ASTM F2768-09

(Specification)Standard Specification for Modified Stub ACME Thread Joint with Elastomeric Seal in Plastic Piping Components (Withdrawn 2016)

Standard Specification for Modified Stub ACME Thread Joint with Elastomeric Seal in Plastic Piping Components (Withdrawn 2016)

SCOPE

1.1 This specification covers a Modified Stub ACME Thread Joint with an Elastomeric Seal used to seal the joint components in plastic piping components, or (if applicable) to components made of other non-plastic materials used for plastic piping components used in turf irrigation systems.

1.2 This specification establishes requirements for dimensions and gauging of Modified Stub ACME Thread and Elastomeric seal.

1.3 Tapered pipe threads are not covered in this specification.

Note 1—The terms “bottom out ” and “back off” are used to imply complete engagement of the threaded connection and un-threading of the connection and do not imply using a pipe wrench or other tools which would damage plastic pipe and fittings.

1.4 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This specification covers a Modified Stub ACME Thread Joint with an Elastomeric Seal used to seal the joint components in plastic piping components, or (if applicable) to components made of other non-plastic materials used for plastic piping components used in turf irrigation systems.

Formerly under the jurisdiction of Committee F17 on Plastic Piping Systems, this specification was withdrawn in November 2016. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2768 −09

StandardSpecification for

Modified Stub ACME Thread Joint with Elastomeric Seal in

Plastic Piping Components

This standard is issued under the fixed designation F2768; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope or Chlorinated Poly (Vinyl Chloride) (CPVC) Systems

1.1 This specification covers a Modified Stub ACME

3. Terminology

Thread Joint with an Elastomeric Seal used to seal the joint

3.1 Terminology is in accordance with Terminology F412

components in plastic piping components, or (if applicable) to

and abbreviations are in accordance with Terminology D1600,

components made of other non-plastic materials used for

unless otherwise indicated.

plastic piping components used in turf irrigation systems.

1.2 This specification establishes requirements for dimen-

4. Significance and Use

sions and gauging of Modified Stub ACME Thread and

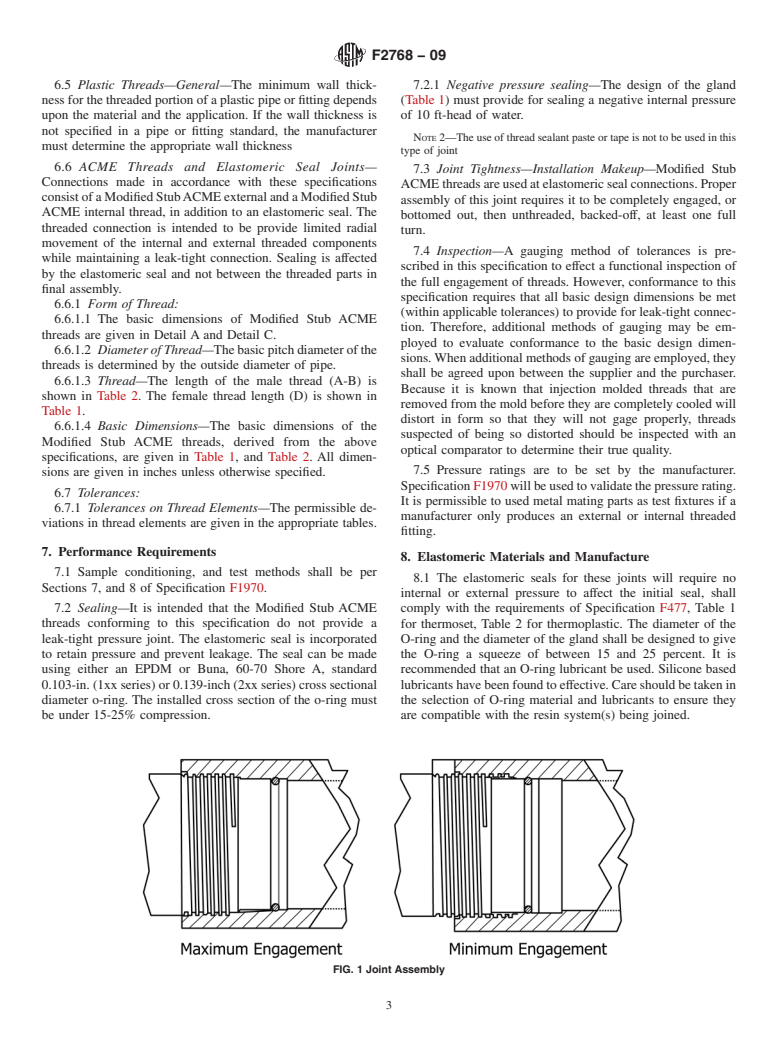

4.1 Connections made in accordance with these specifica-

Elastomeric seal.

tions consist of a Modified Stub ACME external and a

1.3 Tapered pipe threads are not covered in this specifica-

Modified Stub ACME internal thread, in addition to an

tion.

elastomeric seal. The threaded connections are intended to

NOTE 1—The terms “bottom out ” and “back off” are used to imply provide limited radial movement of the internal and external

complete engagement of the threaded connection and un-threading of the

threaded components while maintaining a pressure tight and

connection and do not imply using a pipe wrench or other tools which

leak-tight connection. Sealing is affected by the elastomeric

would damage plastic pipe and fittings.

seal and not between the threaded parts in final assembly.

