ASTM D3242-98

(Test Method)Standard Test Method for Acidity in Aviation Turbine Fuel

Standard Test Method for Acidity in Aviation Turbine Fuel

SCOPE

1.1 This test method covers the determination of the acidity in aviation turbine fuel in the range from 0.000 to 0.100 mg KOH/g.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3242 – 98 An American National Standard

Designation: 354/98

Standard Test Method for

Acidity in Aviation Turbine Fuel

This standard is issued under the fixed designation D 3242; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense. This test method has been approved by the

sponsoring committees and accepted by the cooperating societies in accordance with established procedures.

1. Scope nitrogen bubbling through it and is titrated with standard

alcoholic potassium hydroxide to the end point indicated by the

1.1 This test method covers the determination of the acidity

color change (orange in acid and green in base) of the added

in aviation turbine fuel in the range from 0.000 to 0.100 mg

p-naphtholbenzein solution.

KOH/g.

1.2 The values stated in SI units are to be regarded as the

5. Significance and Use

standard.

5.1 Some acids can be present in aviation turbine fuels due

1.3 This standard does not purport to address all of the

either to the acid treatment during the refining process or to

safety concerns, if any, associated with its use. It is the

naturally occurring organic acids. Significant acid contamina-

responsibility of the user of this standard to establish appro-

tion is not likely to be present because of the many check tests

priate safety and health practices and determine the applica-

made during the various stages of refining. However, trace

bility of regulatory limitations prior to use.

amounts of acid can be present and are undesirable because of

2. Referenced Documents the consequent tendencies of the fuel to corrode metals that it

contacts or to impair the water separation characteristics of the

2.1 ASTM Standards:

aviation turbine fuel.

D 664 Test Method for Acid Number by Potentiometric

5.2 This test method is designed to measure the levels of

Titration

acidity that can be present in aviation turbine fuel and is not

D 1193 Specification for Reagent Water

suitable for determining significant acid contamination.

3. Terminology

6. Apparatus

3.1 Definitions of Terms Specific to This Standard:

6.1 Buret—A 25-mL buret graduated in 0.1-mL subdivi-

3.1.1 acid number—the quantity of base, expressed in

sions, or a 10-mL buret graduated in 0.05-mL subdivisions.

milligrams of potassium hydroxide per gram of sample that is

required to titrate a sample in a specific solvent to a specific

NOTE 1—An automated buret capable of delivering titrant amounts in

end point.

0.05 mL or smaller increments can be used, but the stated precision data

were obtained using manual burets only.

3.1.1.1 Discussion—in this test method, the solvent is a

toluene-water-isopropanol mixture and the end point is deter-

7. Reagents and Materials

mined when a green/green brown color is obtained using the

7.1 Purity of Reagents—Reagent grade chemicals shall be

specified p-naphtholbenzein indicator solution.

used in all tests. Unless otherwise indicated, it is intended that

4. Summary of Test Method

all reagents shall conform to the specifications of the Commit-

tee on Analytical Reagents of the American Chemical Society,

4.1 The sample is dissolved in a mixture of toluene and

where such specifications are available. Other grades may be

isopropyl alcohol containing a small amount of water. The

used, provided it is first ascertained that the reagent is of

resulting single phase solution is blanketed by a stream of

sufficiently high purity to permit its use without lessening the

This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee Reagent Chemicals, American Chemical Society Specifications, American

D02.06 on Analysis of Lubricants. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Current edition approved Jan. 10, 1998. Published July1998. Originally pub- listed by the American Chemical Society, see Analar Standards for Laboratory

lished as D 3242 – 73 T. Last previous edition D 3242 – 93. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Annual Book of ASTM Standards, Vol 05.01. and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

Annual Book of ASTM Standards, Vol 11.01. MD.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3242

W 1000

accuracy of the determination.

p

Normality 5 3 (1)

204.23 V2V

b

NOTE 2—Commercially available reagents may be used in place of

laboratory preparations when they are certified in accordance with 7.1.

where:

W = weight of the potassium acid phthalate, g,

7.2 Purity of Water— References to water shall be under- p

204.23 = molecular weight of the potassium acid phthalate,

stood to mean distilled water as defined by Type III water of

V = volume of titrant used to titrate the salt to the

Specification D 1193.

specific end-point, mL, and

7.3 p-Naphtholbenzein Indicator Solution—The

V = volume of titrant used to titrate the blank, mL.

b

p-naphtholbenzein must meet the specifications given in Annex

7.5.2 Phenolphthalein Indicator Solution—Dissolve 0.1 g

A1. Prepare a solution of p-naphtholbenzein in titration solvent

6 0.01 of pure solid phenolphthalein in 50 mL of water, free of

equal to 10 6 0.01 g/L.

