ASTM F564-02(2006)

(Specification)Standard Specification and Test Methods for Metallic Bone Staples

Standard Specification and Test Methods for Metallic Bone Staples

ABSTRACT

This specification covers characterization of the design and mechanical function of metallic staples used in the internal fixation of the muscular skeletal system. It is not the intention of this specification to describe or specify specific designs for metallic bone staples. Different test methods shall be performed in order to determine the following mechanical properties of metallic bone staples: bending fatigue, pull-out fixation strength, soft tissue fixation strength, and elastic static bending.

SCOPE

1.1 This specification covers characterization of the design and mechanical function of metallic staples used in the internal fixation of the muscular skeletal system. It is not the intention of this specification to describe or specify specific designs for metallic bone staples.

1.2 This specification includes the following four test methods for measuring mechanical properties of metallic bone staples:

1.2.1 Test Method for Constant Amplitude Bending Fatigue Tests of Metallic Bone Staples—Annex A1.

1.2.2 Test Method for Pull-Out Fixation Strength of Metallic Bone Staples—Annex A2.

1.2.3 Test Method for Soft Tissue Fixation Strength of Metallic Bone Staples—Annex A3.

1.2.4 Test Method for Elastic Static Bending of Metallic Bone Staples—Annex A4.

1.3 Unless otherwise indicated, the values stated in SI units are to be regarded as standard. The values given in parentheses are given for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 564 – 02 (Reapproved 2006)

Standard Specification and Test Methods for

Metallic Bone Staples

This standard is issued under the fixed designation F 564; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 122 Practice for Calculating Sample Size to Estimate,

With a Specified Tolerable Error, the Average for a

1.1 This specification covers characterization of the design

Characteristic of a Lot or Process

and mechanical function of metallic staples used in the internal

E 467 Practice for Verification of Constant Amplitude Dy-

fixation of the muscular skeletal system. It is not the intention

namic Forces in an Axial Fatigue Testing System

of this specification to describe or specify specific designs for

F75 Specification for Cobalt-28 Chromium-6 Molybdenum

metallic bone staples.

Alloy Castings and Casting Alloy for Surgical Implants

1.2 This specification includes the following four test meth-

(UNS R30075)

ods for measuring mechanical properties of metallic bone

F86 Practice for Surface Preparation and Marking of Me-

staples:

tallic Surgical Implants

1.2.1 Test Method for ConstantAmplitude Bending Fatigue

F 382 Specification and Test Method for Metallic Bone

Tests of Metallic Bone Staples—Annex A1.

Plates

1.2.2 Test Method for Pull-Out Fixation Strength of Metal-

F 565 Practice for Care and Handling of Orthopedic Im-

lic Bone Staples—Annex A2.

plants and Instruments

1.2.3 Test Method for Soft Tissue Fixation Strength of

F 601 Practice for Fluorescent Penetrant Inspection of Me-

Metallic Bone Staples—Annex A3.

tallic Surgical Implants

1.2.4 Test Method for Elastic Static Bending of Metallic

F 629 Practice for Radiography of Cast Metallic Surgical

Bone Staples—Annex A4.

Implants

1.3 Unless otherwise indicated, the values stated in SI units

are to be regarded as standard.The values given in parentheses

3. Finish

are given for information only.

3.1 Staples conforming to this specification shall be finished

1.4 This standard does not purport to address all of the

and identified in accordance with PracticeF86, as appropriate.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Inspection Practices

priate safety and health practices and determine the applica-

4.1 Staples made in accordance with Specification F75

bility of regulatory limitations prior to use.

should be inspected in accordance with Practice F 601 or

X-rayed in accordance with Practice F 629.

2. Referenced Documents

2.1 ASTM Standards:

5. Care and Handling

E4 Practices for Force Verification of Testing Machines

5.1 Staples should be cared for and handled in accordance

with Practice F 565, as appropriate.

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

6. Keywords

Subcommittee F04.21 on Osteosynthesis.

