ASTM D5640-95(2003)

(Guide)Standard Guide for Selection of Weirs and Flumes for Open-Channel Flow Measurement of Water

Standard Guide for Selection of Weirs and Flumes for Open-Channel Flow Measurement of Water

SIGNIFICANCE AND USE

Each type of weir and flume possesses advantages and disadvantages relative to the other types when it is considered for a specific application; consequently, the selection process often involves reaching a compromise among several features. This guide is intended to assist the user in making a selection that is hydraulically, structurally, and economically appropriate for the purpose.

It is recognized that not all open-channel situations are amenable to flow measurement by weirs and flumes and that in some cases, particularly in large streams, discharges may best be determined by other means. (See 6.2.2.)

SCOPE

1.1 This guide covers recommendations for the selection of weirs and flumes for the measurement of the volumetric flow rate of water and wastewater in open channels under a variety of field conditions.

1.2 This guide emphasizes the weirs and flumes for which ASTM standards are available, namely, thin-plate weirs, broad-crested weirs, Parshall flumes, and Palmer-Bowlus (and other long-throated) flumes. However, reference is also made to other measurement devices and methods that may be useful in specific situations.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5640–95(Reapproved2003)

Standard Guide for

Selection of Weirs and Flumes for Open-Channel Flow

Measurement of Water

This standard is issued under the fixed designation D 5640; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Flow—Constant-Rate Injection Method

1.1 This guide covers recommendations for the selection of

3. Terminology

weirs and flumes for the measurement of the volumetric flow

3.1 Definitions—For definitions of terms used in this guide,

rate of water and wastewater in open channels under a variety

refer to Terminology D 1129.

of field conditions.

3.2 Definitions of Terms Specific to This Standard:

1.2 This guide emphasizes the weirs and flumes for which

3.2.1 blackwater—anincreaseinthedepthofflowupstream

ASTMstandardsareavailable,namely,thin-plateweirs,broad-

of a channel obstruction, in this case a weir or flume.

crested weirs, Parshall flumes, and Palmer-Bowlus (and other

3.2.2 contracted weirs—contractions of thin-plate weirs

long-throated) flumes. However, reference is also made to

refer to the widths of weir plate between the notch and the

other measurement devices and methods that may be useful in

sidewalls of the approach channel. In fully contracted weirs,

specific situations.

the ratio of the notch area to the cross-sectional area of the

1.3 This standard does not purport to address all of the

approach channel is small enough for the shape of the channel

safety concerns, if any, associated with its use. It is the

to have little effect. In suppressed (full-width) rectangular

responsibility of the user of this standard to establish appro-

weirs, the contractions are suppressed, and the weir crest

priate safety and health practices and determine the applica-

extends the full width of the channel.

bility of regulatory limitations prior to use.

3.2.3 crest—in rectangular thin-plate weirs, the horizontal

2. Referenced Documents bottom of the overflow section; in broad-crested weirs and

flumes, the plane, level floor of the flow section.

2.1 ASTM Standards:

3.2.4 critical flow—open-channel flow in which the energy,

D 1129 Terminology Relating to Water

expressed in terms of depth plus velocity head, is a minimum

D 1941 Test Method for Open Channel Flow Measurement

2 for a given flow rate and channel.

of Water with the Parshall Flume

3.2.4.1 Discussion—The Froude number is unity at critical

D 3858 Test Method for Open-Channel Flow Measurement

2 flow.

of Water by Velocity-Area Method

3.2.5 Froude number—a dimensionless number expressing

D 5242 Test Method for Open-Channel Flow Measurement

2 the ratio of inertial to gravity forces in free-surface flow. It is

of Water with Thin-Plate Weirs

equal to the average velocity divided by the square root of the

D 5389 Test Method for Open-Channel Flow Measurement

2 product of the average depth and the acceleration due to

of Water by Acoustic Velocity Meter Systems

gravity.

