is employed. A capacitance sensitivity and readability

4.2 Test Method B—This is a two fluid technique that uses

of about 0.01 pF and a dissipation factor sensitivity and

a rigidly constructed, fully shielded, temperature controlled

readability of at least 0.00001 is needed. One means for

cell.

obtaining this sensitivity at 100 kHz and above is by using

4.2.1 The fluids are:

commercially available resonant circuit apparatus and high Q

4.2.1.1 Two liquids, or

coils (500 minimum).

4.2.1.2 One liquid and a gas such as air or nitrogen.

6.2 Leads and Connectors—Low-loss coaxial connectors

4.2.2 Observations of capacitance and dissipation factor

and leads are recommended for connecting the cell to bridges

from the four following conditions are used to compute relative

equipped with guard circuits for frequencies from 1000 Hz to

permittivity, dissipation factor, and the thickness of the speci-

1 MHz. Terminate the guard as close as possible to the cell.

men:

6.3 A rigid lead construction is necessary for connecting the

4.2.2.1 Without a solid specimen but with a single fluid in

cell to unguarded circuits including resonant circuits. Such

the cell,

construction stabilizes stray capacitance. Bare #10 AWG (2.5

4.2.2.2 Without a solid specimen but with a fluid different

mm dia) copper is suitable if rigidly mounted and maintained

from that in 4.2.1.1,

in the same position throughout the tests. At frequencies of 1

4.2.2.3 With a solid specimen and with the single fluid of

MHz and higher, lead resistance and contact resistance become

4.2.1.1, and

important because they affect dissipation factor measurements

4.2.2.4 With a solid specimen and with the different fluid of

of 0.0001 or less. Contact resistance can be minimized by use

4.2.1.2.

of bright solid copper clips for connections. Such clips should

TEST METHOD A—LIQUID DISPLACEMENT

be small in size to minimize the effect that placement of the

METHOD USING A SINGLE FLUID clip has on the measured capacitance. Take care to keep the

variations in capacitance between leads and surrounding ob-

5. Significance and Use

jects to less than 0.01 pF during measurements.

5.1 Permittivity: 6.4 The measuring cell in which the test specimens are

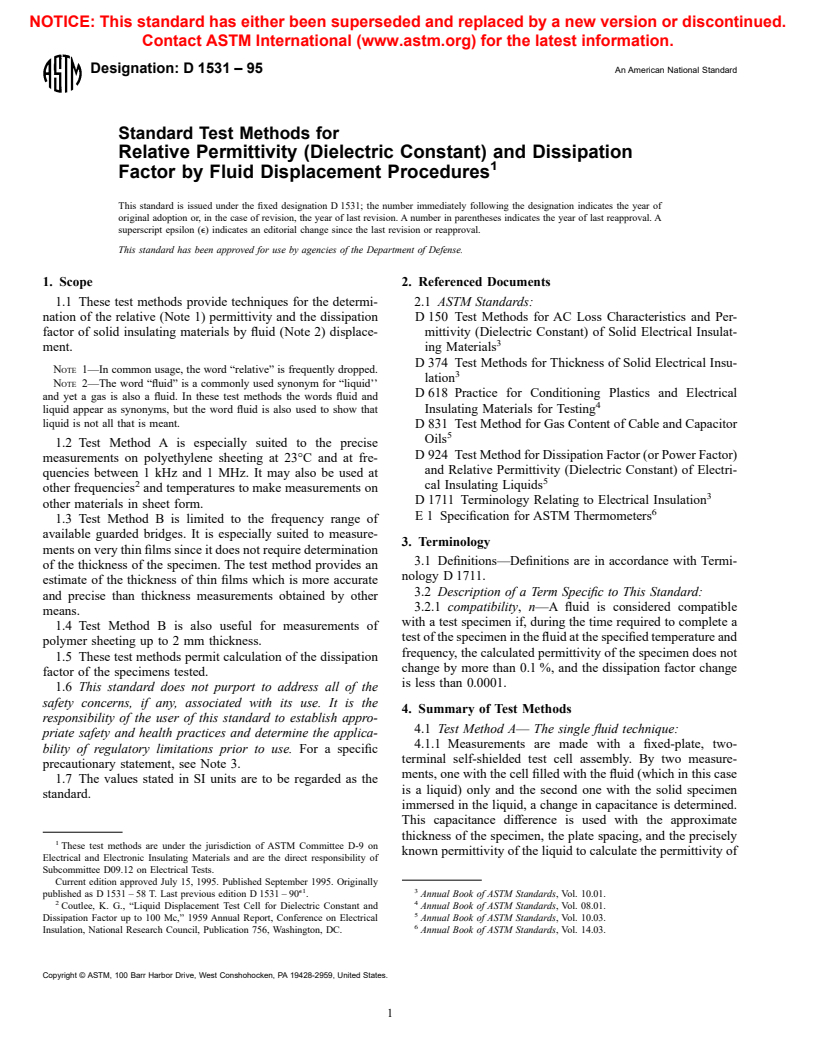

5.1.1 Polyethylene and Materials of Permittivity within 0.1 immersed in the liquid is shown in Fig. 1. It is a two-terminal,

