ASTM G71-81(2014)

(Guide)Standard Guide for Conducting and Evaluating Galvanic Corrosion Tests in Electrolytes

Standard Guide for Conducting and Evaluating Galvanic Corrosion Tests in Electrolytes

SIGNIFICANCE AND USE

3.1 Use of this guide is intended to provide information on the galvanic corrosion of metals in electrical contact in an electrolyte that does not have a flow velocity sufficient to cause erosion-corrosion or cavitation.

3.2 This standard is presented as a guide for conducting galvanic corrosion tests in liquid electrolyte solutions, both in the laboratory and in service environments. Adherence to this guide will aid in avoiding some of the inherent difficulties in such testing.

SCOPE

1.1 This guide covers conducting and evaluating galvanic corrosion tests to characterize the behavior of two dissimilar metals in electrical contact in an electrolyte under low-flow conditions. It can be adapted to wrought or cast metals and alloys.

1.2 This guide covers the selection of materials, specimen preparation, test environment, method of exposure, and method for evaluating the results to characterize the behavior of galvanic couples in an electrolyte. Note 1—Additional information on galvanic corrosion testing and examples of the conduct and evaluation of galvanic corrosion tests in electrolytes are given in Refs (1)2 through (2).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G71 − 81 (Reapproved 2014)

Standard Guide for

Conducting and Evaluating Galvanic Corrosion Tests in

Electrolytes

ThisstandardisissuedunderthefixeddesignationG71;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G16 Guide for Applying Statistics to Analysis of Corrosion

Data

1.1 This guide covers conducting and evaluating galvanic

G31 Guide for Laboratory Immersion Corrosion Testing of

corrosion tests to characterize the behavior of two dissimilar

Metals

metals in electrical contact in an electrolyte under low-flow

G46 Guide for Examination and Evaluation of Pitting Cor-

conditions. It can be adapted to wrought or cast metals and

rosion

alloys.

1.2 This guide covers the selection of materials, specimen

3. Significance and Use

preparation,testenvironment,methodofexposure,andmethod

3.1 Use of this guide is intended to provide information on

for evaluating the results to characterize the behavior of

the galvanic corrosion of metals in electrical contact in an

galvanic couples in an electrolyte.

electrolytethatdoesnothaveaflowvelocitysufficienttocause

NOTE 1—Additional information on galvanic corrosion testing and erosion-corrosion or cavitation.

examples of the conduct and evaluation of galvanic corrosion tests in

2 3.2 This standard is presented as a guide for conducting

electrolytes are given in Refs (1) through (2).

galvanic corrosion tests in liquid electrolyte solutions, both in

1.3 The values stated in SI units are to be regarded as

the laboratory and in service environments. Adherence to this

standard. No other units of measurement are included in this

guide will aid in avoiding some of the inherent difficulties in

standard.

such testing.

1.4 This standard does not purport to address all of the

4. Test Specimens

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 Material—Test specimens should be manufactured from

priate safety and health practices and determine the applica-

thesamematerialasthoseusedintheserviceapplicationbeing

bility of regulatory limitations prior to use.

modeled. Minor compositional or processing differences be-

tween materials or between different heats can greatly affect

2. Referenced Documents

the results in some cases.

2.1 ASTM Standards:

4.2 Size and Shape:

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

4.2.1 Thesizeandshapeofthetestspecimensaredependent

sion Test Specimens

on restrictions imposed by the test location. When determining

G3 Practice for Conventions Applicable to Electrochemical

material behavior in the laboratory, it is advisable to use the

Measurements in Corrosion Testing

largest specimens permissible within the constraints of the test

G4 Guide for Conducting Corrosion Tests in Field Applica-

equipment.Ingeneral,theratioofsurfaceareatometalvolume

tions

should be large in order to favor maximum corrosion loss per

weight. Sufficient thickness should be employed, however, to

minimize the possibility of perforation of the specimens during

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of

the test exposure. When modeling large components, the size

Metals and is the direct responsibility of Subcommittee G01.11 on Electrochemical

Measurements in Corrosion Testing.

of the specimens should be as large as practical. When

Current edition approved May 1, 2014. Published May 2014. Originally

modeling smaller components, specimen size should be as

approved in 1981. Last previous edition approved in 2009 as G71–81(2009). DOI:

close as possible to that of the application being modeled.