D 5390 Test Method for Open-Channel Flow Measurement

2 3.2.6 head—in this context, the depth of flow referenced to

of Water with Palmer-Bowlus Flume

the crest of the weir or flume and measured at a specified

D 5614 Test Method for Open-Channel Flow Measurement

location; this depth plus the velocity head are often termed the

of Water with Broad-Crested Weirs

total head or total energy head.

2.2 ISO Standard:

3.2.7 hydraulic jump—an abrupt transition from supercriti-

ISO 555-1973: Liquid Flow Measurement in Open

caltosubcriticalortranquilflow,accompaniedbyconsiderable

Channels—Dilution Methods for Measurement of Steady

turbulence or gravity waves, or both.

3.2.8 long-throated flume—a flume in which the prismatic

throat is long enough, relative to the head, for a region of

This guide is under the jurisdiction of ASTM Committee D19 on Water and is

the direct responsibility of Subcommittee D19.07 on Sediments, Geomorphology,

essentially critical flow to develop on the crest.

and Open-Channel Flow.

Current edition approved June 10, 2003. Published August 2003. Originally

approved in 1995. Last previous edition approved in 1999 as D 5640 – 95 (1999). Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Annual Book of ASTM Standards, Vol 11.01. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5640–95 (2003)

3.2.9 nappe—the curved sheet or jet of water overfalling a

weir.

3.2.10 notch—theoverflowsectionofatriangularweirorof

a rectangular weir with side contractions.

3.2.11 primary instrument—the device (in this case, a weir

or flume) that creates a hydrodynamic condition that can be

sensed by the secondary instrument.

3.2.12 rangeability—the spread between the maximum,

Qmax, and minimum, Qmin, flow rates that a measuring

instrumentcanusefullyandreliablyaccommodate;thismaybe

described as the ratio Qmax/Qmin.

3.2.13 secondary instrument—in this case, a device that

measurestheheadontheweirorflume;itmayalsoconvertthis

measured head to an indicated flowrate or could totalize the

flow.

3.2.14 subcritical flow—open-channel flow that is deeper

andatalowervelocitythancriticalflowforthesameflowrate;

sometimes called tranquil flow.

3.2.14.1 Discussion—The Froude number is less than unity

for this flow.

3.2.15 submergence—the ratio of downstream head to up-

stream head on a weir or flume. Submergence greater than a

critical value affects the discharge for a given upstream head.

3.2.16 supercritical flow—open-channel flow that is shal-

lowerandathighervelocitythancriticalflowforthesameflow

rate.

3.2.16.1 Discussion—The Froude number is greater than

unity for this flow.

3.2.17 throat—the constricted portion of a flume.

3.2.18 velocity head—the square of the average velocity

divided by twice the acceleration due to gravity.