of that of Polyethylene—Since the permittivity of benzene or 1 self-shielded type cell consisting of a rectangular 6.35 mm ( ⁄4

cSt silicone fluid is very close to that of polyethylene, these in.) thick gold-plated brass center electrode having parallel and

2 2

fluids are recommended for highly accurate and precise testing flat faces, each 58.06 cm (9.00 in. ) in area. This electrode is

of polyethylene or other materials with permittivity close to supported by 5 polytetrafluoroethylene post insulators, and is

that of polyethylene. These properties of the test method make located midway between two gold-plated brass electrodes

it a suitable tool to determine batch to batch uniformity of a which form an integral part of the walls of the cell. The

polyethylene compound in order to meet precise requirements standard spacing between the plates is 1.52 6 0.05 mm (0.060

of high capacitance-uniformity and capacitance-stability in 6 0.002 in.); however, other spacings may be used to accom-

electronic apparatus. It also serves as a means to detect modate test specimens of thicknesses other than 1.27 mm

1 1

impurities, as well as changes resulting from prolonged expo- (0.050 in.), such as 1.6 and 3.2-mm ( ⁄16 and ⁄8-in.) test

sure to high humidity, water immersion, weathering, aging,

specimens. The center electrode slides in grooves and can be

processing treatments, and exposure to radiation. removed readily to permit easy cleaning. The cell is equipped

5.1.2 Other Materials—The test method may provide ad-

with an overflow pipe in order to maintain a constant level of

vantages for routine testing of materials with a poorer match in the liquid with the test specimens either in or out. The cooling

permittivity between these liquids and the specimen than that effect resulting from the evaporation of the liquid is small at the

required above, because of the ease of testing, and the dilution specified test temperature due to the large mass of metal and

of errors due to inaccurate thickness. Correction factors can be the small area of liquid exposed to the air, so that under normal

calculated to account for the bias introduced by the permittivity testing conditions the required stability of capacitance and

mismatch. Also, other compatible liquids of appropriate and temperature can be obtained without the use of a cpover.

known dielectric properties different from the two mentioned 6.5 Thermometer—An ASTM Engler Viscosity Thermom-

above are available. eter having a range from 18 to 28°C and conforming to the

D 1531

Plate assembly shall be a sliding fit in the cell subassembly; if necessary the polytetrafluoroethylene post insulators may be modified very slightly to accomplish this.

The tolerances on the component parts have been apportioned so as to provide a spacing of 1.52 6 0.05 mm (0.060 6 0.002 in.).

FIG. 1 Measuring Cell For Test Method A

requirements for Thermometer 23°C in Specification E 1 can found generally satisfactory. However, in case of a dispute, dry

be used. the benzene as above, or measure the permittivity of the

benzene, or both. The dissipation factor of the benzene shall

7. Standard Liquid Dielectrics

not exceed 0.00001 during test. From 100 kHz to 1 MHz, the

−6 2

7.1 Silicone Liquid—Use a 1.0 cSt (1 3 10 m /s) silicone dissipation factor of ACS reagent-grade benzene is consistently

less than 0.000005. The benzene can be used a number of times

fluid. The permittivity of the liquid changes with temperature

and has to be measured to determine the exact value for each or until an increase in dissipation factor is observed.

lot of material. Use the three-terminal measuring cells and

NOTE 3—Precaution: Observe proper precautions due to the toxicity

procedures of Test Method D 924 for this purpose. The values

and flammability of benzene. Minimize benzene fumes from test speci-

of silicone liquid are quite similar to those of dry ACS grade

mens by dropping the specimens in a beaker and covering it at once. A

benzene as shown in Table 1. The dissipation factor of 1.0 cSt portable hood placed near the cell will also remove benzene fumes.

silicone liquid is less than 0.000005 from 100 kHz to 1 MHz

7.3 Other liquids may be used. Those selected should have

and therefore can be considered zero over this frequency range.

a permittivity which is approximately the same as that of the

The liquid can be used a number of times or until an increase

specimen, and is known precisely; that is to the fourth decimal

in dissipation factor is observed.

place at the test frequency.