1.4 The values stated in inch-pound units are to be regarded

as standard. No other units of measurement are included in this

5. Classification

standard.

5.1 Thread Form—The form of thread profile specified in

1.5 This standard does not purport to address all of the

this specification shall be known as the Modified Stub ACME

safety concerns, if any, associated with its use. It is the

Thread Form. The relations as specified herein, for form of

responsibility of the user of this standard to establish appro-

thread and general notations are shown in Table 1 and Table 2.

priate safety and health practices and determine the applica-

5.2 ThreadDesignations—Thetypeofpipethreadsincluded

bility of regulatory limitations prior to use.

in this specification are designated by specifying in sequence

the nominal pipe size, number of threads per inch, and the

2. Referenced Documents

thread series symbols as follows: 1 ⁄2-10 Modified StubACME

2.1 ASTM Standards:

which indicates a 1 ⁄2 Iron Pipe Size, 10 threads per inch, right

D1600 Terminology forAbbreviatedTerms Relating to Plas-

hand, single thread. For left-hand threads add LH to the

tics

designation, otherwise right-hand threads will be understood.

F412 Terminology Relating to Plastic Piping Systems

For example: 1 ⁄4-10 Modified Stub ACME –LH.

F477 Specification for Elastomeric Seals (Gaskets) for Join-

ing Plastic Pipe

6. Dimensions and Tolerances

F1970 Specification for Special Engineered Fittings,Appur-

6.1 Female Threads:

tenances or Valves for use in Poly (Vinyl Chloride) (PVC)

6.2 Thread Starts—Machined—Feathered starts are pro-

duced by a 45° chamfer on the first thread when the thread is

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

cut with a tap or die. The depth of chamfer shall be from ⁄4 to

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

1 ⁄4 thread deep. Feathered starts are prone to crossing and

Current edition approved Dec. 1, 2009. Published January 2010. DOI: 10.1520/

mutilation and shall not be molded.

F2768–09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.3 Thread Starts—Molded—Internal and external molded

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

threads shall begin with a taper or blunt start. A pilot shall be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. provided from the face of the fitting and at the entering end of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2768−09

TABLE 1 Female Threads

AB C D E F

Bottom Bore Entrance Thread Length Pilot Minor thread diameter

Nominal Pipe Size

Diameter

minimum diameter tolerance maximum length tolerance maximum diameter tolerance

1 1.15 1.197 ± 0.009 0.715 0.590 ± 0.010 1.385 1.252 ± 0.008

1 ⁄4 1.29 1.633 ± 0.008 0.820 0.670 ± 0.010 1.820 1.692 ± 0.008

1 ⁄2 1.38 1.768 ± 0.008 0.870 0.790 ± 0.010 1.940 1.808 ± 0.010

TABLE 2 Male Threads

A

AB C D E

Nominal Pipe Size Length Tube Tube Groove Bottom Major thread diameter

length tolerance length tolerance diameter tolerance Diameter tolerance diameter tolerance

1 1.207 ± 0.013 0.613 ± 0.033 1.180 ± 0.005 0.985 ± 0.003 1.318 ± 0.006

1 ⁄4 1.263 ± 0.023 0.620 ± 0.035 1.613 ± 0.007 1.470 ± 0.005 1.753 ± 0.007

1 ⁄2 1.340 ± 0.040 0.590 ± 0.040 1.748 ± 0.008 1.605 ± 0.005 1.869 ± 0.007

A

Dimensionisforreferenceonly.DimensionmayvarytoaccommodatedifferingO-ringsizes.ThedimensionshouldresultinO-ringcompressionof15-25%wheninstalled

into a mating female component.

the external threads; it shall have a length to the start (flank) of 6.4 Blunt starts on the first thread are formed by the thread

1 3

the first thread, equal to ⁄2 to ⁄4 the width of the thread pitch,

rising from the minimum to maximum diameter while main-

1to1 ⁄4 thread pitch to the centerline. (Thread pitch equals one

taining theACME thread profile.The length of rise shall not be

turn.) The pilot shall be included in the measurement of the

greater than twice the thread height. The blunt start is the

thread length. Taper starts on the first thread are formed by the

preferred thread start.

thread rising from the minimum to maximum diameter while

maintaining the ACME thread profile. The length of rise shall

not exceed ⁄8 turn (45°).

F2768−09

6.5 Plastic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.