4. Significance and Use

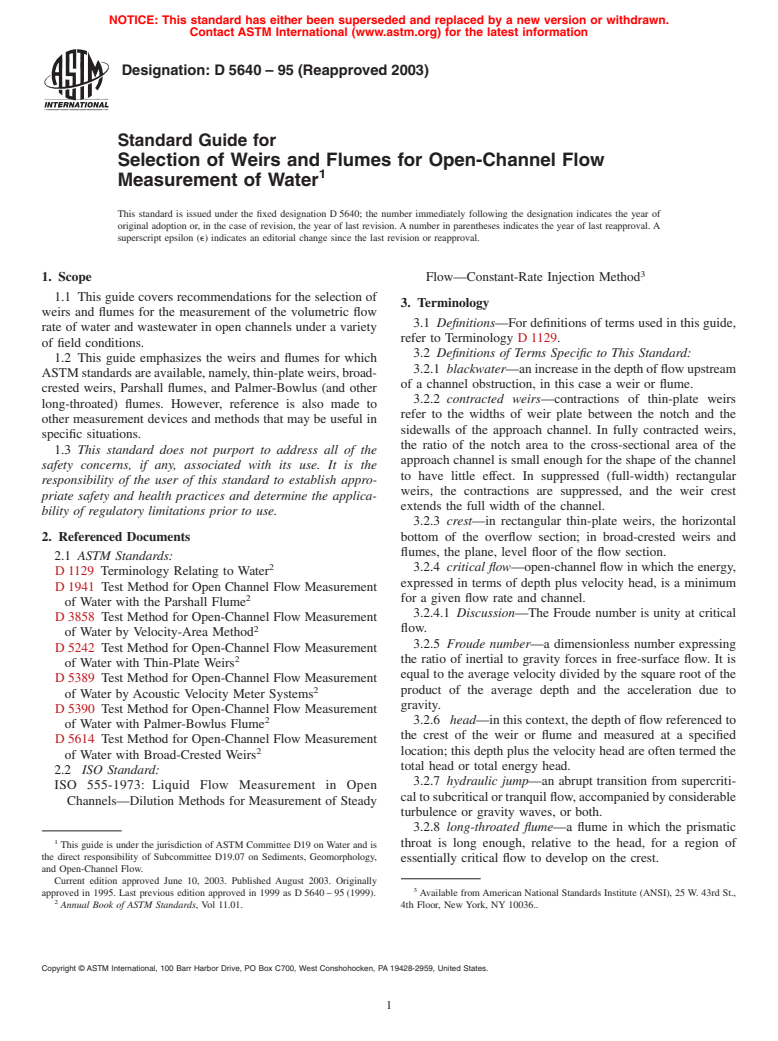

FIG. 1 Rectangular Thin-Plate Weirs

4.1 Each type of weir and flume possesses advantages and

disadvantages relative to the other types when it is considered

for a specific application; consequently, the selection process

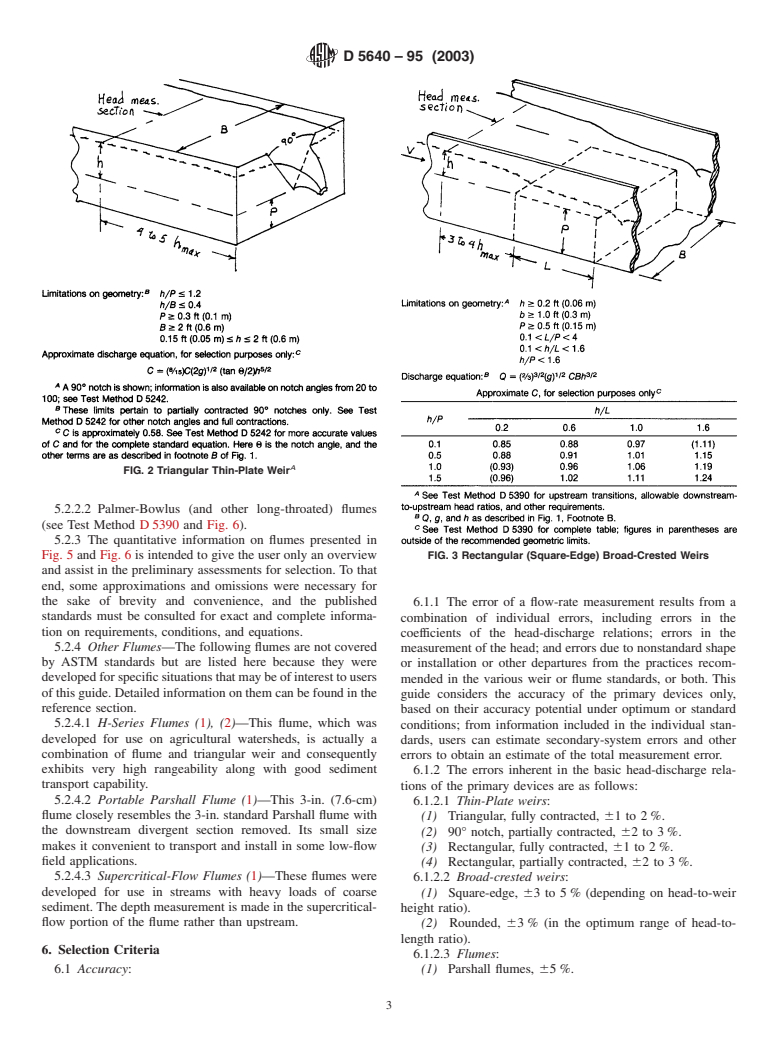

(1) Square-edge (rectangular) weirs (see Fig. 3).

often involves reaching a compromise among several features.