CO , and 50 mL of ethanol.

7.4 Nitrogen, dry-type, carbon dioxide-free.

7.6 Titration Solvent—Add 500 mL of toluene (Warning—

NOTE 3—Warning: Compressed gas under high pressure. Gas reduces

See Note 8.) and 5 mL of water to 495 mL of anhydrous

oxygen available for breathing.

isopropyl alcohol.

7.5 Potassium Hydroxide Solution, Standard Alcoholic

NOTE 8—Warning: Flammable. Vapor harmful. Keep away from heat,

(0.01 N)—Add 0.6 g of solid KOH (Warning—See Note 4.) to

sparks, and open flame.

approximately 1 L of anhydrous isopropyl alcohol

(Warning—See Note 5.) (containing less than 0.9 % water) in 8. Procedure

a 2-L Erlenmeyer flask. Boil the mixture gently for 10 to 15

8.1 Introduce 100 6 5 g of the sample weighed to the

min, stirring to prevent the solids from forming a cake on the

nearest 0.5 g, into a 500-mL wide-mouth Erlenmeyer flask.

bottom. Add at least 0.2 g of barium hydroxide (Ba(OH) )

(One type of suitable modified flask is shown in Fig. 1.) Add

(Warning—See Note 6.) and again boil gently for 5 to 10 min.

100 mL of the titration solvent and 0.1 mL of the indicator

Cool to room temperature, allow to stand for several hours, and

solution. Introduce nitrogen througha6to8mm outside

filter the supernatant liquid through a fine sintered-glass or

diameter glass tube to a point within 5 mm of the flask bottom

porcelain filtering funnel; avoid unnecessary exposure to

at a rate of 600 to 800 mL/min. Bubble the solution for 3 min

carbon dioxide (CO ) during filtration. Store the solution in a

2 6 30 s with occasional mixing.

chemically resistant dispensing bottle out of contact with cork,

8.1.1 The vapor from this treatment contains toluene and

rubber, or saponifiable stopcock lubricant and protected by a

should be removed with adequate ventilation.

guard tube containing soda lime.

8.2 Continue the nitrogen addition and titrate without delay

at a temperature below 30°C. Add 0.01 N KOH solution in

NOTE 4—Warning: Highly corrosive to all body tissue both in solid

form and in solution. increments and swirl to disperse until a green end point is

NOTE 5—Warning: Flammable. Vapor harmful. Keep away from heat, reached that persists for 15 s.

sparks, and open flame.

NOTE 9—The temperature can be measured by any suitable temperature

NOTE 6—Warning: Poisonous if ingested. Strongly alkaline, causes

measuring device.

severe irritation producing dermatitis.

NOTE 7—Because of the relative large coefficient of cubic expansion of

8.3 Blank—Perform a blank titration on 100 mL of the

organic liquids, such as isopropyl alcohol, the standard alcoholic solutions

titration solvent and 0.1 mL of the indicator solution, introduc-

should be standardized at temperatures close to those employed in the

ing the nitrogen in the same manner and titrating to the same

titration of samples.

end point as above.

7.5.1 Standardization of Potassium Hydroxide Solution—

Standardize frequently enough to detect changes of 0.0002N.

One way to accomplish this is as follows. Weigh, to the nearest

0.1 mg, approximately 0.02 g of potassium acid phthalate,

which has been dried for at least1hat110°C 6 1 and dissolve

in 40 6 1 mL of water, free of CO . Titrate with the potassium

hydroxide alcoholic solution to either of the following end-

points: (a) when the titration is electrometric, titrate to a well

defined inflection point at the voltage that corresponds to the

voltage of the basic buffer solution; (b) when the titration is

colorimetric, add 6 drops of phenolphthalein indicator solution

and titrate to the appearance of a permanent pink color.