10.1520/G0071-81R14.

Surface area ratio in the test should be identical to the

The boldface numbers in parentheses refer to a list of references at the end of

this standard.

application being modeled. This ratio is defined as the surface

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

area of one member of the couple divided by the surface area

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of the other member of the couple. Only the area in contact

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. with the electrolyte (wetted area) is used in this calculation. In

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G71 − 81 (2014)

low-resistivity electrolytes, maintaining proximity between the volume of test solution may be varied to closely approximate

materials being coupled may be more important than maintain- the service application.

ing the exact area ratio. Also, with some couples, such as

5.1.2 Galvanic corrosion tests conducted for an extensive

copper coupled to aluminum, there may be effects of corrosion

period of time may exhaust important constituents of the

products washing from one electrode to another which may

original solution. Some accumulated corrosion products may

have to be considered in determining specimen placement.

act as corrosion accelerators or inhibitors.These variables may

4.2.2 Laboratory tests are normally performed on rectangu-

greatly change the end results, and replenishment of the

lar plates or on cylinders.When modeling service applications,

solution should be chosen to be representative of the service

the shapes of the couple members should approximate the

application. A test system using continuously replenished test

shapes in the application. Frequently complex shapes are

electrolytes is often the only solution to this problem.

simplified for testing purposes. The shape of the specimen is

5.1.3 Periodic measurements of the test environment should

more important in electrolytes of low conductivity, where

bemadewhenthetestdurationinafixedvolumesolutionisfor

voltage drop in the electrolyte is significant. In highly conduc-

periods of several days or longer. These observations may

tive electrolytes, the shapes of the couple members may

includetemperature,pH,O ,H S,CO ,NH ,conductivity,and

2 2 2 3

therefore deviate somewhat from the shapes in the application.

pertinent metal ion content.

4.3 Specimen Preparation:

5.2 Field Tests—Field testing should be performed in an

4.3.1 The edges of the test specimens should be prepared so

environment similar to the service environment. Periodic

as to eliminate all sheared or cold-worked metal except that

measurements of those environmental variables which could

cold-working introduced by stamping for identification. Shear-

varywithtime,suchastemperature,dissolvedO ,andsoforth,

ing will, in some cases, cause considerable attack. Therefore,

should be made.

specimens having sheared edges should not be used.The edges

should be finished by machining or polishing. The slight

6. Procedure

amount of cold working resulting from machining will not

6.1 Laboratory Versus Field Testing:

introduce any serious error.

6.1.1 Galvanic corrosion tests are conducted in the labora-

4.3.2 Specimens should be cleaned in accordance with

tory for several purposes: (1) inexpensive screening to reduce

Practice G1, or else the specimen surface condition should be

expensive field testing, (2) study of the effects of environmen-

similar to the application being modeled. The metallurgical

tal variables, and (3) study of the corrosion accelerating or

condition of the specimens should be similar to the application

protective effects of various anode/cathode surface area ratios.

being modeled. In all cases surface contamination, such as dirt,

6.1.2 The materials proven in the laboratory to be the most

grease, oil, and thick oxides, should be removed prior to

promising should also be tested in the field, since it is

weighing and exposure to the test environment.

frequently impossible to duplicate the actual service environ-

4.3.3 The specimen identification system must be one that

ment in the laboratory.