6.1 bendingtest;bonefixation;fatiguetest;fixationdevices;

Current edition approved March 1, 2006. Published April 2006. Originally

approved in 1985. Last previous edition approved in 2002 as F 564 – 02. metallic bone staples; orthopaedic medical devices; pullout

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

test; soft tissue fixation; surgical implants

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 564 – 02 (2006)

ANNEXES

(Mandatory Information)

A1. TEST METHOD FOR CONSTANT AMPLITUDE BENDING FATIGUE TESTS OF METALLIC BONE STAPLES

A1.1 Scope clearance to restrict bending of the staple within the hole. The

staple is fixed securely in the block using a moldable filling or

A1.1.1 This test method covers procedures for the perfor-

grouting agent. The extension design should minimize the

mance of constant amplitude fatigue testing of metallic staples

weight to reduce the influence on the staple while maintaining

used in internal fixation of the musculoskeletal system. This

sufficient stiffness to transfer the load to the staple without

test method may be used when testing in air at ambient

undesirable deflection. Holes for pin and clevis fixation are

temperature or in an aqueous or physiological solution.

optional (see Figs. A1.1-A1.3).

A1.1.2 ThevaluesstatedinSIunitsaretoberegardedasthe

standard.

NOTE A1.1—Variations in fixation hole configuration may be required

A1.1.3 This standard does not purport to address all of the for staple legs with noncircular cross sections. Also, it is necessary to

provide a gap between the underside of the staple bridge and edge of the

safety concerns, if any, associated with its use. It is the

staple extender in most cases. This is necessary to eliminate contact

responsibility of the user of this standard to establish appro-

between the staple bridge (or other bridge features such as tissue spikes)

priate safety and health practices and determine the applica-

and the staple extender. However, this gap should be standardized within

bility of regulatory limitations prior to use.

any test group as required.

A1.4.2.2 4-Point Bend Fixture—A standard or modified

A1.2 Summary of Test Method

bending fixture that produces pure bending in the staple

A1.2.1 Metallic bone staples are tested under bending loads

withoutappreciableshearortorsionwhenusedtoapplyloadto

until the specimen fails or a predetermined number of cycles

the staple through the staple extensions.

has been applied to it. Bending tests may be performed in one

A1.4.2.3 Pin and Clevice Fixture—A standard or modified

of two modes: either pure, in-plane bending; or tension (or

fixture used to apply a distractive or compressive load to the

compression) combined with in-plane bending. Tests using

staple through the staple extensions to produce bending in the

either of these methods may be conducted at ambient condi-

staple similar to that seen in vivo.

tions or in aqueous or physiological solutions (at either room

A1.4.3 Filling or Grouting Agent—A stiff, moldable filler,

temperature or 37°C).

suchasepoxy,acryliccement,oralow-meltingpointalloy(for

example,Wood’smetal)usedtosecurethestaplelegwithinthe

A1.3 Significance and Use

staple extension.

A1.3.1 This test method is used to determine the fatigue

A1.4.4 Aqueous Solution—Tapwater,distilledwater,physi-

resistance of metallic bone staples when subjected to repetitive

ological saline, or similar aqueous solutions, used to immerse

loading for large numbers of cycles.This information may also

the test specimens fully during the test.

be useful for comparing the effect of variations in staple

material, geometry, surface condition, or placement under

certain circumstances.

A1.3.2 It is essential that uniform fatigue practices be

established in order that such basic fatigue data be comparable

and reproducible and can be correlated among laboratories.

A1.3.3 The results of fatigue tests are suitable for direct

application to design only when the service conditions parallel

the test conditions exactly. This test method may not be

appropriate for all types of bone staple applications. The user

is cautioned to consider the appropriateness of the test method

in view of the materials being tested and their potential

application.

A1.4 Apparatus

A1.4.1 Testing Machines,conformingtotherequirementsof

Practices E4 and E 467. The loads used for determining

strengths shall be within the loading range of the testing

machine as defined in PracticesE4 and E 467.

