ASTM D7525-14

(Test Method)Standard Test Method for Oxidation Stability of Spark Ignition Fuel—Rapid Small Scale Oxidation Test (RSSOT)

Standard Test Method for Oxidation Stability of Spark Ignition Fuel—Rapid Small Scale Oxidation Test (RSSOT)

SIGNIFICANCE AND USE

5.1 The induction period may be used as an indication of the oxidation and storage stability of spark ignition fuel.

5.2 Compared to some other oxidation and storage stability test methods, this test method uses a small sample and gives a result in a short time period.

SCOPE

1.1 This laboratory test method covers the quantitative determination of the stability of spark ignition fuel, including those containing alcohols or other oxygenates, under accelerated oxidation conditions, by an automatic instrument (Warning—This test method is not intended for determining the stability of gasoline components, particularly those with a high percentage of low boiling unsaturated compounds, as these can cause explosive conditions with the apparatus.2)

1.2 This test method measures the induction period, under specified conditions, which can be used as an indication of the oxidation and storage stability of spark ignition fuel.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7525 − 14

Standard Test Method for

Oxidation Stability of Spark Ignition Fuel—Rapid Small

1

Scale Oxidation Test (RSSOT)

This standard is issued under the fixed designation D7525; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This laboratory test method covers the quantitative 3.1 Definitions of Terms Specific to This Standard:

determination of the stability of spark ignition fuel, including 3.1.1 break point, n—pressureinthetest apparatus, whichis

those containing alcohols or other oxygenates, under acceler- 10 % below the maximum pressure of the actual test run.

ated oxidation conditions, by an automatic instrument

3.1.2 induction period, n—timeelapsedbetweenstartingthe

(Warning—This test method is not intended for determining

heating procedure of the sample vessel and the break point,

the stability of gasoline components, particularly those with a

measured in minutes.

high percentage of low boiling unsaturated compounds, as

2

these can cause explosive conditions with the apparatus. ) 4. Summary of Test Method

1.2 This test method measures the induction period, under 4.1 A 5 mL sample is introduced into a pressure vessel

specified conditions, which can be used as an indication of the which is then charged with oxygen to 500 kPa at a temperature

oxidation and storage stability of spark ignition fuel. of 15 to 25°C. The test is initiated by starting the heater and

heating the pressure vessel to a temperature of 140°C.

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 4.2 The pressure is recorded continuously until the break-

standard. pointisreached.Alternatively,thetestmaybeterminatedwhen

a predetermined minimum requirement is reached.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 Theinductionperiodmaybeusedasanindicationofthe

priate safety and health practices and determine the applica-

oxidation and storage stability of spark ignition fuel.

bility of regulatory limitations prior to use.

5.2 Compared to some other oxidation and storage stability

2. Referenced Documents

test methods, this test method uses a small sample and gives a

3

result in a short time period.