will endure throughout the test period. Edge notches, drilled

holes, stamped numbers, and tags are some of the methods

6.2 Test Procedure:

used for identification. The identification system must not

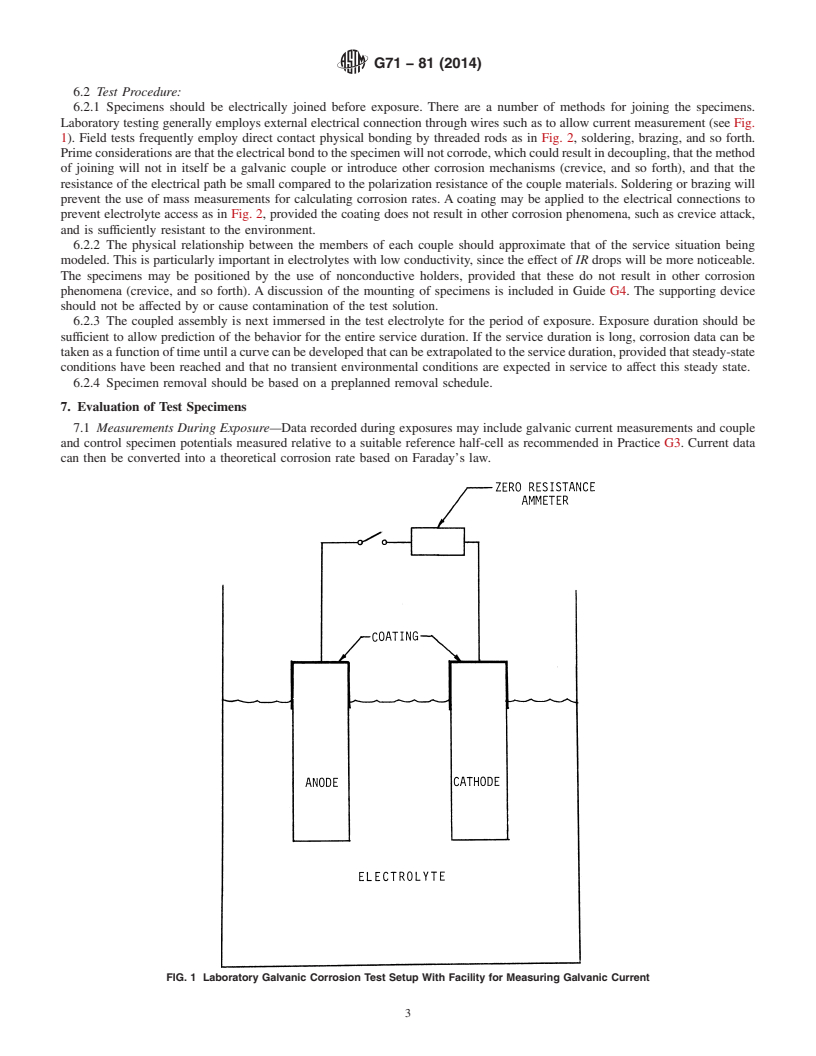

6.2.1 Specimens should be electrically joined before expo-

induce corrosion attack in any way.

sure.Thereareanumberofmethodsforjoiningthespecimens.