A1.4.2 Gripping Devices:

A1.4.2.1 Staple Extensions—Pairs of specially designed

metal blocks that permit the holding of individual staples for

theapplicationofbendingfatigueloads.Thelegsofeachstaple

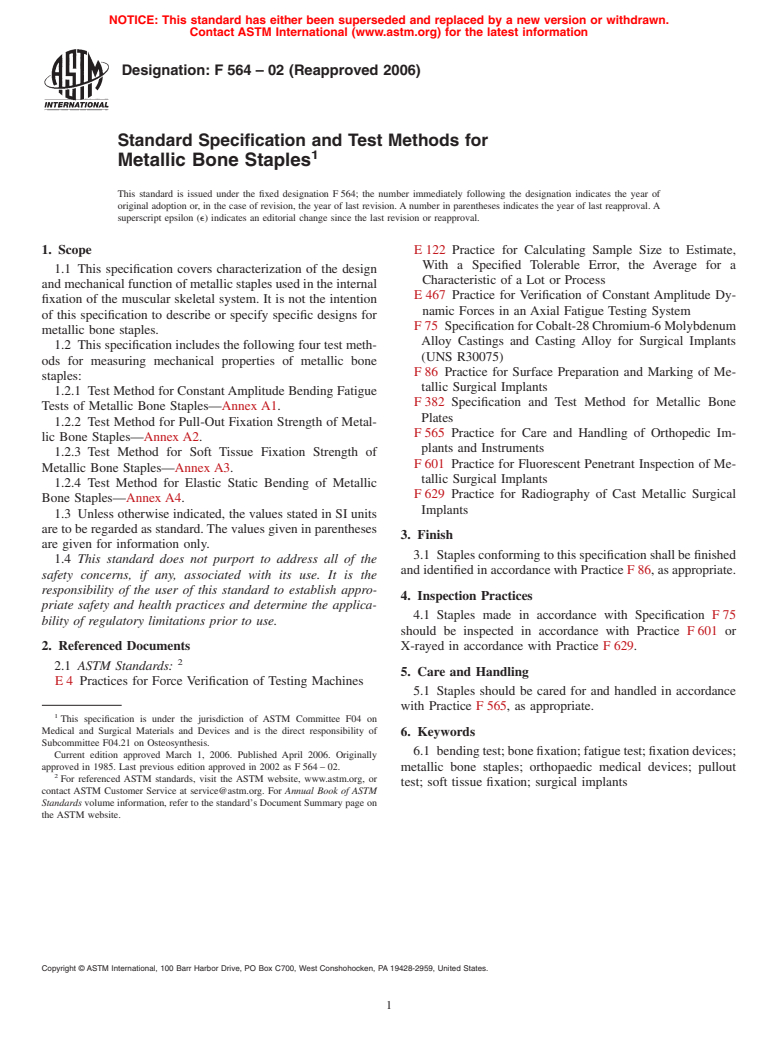

are fitted into fixation holes in each block with minimal FIG. A1.1 4-Point Bending of Staples in Extension

F 564 – 02 (2006)

A1.5.2 Staple Leg—The parallel or nearly parallel exten-

sions that are intended to penetrate the bone tissue; these may

be round, square, or polygonal in cross section, and they may

possess serrations or barbs to increase the fixation or purchase

strength in the bone.

A1.5.3 Staple Bridge—The cross member of the staple

connecting the legs; the bridge may be smooth or possess

spikes or projections on the underside for the retention of soft

tissue or other material.

A1.6 Procedure

A1.6.1 Mounting the Specimen—Fix the staple leg in an

extensionblockusingthefillingagent.Afixtureshouldbeused

to ensure proper in-plane alignment of the two extensions and

the staple during this process.Also, each staple should be fixed

such that the bridge is the same distance from the top of each

extension.

NOTE A1.2—This distance is at the discretion of the operator, but it

determines the portion of the staple subjected to the bending loads.