7.2 Benzene—Use certified ACS reagent-grade (thiophene-

7.4 Avoid liquids that dissolve any constituents of the

free) benzene having a permittivity as specified in Table 1 as

specimen, result in swelling of the specimen, or are absorbed

the referee liquid. As the permittivity of a liquid is a function

within the body of the specimen.

of temperature, measure the temperature of the cell to an

7.5 Avoid liquids that exhibit peaks in dissipation factor in

accuracy of 60.1°C both with the test specimens in and out.

excess of 0.00005 in the frequency range 650 % of the test

The permittivity values shown in Table 1 are for benzene that

frequency.

has been dried over powdered calcium hydride for 3 months.

U.S. commercial certified ACS reagent-grade benzene has been

8. Sampling

8.1 Take samples according to the applicable material speci-

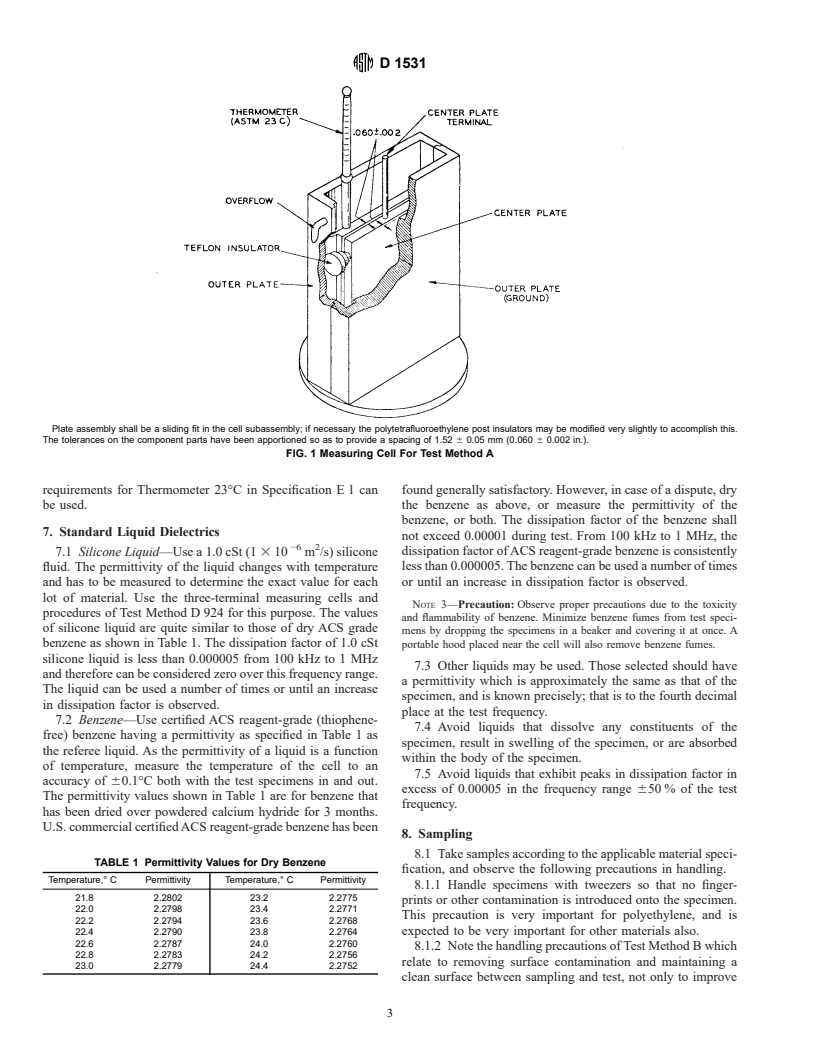

TABLE 1 Permittivity Values for Dry Benzene

fication, and observe the following precautions in handling.

Temperature,° C Permittivity Temperature,° C Permittivity

8.1.1 Handle specimens with tweezers so that no finger-

21.8 2.2802 23.2 2.2775

prints or other contamination is introduced onto the specimen.

22.0 2.2798 23.4 2.2771

This precaution is very important for polyethylene, and is

22.2 2.2794 23.6 2.2768

22.4 2.2790 23.8 2.2764 expected to be very important for other materials also.

22.6 2.2787 24.0 2.2760

8.1.2 Note the handling precautions of Test Method B which

22.8 2.2783 24.2 2.2756

relate to removing surface contamination and maintaining a

23.0 2.2779 24.4 2.2752

clean surface between sampling and test, not only to improve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.