(2) Rounded-edge weirs (see Fig. 4).

This guide is intended to assist the user in making a selection

5.1.3 The quantitative information on weirs presented in

that is hydraulically, structurally, and economically appropriate

Figs. 1-4 is intended to give the user only an overview and

for the purpose.

assist in the preliminary assessments for selection. To that end,

4.2 It is recognized that not all open-channel situations are

some approximations and omissions were necessary for the

amenable to flow measurement by weirs and flumes and that in

sake of brevity and convenience, and the published standards

some cases, particularly in large streams, discharges may best

must be consulted for exact and complete information on

be determined by other means. (See 6.2.2.)

requirements, conditions, and equations.

5. Weirs and Flumes

5.2 Flumes:

5.2.1 Flumes use sidewall constrictions or bottom shapes or

5.1 Weirs:

slopes of specified geometries, or both, to cause the flow to

5.1.1 Weirs are overflow structures of specified geometries

pass through the critical condition; this permits determination

for which the volumetric flow rate is a unique function of a

of the flow rate from a measured head and a head-discharge

single measured upstream head, the other elements in the

relation that has been experimentally or analytically obtained.

head-discharge relation having been experimentally or analyti-

Details of the individual flumes may be found in the ASTM

cally determined. Details of the individual weirs may be found

standards cited as follows:

in the ASTM standards cited as follows:

5.2.2 Standard Flumes—The following flumes, for which

5.1.2 Standard Weirs—The following weirs, for which

ASTM standards are available, are considered in this guide: ASTM standards are available, are emphasized in this guide.

Other flumes, which may be useful in specific situations, are

5.1.2.1 Thin-plate weirs (see Test Method D 5242).

(1) Rectangular weirs (see Fig. 1). cited in 5.2.4.

(2) Triangular (V-notch) weirs (see Fig. 2). 5.2.2.1 Parshallflumes(seeTestMethodD 1941,Fig.5,and

5.1.2.2 Broad-crested weirs (see Test Method D 5614). Table 1).

D5640–95 (2003)

A

FIG. 2 Triangular Thin-Plate Weir

5.2.2.2 Palmer-Bowlus (and other long-throated) flumes

(see Test Method D 5390 and Fig. 6).

5.2.3 The quantitative information on flumes presented in

Fig. 5 and Fig. 6 is intended to give the user only an overview FIG. 3 Rectangular (Square-Edge) Broad-Crested Weirs

and assist in the preliminary assessments for selection. To that

end, some approximations and omissions were necessary for

the sake of brevity and convenience, and the published

6.1.1 The error of a flow-rate measurement results from a

standards must be consulted for exact and complete informa-

combination of individual errors, including errors in the

tion on requirements, conditions, and equations.

coefficients of the head-discharge relations; errors in the

5.2.4 Other Flumes—The following flumes are not covered

measurement of the head; and errors due to nonstandard shape

by ASTM standards but are listed here because they were

or installation or other departures from the practices recom-

developedforspecificsituationsthatmaybeofinteresttousers

mended in the various weir or flume standards, or both. This

of this guide. Detailed information on them can be found in the

guide considers the accuracy of the primary devices only,

reference section.

based on their accuracy potential under optimum or standard

5.2.4.1 H-Series Flumes (1), (2)—This flume, which was conditions; from information included in the individual stan-

developed for use on agricultural watersheds, is actually a

dards, users can estimate secondary-system errors and other

combination of flume and triangular weir and consequently errors to obtain an estimate of the total measurement error.

exhibits very high rangeability along with good sediment

6.1.2 The errors inherent in the basic head-discharge rela-

transport capability.

tions of the primary devices are as follows:

5.2.4.2 Portable Parshall Flume (1)—This 3-in. (7.6-cm)

6.1.2.1 Thin-Plate weirs:

flume closely resembles the 3-in. standard Parshall flume with

(1) Triangular, fully contracted, 61to2%.

the downstream divergent section removed. Its small size

(2) 90° notch, partially contracted, 62to3%.

makes it convenient to transport and install in some low-flow

(3) Rectangular, fully contracted, 61to2%.

field applications.