Perform the blank titration on the water used to dissolve the

potassium acid phthalate. Calculate the normality using the

equation:

In a 1992 study, only Kodak and Fisher p-naphtholbenzein were found to meet

the specifications in Annex A1. The Fisher Reagent Solution was the only

commercially available solution to meet the specifications. FIG. 1 Titration Flask

D 3242

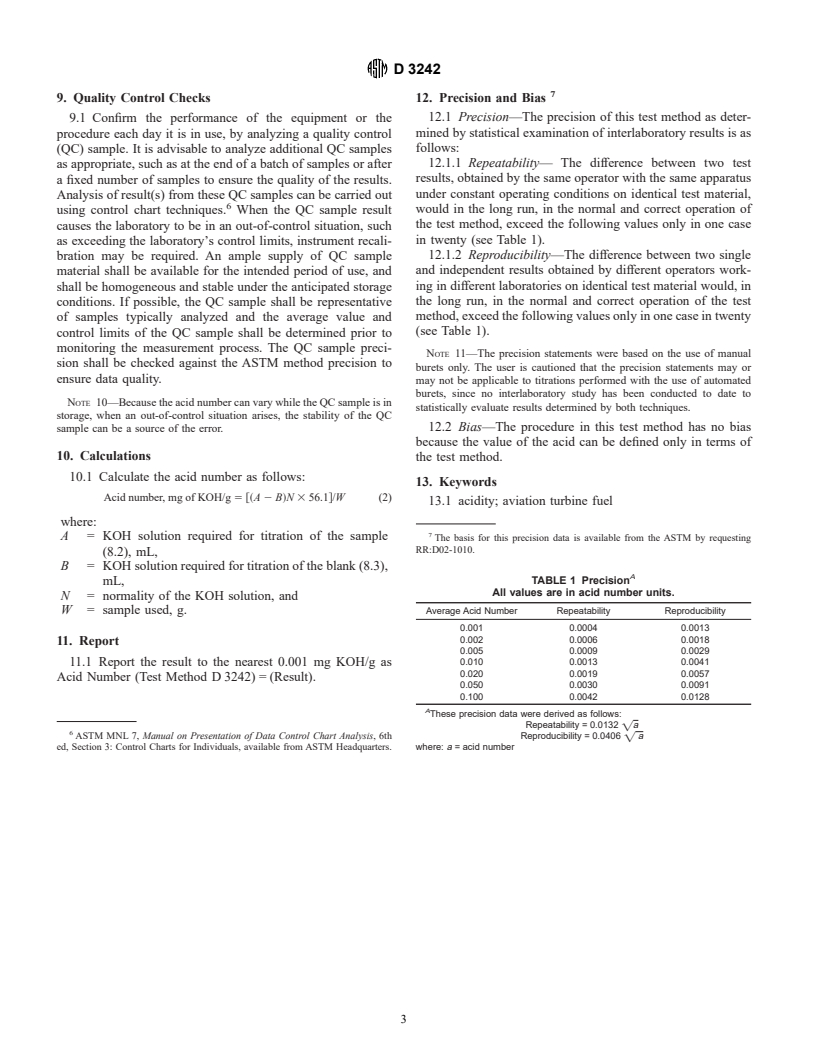

9. Quality Control Checks 12. Precision and Bias

12.1 Precision—The precision of this test method as deter-

9.1 Confirm the performance of the equipment or the

mined by statistical examination of interlaboratory results is as

procedure each day it is in use, by analyzing a quality control

follows:

(QC) sample. It is advisable to analyze additional QC samples

12.1.1 Repeatability— The difference between two test

as appropriate, such as at the end of a batch of samples or after

results, obtained by the same operator with the same apparatus

a fixed number of samples to ensure the quality of the results.

under constant operating conditions on identical test material,

Analysis of result(s) from these QC samples can be carried out

would in the long run, in the normal and correct operation of

using control chart techniques. When the QC sample result

the test method,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.