ASTM E2625-09

(Practice)Standard Practice for Controlling Occupational Exposure to Respirable Crystalline Silica for Construction and Demolition Activities

Standard Practice for Controlling Occupational Exposure to Respirable Crystalline Silica for Construction and Demolition Activities

SIGNIFICANCE AND USE

These practices and criteria were developed for occupational exposures during construction and demolition activities. They are intended to (a) protect against clinically significant disease from exposure to respirable crystalline silica, (b) be measurable by techniques that are valid, reproducible, and readily available, and (c) be attainable with existing technology and protective practices.

SCOPE

1.1 This practice describes several actions to reduce the risk of harmful occupational exposures in environments containing respirable crystalline silica. This practice is intended for the unique conditions during construction and demolition activities.

1.2 Health requirements relating to occupational exposure to respirable crystalline silica not covered in this practice fall under the jurisdiction of Practice E 1132.

1.3 Nothing in this practice shall be interpreted as requiring any action that violates any statute or requirement of any federal, state, or other regulatory agency.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2625 − 09

Standard Practice for

Controlling Occupational Exposure to Respirable Crystalline

Silica for Construction and Demolition Activities

This standard is issued under the fixed designation E2625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Silicondioxide(silica,SiO )isencounteredinnatureandindustryinawidevarietyofforms.These

range from essentially anhydrous types with or without a very high degree of crystallinity, to highly

hydroxylated or hydrated types which are amorphous by X-ray diffraction examination. Crystalline

silica exists in a number of forms or polymorphs. The three major forms, quartz, cristobalite, and

tridymite, pertain to this practice. Quartz (or alpha quartz) is the more common form encountered as

airborne particulates. Two of the polymorphs, cristobalite and tridymite, are formed at elevated

temperatures and are much less common in nature, but might be encountered in several occupations

where silicas are fired (calcined) at high temperatures. These silica materials have a broad range of

physical and chemical properties.

1. Scope 2. Referenced Documents

1.1 This practice describes several actions to reduce the risk 2.1 ASTM Standards:

of harmful occupational exposures in environments containing D4532 Test Method for Respirable Dust in Workplace At-

respirable crystalline silica. This practice is intended for the mospheres Using Cyclone Samplers

unique conditions during construction and demolition activi- E1132 Practice for Health Requirements Relating to Occu-

ties. pational Exposure to Respirable Crystalline Silica

2.2 ANSI Standards:

1.2 Health requirements relating to occupational exposure

Z88.2 1992 American National Standard Practice for Respi-

to respirable crystalline silica not covered in this practice fall

ratory Protection

under the jurisdiction of Practice E1132.

ANSI/AIHAZ9.22001 FundamentalsGoverningtheDesign

1.3 Nothing in this practice shall be interpreted as requiring

and Operation of Local Exhaust Systems

any action that violates any statute or requirement of any 6

2.3 Code of Federal Regulations:

federal, state, or other regulatory agency.

29 CFR 1910.134 Respiratory Protection

1.4 This standard does not purport to address all of the

29 CFR 1910.1000 Air Contaminants

safety concerns, if any, associated with its use. It is the

29 CFR 1910.1200 Hazard Communication

responsibility of the user of this standard to establish appro-

42 CFR 84 Title 42, Part 84 Approval of Respiratory

priate safety and health practices and determine the applica-

Protective Devices, Tests for Permissibility, Fees

bility of regulatory limitations prior to use.

30 CFR 56, Title 30, Subpart D Air Quality, Radiation, and

Physical Agents (MSHA)

This practice is under the jurisdiction of ASTM Committee E34 on Occupa-

tional Health and Safety and is the direct responsibility of Subcommittee E34.80 on

Industrial Heath. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2009. Published May 2009. DOI: 10.1520/ contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

E2625-09. Standards volume information, refer to the standard’s Document Summary page on

Smith, Deane K., Opal, cristobalite, and tridymite: Noncrystallinity versus the ASTM website.

crystallinity, nomenclature of the silica minerals and bibliography, Powder Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Diffraction, Vol 13, 1998, pp 1–18. 4th Floor, New York, NY 10036, http://www.ansi.org.