(4) Rectangular, partially contracted, 62to3%.

5.2.4.3 Supercritical-Flow Flumes (1)—These flumes were

6.1.2.2 Broad-crested weirs:

developed for use in streams with heavy loads of coarse

(1) Square-edge, 63 to 5 % (depending on head-to-weir

sediment. The depth measurement is made in the supercritical-

height ratio).

flow portion of the flume rather than upstream.

(2) Rounded, 63 % (in the optimum range of head-to-

length ratio).

6. Selection Criteria

6.1.2.3 Flumes:

6.1 Accuracy: (1) Parshall flumes, 65%.

D5640–95 (2003)

thin-plate weirs are most suitable for lower flow rates, with the

triangular notches most appropriate for the smallest flows.

Small Parshall and Palmer-Bowlus flumes are also available

for low flows; these improve on the thin-plate weirs in

sediment passage and head loss, but at some sacrifice of

potential accuracy (6.1).

6.2.2.2 Large Flows—Large discharges are best measured

with flumes and broad-crested weirs, which can accommodate

large heads and flows and, given proper construction, are

inherently sturdy enough to withstand them. For example, the

50-ft (15.24-m) Parshall flume can be used for flow rates up to

3 3

about 3200 ft /s (90 m /s). However, flumes and broad-crested

weirs that are adequate for very large flows require major

construction, and users may wish to consider establishing a

measuring station (3), (4) with other methods of discharge

measurement, for example, velocity-area method (Test Method

D 3858), acoustic velocity meters (Test Method D 5389), or

tracer dilution (ISO 555).

6.2.3 Range of Flow Rate:

6.2.3.1 Triangular thin-plate weirs have the largest range-

ability of the standard devices because of their 2.5-power

dependence on head. This rangeability can vary from slightly

under 200 for fully contracted weirs to about 600 for partially

contracted 90° notches that can utilize the allowable range of

head.

6.2.3.2 For rectangular thin-plate weirs, the rangeability

varies somewhat with the crest length-to-channel width ratio

FIG. 4 Rounded Broad-Crested Weirs

and is typically about 90, increasing to about 110 for full-width

weirs. These results are based on a minimum head of 0.1 ft

(0.03 m) and a suggested (although not absolute) maximum

(2) Palmer Bowlus and long-throated flumes, 63to5%

head of 2 ft (0.6 m). However, the rangeability of smaller

(depending on head-to-length ratio).

rectangular weirs can be significantly less.

6.1.2.4 This listing indicates that, with no consideration of

6.2.3.3 The rangeability of the rounded broad-crested weir

otherselectioncriteria,thin-plateweirsarepotentiallythemost

is close to 40. However, large square-edge weirs, if used to the

accurate of the devices.

geometric limits of the standard, exhibit a rangeability of about

6.1.3 Sensitivity—The discharge of weirs and flumes de-

90.

pends upon the measured head to the three-halves power for

6.2.3.4 The rangeability of Parshall flumes varies widely

rectangular control sections (this is an approximation in the

with size. (See Fig. 5 and Table 1.)

case of Parshall flumes), to the five-halves power for triangular

6.2.3.5 For Palmer-Bowlus and other long-throated flumes,

sections, and to intermediate powers for intermediate trapezoi-

the rangeability depends on the shape of the throat cross

dal sections. Consequently, the accuracy of a flow-rate mea-

section,increasingasthatshapevariesfromrectangulartoward

surement is sensitive to errors in head measurement and

triangular. For the typical commercial Palmer-Bowlus flume of

particularly so in the case of triangular control sections. It

trapezoidal section, at least one manufacturer cites maximum-

follows that in all weirs and flumes operating at or near

to-minimum flow-rate ratios up to, and in some cases exceed-

minimum head, even a modest error or change in head can

ing, 100; (5) however, the head range is often beyond the

have a significant effect on the measured flow rate. Therefore,

reco

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.