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and

6. Apparatus

Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and

6.1 General—This test method uses an automatically con-

4

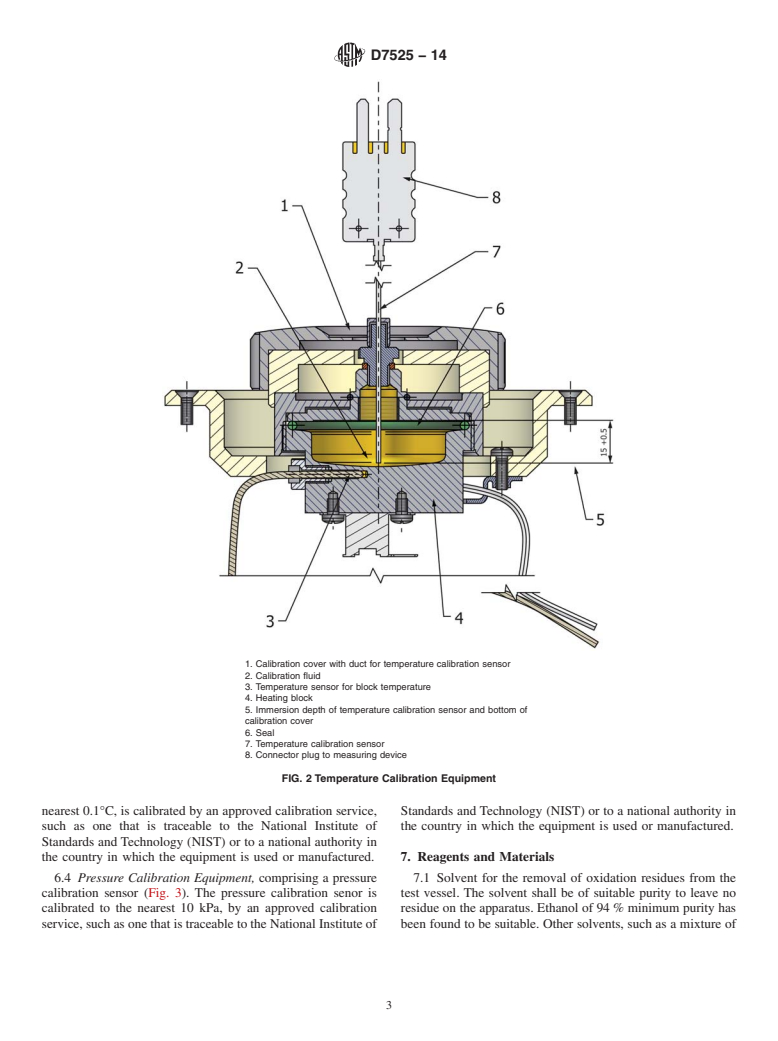

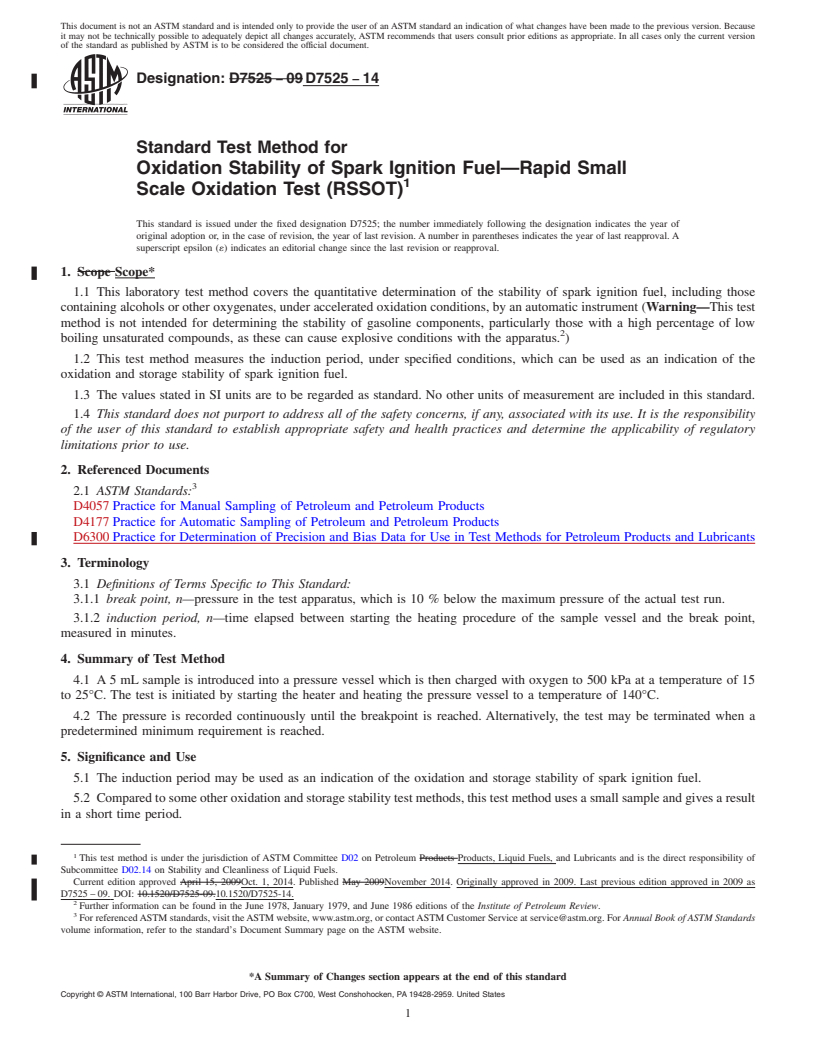

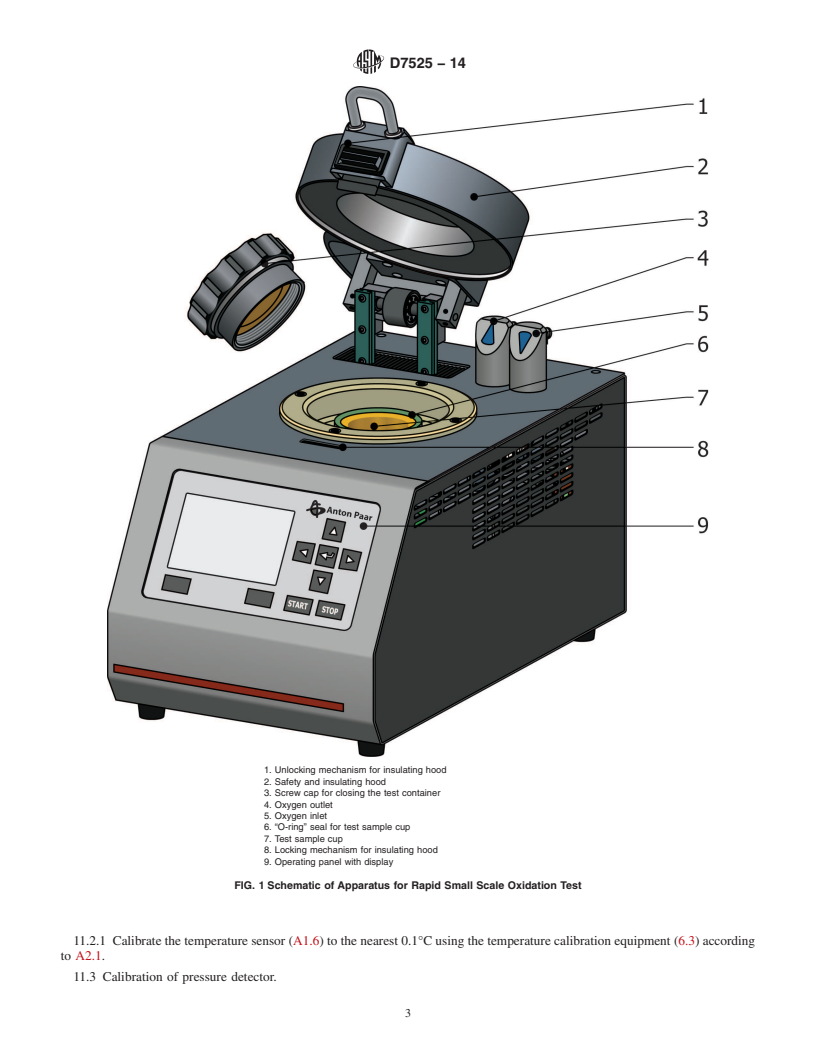

Petroleum Products trolled oxidation tester (Fig. 1) comprising an oxidation

D6300 Practice for Determination of Precision and Bias pressure vessel containing a test sample cup capable of being

Data for Use in Test Methods for Petroleum Products and rapidly heated, fitted with a pressure sensor capable of mea-

Lubricants suring pressures up to 2000 kPa and a temperature sensor

capable of reading to 0.1°C. Pressure and temperature in the

oxidation vessel are recorded continuously during the test. The

1

This test method is under the jurisdiction of ASTM Committee D02 on

oxidation pressure vessel is fitted with filling and relief valves

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

and a means of automatically releasing the pressure at the end

Subcommittee D02.14 on Stability and Cleanliness of Liquid Fuels.

of the test. The integrated cooling fan cools the pressure vessel

Current edition approved Oct. 1, 2014. Published November 2014. Originally

approved in 2009. Last previous edition approved in 2009 as D7525 – 09. DOI:

10.1520/D7525-14.

2 4

Further information can be found in the June 1978, January 1979, and June The sole source of supply of the apparatus known to the committee at this time

1986 editions of the Institute of Petroleum Review. is Anton Paar’s PetroOxy apparatus, available from Anton Paar ProveTec GmbH,

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Ludwig-Erhard-Ring 13, 15827 Blankenfelde-Mahlow, Germany, www.anton-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM paar.com. If you are aware of alternative suppliers, please provide this information

Standards volume information, refer to the standard’s Document Summary page on to ASTM International Headquarters. Your comments will receive careful consid-

1

the ASTM website. eration at a meeting of the responsible technical committee, which you may attend.

*A Summary of Changes section appears at the end of t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7525 − 09 D7525 − 14

Standard Test Method for

Oxidation Stability of Spark Ignition Fuel—Rapid Small

1

Scale Oxidation Test (RSSOT)

This standard is issued under the fixed designation D7525; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This laboratory test method covers the quantitative determination of the stability of spark ignition fuel, including those