3 6

Miles, W.J., Crystalline silica analysis of Wyoming bentonite by X-ray AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

diffraction after phosphoric acid digestion, Analytical Chemistry Acta, Vol 286, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

1994, pp 97–105. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2625 − 09

2.4 NIOSH Publications: standards given in 4.1, and to establish a baseline exposure

Manual of Analytical Methods, 4th Ed., DHHS (NIOSH), level in all areas where workers are or have the potential to be

Publication No. 94-113 August 1994. exposed to silica. Initial task sampling would be not required

Method 7500 for Silica, Crystalline, Respirable (XRD) for short duration or transient tasks, tasks where sampling

Method 7601 for Silica, Crystalline Visible Absorption results would not be timely, representative concentrations are

Spectrophotometry already known or proven task protection is in place. Conduct

Method 7602 for Silica, Crystalline (IR) exposure sampling when needed to prevent a significant and

2000 Guidelines for the Use of ILO International Classifi- deleteriouschangeinthecontaminantgenerationprocessorthe

cation of Radiographs of Pneumoconioses exposure controls so that overexposures do not go undetected.

This is particularly true for areas or operations where condi-

2.5 Other References:

tions can change dramatically within a short span of time.

American Thoracic Society, Standardization of

Spirometry—1994 Update 4.2.3 Recordkeeping required under this practice shall be

maintained and made available for review by employees.

3. Significance and Use

4.2.4 For workers with regular exposure to high silica

concentrationswhoareplacedinsideofsuppliedairrespirators

3.1 These practices and criteria were developed for occu-

pational exposures during construction and demolition activi- or ventilated enclosures, such as in sandblasting, conduct

sampling inside of the control device to determine employee

ties. They are intended to (a) protect against clinically signifi-

cant disease from exposure to respirable crystalline silica, (b) exposure. The sampling line shall not interfere with the fit of

therespirator.Itispossiblethatconsultationwiththerespirator

be measurable by techniques that are valid, reproducible, and

readilyavailable,and(c)beattainablewithexistingtechnology manufacturer will be necessary to achieve the above require-

ment.

and protective practices.

4.2.5 In areas where overexposures are persistent, a written

4. General Requirements

exposure control plan shall be established to implement

engineering, work practice, and administrative controls to

4.1 Occupational Exposure Limit:

reduce silica exposures to below the PEL, or other elected

4.1.1 Permissible Exposure Limit (PEL)—U.S. Occupa-

limit, whichever is lower, to the extent feasible. Conduct a root

tional Health and Safety Administration (OSHA) General

cause analysis for all exposures in excess of the PEL that

Industry (see 29 CFR 1910.1000)—Workers shall not be

cannot be accounted for. Root cause analysis involves investi-

exposed to respirable dust containing 1 % or more quartz

gatingcause(s)fortheexcessiveexposure,providingremedies,

exceeding 10/(% quartz + 2) mg/m as an 8-h time weighted

and conducting follow-up sampling to document that expo-

average in any 8-h work shift of a 40-h work week or, for total

sures are below the PEL.

dust(respirableplusnon-respirable),30/(%quartz+2)mg/m .

ThePELforrespirablecristobaliteandtridymiteisone-halfthe

4.2.6 The employer shall re-assess exposures when there

value for quartz. has been a change in the process, equipment, work practices or

3 control methods that have the potential to result in new or

PEL ~mg/m !~respirablefraction! 5 10÷@% quartz1~% cristobalite

additional exposures to crystalline silica or when the employer

32!1~% tridymite 32!12#

hasanyreasontobelievethatneworadditionalexposureshave

PEL mg/m totaldust 5 30÷ % quartz1 % cristobalite 32

~ !~ ! @ ~ !

occurred.

1 % tridymite 32 12

~ ! #

4.2.7 Measurement of worker occupational exposures shall

4.1.2 Federal OSHA PEL is approximately equivalent to a

be within the worker’s breathing zone and shall meet the

quartz level of 100µg/m . criteria of this section. Such measurements need to be repre-

4.1.3 Employer shall determine the appropriate PEL for

sentative of the worker’s customary activity and be represen-

their operation, but in no case shall the PEL be less stringent tative of work shift exposure. Use area sampling to character-

than the applicable government limit.

ize exposures and identify effective controls when appropriate

to the circumstances.