A1.6.2 4-Point Bend Testing:

A1.6.2.1 Place the staple and attached staple extensions in

the 4-point bending fixture such that the loading point and

support rollers contact the staple extensions on either side of

the staple; direct contact of the rollers with the staple shall not

be permitted during the test. Alignment of the loading point

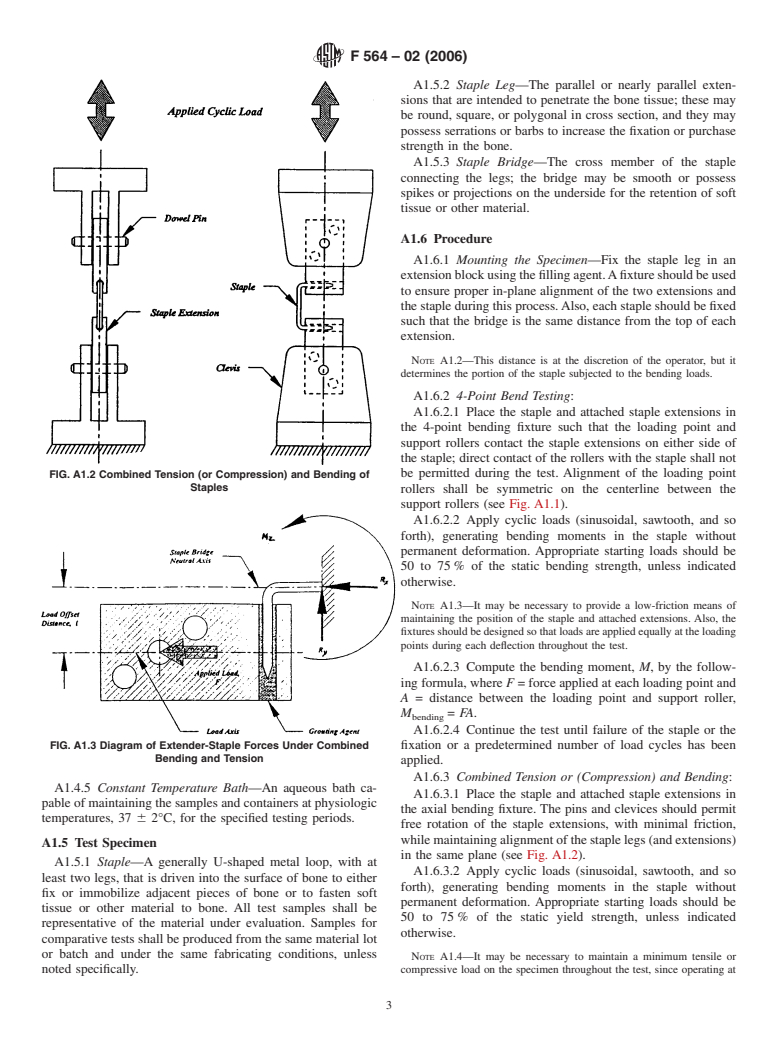

FIG. A1.2 Combined Tension (or Compression) and Bending of

Staples

rollers shall be symmetric on the centerline between the

support rollers (see Fig. A1.1).

A1.6.2.2 Apply cyclic loads (sinusoidal, sawtooth, and so

forth), generating bending moments in the staple without

permanent deformation. Appropriate starting loads should be

50 to 75 % of the static bending strength, unless indicated

otherwise.

NOTE A1.3—It may be necessary to provide a low-friction means of

maintaining the position of the staple and attached extensions. Also, the

fixtures should be designed so that loads are applied equally at the loading

points during each deflection throughout the test.

A1.6.2.3 Compute the bending moment, M, by the follow-

ing formula, where F = force applied at each loading point and

A = distance between the loading point and support roller,

M = FA.

bending

A1.6.2.4 Continue the test until failure of the staple or the

FIG. A1.3 Diagram of Extender-Staple Forces Under Combined fixation or a predetermined number of load cycles has been

Bending and Tension

applied.