4.4 Number of Specimens:

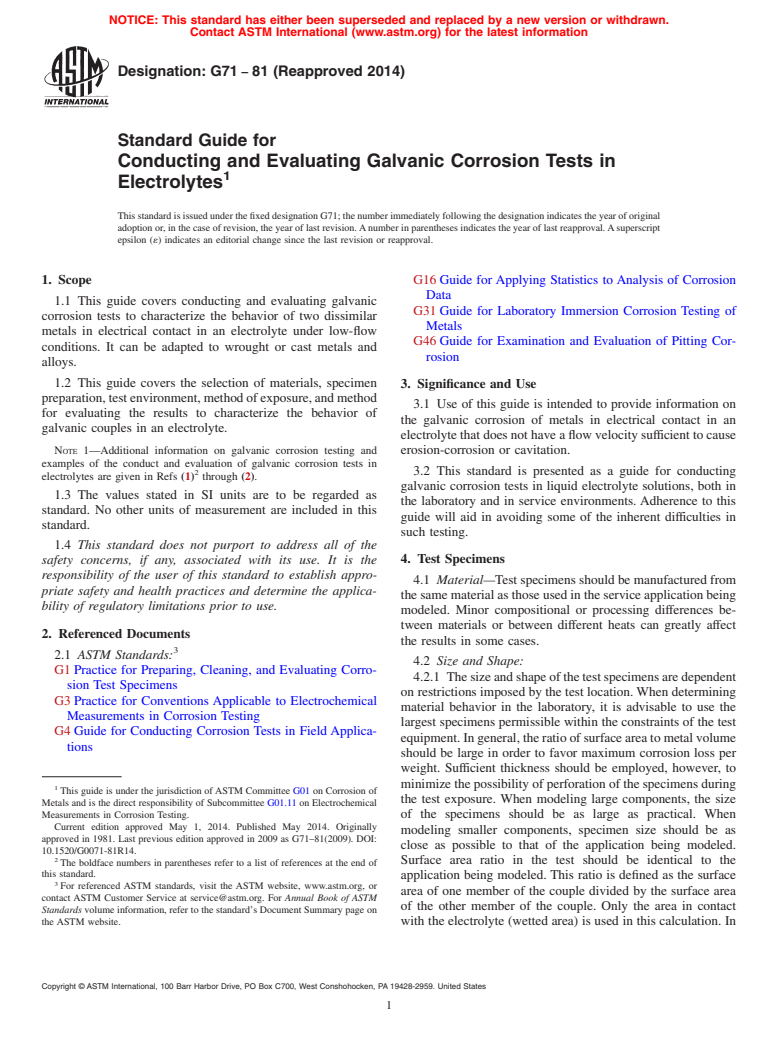

Laboratory testing generally employs external electrical con-

4.4.1 The number of galvanic couples to be tested will be

nection through wires such as to allow current measurement

determined by whether or not one or more periodic specimen

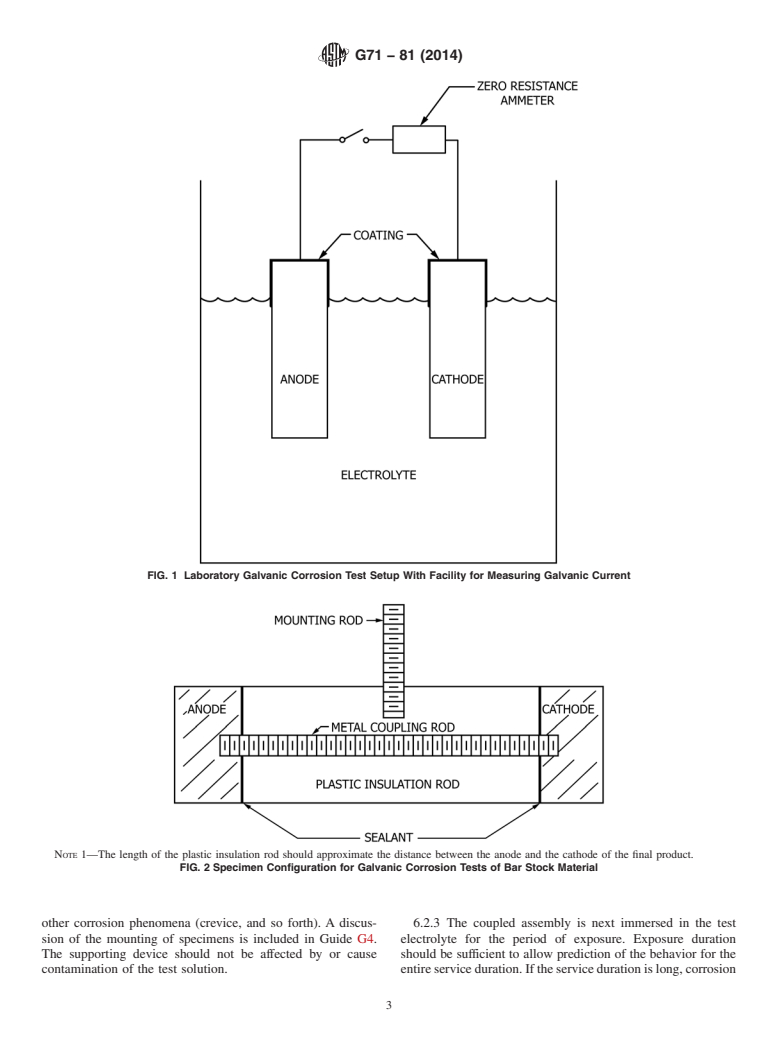

(see Fig. 1). Field tests frequently employ direct contact

removals are scheduled during the course of the test. As a

physical bonding by threaded rods as in Fig. 2, soldering,

minimum, duplicate and preferably triplicate specimens should

brazing, and so forth. Prime considerations are that the

be tested for any given test period to determine the variability

electrical bond to the specimen will not corrode, which could

in the galvanic corrosion behavior. The effect of the number of

resultindecoupling,thatthemethodofjoiningwillnotinitself

replications on the application of the results is set f

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G71 − 81 (Reapproved 2009) G71 − 81 (Reapproved 2014)

Standard Guide for

Conducting and Evaluating Galvanic Corrosion Tests in

Electrolytes

This standard is issued under the fixed designation G71; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers conducting and evaluating galvanic corrosion tests to characterize the behavior of two dissimilar metals

in electrical contact in an electrolyte under low-flow conditions. It can be adapted to wrought or cast metals and alloys.

1.2 This guide covers the selection of materials, specimen preparation, test environment, method of exposure, and method for

evaluating the results to characterize the behavior of galvanic couples in an electrolyte.

NOTE 1—Additional information on galvanic corrosion testing and examples of the conduct and evaluation of galvanic corrosion tests in electrolytes