4.2 Exposure Assessment and Monitoring:

4.2.8 Respirable dust samples are to be collected in accor-

4.2.1 Risk can be assessed qualitatively based on material

dance with accepted methods. Refer to D4532.

safety data sheets (MSDS), historical data, likelihood of dust

generation,proximityofairbornedusttoworkers,natureofthe 4.2.9 Sample data records shall include employee

construction process (for example, wet work—low risk; dry identification, a log of the date and time of sample collection,

work—higher risk), and location of workers (for example, sampling time duration, volumetric flow rate of sampling,

closed equipment cab). Note that the absence of visible dust is documentation of pump calibration, and description of the

not a guarantee of lack of risk. sampling location, analytical methods, and other pertinent

4.2.2 Where qualitative risk assessment indicates that a information.

potential risk is present, initial sampling of tasks or represen-

4.2.10 Analyze samples for silica content analysis by an

tative workers’ exposures shall be made to characterize the

AIHA-accredited laboratory.

exposure and its variability, to determine compliance with

4.3 Exposure Monitoring:

4.3.1 The employer shall provide employees with an expla-

CDC/NIOSH, 4676 Columbia Pkwy, Cincinnati, OH 45226-1998. nation of the sampling procedure.

E2625 − 09

4.3.2 Whenever exposure monitoring activities require en- (3) Enclosed workstations, such as control booths and

try into an area where the use of respirators, protective equipment cabs, designed for protection against respirable

clothing, or equipment is required, the employer shall provide crystalline silica dust, shall be provided with filtered air to

and ensure the use of such personal protective equipment and reduce exposures.

shall require compliance with all other applicable safety and (4) Engineering design of tools and equipment shall

health procedures. include, where feasible, provisions to minimize exposure of

4.3.3 Affected employees shall be provided with copies of workers to respirable crystalline silica dust to the PEL or

their sampling results when returned by the laboratory and below. If ventilation systems are used, they shall be designed

explanations of the data. and maintained to prevent the accumulation and re-circulation

of respirable crystalline silica dust in the working environment

4.4 Methods of Compliance:

(see ANSI Z9.2). If wet suppression systems are used, spray

4.4.1 Task-based Control Strategies—Where exposure lev-

nozzles and associated piping shall be maintained to ensure

els are known from empirical data, a task based control

that adequate wetting agent is applied where needed to control

strategy shall be applied that matches tasks with controls. The

respirable crystalline silica dust.

following lists examples of this approach.

(5) All engineering controls shall be properly maintained

4.4.1.1 Abrasive Blasting—OSHA has already established

and periodically evaluated and brought up to specifications,

standards for abrasive blasting work requiring ventilation (29

when needed.

C.F.R. 1926.57) and respiratory protection (29 C.F.R.

4.4.3 Work Practices and Administrative Controls:

1926.103). In the case of abrasive blasting operations, it is

4.4.3.1 Ensure that workers do not work in areas of visible

recommended that the employer provide a Type CE, pressure

dust generated from materials known to contain a significant

demand or positive-pressure, abrasive blasting respirator (APF

percentage of respirable crystalline silica without use of

of 1000 or 2000).

respiratoryprotection,unlessproventaskprotectionisinuseor

4.4.1.2 Otherengineeringcontrolswiththepotentialtolimit

air sampling shows exposures less than the PEL.

exposure are:

4.4.3.2 Workers shall not use compressed air to blow

(1) Using alternative materials

respirable crystalline silica-containing materials from surfaces

(2) Wet suppression systems

or clothing, unless the method has been approved by an

(3) Exhaust ventilation

appropriate Regulatory agency.