A1.6.3 Combined Tension or (Compression) and Bending:

A1.4.5 Constant Temperature Bath—An aqueous bath ca-

A1.6.3.1 Place the staple and attached staple extensions in

pable of maintaining the samples and containers at physiologic

the axial bending fixture. The pins and clevices should permit

temperatures, 37 6 2°C, for the specified testing periods.

free rotation of the staple extensions, with minimal friction,

whilemaintainingalignmentofthestaplelegs(andextensions)

A1.5 Test Specimen

in the same plane (see Fig. A1.2).

A1.5.1 Staple—A generally U-shaped metal loop, with at

A1.6.3.2 Apply cyclic loads (sinusoidal, sawtooth, and so

least two legs, that is driven into the surface of bone to either

forth), generating bending moments in the staple without

fix or immobilize adjacent pieces of bone or to fasten soft

permanent deformation. Appropriate starting loads should be

tissue or other material to bone. All test samples shall be

50 to 75 % of the static yield strength, unless indicated

representative of the material under evaluation. Samples for

otherwise.

comparative tests shall be produced from the same material lot

or batch and under the same fabricating conditions, unless

NOTE A1.4—It may be necessary to maintain a minimum tensile or

noted specifically. compressive load on the specimen throughout the test, since operating at

F 564 – 02 (2006)

or near zero load may result in either loss of machine control due to

A1.8.1.1 Staple Description—Type, size, special features

discontinuity in the load feedback loop or undesirable transient loading of

(barbs, spikes, and so forth), manufacturer, material, batch or

the staple.

lot number, and dimensions (including leg length, bridge

A1.6.3.3 Compute the bending moment in the staple bridge,

width, and length), as appropriate.

M, by the following formula, where F = force applied at each A1.8.1.2 Test Type—4-point or combined tension (or com-

center of each pin and L = distance between the load applica-

pression) and bending.

tion axis, that is, the pin center, and the neutral axis of the A1.8.1.3 Fixation Geometry—Load point separation dis-

staple bridge, M = FL (see Fig. A1.3).

tances (4-point bending), load offset distance (combined ten-

bending

sion and bending), staple bridge-extension distance, and so

NOTE A1.5—The application of this test method produces bending,

forth.

tensile(orcompressive),andshearstressesinthestaple.Thedirectionand

A1.8.1.4 Minimum and maximum cycle loads, test fre-

magnitudes of these stresses should be analyzed using superposition

theory or other suitable methods. quency(forexample,cycles/s),andforcingfunctiontype(sine,

ramp, saw tooth, and so forth).

A1.6.3.4 Continue the test until failure of the staple or the

A1.8.1.5 Bending moment, M (N-m).

fixation or a predetermined number of load cycles has been

A1.8.1.6 Load ratio, R, where R = minimum load/maximum

applied.

load.

A1.6.4 Stress Verification—It is recommended that strain

A1.8.1.7 Test Environment—Ambient air or physiological

gages(orextensometry)beusedtomeasurethebendingstrains

solution.

induced in the specimen. This is accomplished most easily on

A1.8.1.8 Number of cycles at failure or test termination

thestaplebridge,butitmaybepossibletoperformonaportion

(runout).

of the staple leg or at the leg-bridge junction under certain

A1.8.1.9 Location of fatigue fracture (if applicable).

circumstances and with certain staple designs. The recom-

A1.8.1.10 Reason for test termination, that is, staple failure,

mended technique is to strain gage the actual fatigue test

fixation failure, runout to specified cycle limit, and so forth.

specimens, if possible, provided that the installation of strain

gage will not influence the test results.

A1.9 Precision

A1.7 Test Termination

A1.9.1 Intralaboratory and interlaboratory reproducibility

have not been determined systematically.

A1.7.1 Continue the tests until the specimen fails or a

predetermined number of cycles has been applied to the

A1.10 Rationale (Nonmandatory Information)

specimen. Failure should be defined as complete separation, a

A1.10.1 Thistestmethodisintendedtoaidincharacterizing

crack visible at a specified ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.