are given in Refs (1) through (2).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

G1 Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens

G3 Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing

G4 Guide for Conducting Corrosion Tests in Field Applications

G16 Guide for Applying Statistics to Analysis of Corrosion Data

G31 Guide for Laboratory Immersion Corrosion Testing of Metals

G46 Guide for Examination and Evaluation of Pitting Corrosion

3. Significance and Use

3.1 Use of this guide is intended to provide information on the galvanic corrosion of metals in electrical contact in an electrolyte

that does not have a flow velocity sufficient to cause erosion-corrosion or cavitation.

3.2 This standard is presented as a guide for conducting galvanic corrosion tests in liquid electrolyte solutions, both in the

laboratory and in service environments. Adherence to this guide will aid in avoiding some of the inherent difficulties in such testing.

4. Test Specimens

4.1 Material—Test specimens should be manufactured from the same material as those used in the service application being

modeled. Minor compositional or processing differences between materials or between different heats can greatly affect the results

in some cases.

4.2 Size and Shape:

4.2.1 The size and shape of the test specimens are dependent on restrictions imposed by the test location. When determining

material behavior in the laboratory, it is advisable to use the largest specimens permissible within the constraints of the test

This guide is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.11 on Electrochemical

Measurements in Corrosion Testing.

Current edition approved May 1, 2009May 1, 2014. Published May 2009May 2014. Originally approved in 1981. Last previous edition approved in 20032009 as

G71–81(2003).G71–81(2009). DOI: 10.1520/G0071-81R09.10.1520/G0071-81R14.