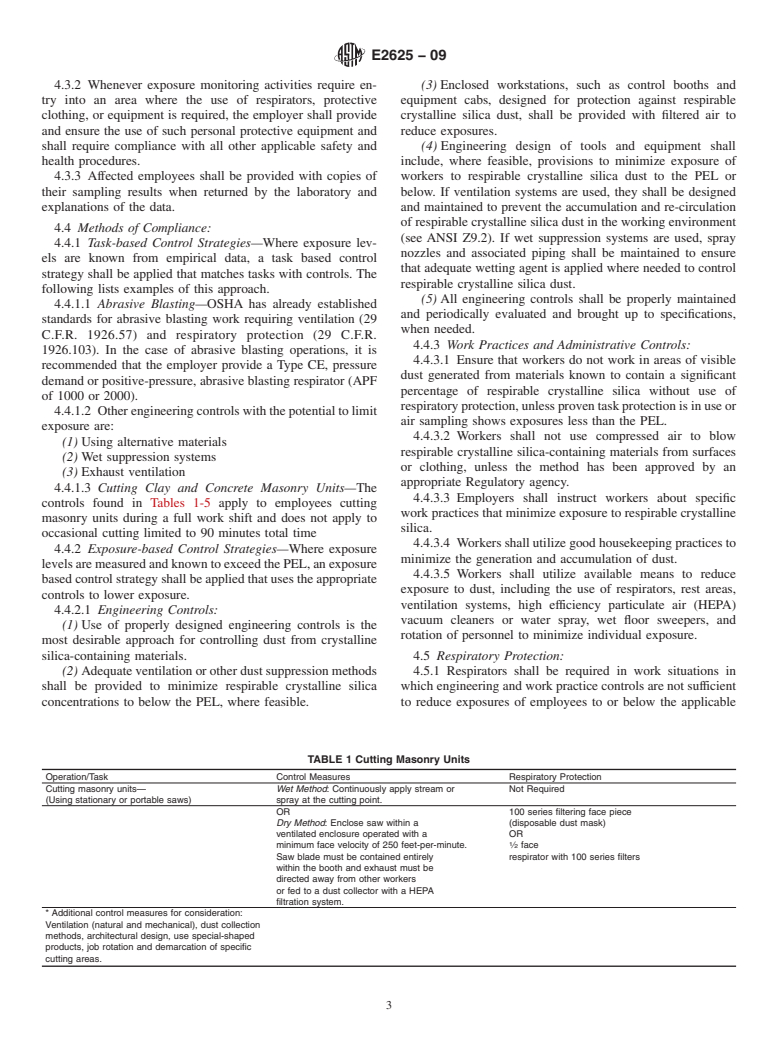

4.4.1.3 Cutting Clay and Concrete Masonry Units—The

4.4.3.3 Employers shall instruct workers about specific

controls found in Tables 1-5 apply to employees cutting

work practices that minimize exposure to respirable crystalline

masonry units during a full work shift and does not apply to

silica.

occasional cutting limited to 90 minutes total time

4.4.3.4 Workersshallutilizegoodhousekeepingpracticesto

4.4.2 Exposure-based Control Strategies—Where exposure

minimize the generation and accumulation of dust.

levelsaremeasuredandknowntoexceedthePEL,anexposure

4.4.3.5 Workers shall utilize available means to reduce

basedcontrolstrategyshallbeappliedthatusestheappropriate

exposure to dust, including the use of respirators, rest areas,

controls to lower exposure.

ventilation systems, high efficiency particulate air (HEPA)

4.4.2.1 Engineering Controls:

vacuum cleaners or water spray, wet floor sweepers, and

(1) Use of properly designed engineering controls is the

rotation of personnel to minimize individual exposure.

most desirable approach for controlling dust from crystalline

silica-containing materials. 4.5 Respiratory Protection:

(2) Adequateventilationorotherdustsuppressionmethods 4.5.1 Respirators shall be required in work situations in

shall be provided to minimize respirable crystalline silica which engineering and work practice controls are not sufficient

concentrations to below the PEL, where feasible. to reduce exposures of employees to or below the applicable

TABLE 1 Cutting Masonry Units

Operation/Task Control Measures Respiratory Protection

Cutting masonry units— Wet Method: Continuously apply stream or Not Required

(Using stationary or portable saws) spray at the cutting point.

OR 100 series filtering face piece

Dry Method: Enclose saw within a (disposable dust mask)

ventilated enclosure operated with a OR

minimum face velocity of 250 feet-per-minute. ⁄2 face

Saw blade must be contained entirely respirator with 100 series filters

within the booth and exhaust must be

directed away from other workers

or fed to a dust collector with a HEPA

filtration system.

*

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.