ASTM E81-96(2001)

(Test Method)Standard Test Method for Preparing Quantitative Pole Figures

Standard Test Method for Preparing Quantitative Pole Figures

SCOPE

1.1 This test method covers the use of the X-ray diffractometer to prepare quantitative pole figures.

1.2 The test method consists of several experimental procedures. Some of the procedures (1-5) permit preparation of a complete pole figure. Others must be used in combination to produce a complete pole figure.

1.3 Pole figures (6) and inverse pole figures (7-10) are two-dimensional averages of the three-dimensional crystallite ori- entation distribution. Pole figures may be used to construct either inverse pole figures (11-13) or the crystallite orientation distribution (14-21). Development of series expansions of the crystallite orientation distribution from reflection pole figures (22, 23) makes it possible to obtain a series expansion of a complete pole figure from several incomplete pole figures. Pole figures or inverse pole figures derived by such methods shall be termed calculated. These techniques will not be described herein.

1.4 Provided the orientation is homogeneous through the thickness of the sheet, certain procedures (1-3) may be used to obtain a complete pole figure.

1.5 Provided the orientation has mirror symmetry with respect to planes perpendicular to the rolling, transverse, and normal directions, certain procedures (4, 5, 24) may be used to obtain a complete pole figure.

1.6 The test method emphasizes the Schulz reflection technique (25). Other techniques (3, 4, 5, 24) may be considered variants of the Schulz technique and are cited as options, but not described herein.

1.7 The test method also includes a description of the transmission technique of Decker, et al (26), which may be used in conjunction with the Schulz reflection technique to obtain a complete pole figure.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 81 – 96 (Reapproved 2001)

Standard Test Method for

1

Preparing Quantitative Pole Figures

ThisstandardisissuedunderthefixeddesignationE81;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method covers the use of the X-ray diffracto-

meter to prepare quantitative pole figures.

2. Summary of Test Method

1.2 The test method consists of several experimental proce-

2 2.1 The test method consists of characterizing the distribu-

dures. Some of the procedures (1-5) permit preparation of a

tion of orientations of selected lattice planes with respect to

complete pole figure. Others must be used in combination to

sample-fixed coordinates (6). The distribution will usually be

produce a complete pole figure.

obtained by measurement of the intensity of X rays diffracted

1.3 Pole figures (6) and inverse pole figures (7-10) are two

by the sample. In such measurements the detector and associ-

dimensional averages of the three-dimensional crystallite ori-

ated limiting slits are fixed at twice the appropriate Bragg

entation distribution. Pole figures may be used to construct

angle,andthediffractedintensityisrecordedastheorientation

either inverse pole figures (11-13) or the crystallite orientation

of the sample is changed (1-6, 25, 26, 27).After the measured

distribution (14-21). Development of series expansions of the

data have been corrected, as necessary, for background, defo-

crystallite orientation distribution from reflection pole figures

cusing, and absorption, and normalized to have an average

(22, 23) makes it possible to obtain a series expansion of a

value of unity, the results may be plotted in stereographic or

completepolefigurefromseveralincompletepolefigures.Pole

equal-area projection.

figuresorinversepolefiguresderivedbysuchmethodsshallbe

2.2 The geometry of the Schulz (25) reflection method is

termed calculated. These techniques will not be described

illustrated in Fig. 1. Goniometers employing this geometry are

herein.

3

commercially available. The source of X rays is indicated by

1.4 Provided the orientation is homogeneous through the

L.SlitS1limitsdivergenceoftheincidentbeamintheplaneof

thickness of the sheet, certain procedures (1-3) may be used to

projection. Slit S2 limits divergence perpendicular to the plane

obtain a complete pole figure.

of projection. The sample, indicated by crosshatching, may be

1.5 Provided the orientation has mirror symmetry with

tilted about the axis FF8, which is perpendicular to the

respect to planes perpendicular to the rolling, transverse, and

diffractometer axis and lies in the plane of the sample. The tilt

normal directions, certain procedures (4, 5, 24) may be used to

angle was denoted f by Schulz (25). The sample position

obtain a complete pole figure.

shown in Fig. 1 corresponds to f=0 deg, for which approxi-

1.6 The test method emphasizes the Schulz reflection tech-

mateparafocusingconditionsexistatthedetectorslit,S3.With

nique (25). Other techniques (3, 4, 5, 24) may be considered

theapplicationofadefocusingcorrection,thismethodisuseful

variants of the Schulz technique and are cited as options, but

over a range of colatitude f from 0 deg to approximately 75

not described herein.

deg.