containing alcohols or other oxygenates, under accelerated oxidation conditions, by an automatic instrument (Warning—This test

method is not intended for determining the stability of gasoline components, particularly those with a high percentage of low

2

boiling unsaturated compounds, as these can cause explosive conditions with the apparatus. )

1.2 This test method measures the induction period, under specified conditions, which can be used as an indication of the

oxidation and storage stability of spark ignition fuel.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 break point, n—pressure in the test apparatus, which is 10 % below the maximum pressure of the actual test run.

3.1.2 induction period, n—time elapsed between starting the heating procedure of the sample vessel and the break point,

measured in minutes.

4. Summary of Test Method

4.1 A 5 mL sample is introduced into a pressure vessel which is then charged with oxygen to 500 kPa at a temperature of 15

to 25°C. The test is initiated by starting the heater and heating the pressure vessel to a temperature of 140°C.

4.2 The pressure is recorded continuously until the breakpoint is reached. Alternatively, the test may be terminated when a

predetermined minimum requirement is reached.

5. Significance and Use

5.1 The induction period may be used as an indication of the oxidation and storage stability of spark ignition fuel.

5.2 Compared to some other oxidation and storage stability test methods, this test method uses a small sample and gives a result

in a short time period.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved April 15, 2009Oct. 1, 2014. Published May 2009November 2014. Originally approved in 2009. Last previous edition approved in 2009 as

D7525 – 09. DOI: 10.1520/D7525-09.10.1520/D7525-14.

2

Further information can be found in the June 1978, January 1979, and June 1986 editions of the Institute of Petroleum Review.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7525 − 14

6. Apparatus

4

6.1 General—This test method uses an automatically controlled oxidation tester (Fig. 1) comprising an oxidation pressure

vessel containing a test sample cup capable of being rapidly heated, fitted with a pressure sensor capable of measuring pressures

up to 2000 kPa and a temperature sensor capable of reading to 0.1°C. Pressure and temperature in the oxidation vessel are recorded

continuously during the test. The oxidation pressure vessel is fitted with filling and relief valves and a means of automatically

releasing the pres

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.