The boldface numbers in parentheses refer to a list of references at the end of this standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G71 − 81 (2014)

equipment. In general, the ratio of surface area to metal volume should be large in order to favor maximum corrosion loss per

weight. Sufficient thickness should be employed, however, to minimize the possibility of perforation of the specimens during the

test exposure. When modeling large components, the size of the specimens should be as large as practical. When modeling smaller

components, specimen size should be as close as possible to that of the application being modeled. Surface area ratio in the test

should be identical to the application being modeled. This ratio is defined as the surface area of one member of the couple divided

by the surface area of the other member of the couple. Only the area in contact with the electrolyte (wetted area) is used in this

calculation. In low-resistivity electrolytes, maintaining proximity between the materials being coupled may be more important than

maintaining the exact area ratio. Also, with some couples, such as copper coupled to aluminum, there may be effects of corrosion

products washing from one electrode to another which may have to be considered in determining specimen placement.

4.2.2 Laboratory tests are normally performed on rectangular plates or on cylinders. When modeling service applications, the

shapes of the couple members should approximate the shapes in the application. Frequently complex shapes are simplified for

testing purposes. The shape of the specimen is more important in electrolytes of low conductivity, where voltage drop in the

electrolyte is significant. In highly conductive electrolytes, the shapes of the couple members may therefore deviate somewhat from

the shapes in the application.

4.3 Specimen Preparation:

4.3.1 The edges of the test specimens should be prepared so as to eliminate all sheared or cold-worked metal except that

cold-working introduced by stamping for identification. Shearing will, in some cases, cause considerable attack. Therefore,

specimens having sheared edges should not be used. The edges should be finished by machining or polishing. The slight amount

of cold working resulting from machining will not introduce any serious error.

4.3.2 Specimens should be cleaned in accordance with Practice G1, or else the specimen surface condition should be similar

to the application being modeled. The metallurgical condition of the specimens should be similar to the application being modeled.

In all cases surface contamination, such as dirt, grease, oil, and thick oxides, should be removed prior to weighing and exposure

to the test environment.

4.3.3 The specimen identification system must be one that will endure throughout the test period. Edge notches, drilled holes,

stamped numbers, and tags are some of the methods used for identification. The identification system must not induce corrosion

attack in any way.

4.4 Number of Specimens:

4.4.1 The number of galvanic couples to be tested will be determined by whether or not one or more periodic specimen removals

are scheduled during the course of the test. As a minimum, duplicate and preferably triplicate specimens should be tested for any

given test period to determine the variability in the galvanic corrosion behavior. The effect of the number of replications on the

application of the results is set forth in Guide G16.

4.4.2 Control specimens should also be tested to provide corrosion rates of the individual metals and alloys without coupling

for comparisons. These specimens should be of the same alloys, shapes, sizes, and metallurgical conditions as the materials in the

couple.

5. Test Environment

5.1 Laboratory Tests:

5.1.1 In the laboratory, the test solution should closely approximate the service environment. The amount of test solution used

3 2

depends on the size of the test specimens. A good rule of thumb is to use 40 cm of test solution for every 1 cm of exposed surface

area of both members of the couple. The volume of test solution may be varied to closely approximate the service application.

5.1.2 Galvanic corrosion tests conducted for an extensive period of time may exhaust important constituents of the original

solution. Some accumulated corrosion products may act as corrosion accelerators or inhibitors. These variables may greatly change

the end results, and replenishment of the solution should be chosen to be representative of the service application. A test system

using continuously replenished test electrolytes is often the only solution to this problem.

5.1.3 Periodic measurements of the test environment should be made when the test duration in a fixed volume solution is for

periods of several days or longer. These observations may include temperature, pH, O , H S, CO , NH , conductivity, and pertinent

2 2 2 3

metal ion content.

5.2 Field Tests—Field testing should be performed in an environment similar to the service environment. Periodic measurements

of those environmental variables which could vary with time, such as temperature, dissolved O , and so forth, should be made.

6. Procedure

6.1 Laboratory Versus Field Testing:

6.1.1 Galvanic corrosion tests are conducted in the laboratory for several purposes: (1) inexpensive screening to reduce

expensive field testing, (2) study of the effects of environmental variables, and (3) stu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.