1.7 The test method also includes a description of the

2.2.1 Tilting the sample about FF8, so as to reduce the

transmission technique of Decker, et al (26), which may be

distance between L and points in the sample surface above the

used in conjunction with the Schulz reflection technique to

plane of projection, causes X rays diffracted from these points

obtain a complete pole figure.

to be displaced to the left of the center of S3, while X rays

1.8 This standard does not purport to address all of the

diffractedfrompointsinthesamplesurfacebelowtheplaneof

safety concerns, if any, associated with its use. It is the

projection are displaced to the right of the center of S3. The

responsibility of the user of this standard to establish appro-

displacement is equal to 2D tan f cos u, where D is the

distance above or below the plane of projection. The inte-

1

This test method is under the jurisdiction of ASTM Committee E04 on grated, or total, diffracted intensity is influenced only slightly

Metallography and is the direct responsibility of Subcommittee E04.11 on X-Ray

by tilting the sample (28). Insofar as possible, the detector slit

and Electron Metallography.

Current edition approved May 10, 1996. Published July 1996. Originally

published as E81–49T. Last previous edition E81–90.

2 3

Theboldfac

...

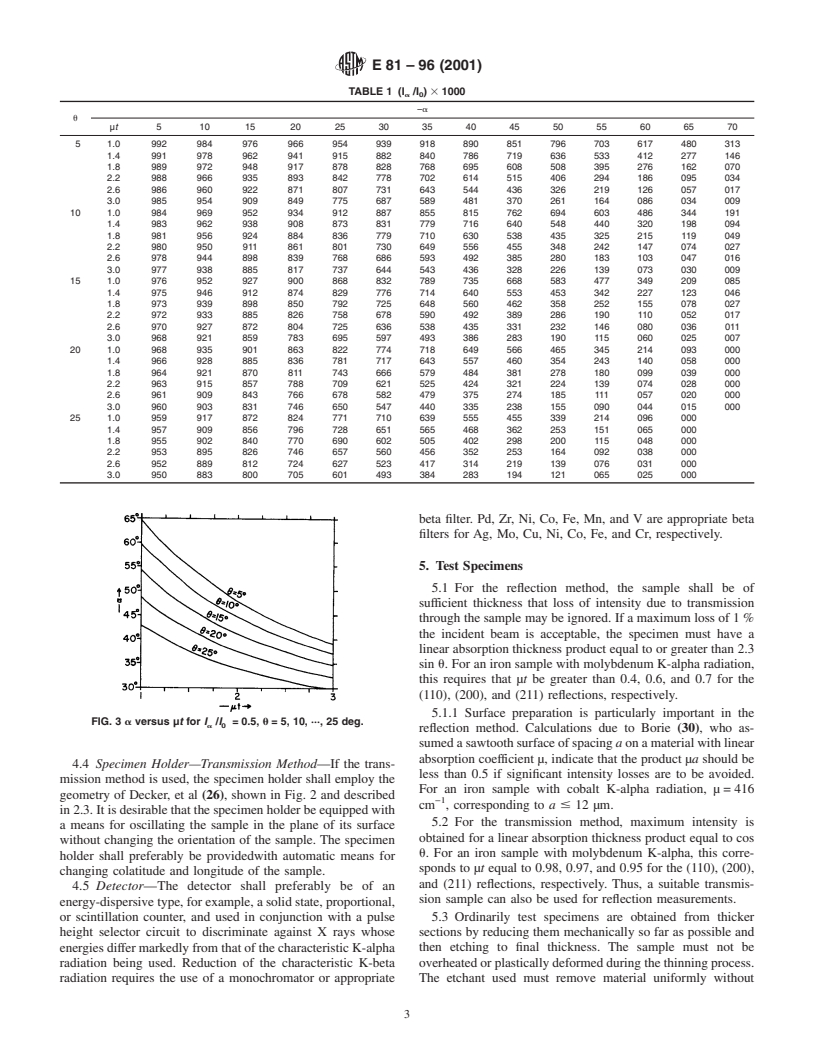

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.